Table of Contents

Market Insight: Aluminum Plates

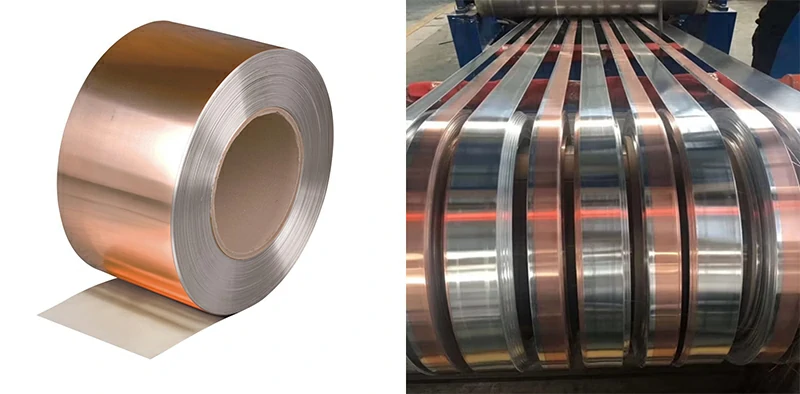

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for aluminum transformer strip and foil is experiencing sustained growth, driven primarily by the accelerating energy transition and critical grid infrastructure modernization. The expansion of renewable energy integration, particularly solar and wind farms, necessitates extensive new substation construction and transformer deployment to manage variable power flows and connect distributed generation. Concurrently, aging electrical grids in developed economies require significant replacement and upgrade cycles, while emerging markets undergo substantial grid expansion to support industrialization and electrification. Electric vehicle charging infrastructure proliferation further intensifies demand for distribution transformers. Aluminum strip and foil serve as the essential conductive material within transformer windings, offering a compelling balance of electrical conductivity, lightweight properties, and cost-effectiveness compared to copper, especially in distribution and power transformers above 500 kVA where weight and material cost become dominant factors. While copper retains advantages in ultimate conductivity for specific high-efficiency applications, aluminum’s superior conductivity-to-weight ratio and lower raw material cost solidify its position as the dominant material for the vast majority of new transformer production globally, underpinning consistent market expansion projected at 4-6% CAGR through 2030.

The criticality of material quality in aluminum transformer strip and foil cannot be overstated, as it directly dictates transformer performance, longevity, and operational safety. Electrical conductivity, measured against the International Annealed Copper Standard (IACS), is paramount; even minor deviations below 61.0% IACS significantly increase resistive losses (I²R losses), reducing efficiency and generating excess heat. This heat accelerates insulation degradation, the leading cause of premature transformer failure. Achieving and maintaining high conductivity requires exceptionally low levels of detrimental impurities such as iron, silicon, and titanium, often necessitating refined primary aluminum or meticulously controlled recycled feedstocks processed under stringent atmospheric conditions. Beyond conductivity, precise mechanical properties are vital. The strip must exhibit consistent tensile strength and elongation to withstand the significant stresses of winding without cracking or excessive deformation, while maintaining flatness and edge quality to prevent insulation damage during coil formation. Surface cleanliness is equally critical; residual oils, oxides, or particulate contamination act as initiation sites for partial discharges within the winding, progressively eroding insulation integrity. Suboptimal recrystallization behavior during annealing can lead to inconsistent grain structure, impacting both formability and long-term thermal stability under load cycles.

Compromised material quality introduces severe downstream risks that far outweigh initial procurement savings. Inconsistent conductivity directly translates to higher energy losses over the transformer’s 25-40 year operational life, violating increasingly stringent global efficiency regulations (e.g., DOE 2016, EU Ecodesign Lot 10) and incurring substantial lifetime energy cost penalties. Microstructural defects or surface imperfections significantly increase the probability of in-service failures, leading to costly unplanned outages, expensive field repairs, and potential safety hazards. Transformer manufacturers face immense reputational and financial liability for failures traced to substandard core materials. Luoyang Xinzhaohe Aluminum leverages over two decades of specialized production expertise to deliver aluminum strip and foil meeting the most rigorous international standards (ASTM B491/B492, IEC 60137). Our vertically integrated process control, from molten metal treatment through precision cold rolling, continuous annealing, and slitting, ensures exceptional batch-to-batch consistency in conductivity, mechanical properties, surface integrity, and dimensional tolerances. This unwavering quality commitment is fundamental to enabling transformer manufacturers to produce reliable, efficient, and compliant equipment for the modern grid.

Technical Specs: Aluminum Plates

Technical Specifications for Aluminum Plates – Transformer Strip/Foil Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision aluminum plates tailored for transformer strip and foil applications, where dimensional accuracy, edge quality, and electrical performance are critical. With over two decades of metallurgical and production expertise, our aluminum plates are engineered to meet the stringent demands of power transmission and electronic component manufacturing. The following technical specifications define the performance benchmarks of our aluminum plate products, ensuring compatibility with high-efficiency transformer windings and conductive systems.

Dimensional precision is paramount in transformer applications to ensure uniform winding tension, thermal management, and space optimization within core assemblies. Our aluminum plates are produced through a precision slitting process capable of maintaining width tolerances within ±0.002 mm. This level of control is achieved using CNC-guided rotary slitting lines with real-time laser monitoring, minimizing edge deviation and ensuring consistent strip geometry across extended production runs. The slit edges exhibit no measurable burr formation, a result of optimized blade clearance, high-grade tool steel dies, and post-slitting edge inspection via optical profilometry. Burr-free edges reduce the risk of dielectric breakdown in wound components and eliminate the need for secondary deburring operations, thereby enhancing downstream processing efficiency.

Surface integrity is maintained through controlled rolling and cleaning processes that prevent microcracking and surface oxidation. All plates are supplied with a clean, oxide-stable finish suitable for direct insulation coating or lamination. The material is available in tempers ranging from H18 to O (annealed), depending on required ductility and tensile strength, with typical yield strengths between 120–180 MPa and elongation of 2–6% as measured per ASTM E8.

Electrical conductivity is a core performance metric for transformer-grade aluminum. Our plates, manufactured from high-purity 1060, 1070, or 1350 alloys, achieve a minimum conductivity of 59.5% IACS (International Annealed Copper Standard) at 20°C, as verified by eddy current testing and four-point probe resistivity measurements. This ensures low resistive losses and high energy transfer efficiency in service. Trace alloying elements are tightly controlled, with iron and silicon content limited to ≤0.35% and ≤0.25% respectively, to preserve conductivity and prevent intermetallic phase formation.

All batches undergo full material traceability and are certified to ISO 9001:2015 standards. Mechanical, dimensional, and electrical test reports are available upon request.

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Grades | 1060, 1070, 1350 | GB/T 3190 |

| Thickness Range | 0.10 – 3.00 mm | ASTM B479 |

| Width Tolerance | ±0.002 mm | ASTM B928 |

| Edge Quality | Burr-free, no edge deformation | Visual & Microscopic |

| Conductivity (20°C) | ≥59.5% IACS | ASTM E1004 |

| Tensile Strength | 110–190 MPa | ASTM E8 |

| Yield Strength | 120–180 MPa | ASTM E8 |

| Elongation | 2–6% | ASTM E8 |

| Surface Finish | Clean, oxide-stable, no scratches | Visual Inspection |

| Temper Options | O, H14, H18 | GB/T 16475 |

| Coil Inner Diameter | 200 mm, 300 mm, 505 mm | Customizable |

| Packaging | Waterproof wrapping, wooden pallets | Export Standard |

Factory Tour: Manufacturing

Our Manufacturing Process for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in producing high-integrity aluminum and copper transformer strip and foil. Our vertically integrated process ensures stringent control over critical material properties essential for transformer core performance and manufacturing efficiency. The sequence begins with precision cold rolling of pre-annealed coil stock. Utilizing state-of-the-art 20-high cluster mills equipped with automatic gauge control (AGC) systems, we achieve final thicknesses ranging from 0.10 mm to 3.00 mm with exceptional uniformity. Critical parameters including rolling speed, interstand tension, and coolant application are meticulously monitored and adjusted in real-time to minimize residual stress, control surface roughness (Ra typically < 0.5 μm), and ensure consistent mechanical properties across the entire coil length. In-process quality control employs laser micrometers for continuous thickness profiling and surface inspection systems to detect defects such as scratches or inclusions, guaranteeing compliance with tight tolerances before progression.

The cold-rolled coil then undergoes precision slitting to the customer-specified width. This critical stage employs high-precision rotary shear lines featuring hardened tool steel knives with optimized clearance settings and advanced strip guiding systems. Precise knife geometry and alignment are paramount to prevent edge damage, minimize burr formation, and maintain dimensional accuracy. Width tolerance is rigorously controlled to ±0.10 mm or tighter, as required by transformer lamination stacking specifications. Continuous monitoring during slitting includes real-time width measurement via non-contact laser sensors and visual edge inspection. Any deviation triggers immediate process correction. Slitting parameters are specifically tailored to the alloy and temper to avoid edge cracking or excessive work hardening, which could compromise subsequent stamping or stacking operations.

Edge conditioning represents a vital, often overlooked, step where Luoyang Xinzhaohe applies significant proprietary knowledge. Following slitting, the strip edges undergo specialized processing to eliminate micro-burrs and achieve a consistent, rounded profile. Our process utilizes controlled abrasive techniques or precision brushing systems calibrated to remove sharp protrusions without distorting the strip edge geometry or introducing surface damage. This step is non-negotiable for transformer applications; unconditioned edges can puncture insulation during core stacking, leading to catastrophic interlaminar shorts and reduced transformer efficiency. Final quality verification includes microscopic edge profile analysis to confirm the absence of burrs and the achievement of the specified edge radius or chamfer (typically 45° at 0.05-0.10 mm). Comprehensive final inspection encompasses dimensional checks, surface quality assessment under controlled lighting, and verification of mechanical properties via sample testing per ASTM or customer-specific standards. This integrated, QC-embedded manufacturing sequence ensures the dimensional precision, edge integrity, and surface quality demanded by the most rigorous transformer manufacturing environments.

Packaging & Logistics

Export Packaging for Aluminum Transformer Strip and Foil

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and international distribution of aluminum and copper transformer strips and foils, we maintain rigorous standards in export packaging to ensure product integrity during global transit. Our packaging methodology is engineered specifically to address the challenges associated with long-distance sea freight, where exposure to humidity, mechanical stress, and variable climatic conditions pose significant risks to sensitive metallic coil products.

All transformer-grade aluminum strips and foils are systematically palletized using high-strength wooden pallets constructed from kiln-dried, fumigation-treated hardwood. These pallets comply with International Standards for Phytosanitary Measures No. 15 (ISPM-15), ensuring global customs acceptance and eliminating the risk of pest contamination. The structural design of the pallets supports uniform load distribution, minimizing coil deformation during stacking and handling. Each coil is securely fastened to the pallet using steel or PET strapping, with edge protectors applied to prevent mechanical damage to the outer wraps during transportation.

A critical component of our packaging system is the multi-layer moisture-proof barrier. After palletization, each coil is wrapped in industrial-grade moisture-proof film, typically consisting of laminated aluminum-polyethylene composites. This vapor barrier provides a hermetic seal that effectively prevents the ingress of ambient moisture, a primary cause of surface oxidation and interlayer corrosion in aluminum strips during extended maritime shipping. The wrapping process is performed in a climate-controlled environment to minimize trapped humidity, and sealed seams are thermally bonded to ensure continuity.

Additional protective measures include the use of desiccant packs placed within the sealed wrapping to absorb residual moisture, and corrosion-inhibiting VCI (volatile corrosion inhibitor) paper interlayers when specified by customer requirements or destination climate profiles. For shipments to regions with high tropical humidity or prolonged ocean exposure, we implement double-layer wrapping protocols with intermediate inspection checks to guarantee barrier integrity.

All packaged units are labeled with durable, weather-resistant identification tags indicating product specifications, batch numbers, net and gross weights, handling instructions, and orientation markings. This traceability system supports efficient logistics management and ensures compliance with international shipping regulations.

Our packaging protocol has been validated through extensive real-world performance data across major trade routes, including trans-Pacific and trans-Indian Ocean shipments. By integrating structural stability, environmental protection, and regulatory compliance, Luoyang Xinzhaohe ensures that aluminum transformer strips and foils arrive at their destination in optimal condition, ready for immediate processing and integration into high-performance electrical systems.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Aluminum Solutions for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum plates and strips for transformer core manufacturing. Our deep understanding of electromagnetic performance requirements drives every stage of production, ensuring materials meet the stringent demands of high-efficiency power and distribution transformers. We focus exclusively on the technical nuances of aluminum and copper transformer strip and foil, translating material science into reliable electrical performance.

Our integrated manufacturing facility in Luoyang, China, provides complete control over the metallurgical pathway from high-purity ingot to finished coil. Advanced twin-roll casting and precision cold rolling lines operate under strict atmospheric controls to achieve exceptional purity levels exceeding 99.99% Al for critical applications. We consistently produce material with tightly controlled grain structure, minimized residual stress, and optimal surface integrity – factors directly impacting core loss (W15/50) and magnetic permeability. Our process capability ensures thickness tolerances down to ±0.002mm for foil and ±0.005mm for plate, with surface roughness (Ra) maintained within 0.25-0.80µm as required by lamination and insulation processes. Key dimensional and purity specifications are summarized below.

| Parameter | Typical Range | Critical Tolerance Control |

|---|---|---|

| Thickness | 0.10mm – 3.00mm (Plate) | ±0.005mm (Plate) |

| 0.05mm – 0.50mm (Strip/Foil) | ±0.002mm (Foil ≤0.10mm) | |

| Aluminum Purity | 99.70% – 99.99%+ | Fe+Si ≤ 0.15% (High Grade) |

| Surface Roughness | Ra 0.25µm – 0.80µm | Consistency across width |

| Coil Inner Diameter | 508mm / 610mm | Customizable |

Vertical integration is fundamental to our supply chain resilience. Controlling primary casting, homogenization, hot/cold rolling, and tension leveling within one facility eliminates cross-contamination risks and ensures batch traceability from raw material certification to final shipment. This integrated approach, combined with an annual production capacity exceeding 50,000 metric tons, guarantees stable supply for global transformer OEMs and tier suppliers. Our quality management system is ISO 9001:2015 certified, with rigorous in-process testing including OES for chemical composition, XRD for crystallographic analysis, and dedicated core loss validation protocols using Epstein frames. Every coil undergoes 100% surface inspection via automated vision systems to eliminate defects impacting varnish adhesion or lamination.

Partnering with Luoyang Xinzhaohe means accessing not just material, but collaborative engineering support. Our metallurgists work directly with your design and procurement teams to optimize alloy selection, temper, and dimensional parameters for your specific core construction and efficiency targets. We understand that transformer material performance directly impacts your product’s total cost of ownership through reduced no-load losses. Our commitment to on-time delivery, backed by strategic raw material inventory management and flexible logistics coordination, minimizes your production line disruption risk.

Initiate a technical consultation to discuss how our precision aluminum plates and strips can enhance your transformer core performance and supply chain stability. Contact our dedicated sourcing team at cathy@transformerstrip.com to request detailed technical datasheets, sample protocols, or schedule a metallurgical review. Let Luoyang Xinzhaohe become your engineered material partner for superior electromagnetic performance.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum plates directly from China.