Table of Contents

Market Insight: Aluminum Plate Sheet

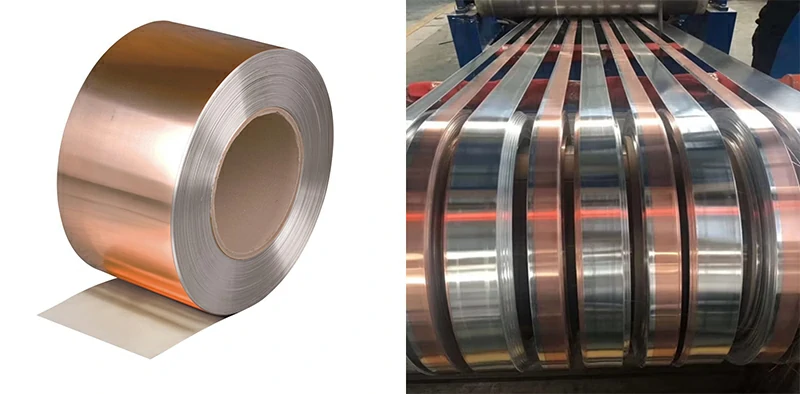

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

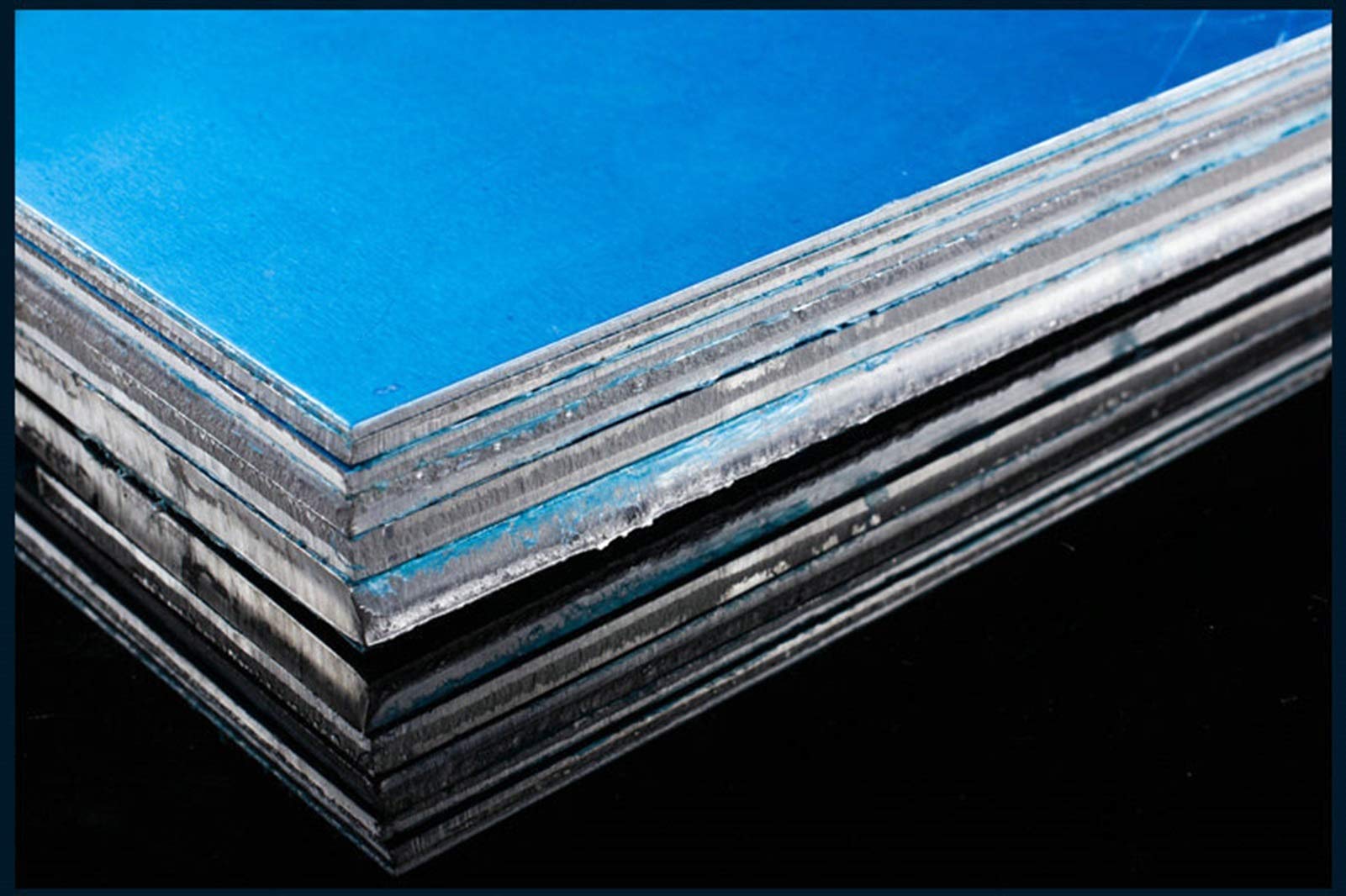

The global demand for aluminum plate and sheet in transformer applications has grown steadily, driven by the expansion of power infrastructure, renewable energy integration, and the need for lightweight, cost-effective conductive materials. While copper remains the traditional choice for high-efficiency transformers due to its superior electrical conductivity, aluminum has emerged as a competitive alternative—particularly in distribution transformers and large power transformers where weight reduction and material cost are critical factors. Aluminum plate and sheet, when manufactured to precise metallurgical and dimensional specifications, serve as the foundation for transformer windings, busbars, and shielding components, especially in medium- and low-voltage systems.

Industrial demand for aluminum transformer strip and foil is particularly strong in regions undergoing grid modernization, such as Southeast Asia, India, and parts of Africa, where cost-efficient solutions are prioritized without compromising long-term reliability. In China, domestic demand is sustained by state-backed smart grid initiatives and the rapid deployment of distributed energy resources. Aluminum’s lower density—approximately one-third that of copper—makes it ideal for applications where transportation and installation logistics are a concern. Additionally, aluminum offers favorable thermal expansion characteristics and corrosion resistance when properly coated or alloyed, contributing to extended service life in harsh environments.

Despite these advantages, the performance of aluminum in transformer applications is highly dependent on material quality. Impurities, inconsistent thickness, poor surface finish, or inadequate mechanical properties can lead to increased resistivity, hot-spot formation, and premature failure. Transformer-grade aluminum must meet stringent international standards such as ASTM B408, IEC 60164, and GB/T 3190, which govern chemical composition, electrical conductivity, tensile strength, and elongation. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized production experience, we ensure that all aluminum plate and sheet products for transformer applications undergo rigorous quality control, including spectrographic analysis, eddy current testing, and precise thickness profiling.

Consistency in coil-to-coil performance is equally critical. Variability in strip dimensions or mechanical behavior can disrupt downstream processes such as winding, welding, and insulation wrapping, leading to production inefficiencies and field failures. High-purity aluminum (99.7% minimum Al) with controlled iron and silicon content minimizes resistive losses and enhances long-term thermal stability. Furthermore, surface cleanliness and edge quality are paramount to prevent dielectric breakdown in insulated winding systems.

The shift toward energy-efficient transformers (as mandated by DOE and EU Ecodesign regulations) places additional emphasis on material performance. High-quality aluminum strip reduces no-load and load losses, directly contributing to compliance with Tier 1 and Tier 2 efficiency standards. As the industry moves toward smart transformers and hybrid aluminum-copper designs, the role of precision-engineered aluminum plate and sheet will continue to expand.

In summary, while aluminum offers compelling economic and logistical benefits in transformer manufacturing, its success hinges on metallurgical integrity and dimensional precision. For OEMs and tier suppliers, partnering with a proven, quality-focused producer is essential to ensure reliability, regulatory compliance, and optimal transformer performance across the operational lifecycle.

Technical Specs: Aluminum Plate Sheet

Technical Specifications: Precision Aluminum Plate Sheet for Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized metallurgical expertise to deliver aluminum plate sheet meeting the exacting demands of transformer core and winding manufacturing. Our technical parameters are engineered for zero-compromise performance in high-efficiency electrical systems, with rigorous adherence to ASTM B209 and GB/T 3880 standards. Critical focus areas include dimensional stability, edge integrity, and electrical properties, all validated through in-line metrology and third-party certification.

The following table details core specifications for our transformer-grade aluminum plate sheet, primarily utilizing 1060/1070 alloys optimized for magnetic flux efficiency. All tolerances are non-negotiable and maintained under SPC-controlled production lines with real-time laser gauging.

| Parameter | Specification | Test Standard | Relevance to Transformer Performance |

|---|---|---|---|

| Thickness Range | 0.5 mm – 3.0 mm | ASTM E29 | Ensures consistent lamination stacking and core loss control |

| Thickness Tolerance | ±0.01 mm (for 0.5–1.0 mm) | ASTM B49/B958 | Minimizes air gaps in stacked cores, reducing eddy current losses |

| Slit Width Tolerance | ±0.002 mm | ISO 2768-mK | Guarantees precise coil winding tension and layer alignment |

| Edge Burr Height | ≤ 0.005 mm (no detectable burr) | ISO 1302 | Prevents insulation damage during winding and eliminates short-circuit risks |

| Surface Roughness (Ra) | ≤ 0.4 μm | ISO 4287 | Optimizes varnish adhesion and reduces interfacial losses |

| Conductivity (%IACS) | 59.5–61.0% (20°C) | ASTM E1004 | Maximizes current-carrying capacity while minimizing resistive heating |

| Flatness Deviation | ≤ 2 mm/m | ASTM B666 | Ensures uniform pressure distribution in wound cores |

| Tensile Strength | 65–85 MPa | ASTM E8 | Balances formability during slitting with mechanical stability in operation |

Precision slitting at ±0.002 mm is achieved through servo-driven knife systems with sub-micron positional feedback, eliminating width variation that causes winding skew or tension spikes. Burr-free edges are non-negotiable; we employ high-precision shear knives with 0.001 mm runout tolerance and automated edge inspection via optical profilometry, rejecting any material exceeding 5μm burr height. Conductivity is maintained through strict melt chemistry control (Fe+Si ≤ 0.15%, Cu ≤ 0.01%) and optimized annealing cycles, with 100% lot verification via eddy current testing per ASTM E1004. Surface finish is critical for dielectric integrity; our sheets undergo tension-leveling and chemical cleaning to achieve Ra ≤ 0.4 μm, verified by profilometer scans at 500 mm intervals.

All material undergoes 100% width and thickness validation during slitting, with digital logs traceable to individual coils. We reject industry-standard “nominal” tolerances in favor of guaranteed performance metrics that directly impact transformer efficiency, longevity, and safety. Custom alloys and tighter tolerances are available for specialized high-frequency or high-voltage applications. Partner with Xinzhaohe for specifications engineered to eliminate field failures, not merely meet minimum standards.

Factory Tour: Manufacturing

Manufacturing Process for High-Precision Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaohe Aluminum CO., Ltd, the production of aluminum plate sheet for transformer strip and foil applications follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, surface integrity, and electrical performance. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent requirements of the power transmission and distribution sector.

The manufacturing sequence begins with cold rolling, where pre-annealed aluminum alloy ingots or hot-rolled slabs are processed through a series of reversing or tandem rolling stands. This stage reduces material thickness with high uniformity, achieving tight tolerances as low as ±0.01 mm. Cold rolling enhances mechanical strength through strain hardening while improving surface finish critical for insulation layer adhesion in transformer windings. All rolling parameters—rolling speed, reduction ratio, and interstand tension—are monitored in real time using automated control systems to maintain consistency across production batches. Lubrication and cooling are precisely managed to prevent thermal distortion and surface defects such as scratches or roll marks.

Following cold rolling, the material undergoes precision slitting, a critical operation for transformer strip applications requiring narrow widths and exact coil dimensions. Slitting is performed on high-accuracy rotary shear lines equipped with tungsten carbide circular knives, ensuring clean, burr-free cuts. Strip widths can be adjusted from 10 mm to over 600 mm, with edge runout controlled within ±0.05 mm. Tension leveling during slitting minimizes camber and ensures flatness, which is essential for automated winding processes in transformer manufacturing. Each slit coil is wound under constant tension using mandrel winding systems to prevent telescoping and edge damage.

Edge conditioning is the final mechanical processing step, designed to eliminate micro-burrs and sharp edges generated during slitting. This is achieved through a combination of brushing, edge rolling, or precision chamfering techniques, depending on customer specifications. Properly conditioned edges reduce the risk of dielectric breakdown in transformer windings and enhance safety during handling and assembly.

Throughout the production cycle, comprehensive quality control protocols are enforced. In-process inspections include surface defect scanning via high-resolution optical systems, thickness measurement using laser micrometers, and flatness evaluation through profilometry. Mechanical properties are verified via tensile testing, while microstructural analysis ensures proper grain structure and absence of intermetallic segregation. Final coils are subjected to 100% visual inspection and packaged with protective interleafing to prevent transit damage.

This integrated approach—combining cold rolling, precision slitting, and edge conditioning under rigorous quality surveillance—ensures that every batch of aluminum transformer strip and foil meets international standards such as GB/T 3880 and ASTM B209, delivering reliability and performance in critical electrical applications.

Packaging & Logistics

Export Packaging Standards for Aluminum Plate Sheet Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard aluminum plate sheet integrity during global maritime transit. Given aluminum’s susceptibility to moisture-induced corrosion and physical abrasion, our methodology transcends basic industry norms, directly addressing the unique challenges of ocean freight environments characterized by prolonged humidity exposure, salt air, and dynamic cargo handling stresses. This systematic approach ensures product conformance upon arrival, minimizing claims and supply chain disruptions for our international partners.

All aluminum plate sheet shipments are secured on custom-engineered, kiln-dried hardwood pallets compliant with ISPM 15 international phytosanitary regulations. These pallets feature reinforced stringers and deck boards capable of supporting concentrated loads exceeding 2,500 kg per unit, preventing structural deformation during stacking and containerization. Critical load-bearing surfaces incorporate non-slip rubberized coatings to eliminate lateral movement during vessel motion, while corner posts and edge protectors shield sheet edges from impact damage during crane operations and terminal handling. Pallet dimensions are optimized for standard 20ft and 40ft dry freight containers, maximizing cubic utilization without compromising stability.

The primary moisture barrier consists of a multi-layer co-extruded polyethylene film system with integrated vapor retardant properties. Each sheet stack undergoes a three-stage encapsulation process: initial wrapping with anti-corrosion VCI paper, followed by hermetic sealing within 125-micron moisture-proof film exhibiting a water vapor transmission rate (WVTR) below 0.5 g/m²/24hr per ASTM F1249, and final overwrapping with UV-stabilized polypropylene shrink film. This composite barrier maintains internal relative humidity below 45% throughout voyages exceeding 45 days, effectively preventing white rust formation and interfacial corrosion. Desiccant packs are strategically placed within the sealed envelope based on cargo volume and seasonal humidity projections.

Our packaging validation protocol includes accelerated salt spray testing per ASTM B117 and real-time humidity chamber monitoring at 85% RH for 60 days, simulating worst-case transit scenarios. Documentation packages include ISPM 15 certification for wooden components, WVTR test reports for barrier films, and detailed stowage plans verifying center of gravity calculations. This integrated system has achieved a 99.87% damage-free delivery rate across 1,200+ ocean shipments since 2020, significantly reducing insurance premiums and demurrage costs for clients. Adherence to these specifications is non-negotiable in our EXW, FOB, and CIF export frameworks, forming a critical component of our ISO 9001:2015 certified quality management system for transformer-grade aluminum products. Partnering with Xinzhaohe guarantees metallurgical integrity from furnace to final destination, regardless of maritime route complexity.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner in the production of high-precision aluminum and copper transformer strips and foils. Our facility integrates advanced metallurgical engineering with rigorous quality assurance protocols to deliver materials that meet the exacting demands of power transformer, reactor, and high-efficiency electrical equipment manufacturers worldwide.

Our production complex is equipped with fully automated rolling lines, precision slitting systems, and controlled atmosphere annealing furnaces, enabling consistent thickness tolerances down to ±0.005 mm for foil products and ±0.01 mm for strip materials. This level of dimensional accuracy ensures optimal winding performance and core efficiency in transformer applications. We specialize in processing 1000, 3000, and 8000 series aluminum alloys, as well as electrolytic tough pitch (ETP) copper, tailored to customer conductivity, elongation, and surface finish requirements.

Material purity and microstructure homogeneity are maintained through our in-house melt refining and casting operations, which include degassing, filtration, and grain refinement stages. All incoming billets undergo spectrographic analysis to verify alloy composition, while final products are tested for tensile strength, resistivity, and surface defects using state-of-the-art metrology equipment. Our quality management system is compliant with ISO 9001:2015 standards, and we provide full material test reports (MTRs) with every shipment.

We offer a comprehensive range of standard and custom specifications, including:

| Parameter | Aluminum Foil Range | Aluminum Strip Range | Copper Strip Range |

|---|---|---|---|

| Thickness | 0.01 – 0.5 mm | 0.1 – 6.0 mm | 0.1 – 5.0 mm |

| Width | 20 – 1200 mm | 50 – 1500 mm | 50 – 1200 mm |

| Temper | O, H14, H16, H18 | O, H14, H24, H26 | M, Y2, Y |

| Max Coil Weight | 5,000 kg | 8,000 kg | 4,000 kg |

Our strategic location in Luoyang, China, provides efficient access to raw material supply chains and major export hubs, enabling reliable lead times and cost-effective logistics for global clients. We support low-volume prototyping and high-volume production runs, backed by technical consultation for material selection and process integration.

For engineering teams seeking a stable, high-performance supply of transformer conductive materials, Luoyang Xinzhaohe offers proven metallurgical expertise, scalable production capacity, and long-term partnership stability.

Contact us today to discuss your technical requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

Established 2003 – Precision in Every Coil

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum plate sheet directly from China.