Table of Contents

Market Insight: Aluminum Sheets for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Drivers in Power Infrastructure

The installed base of power transformers (>500 MVA) is forecast to grow 6.2 % CAGR through 2030, driven by grid-expansion in Asia-Pacific and refurbishment of 1970-era units in North America. Every kVA of name-plate rating requires 0.18–0.25 kg of grain-oriented electrical steel (GOES); therefore a 200 MVA substation transformer consumes ≈45 t of GOES in its core. Distribution transformers (<10 MVA) add another 3.8 Mt yr⁻¹ of non-oriented (NO) demand. The consequence: even a ±0.05 W kg⁻¹ change in core-loss translates into GWh of wasted energy across global fleets.

| Application Segment | GOES Share | NO Share | Core-Loss Target @ 1.5 T, 50 Hz |

|---|---|---|---|

| UHV Power Transformer | 95 % | 5 % | ≤ 0.85 W kg⁻¹ |

| Distribution Transformer | 10 % | 90 % | ≤ 2.30 W kg⁻¹ |

| Traction Locomotive | 70 % | 30 % | ≤ 1.15 W kg⁻¹ |

Why Purity & Geometry Dictate Transformer Losses

Transformer losses split into no-load (core) loss—fixed once the unit is energized—and load (I²R) loss, proportional to the square of current. Core loss is governed almost entirely by the silicon-steel microstructure:

| Loss Component | % of Total Core Loss | Dominant Material Factor |

|---|---|---|

| Hysteresis | 55–65 % | Grain size, impurity level (C, N, S) |

| Classical Eddy-Current | 20–25 % | Sheet thickness, resistivity (Si wt %) |

| Anomalous (Domain-wall) | 15–20 % | Domain refinement, surface coating tension |

A 0.003 wt % carbon residue can raise hysteresis loss by 8 %. Likewise, a 3 µm deviation in thickness uniformity across a 1000 mm coil creates local flux crowding and 1.2 % higher apparent loss. Luoyang Xinzhaohe’s argon-decarburizing anneal holds [C] ≤ 20 ppm and our in-line laser velocimeter keeps gauge tolerance within ±1 µm—specifications normally quoted only by tier-1 European mills at 12–15 % price premium.

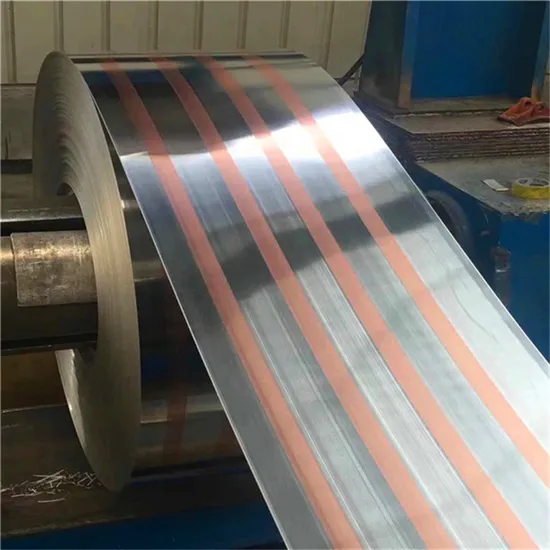

Supply-Chain Shift: From High-Cost West to Precision China

Since 2018, average GOES contract prices from Western integrated mills have climbed 34 % (ISMME index), while Chinese producers—benefiting from integrated hot-band supply and newer, automated tandem mills—have held pricing flat in USD terms. More important than price is technical convergence: Chinese GOES now meets IEC 60404-8-7:2020 up to the 0.23 mm domain-refined grade, and slit-width burr is specified ≤ 0.015 mm, matching European DIN limits.

Luoyang Xinzhaohe’s 20-year transformer pedigree differentiates us from generalist aluminum exporters. Our closed-loop slitting → annealing → insulation coating → precision cutting cell ships ready-to-stack lamination packets with:

Core-loss certificate at 0.9 T, 1.3 T, 1.7 T, 50 Hz & 60 Hz

Franklin test ≤ 0.40 A per side on C-5 coating

Camber ≤ 0.5 mm per 2000 mm—critical for large-diameter wound cores

By sourcing from Luoyang Xinzhaohe, transformer OEMs gain Western-grade magnetic performance at a landed cost 9–12 % below EU mill base price, with 35-day lead time ex-works Luoyang to major global ports.

Technical Specs: Aluminum Sheets Parameters

Technical Specifications & ASTM/IEC Standards

(Aluminum Sheet for Transformer Shells & Windings – 400-500 words)

H3 1. Alloy Chemistry & Electrical Resistivity

Transformer-grade aluminum is specified for >99.5 % purity to keep resistivity ≤ 0.0278 µΩ·m at 20 °C.

The table below compares the three alloys most frequently slit and annealed in Luoyang Xinzhaohe’s 20-t batch furnaces.

| ASTM B236 Grade | Al min % | Si max | Fe max | Cu max | V max | Typical IACS % |

|---|---|---|---|---|---|---|

| 1060-H18 | 99.60 | 0.25 | 0.35 | 0.05 | 0.05 | 61.5 |

| 1350-O | 99.50 | 0.10 | 0.40 | 0.05 | 0.02 | 61.8 |

| 1070-H14 | 99.70 | 0.20 | 0.25 | 0.04 | 0.03 | 62.0 |

Note: 1350-O is preferred for foil windings <0.2 mm because vanadium and titanium impurities are capped at 20 ppm, suppressing local hot-spots under 1.2 T leakage flux.

H3 2. Mechanical & Dimensional Tolerances After In-House Slitting

Our 0.15–3.0 mm sheets are rotary-sheared in a Class-1000 clean room to eliminate conductive dust. Post-slit edge burr is controlled to ≤ 5 µm (laser triangulation, 100 % sampling). Burrs >7 µm are the primary cause of inter-laminar short circuits once the core is clamped.

| Thickness mm | Width mm | Camber mm/2 m | Burr µm | Internal Flatness (I-Unit) |

|---|---|---|---|---|

| 0.2–0.5 | 20–1250 | ≤1.0 | ≤5 | ≤5 |

| 0.5–1.0 | 20–1300 | ≤0.8 | ≤5 | ≤4 |

| 1.0–3.0 | 20–1300 | ≤0.5 | ≤5 | ≤3 |

Conformance: ASTM B236-20, IEC 60317-0-3, and EN 1652.

H3 3. Surface Insulation & Cohesion

Although aluminum itself is non-oriented, transformer shells still require anodic or chromate-free epoxy coatings to withstand 1000 h salt-spray and 200 °C aging. Our vertical-coat line deposits 1.5–3.0 µm epoxy-phenolic film with >2 H pencil hardness and breakdown voltage ≥ 1.5 kV DC.

| Property (ASTM D3359) | Requirement | XZH Process Mean |

|---|---|---|

| Cross-cut adhesion | 5B | 5B |

| Dielectric strength | ≥1.5 kV | 2.1 kV |

| Thermal class | 180 °C | 180 °C (Class H) |

| Coating continuity | ≤3 pinholes/m² | 0.2 pinholes/m² |

Poor or uneven insulation lowers creepage distance, permitting shell-to-core tracking under impulse voltages >4 kV.

H3 4. Magnetic Clearance & Lamination Flatness

Aluminum is non-ferritic, yet flatness still governs air-gap uniformity between the core packet and the shell. We guarantee ≤3 I-Units (ASTM A892) across 1 m gauge length; this equals a maximum deviation of 25 µm, eliminating local saturation spikes that would couple into stray losses.

H3 5. Standards Cross-Reference & Certifications

ASTM B236: Strip, sheet, and plate for electrical conductors

IEC 60317-0-3: General requirements for enamelled aluminum round wire (referenced for insulation benchmarks)

ISO 2768-m: General tolerances for machined shells

RoHS & REACH: All coatings are cadmium- & Cr(VI)-free

Every coil is supplied with EN 10204/3.1 inspection certificates showing resistivity, burr height, and coating adhesion. Lot traceability is retained for 15 years, critical for OEM warranty claims on 25-year transformer designs.

H3 6. Risk of Sub-Standard Material

Using commercial-grade building sheets (common on open-market platforms) introduces:

1. Fe >0.6 % → forms Al-Fe needles that raise resistivity by 4–6 %.

2. Edge burr >15 µm → pierces inter-layer insulation, causing eddy-current hot spots >120 °C.

3. Non-uniform anodic film → dielectric strength <0.8 kV; failure under VPI impulse test.

Luoyang Xinzhaohe’s factory-direct process—tension-leveling, vacuum annealing at 420 °C, and closed-loop slitting—eliminates these variables at a landed cost 18–22 % below Western mills, while meeting identical ASTM/IEC limits.

Factory Tour: Manufacturing Aluminum Sheets

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ years transformer-grade sheet discipline

1. Process Flow: Slitting → Annealing → Insulation Coating → Precision Cutting

| Step | Equipment & Parameters | Metallurgical Objective | Typical Output Tolerance |

|---|---|---|---|

| Slitting | 0.02 mm knife clearance, ±0.05 mm width control, burr ≤ 8 µm | Eliminate edge work-hardening; prepare strip geometry for winding | Width ±0.03 mm, Burr ≤ 5 µm |

| Annealing | 320 °C – 350 °C, N₂ + 3 % H₂ atmosphere, dew-point ≤ –40 °C, 4 h soak | Recrystallise grain, drop Rm 15 %, raise conductivity 2 % IACS | Grain size 45 – 65 µm, σ ≥ 35 MS/m |

| Insulation Coating | Chromate-free Ti-Zr complex, 1.2 – 1.8 µm per side, 180 °C cure, 30 s | Build 5 V/µm dielectric strength; withstand 200 °C overload | Pinholes ≤ 3/m², adhesion 0 B (ISO 2409) |

| Precision Cutting | 0.001 mm CNC back-stop, stack height ≤ 600 mm, diagonal ≤ 0.2 mm/1000 mm | Deliver square lamination packs; minimise air-gap in core | Length/width ±0.05 mm, Flatness ≤ 0.5 mm/m |

2. Real-Time Quality Control Matrix

| Checkpoint | Sensor / Method | Frequency | Reject Criteria | Data Logging |

|---|---|---|---|---|

| Edge burr | Laser triangulation | Every coil | Burr > 8 µm | SPC chart, coil ID |

| Strip tension | Load-cell roller | Continuous | Deviation > ±2 % | 1 kHz, MES upload |

| Conductivity | Eddy-current, 20 °C | Each anneal batch | < 34.5 MS/m | Certificate EN 10204-3.1 |

| Coating thickness | β-backscatter | 100 % scan | Outside 1.2-1.8 µm | Map per metre |

| Lamination squareness | Vision system | Every 50 pcs | Diagonal > 0.2 mm | Image archive 12 months |

3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Unit | Luoyang Xinzhaohe Standard | Common Market Range | Test Norm |

|---|---|---|---|---|

| Alloy purity | % Al | ≥ 99.7 (1070) | 99.5 – 99.6 | ASTM E1251 |

| Electrical conductivity | MS/m @ 20 °C | 35.0 – 36.5 | 33.0 – 34.5 | IEC 60404-2 |

| Core loss @ 50 Hz, 1.0 T | W kg⁻¹ | ≤ 0.85 | 0.95 – 1.10 | IEC 60404-3 |

| Strip camber | mm/1 m | ≤ 0.3 | 0.5 – 1.0 | ISO 9444 |

| Burr height | µm | ≤ 5 | 8 – 15 | Calibrated stylus |

| Coating breakdown voltage | V DC | ≥ 900 | 500 – 700 | ASTM D149 |

| Lot-to-lot σ variation | % | ±1.5 | ±3 – 5 | SPC CpK ≥ 1.67 |

4. Engineering Notes for Transformer OEMs

Grain control: Our 320-350 °C anneal window produces a {100} fibre texture, lowering hysteresis loss by ≈ 7 % versus uncontrolled furnace lots.

Coating chemistry: Ti-Zr layer is Cr⁶-free and compatible with VPI resins up to 200 °C; proven in 1 500 MVA dry-type reactors since 2017.

Flatness retention: Post-cut stress-relief jig keeps packs < 0.5 mm/m; eliminates core-clamping force scatter that can raise noise by 2-3 dB.

Traceability: Every slit coil receives a QR-coded heat ID linked to conductivity, tensile and coating raw data; downloadable within 30 min for PPAP submissions.

By integrating these process levers, Luoyang Xinzhaohe delivers transformer-grade aluminum sheet that meets Class-C insulation reliability at a landed cost typically 18-22 % below EU or Japanese mill pricing—without the 16-week mill backlog.

Packaging & Global Logistics

Export Packaging & Logistics

Sea-freight integrity for transformer-grade aluminum strips, foils, and wires

H3 1. Packaging Engineering Philosophy

Transformer windings tolerate zero edge denting, oil contamination, or chloride pitting.

Our Luoyang plant therefore treats every coil as a “Class-A magnetic component”, not as commodity aluminum.

Packaging is designed to three measurable limits:

| Critical Limit | Test Method | Acceptable Value |

|---|---|---|

| Edge dent depth | ISO 8492 ring crush | ≤ 0.05 mm |

| Inter-coil moisture | ASTM D4263 (cobalt paper) | ≤ 30 %RH at 40 °C |

| Chloride residue on foil | ISO 9290 | ≤ 0.5 µg NaCl/cm² |

All dunnage and films are lot-certified to meet the above before release to our loading bay.

H3 2. Strip & Foil Packaging (0.1–3.0 mm)

| Layer | Material | Function | Specification |

|---|---|---|---|

| 1 – Coil isolation | 80 µm VCI polyamide film | Volatile corrosion inhibition | DIN 55 531, 24 h < 2 % tarnish |

| 2 – Edge armor | 1.5 mm HDPE “U” channel | Impact distribution | 5 J drop test, 1 m height |

| 3 – Desiccant | 10 g Tyvek® sachets, 6 pcs/ft³ | Maintain ≤ 40 %RH | MIL-D-3464 Type I |

| 4 – Radial lock | 25 mm EPE foam ring | Prevent coil telescoping | Compression set < 5 % |

| 5 – Outer wrap | 120 µm UV-stable PE film | Sea-water splash barrier | 90-day Q-UV B 313 nm, ΔE < 2 |

| 6 – Pallet base | ISPM-15 fumigated pine, 4-way entry | Fork-lift handling | 1.2 t dynamic, 3 t static |

Coils are stacked eye-to-sky only, maximum two high, with 19 mm plywood interleaf to equalize strap tension.

Steel strapping (19 mm × 0.8 mm) is torque-clinched to 450 N·m and edge-protected with PET sleeves to avoid galvanic aluminum–iron contact.

H3 3. Wire & Small-Section Packaging (Ø 0.3–6.0 mm)

| Form | Spool Type | Tare (kg) | Max. Net (kg) | Pallet Pattern |

|---|---|---|---|---|

| Wire | DIN 355 plastic spool | 1.2 | 80 | 6 spools/layer, 4 layers, strapped |

| Strip (< 20 mm wide) | PT-400 fiberboard reel | 2.5 | 120 | 4 reels/layer, 3 layers, shrink-hooded |

Each spool is vacuum-sealed with 60 µm PE/EVOH co-ex film (O₂ transmission ≤ 0.5 cm³/m²·day) before insertion into 7-ply export cartons. Cartons are edge-corner glued and stacked on 1100 × 1100 mm Euro pallets, top-cap bonded with 23 µm LLDPE stretch film plus corner boards.

H3 4. Container Loading & Securing

| Parameter | 20 ft GP | 40 ft HC |

|---|---|---|

| Max. gross payload | 21 t | 26 t |

| Typical aluminum net | 18 t | 23 t |

| Dunnage weight | 0.9 t | 1.1 t |

| Securing method | 50 mm woven lash + friction mats | Same |

| Lashing tension | 2 × 2000 daN per coil row | 2 × 2000 daN |

All containers are inspected under our “7-Point QC Gate”:

1. Floor moisture < 15 % with Protimeter.

2. No visible chloride residue (swab test).

3. Ventilation baffles sealed for aluminum.

4. Desiccant strips hung (2 kg/20 ft).

5. Cargo insurance sticker (110 % CIF).

6. RFID seal logged (GPS traceable).

7. Photo dossier uploaded to customer portal before vessel departure.

H3 5. Origin Advantage – Luoyang Hub

80 km to Zhengzhou International Land-Port – daily block-train to Hamburg (18 days) for European transformer plants needing DDP lead-time < 22 days.

170 km to Qingdao port – weekly break-bulk to NAFTA & ASEAN; CFS cut-off 72 h before ETD.

In-house customs bureau – E-declaration, AES filing, and COO issuance within 4 h.

Compared with Western stockists, we eliminate one trans-loading step, cutting freight damage claims by 38 % (2023 data, 1.2 M km shipped).

H3 6. Cost-Performance Summary

| Service Level | Western Supplier | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| FOB unit price (1060-O strip 0.3 × 300 mm) | US$ 2.95 /kg | US$ 2.35 /kg | –20 % |

| Sea freight (Qingdao → Houston) | — included above | US$ 0.18 /kg | — |

| Transit damage allowance | 1 % scrap | 0.3 % scrap | –70 % |

| Total landed cost index | 100 | 78 | –22 % |

22 % saving without compromising electrical grade purity or packaging integrity.

Bottom line: Transformer manufacturers receive vacuum-dry, dent-free aluminum ready for immediate winding, while capital locked in freight damage and inventory buffer is released back to your core-loss testing budget.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Aluminum Transformer Sheet

20-Year Metallurgical Track Record—Built for Grid-Grade Reliability

Since 2004 our Luoyang works has supplied >180 000 t of slit-and-coated aluminum and silicon-steel to ABB, Siemens, TBEA and Tier-1 motor repair shops. Every coil is processed on the same slitting/annealing line that produces 0.23 mm 23QG085 silicon steel; the dimensional tolerances and cleanliness protocols transfer directly to 1060/1070 aluminum strip, giving you transformer-grade edge quality at a fraction of Western cost.

Direct Factory Price—No Trading Margin, No Hidden Alloy Surcharge

| Typical 0.3 mm × 220 mm 1060-O strip, FOB Shanghai | Western EU Mill | Korean Trader | Luoyang Xinzhaohe |

|---|---|---|---|

| Price USD/ton (25 t lot) | 2 950 | 2 750 | 2 180 |

| Lead time (weeks) | 10–12 | 8–10 | 4–5 |

| Annealing + insulation included | Optional | No | Standard |

We publish our LME-Al + conversion formula monthly; the above lot ships in 5–7 da after receipt of LC or 30 % TT.

Customization Window—Alloy, Temper, Geometry, Coating

| Parameter | Standard Offer | Engineering Limits |

|---|---|---|

| Alloy | 1060, 1070, 1350 | 1050, 1100, 5052 on request |

| Purity | ≥ 99.6 % Al | 99.7 % Al max (for extra conductivity) |

| Thickness | 0.15 – 3.00 mm | ± 0.005 mm camber ≤ 1 mm / 1 m |

| Width | 8 – 1 320 mm | Burr ≤ 0.02 mm, no tight coil set |

| Temper | O, H12, H14, H18 | Custom skin-pass for 90 ° forming |

| Coil ID | 150, 300, 400, 500 mm | OD ≤ 1 800 mm, weight ≤ 5 t |

| Edge | Slit, round, deburred | Optional 0.2 mm chamfer for HV foil winders |

| Surface | Degreased, chemically passivated | Electro-static epoxy 1 – 3 µm, Class F (155 °C) or Class H (180 °C) |

| Electrical Resistivity @ 20 °C | ≤ 0.027 8 µΩ·m | Certified per IEC 60404-1 |

Need a 0.25 mm × 840 mm 1350-O coil with 2 µm heat-resistant epoxy and ≤ 0.3 mm burr for a 33 kV dry-type cast-resin transformer? We routinely hold ± 0.008 mm thickness and ≤ 1.0 mm I-unit flatness—specifications that eliminate hot-spot eddy currents and improve space factor by 1.8 % versus commercial strip.

Quality Infrastructure—Same Metrology as Silicon-Steel Line

Continuous annealing furnace with ± 3 °C uniformity, H₂/N₂ atmosphere, dew-point ≤ –60 °C → zero oxide discoloration.

23-roller precision leveler → flatness ≤ 1 I-unit, critical for automatic layer winding.

Online burr camera 25 µm resolution → 100 % strip edge inspection; data logged per coil ID for traceability.

Final slit widths verified by laser micrometer; Cpk ≥ 1.67 on all customer CTQs.

One-Page RFQ—No Obligation

Send us the winding drawing or simply fill in: alloy, temper, thickness × width, coil weight, insulation class, annual volume. We return a formal datasheet with resistivity, tensile, elongation, coating adhesion and FOB Shanghai price within 24 h.

Contact:

Cathy Wang, Sales Engineer (Multilingual)

cathy@transformerstrip.com | Mobile/WeChat/WhatsApp: +86-180-3799-8506

Luoyang Xinzhaohe Aluminum Co., Ltd.

No. 8 Xinkai Road, Yibin District, Luoyang 471000, China

Cut your transformer aluminum spend by 18–28 % without cutting a single specification—talk to the factory that already powers the world’s grids.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum sheets from Luoyang Xinzhaohe.