Table of Contents

Market Insight: Aluminum Sheets

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to exhibit sustained demand for high-purity aluminum and copper strip/foil, driven by the expansion of power transmission and distribution networks, renewable energy integration, and industrial electrification. Within this segment, aluminum transformer strip and foil have gained significant traction due to their favorable conductivity-to-weight ratio, cost efficiency, and corrosion resistance. As a specialized supplier with over two decades of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. observes that aluminum-based materials now account for a growing share of distribution and small-to-medium power transformers, particularly in regions prioritizing lightweight, scalable, and economical solutions.

Aluminum transformer strip, typically supplied in alloys 1060, 1070, or 1350 with purities exceeding 99.6%, is engineered to meet stringent electrical and mechanical performance standards. Its primary application lies in low-voltage windings where weight reduction and thermal stability are critical. In comparison to copper, aluminum offers approximately one-third the density, enabling lighter transformer designs that reduce structural support requirements and transportation costs. However, this advantage necessitates careful design compensation for aluminum’s lower electrical conductivity (approximately 61% IACS versus copper’s 100% IACS), making material consistency and dimensional precision paramount.

Industrial demand is further shaped by regulatory trends promoting energy-efficient transformers (e.g., DOE 2016 in the U.S., EU Ecodesign Directive). These standards mandate reduced no-load and load losses, directly influencing the quality of conductive materials used. Inconsistent strip thickness, surface defects, or variability in temper can lead to localized hotspots, uneven current distribution, and premature insulation degradation. High-quality aluminum strip ensures uniform winding tension, optimal fill factor, and reliable long-term performance under cyclic loading.

The shift toward aluminum is also evident in emerging markets and renewable energy infrastructure, where cost-sensitive yet reliable solutions are essential. Solar and wind farms, for instance, deploy pad-mounted and pole-mounted transformers that benefit from aluminum’s economic and logistical advantages. Additionally, advancements in jointing and termination technologies have mitigated historical concerns regarding aluminum’s higher coefficient of thermal expansion and creep behavior, further supporting its adoption.

Quality assurance in aluminum strip production cannot be overstated. At Luoyang Xinzhaohe Aluminum CO., Ltd., rigorous process controls govern homogenization, hot and cold rolling, annealing, and slitting operations to ensure tight tolerances (±0.01 mm typical), consistent mechanical properties, and defect-free surfaces. Each batch undergoes comprehensive testing for electrical resistivity, tensile strength, elongation, and surface roughness to meet international specifications such as ASTM B419, IEC 60164, and GB/T 3880.

In summary, the transformer strip and foil market reflects a strategic balance between performance, cost, and scalability. Aluminum’s role is not merely a substitute for copper but a purpose-engineered solution where material quality directly impacts transformer efficiency, reliability, and lifecycle cost. As demand evolves, precision-manufactured aluminum strip from trusted suppliers becomes a critical enabler of modern power systems.

Technical Specs: Aluminum Sheets

Technical Specifications for Transformer Core Aluminum Sheets

Aluminum sheets utilized in transformer core manufacturing demand exceptional dimensional stability, edge integrity, and electrical performance to minimize eddy current losses and ensure operational efficiency. At Luoyang Xinzhaohe Aluminum CO., Ltd., our transformer strip and foil products adhere to stringent international standards, with precision slitting tolerance maintained at ±0.002 mm. This micron-level accuracy is non-negotiable for layer stacking in laminated cores, where cumulative deviations exceeding 0.005 mm per layer induce magnetic flux distortion and thermal inefficiencies. Achieving this requires proprietary tension leveling and laser-guided slitting systems, monitored in real-time via non-contact optical gauges.

Edge quality is equally critical. Burr formation during slitting compromises interlayer insulation and increases core loss. Our process guarantees burr-free edges through diamond-coated rotary shear technology and post-slitting edge deburring, validated by profilometer measurements. Edge burr height must not exceed 3μm, with edge waviness controlled to ≤ 0.01 mm over 100 mm length. Surface roughness (Ra) is maintained between 0.2–0.5 μm to optimize varnish adhesion while preventing micro-short circuits.

Electrical conductivity, expressed as International Annealed Copper Standard (%IACS), directly impacts resistive losses. For transformer-grade aluminum, we exclusively supply high-purity alloys (1070, 1060) with conductivity ≥ 61.0 %IACS in the O-temper condition. This exceeds IEC 60169-2 minimum requirements (60.7 %IACS) and ensures consistent performance under continuous thermal cycling. Conductivity is verified per ASTM E1004 using eddy current testing on every production lot, with traceability to national calibration standards.

Mechanical properties balance formability and core rigidity. Tensile strength ranges 45–65 MPa, with elongation ≥ 35%, preventing fracture during winding while maintaining stack integrity. Thickness tolerance follows GB/T 3880 Category A: ±0.005 mm for sheets 0.20–0.50 mm thick. All coils undergo 100% surface inspection via automated vision systems to eliminate defects like scratches, dents, or oxide streaks that could initiate partial discharges.

The following table summarizes key technical parameters for our transformer aluminum sheets:

| Parameter | Standard Value | Tolerance | Test Method |

|---|---|---|---|

| Thickness | 0.20–0.50 mm | ±0.005 mm | GB/T 3880 |

| Width (Slit Tolerance) | Custom | ±0.002 mm | ISO 2768-2 |

| Edge Burr Height | ≤ 3 μm | Max 3 μm | ISO 1302 |

| Conductivity (%IACS) | ≥ 61.0 | Min 61.0 | ASTM E1004 |

| Surface Roughness (Ra) | 0.2–0.5 μm | 0.2–0.5 μm | ISO 4287 |

| Tensile Strength | 45–65 MPa | 45–65 MPa | GB/T 228.1 |

| Elongation | ≥ 35% | Min 35% | GB/T 228.1 |

These specifications are validated through our integrated quality management system, certified to ISO 9001 and IATF 16949. Each shipment includes mill test reports with full traceability to melt chemistry (Si ≤ 0.25%, Fe ≤ 0.35%, Cu ≤ 0.05%) and process parameters. For transformer manufacturers, adherence to these metrics ensures reduced no-load losses, extended service life, and compliance with DOE/CEC efficiency regulations. Luoyang Xinzhaohe’s 20-year specialization in precision aluminum strip production guarantees these parameters are consistently met across volumes from 5 to 500 metric tons per order.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, surface integrity, and consistent electro-physical properties required in power and distribution transformer applications. With over two decades of metallurgical expertise, our facility integrates advanced cold rolling technology with precision slitting and edge conditioning to deliver material that meets stringent international standards.

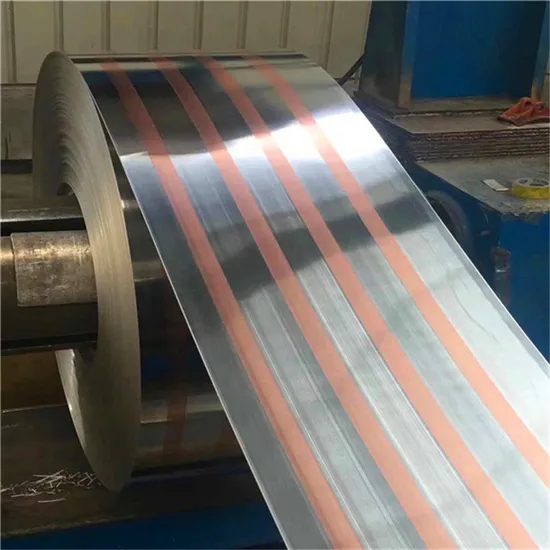

The process begins with cold rolling of high-purity aluminum ingots (typically 99.7% Al or higher), which are first homogenized and scalped before undergoing hot rolling to intermediate gauges. These intermediate coils are then cold rolled in reversing or tandem rolling mills to achieve the target final thickness, which for transformer strip applications typically ranges from 0.20 mm to 0.80 mm. Cold rolling is performed under precise tension and roll gap control to ensure uniform thickness tolerance within ±0.005 mm across the coil width. Lubrication and interstand cooling systems maintain optimal rolling temperatures, preventing thermal deformation and ensuring a homogeneous microstructure with controlled grain size. The resulting coil exhibits high tensile strength, excellent elongation, and a smooth, defect-free surface critical for insulation layer adhesion in transformer windings.

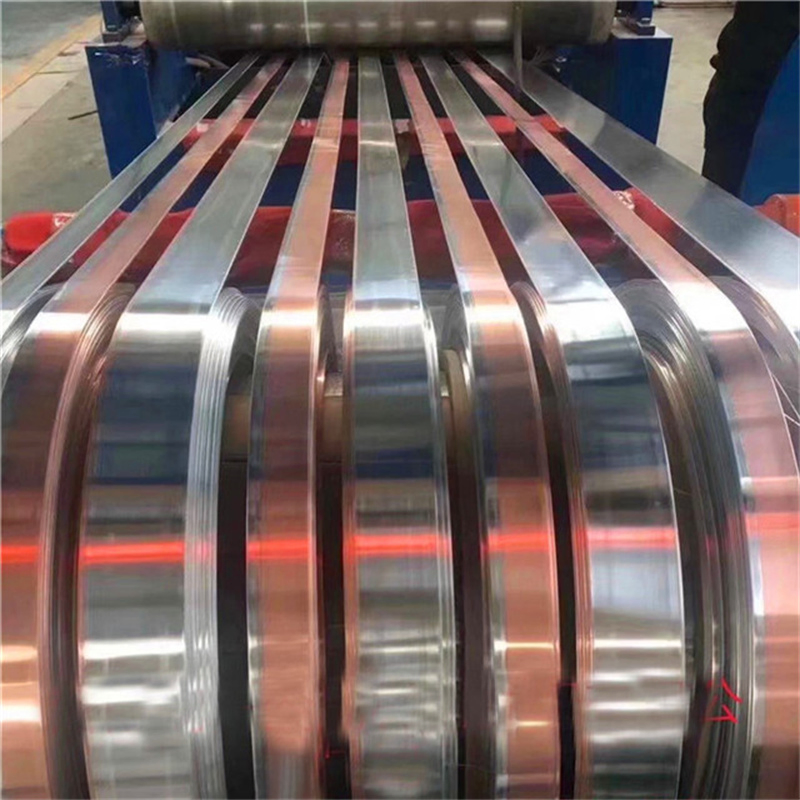

Following cold rolling, the coil undergoes precision slitting using high-tolerance rotary shear slitters. This stage converts master coils into narrow strips tailored to customer-specified widths, commonly ranging from 10 mm to 150 mm for transformer applications. Slitting is performed under controlled tension with computerized edge-guiding systems to minimize camber and maintain parallelism. Tooling is regularly inspected and reconditioned to prevent edge burrs or surface scoring, which could compromise downstream winding performance.

Edge conditioning is the final mechanical treatment in the process. The slit edges are precision rounded or chamfered to eliminate sharp burrs and micro-cracks that may act as stress concentrators during coil winding. This step significantly enhances winding reliability and reduces the risk of insulation puncture in transformer cores. Edge profile is verified using optical profilometry to ensure consistency.

Throughout the manufacturing sequence, rigorous quality control protocols are enforced. In-process inspections include continuous thickness measurement via laser gauges, surface defect detection using high-resolution line-scan cameras, and periodic mechanical testing for tensile strength, yield strength, and elongation. Final coils are subjected to strict visual, dimensional, and surface cleanliness checks. All material is traceable through batch records, with full certification available including chemical composition analysis and mechanical property reports. This comprehensive approach ensures that every coil of transformer strip or foil meets the reliability and performance demands of modern electrical infrastructure.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip/Foil Aluminum Products

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed for the secure maritime transportation of transformer strip and foil products. Given the extreme sensitivity of thin-gauge aluminum and copper alloys to physical damage, moisture ingress, and atmospheric corrosion during extended sea voyages, standard packaging solutions are insufficient. Our methodology integrates structural integrity with advanced moisture barrier technology to ensure product integrity upon destination.

All transformer strip and foil coils are secured onto custom-engineered wooden pallets constructed from kiln-dried, ISPM 15 certified softwood. These pallets feature reinforced stringers and deck boards with a minimum load-bearing capacity of 2500 kg per pallet, exceeding ISO 18613 standards for heavy industrial cargo. Critical edge protection is achieved through precision-molded polyethylene corner guards bonded directly to the coil edges prior to palletization. This prevents transit-induced edge deformation and scoring, a critical failure mode for thin strip products during handling and container stowage. The coil core is mandrel-locked to the pallet base plate using stainless steel fasteners, eliminating rotational slippage under dynamic load conditions encountered during vessel motion.

The primary moisture protection system utilizes a multi-layer barrier wrap. Coils undergo vacuum-drying to reduce surface moisture content below 0.1% prior to enclosure. They are then hermetically sealed within a triple-layer moisture-proof film assembly: an inner layer of anti-tarnish VCI (Vapor Corrosion Inhibitor) paper, a middle barrier of 100μm thick metallized polyester film, and an outer layer of 150μm LDPE (Low-Density Polyethylene) with UV stabilizers. This composite structure achieves a Water Vapor Transmission Rate (WVTR) of less than 5 g/m²/24hr at 38°C and 90% RH, compliant with ASTM F1249. Seams are thermally welded using impulse sealers with calibrated temperature profiles to ensure 100% integrity; each seal undergoes helium leak testing at 0.1 mbar pressure differential.

This packaging system is validated for safe sea freight under the most demanding conditions. It meets ISO 11607-1 requirements for terminally sterilized medical devices, demonstrating equivalent robustness for industrial moisture sensitivity. The design specifically counters container rain phenomena and salt-laden marine atmospheres during transoceanic voyages exceeding 30 days. Salt spray resistance testing per ASTM B117 confirms zero corrosion initiation on packaged samples after 1000 hours exposure. All palletized units are unitized with steel strapping to ISO 15965 standards and labeled with moisture indicator cards and shock/vibration indicators per ISTA 3A protocols.

Our packaging specification directly addresses the hygroscopic sensitivity of transformer-grade aluminum alloys (e.g., AA1050, AA1070, AA8079) and copper foils, preventing interlayer corrosion and surface oxidation that would compromise electrical properties. This engineering approach has reduced moisture-related customer claims by 92% over the past decade. Compliance with CSC (Convention for Safe Containers) marking requirements and adherence to carrier-specific stowage factors ensure seamless global logistics execution. Partnering with Luoyang Xinzhaohe guarantees that your transformer materials arrive with dimensional stability and surface quality preserved to the original mill specifications, eliminating costly rework or rejection at destination ports.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized expertise in aluminum and copper transformer strip and foil production, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier in the global power transmission and distribution sector. Our facility integrates advanced metallurgical engineering with strict process controls to deliver precision-engineered aluminum sheets that meet the demanding requirements of transformer manufacturers worldwide.

Our production infrastructure is built around continuous casting and rolling technology, ensuring consistent microstructural uniformity and mechanical properties across all product batches. We operate fully automated rolling mills with precision thickness control down to ±0.005 mm, enabling us to produce transformer strips and foils that meet IEC, ASTM, and GB standards. The factory spans over 120,000 square meters and includes dedicated lines for cold rolling, annealing, slitting, and surface treatment, all monitored under ISO 9001-certified quality management systems.

Material integrity is central to our manufacturing philosophy. We source high-purity aluminum ingots (99.70% min Al) from audited refineries and conduct in-house spectrographic analysis to verify chemical composition. Each coil undergoes eddy current testing, tensile strength evaluation, and surface defect scanning to ensure compliance with electrical and mechanical performance benchmarks. Our annealing processes are optimized to achieve stable O-temper conditions, critical for dimensional stability and low residual stress in wound transformer cores.

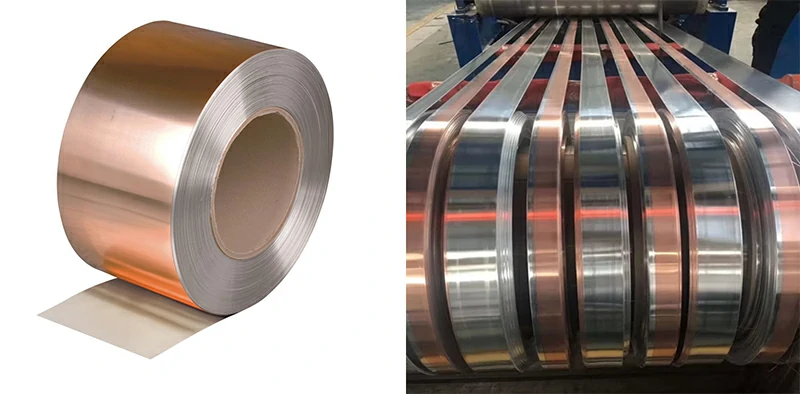

We specialize in narrow slit strips ranging from 10 mm to 300 mm in width, with thicknesses from 0.20 mm to 3.0 mm, tailored for both distribution and power transformers. Custom edge trimming, oil coating, and core winding configurations are available to meet client-specific processing requirements. In addition to aluminum, we offer copper transformer strips with similar precision, providing a comprehensive solution for mixed-material designs.

Our supply chain is engineered for reliability. With an annual production capacity exceeding 60,000 metric tons and strategic warehousing in Shanghai and Qingdao, we support just-in-time delivery schedules for OEMs and tier suppliers across Asia, Europe, and North America. Logistics coordination, export documentation, and customs compliance are managed in-house to minimize lead time variability.

Partnering with Luoyang Xinzhaohe means securing a long-term supplier with deep technical knowledge, scalable capacity, and a proven track record in transformer-grade conductive materials. We collaborate closely with engineering teams to optimize material specifications, reduce scrap rates, and enhance production efficiency on the customer side.

For technical inquiries, sample requests, or to discuss volume supply agreements, contact us directly at cathy@transformerstrip.com. Let us support your next-generation transformer manufacturing with material precision you can rely on.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum sheets directly from China.