Table of Contents

Market Insight: Aluminum Rectangle

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

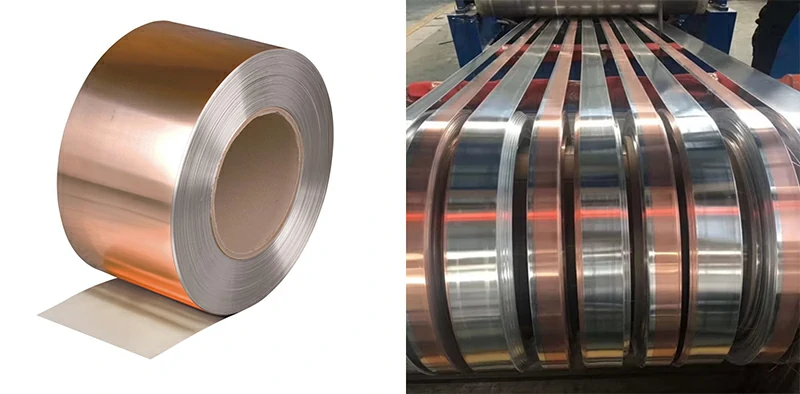

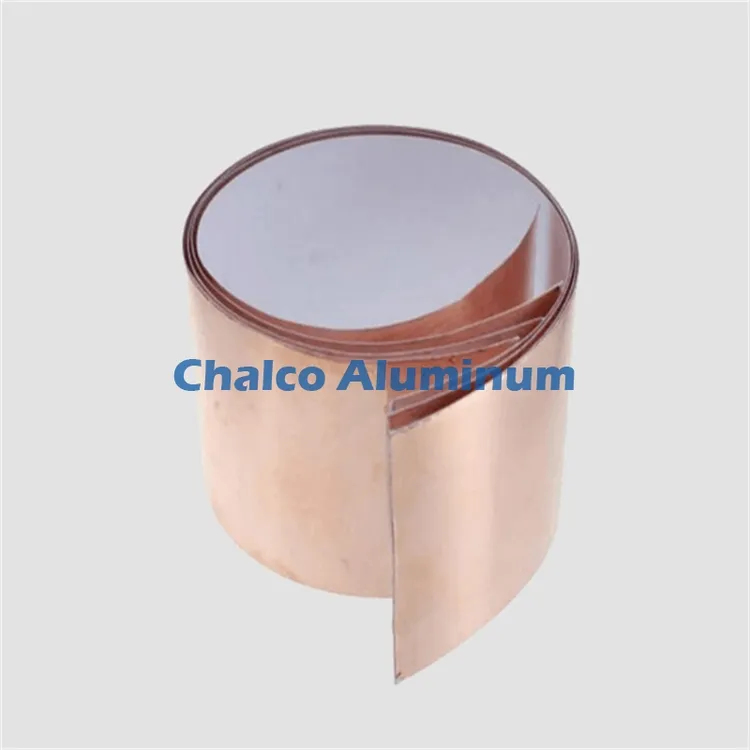

The global transformer industry continues to expand in response to rising electricity demand, grid modernization initiatives, and the integration of renewable energy sources. Within this landscape, aluminum rectangle strip—specifically engineered for use in transformer windings—plays a critical role in medium and large power transformers, particularly where weight reduction, cost efficiency, and conductivity balance are paramount. Aluminum rectangle strips are primarily used in low-voltage (LV) windings, offering a lightweight alternative to copper while maintaining adequate electrical performance. The demand for high-purity, precision-finished aluminum strip in transformer applications has grown steadily, driven by infrastructure development in emerging economies and the push for energy-efficient transformer designs compliant with IEC and IEEE standards.

Aluminum’s conductivity-to-weight ratio makes it especially suitable for distribution and power transformers where transport and installation logistics are critical. Modern aluminum rectangle strips used in transformer windings typically conform to alloy standards such as 1060, 1070, or 1350, with purity levels exceeding 99.6%. These grades ensure minimal resistive losses and enhanced thermal stability under continuous load. The rectangular cross-section allows for optimized space utilization within the winding structure, improving fill factor and cooling efficiency. As transformers are designed for operational lifespans exceeding 30 years, the long-term reliability of winding materials is non-negotiable.

Quality in aluminum rectangle strip directly impacts transformer performance, efficiency, and safety. Dimensional precision—particularly in thickness, width, and edge straightness—is essential to ensure uniform winding tension and prevent inter-turn insulation damage during coil fabrication. Surface integrity is equally critical; scratches, pits, or oxide inclusions can initiate localized heating and reduce dielectric strength. Furthermore, consistent mechanical properties, including controlled tensile strength and elongation, are required to maintain winding integrity under short-circuit forces. Any deviation in material quality can lead to premature transformer failure, increased no-load and load losses, or non-compliance with energy efficiency regulations such as DOE 2016 or EU EcoDesign.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production experience in transformer-grade aluminum and copper foils and strips, we emphasize metallurgical consistency and process control. Our aluminum rectangle strips are manufactured under strict ISO 9001-certified protocols, featuring continuous casting and rolling processes that minimize hydrogen content and inclusions. Each batch undergoes rigorous testing for electrical resistivity, surface roughness, and dimensional tolerance, ensuring compliance with international transformer manufacturing requirements.

The competitive dynamics of the transformer materials market underscore the importance of supplier reliability, technical support, and traceability. As original equipment manufacturers (OEMs) face tighter delivery schedules and higher quality expectations, partnerships with vertically integrated, technically proficient suppliers become strategic advantages. In this context, aluminum rectangle strip is not merely a commodity input but a performance-critical component whose quality directly influences the efficiency, longevity, and safety of power transmission infrastructure.

Technical Specs: Aluminum Rectangle

Technical Specifications: Precision Aluminum Rectangle for Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver aluminum rectangle strip meeting the exacting demands of transformer core and foil manufacturing. Our production process prioritizes dimensional stability, electrical performance, and edge integrity critical for minimizing eddy current losses and ensuring long-term operational reliability in high-efficiency transformers.

Precision slitting to tolerances of ±0.002 mm is non-negotiable for maintaining consistent magnetic flux distribution within transformer laminations. Deviations beyond this threshold induce localized heating and reduce core efficiency. Our proprietary tension-controlled slitting lines, coupled with real-time laser micrometry feedback, guarantee uniform strip width across entire coils. This precision directly supports tighter stacking factors and reduced no-load losses in grain-oriented electrical steel assemblies. Burr-free edges are equally critical; microscopic edge deformations compromise dielectric integrity between lamination layers, accelerating insulation breakdown. We achieve burr heights ≤ 3 μm through precision-ground rotary shear blades, optimized blade clearance settings calibrated to material thickness, and inline edge inspection via high-resolution optical profilometry.

Electrical conductivity, measured per ASTM E1004, must consistently exceed 61.0% IACS for EC-grade aluminum used in transformer windings and shielding. Conductivity directly impacts resistive losses and thermal management. Our material undergoes strict homogenization and annealing protocols to ensure minimal intermetallic segregation, achieving conductivity in the range of 61.5–62.0% IACS. Surface quality is maintained to Ra ≤ 0.4 μm via controlled rolling and cleaning processes, preventing particle entrapment that could initiate partial discharges.

The following table details our certified technical parameters for aluminum rectangle strip in transformer applications:

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Designation | 1070, 1060, 1350 (EC Grade) | GB/T 3880.1 |

| Thickness Range | 0.10 mm – 3.00 mm | GB/T 3880.2 |

| Width Range | 10 mm – 1,500 mm | GB/T 3880.2 |

| Slitting Tolerance | ±0.002 mm | ISO 2178 |

| Edge Burr Height | ≤ 3 μm | ISO 4287 |

| Surface Roughness (Ra) | ≤ 0.4 μm | ISO 4287 |

| Tensile Strength | 60–95 MPa | GB/T 228.1 |

| Elongation | ≥ 25% | GB/T 228.1 |

| Electrical Conductivity | 61.5–62.0% IACS | ASTM E1004 |

| Flatness | ≤ 5 I-Units | ASTM E2907 |

| Coil Inner Diameter | 508 mm (20″) Standard | Customer Specific |

All material undergoes 100% inline eddy current testing for subsurface defects and laminar inclusions. Final certification includes traceable mill test reports confirming chemical composition per GB/T 3190, mechanical properties, and conductivity. Our vertical integration—from molten metal purification to precision slitting—ensures batch-to-batch consistency essential for transformer manufacturers optimizing for IE5+ efficiency standards. Dimensional integrity and surface perfection are validated at shipment, eliminating downstream processing rejects and safeguarding your production throughput.

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Rectangle Transformer Strip

The production of aluminum rectangle strips at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning, ensuring dimensional accuracy, surface integrity, and electrical performance required for transformer applications. With over two decades of metallurgical expertise, our process is engineered to meet international standards including GB/T, ASTM, and IEC specifications for conductivity, mechanical strength, and surface finish.

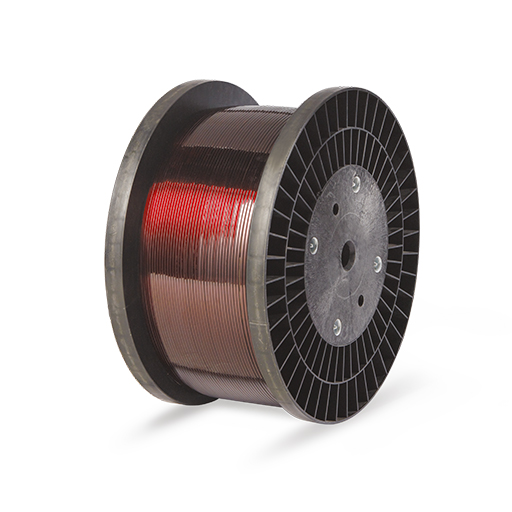

The process begins with high-purity aluminum ingots (typically 1060, 1070, or 1350 alloys) that are homogenized, hot-rolled into intermediate coils, and then subjected to cold rolling. Cold rolling is performed on precision reversing mills under controlled reduction ratios and interpass annealing conditions to achieve the target thickness, which commonly ranges from 0.2 mm to 6.0 mm for rectangular strip applications. This stage is critical for developing a uniform grain structure, enhancing tensile strength, and ensuring consistent elongation properties. Rolling parameters such as roll gap, rolling speed, and lubricant flow are continuously monitored using automated control systems to maintain thickness tolerances within ±0.02 mm.

Following cold rolling, the master coils undergo precision slitting to produce rectangular strips of specified widths, typically between 10 mm and 300 mm. Slitting is conducted on high-accuracy tension leveling lines equipped with rotary shear blades or circular knives, minimizing edge burr and camber deviation. The slit lines are synchronized with laser-based width measurement systems to ensure edge parallelism within 0.1 mm per meter of length. During this stage, strip surface is protected by anti-scratch coatings or interleaf paper to prevent transit damage.

Edge conditioning is the final mechanical treatment, essential for transformer-grade aluminum to eliminate stress concentration points and reduce corona discharge risk in high-voltage environments. The edges are uniformly rounded via roller burnishing or abrasive edge rolling, achieving a consistent radius of 0.1–0.3 mm. This process eliminates micro-cracks and burrs that could initiate failure during winding or under thermal cycling.

Quality control is integrated throughout each phase. Incoming billets are spectroscopically analyzed for alloy composition. During cold rolling,在线 thickness gauges (X-ray or beta gauge) provide real-time feedback. Post-slitting, samples undergo tensile testing, eddy current conductivity checks (ensuring ≥59% IACS), and surface profilometry. Final inspection includes visual examination under controlled lighting, edge profile measurement, and dimensional audit using calibrated micrometers and optical comparators. All test data are documented per batch for full traceability.

This end-to-end manufacturing protocol ensures that every aluminum rectangle strip delivered by Luoyang Xinzhaohe Aluminum Co., Ltd. meets the rigorous demands of transformer core and winding applications, combining metallurgical integrity with geometric precision.

Packaging & Logistics

Export Packaging Protocol for Aluminum Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard aluminum rectangle products—primarily transformer strip and foil—during global maritime transit. With over two decades of metallurgical and supply chain expertise, our methodology prioritizes structural integrity and environmental protection against the hygroscopic nature of aluminum oxide and the corrosive hazards of sea freight.

All shipments commence with ISPM-15 certified wooden pallets, constructed from kiln-dried hardwood meeting international phytosanitary standards. These pallets undergo mandatory heat treatment to eliminate biological contaminants, ensuring compliance with global customs regulations. Pallet dimensions are optimized for containerization efficiency while maintaining load stability:

| Parameter | Specification |

|---|---|

| Pallet Thickness | 180–220 mm |

| Load Capacity | 2,500–3,000 kg |

| Base Dimensions | 1,100 × 1,100 mm |

The aluminum coil or sheet assembly is secured to the pallet using high-tensile steel strapping (minimum 15 mm width, 15 kN breaking strength) tensioned to 25% of ultimate load capacity. Critical edge protection is achieved through laminated corner boards with 8 mm edge radius, preventing deformation during handling and vessel motion.

Moisture mitigation constitutes the core safeguard for aluminum transformer materials. Each unit is hermetically sealed within triple-layer moisture-proof film comprising:

Inner layer: 50 μm anti-static LDPE to prevent surface oxidation during unwrapping

Middle layer: 40 μm aluminum foil vapor barrier (WVTR < 0.1 g/m²/day)

Outer layer: 60 μm UV-stabilized LDPE for puncture resistance

This composite film achieves a total thickness of 150 μm, validated through ASTM E96 desiccant testing to maintain internal humidity below 40% RH for 90+ days. Desiccant units (60 g/m³ capacity) are strategically positioned within the sealed envelope, with humidity indicator cards placed at load extremities for post-transit verification.

Marine transit demands dynamic load management. Palletized units are further stabilized within containers using dunnage bags inflated to 0.15 bar pressure, eliminating lateral movement during vessel roll exceeding 15 degrees. All packaging components undergo salt-spray testing (ASTM B117) for 96 hours to confirm corrosion resistance. Documentation includes a moisture barrier certification report and container stowage plan aligned with IMO CTU Code Annex 4 requirements.

This integrated system—validated across 12,000+ TEUs of annual exports—ensures zero moisture ingress and dimensional stability through humidity excursions from -20°C to 60°C. For transformer-grade aluminum, where surface purity directly impacts dielectric performance, our packaging is not merely transport infrastructure but a critical extension of metallurgical quality control. Partnering with Xinzhaohe guarantees that your aluminum rectangle products arrive with uncompromised surface integrity, ready for precision slitting or lamination operations.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Aluminum Rectangle Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd brings over two decades of specialized expertise in the production and supply of high-precision aluminum rectangular strips and foils, serving critical applications in transformer manufacturing and advanced electrical systems. As a vertically integrated industrial partner, we combine advanced metallurgical engineering with rigorous quality control to deliver aluminum rectangle products that meet exacting international standards, including GB/T, ASTM, and IEC specifications.

Our manufacturing facility spans over 120,000 square meters, equipped with fully automated rolling lines, precision slitting machines, and state-of-the-art annealing furnaces capable of controlled atmosphere processing. This infrastructure enables us to produce aluminum rectangle strips with tight dimensional tolerances—ranging from 0.1 mm to 6.0 mm in thickness and up to 1,600 mm in width—while maintaining superior surface finish and mechanical consistency. We utilize high-purity aluminum ingots (99.70% min Al) sourced from certified suppliers, ensuring low hydrogen content, minimal inclusions, and optimal electrical conductivity for transformer-grade performance.

The core of our technical advantage lies in our in-house metallurgical laboratory, which conducts comprehensive material analysis using OES spectrometry, metallographic microscopy, tensile testing, and eddy current inspection. Every production batch undergoes strict quality verification for parameters such as resistivity, elongation, grain structure, and surface defects, ensuring full traceability and compliance with customer-specific requirements. Our process control systems are ISO 9001:2015 certified, reflecting our commitment to operational excellence and continuous improvement.

We specialize in customized solutions for transformer manufacturers requiring tailored tempers (O, H14, H16, H18), edge conditioning (trimmed or slit edge), and coil configurations (ID 508 mm / 610 mm, max OD 2,000 mm). Our R&D team collaborates directly with clients to optimize material performance for high-efficiency transformers, including amorphous core and dry-type designs, where thermal stability and lamination integrity are critical.

With an annual production capacity exceeding 35,000 metric tons and a logistics network covering Asia, Europe, and North America, Luoyang Xinzhaohe ensures reliable delivery and supply chain resilience. Our technical sales team provides full documentation packages, including mill test certificates (MTCs), material certifications, and processing reports, to support seamless integration into your manufacturing workflow.

For sourcing managers and engineering teams seeking a long-term partner in aluminum rectangle supply, Luoyang Xinzhaohe offers proven capability, technical depth, and responsive service. We invite you to contact us directly to discuss your specifications and explore how our manufacturing precision can enhance your product performance.

Contact us at cathy@transformerstrip.com to initiate technical consultation or request sample submissions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum rectangle directly from China.