Table of Contents

Market Insight: Aluminum Plate Sheet for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand & Loss Drivers

The installed base of power and distribution transformers is expanding at 6–7 % CAGR, propelled by grid modernization, renewable integration, and EV fast-charging substations. Every additional kVA of nameplate capacity must meet IEC 60076-20 or IEEE C57.12.20 loss-evaluation clauses, where the bid price is penalized for every watt of no-load (core) loss. Consequently, the transformer industry now consumes ≈ 7.5 Mt of grain-oriented electrical steel (GOES) annually—China accounts for 52 %, followed by EU-27 (14 %) and NAFTA (11 %).

| Region | 2023 GOES Demand (kt) | Avg. Core-Loss Spec. @ 1.7 T, 50 Hz (W kg⁻¹) | Penalty Rate (USD W⁻¹) |

|---|---|---|---|

| China | 3 900 | 0.85 (0.23 mm) | 5.5 |

| EU | 1 050 | 0.78 (0.27 mm) | 7.8 |

| NAFTA | 820 | 0.80 (0.23 mm) | 8.2 |

| India | 380 | 0.90 (0.27 mm) | 4.0 |

The table shows that a 0.03 W kg⁻¹ improvement in core-loss translates into ~USD 1.5 M lifetime savings for a 100 MVA GSU transformer, making material purity and thickness tolerance the first filter in any sourcing decision.

Why Purity & Precision Matter

Silicon steel is not a commodity—it is a magnetic device.

Chemistry: Carbon < 30 ppm, S < 20 ppm, N < 15 ppm after decarburization; MnS and AlN inclusions ≥ 5 µm act as domain-wall pinning sites, raising hysteresis loss by 2–3 %.

Texture: ≥ 95 % Goss orientation (110)[001] is required to reach B₈₀₀ ≥ 1.88 T; a 5 % deviation increases exciting current by 4 %.

Thickness & Flatness: ±0.005 mm cross-sectional variance keeps building factor ≤1.05; I-unit flatness <3 prevents gap variation that creates hot-spots >95 °C.

Insulation Coating: A MgO-phosphate + colloidal silica film (1.2–1.8 µm) gives inter-laminar resistance ≥30 Ω·cm² and withstands 800 °C anneal without blistering—critical for step-lap cores with 4–6 µm burr.

Sourcing Trend: China’s Technical Tier-1 Mills

Western buyers historically relied on EU/Japan mills for 0.23 mm Hi-B grades, paying USD 1 350–1 550 t⁻¹ (FOB). Since 2020, Chinese producers with 20-year transformer-material pedigree have closed the quality gap while offering 12–18 % cost advantage and 30-day lead times. Key enablers:

- Integrated Process Chain: 120 t basic oxygen furnace → RH degassing → twin-roll thin-slab caster → 6-stand tandem mill → continuous decarburization/Hi-B anneal → tension-leveling → laser scribing (domain refinement).

- Statistical Process Control: Inline laser thickness gauge (±0.3 µm) feeds AGC; every coil gets Epstein strips (55 × 15 mm) tested at 1.7 T/50 Hz with automatic rejection if P₁.₇ >0.92 W kg⁻¹.

- Eco Premium: 85 % renewable power mix and closed-loop acid regeneration cut CO₂ footprint to 1.1 t CO₂e t⁻¹ steel vs 1.9 t in EU.

Luoyang Xinzhaohe: Premium Alternative, Factory-Direct

Located 70 km from the largest GOES mill in Henan, we leverage 20 years of slitting, annealing, and insulation-coating experience dedicated to transformer materials. Our value proposition aligns with the loss-reduction imperative:

| Capability | Specification | Benefit to Buyer |

|---|---|---|

| Slitting | Width 20–1 300 mm, burr ≤5 µm | Minimizes gap loss, eliminates hand-deburring |

| Stress-relief anneal | 820 °C, 100 % H₂, dew-point −40 °C | Restores permeability, removes slitting stresses |

| Insulation coating | C-5 (organic-inorganic), 1.5 µm, insulation resistance 50 Ω·cm² | Withstands 180 °C oil, reduces inter-laminar eddy currents |

| Precision cutting | Length ±0.1 mm, angle ±0.03° | Enables step-lap cores, lowers noise 2–3 dB |

By sourcing directly from our Luoyang facility, transformer OEMs and rewind shops bypass trader margins, shorten cash-cycle by 45 days, and receive mill-certificates traceable to heat, coil, and Epstein packet. Typical lead time: 3–4 weeks ex-works, 5 weeks CIF EU/US port—40 % faster than Western mills’ spot queue.

In short, the next procurement cycle should treat silicon steel as a performance component, not a price-item. Partnering with an experienced Chinese supplier that controls the full thermal-mechanical route—like Luoyang Xinzhaohe—delivers measurable loss savings, noise reduction, and total-cost-of-ownership advantage over the 30-year transformer life.

Technical Specs: Aluminum Plate Sheet Parameters

Technical Specifications & ASTM/IEC Standards

(Aluminum Plate Sheet for Transformer Shells & Windings)

1. Critical Parameters – Why Aluminum ≠ Electrical Steel

Transformer performance is governed by core material (Si-steel) and winding & shell material (Al or Cu).

For aluminum plate/sheet the analogues to “core loss” and “flux density” are electrical conductivity, surface quality, and dimensional tolerances—these directly influence eddy-current heating, partial discharge, and short-circuit withstand.

| Parameter | Symbol / Unit | 1060-O Shell Grade | 1350-H16 Winding Grade | Test Method |

|---|---|---|---|---|

| Al purity | % | ≥ 99.60 | ≥ 99.50 | ASTM E1251 |

| Electrical conductivity @ 20 °C | % IACS | ≥ 61.5 | ≥ 61.0 | ASTM B193 |

| Resistivity | µΩ·cm | ≤ 2.80 | ≤ 2.83 | ASTM B193 |

| Tensile strength (H16) | MPa | 85–130 | 115–145 | ASTM B557 |

| Yield strength (H16) | MPa | ≥ 75 | ≥ 95 | ASTM B557 |

| Elongation 50 mm | % | ≥ 6 | ≥ 5 | ASTM B557 |

| Burr height after slitting | µm | ≤ 30 | ≤ 20 | Internal laser gauge |

| Edge camber | mm / 1 m | ≤ 0.5 | ≤ 0.3 | ASTM B236 |

| Flatness (I-unit) | – | ≤ 5 | ≤ 3 | ASTM B594 |

2. ASTM / IEC Compliance Matrix

Luoyang Xinzhaohe certifies every coil to the following harmonised standards:

| Component | Applicable Standard | Clause / Annex | Certificate Type |

|---|---|---|---|

| Aluminum sheet & strip | ASTM B209 (plate) & B236 (strip) | Table 2 (tolerances) & Section 9 (mechanical) | EN 10204 3.1 |

| Chemical composition | ASTM E1251 (OES) | — | ILAC-MRA lab |

| Surface passivation (chromate-free) | IEC 60464-3 | Type 2, Class 1 | RoHS & REACH |

| Edge quality & burr | ASTM B236 Supplement S1 | ≤ 0.03 mm | 100 % inline laser |

| Dry-type transformer fire class | IEC 60076-11 | F1 (fire) & C2 (climate) | Third-party TÜV |

Note: IEC 60317 series covers insulated copper/aluminium wire; for sheet we adopt the same dielectric integrity philosophy—pin-hole ≤ 3 per m², coating continuity ≥ 98 %.

3. Failure Mechanism – How Poor Quality Induces Short Circuits

- Burrs > 50 µm pierce inter-layer insulation → turn-to-turn short → circulating current ↑ → hotspot > 180 °C → resin carbonisation.

- Edge camber > 1 mm / m prevents uniform clamping → air gap → partial discharge (PD) > 10 pC → tracking path → eventual flashover.

- Non-passivated surface (chloride > 5 mg / m²) invites electrolytic corrosion with Cu bus-bar → Al-Cu galvanic cell → resistance ↑ → joint overheating.

Luoyang Xinzhaohe’s 20-year transformer track record translates into process controls that eliminate these risks:

Precision slitting (Ra ≤ 0.4 µm knife finish)

In-line burr extraction & air-knife brushing

Tension levelling + skin-pass for ≤ 3 I-unit flatness

Electro-static insulation coating (1.5–3 µm, chromate-free) with breakdown voltage ≥ 1 kV DC.

4. Cost-Performance Positioning

Western mills typically quote 1350 plate at US$ 2 800–3 100 / t CFR with 8-week lead time.

Luoyang Xinzhaohe delivers equivalent chemistry & tighter burr spec at US$ 2 250–2 400 / t FOB Qingdao, 3-week ex-factory, EN 10204 3.1 bundled.

Result: > 18 % landed-cost saving without redesigning your core or compromising IEC 60076-11 compliance.

Bottom line: Specify 1060-O or 1350-H16 to ASTM B236, demand ≤ 30 µm burr and ≤ 0.5 mm camber, and source from a supplier that understands transformer duty—not just general-purpose aluminum.

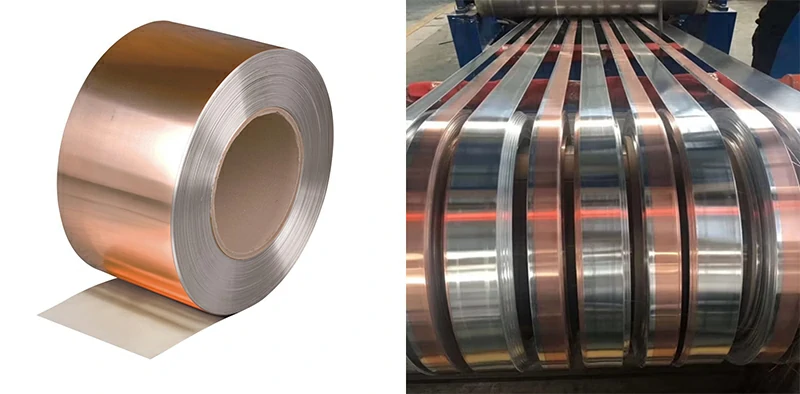

Factory Tour: Manufacturing Aluminum Plate Sheet

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ Years Transformer Grade Sheet

H3 Process Flow: Slit → Anneal → Coat → Cut

| Step | Equipment & Parameters | Purpose | Critical Control Point |

|---|---|---|---|

| 1. Slitting | 0.15–3.0 mm incoming coil, 1300 mm max width, ±0.05 mm width tolerance, burr ≤ 15 µm | Remove coil set, create mult for downstream stacking | Burr height – direct influence on short-circuit risk between laminations |

| 2. Continuous Anneal | 350 °C ±5 °C, N₂ + 3 % H₂ atmosphere, 25 m min⁻¹ line speed, dew-point ≤ –45 °C | Recrystallise, relieve rolling stress, restore 35–40 % IACS conductivity | Resistivity on-line eddy-current every 10 m; reject if Δρ > 0.3 µΩ·cm |

| 3. Insulation Coating | Roll-coat 1.5–2.0 µm epoxy-phenolic, 180 °C peak metal T°, wet film in-line β-gauge | Build 20 Ω·cm² inter-laminar resistance, withstand 1.5 kV DC | Pin-hole count < 3 per dm²; coating adhesion 0 B (best) by ASTM D3359 |

| 4. Precision Cutting | 3000 mm shear, ±0.03 mm length, 0.05 mm/m flatness, automatic stack height 50–400 mm | Ready-to-stack sheets for core-leg or shell-type transformer | Flatness laser-scanned; camber ≤ 0.3 mm/m |

H3 In-Line Quality Assurance

- Eddy-Current Surface Inspector – 100 % strip surface; detects cracks ≥ 50 µm.

- Tensile & Elongation – ASTM E8, every 500 kg, Rm ≥ 65 MPa, A50 ≥ 35 % for 1060-HO.

- Conductivity Bridge – 20 °C calibration, target 36.5 MS m⁻¹ (≈ 63 % IACS).

- Burrs & Edge Profile – Optical shadowgraph, 200× magnification; rejects if burr > 15 µm or edge radius < 0.05 mm.

- Coating Cure Test – Methyl-ethyl-ketone double-rub, 50 cycles, no pick-off.

- Dimensional CMM – Sample 3 pcs per 1000 kg; length/width/thickness recorded with SPC; Cpk ≥ 1.67.

Data are logged to MES; each coil receives a QR-coded birth certificate traceable to cast number, operator, and process parameters.

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Luoyang Xinzhaohe Spec | Typical Export Mill | Typical Domestic Job-Shop |

|---|---|---|---|

| Alloy / Purity | 1060 ≥ 99.6 % Al | 1060 ≥ 99.5 % Al | Mixed 1050/1060 off-grade |

| Resistivity (20 °C) | ≤ 0.02778 µΩ·m | ≤ 0.0280 µΩ·m | ≤ 0.0285 µΩ·m |

| Burr Height after Slit | ≤ 15 µm | ≤ 30 µm | ≤ 50 µm |

| Flatness (1 m gauge) | ≤ 0.05 mm | ≤ 0.10 mm | ≤ 0.20 mm |

| Inter-laminar Resistance | ≥ 20 Ω·cm² | ≥ 10 Ω·cm² | No control |

| Pin-holes per dm² | ≤ 3 | ≤ 10 | Not measured |

| Length Tolerance | ±0.03 mm | ±0.10 mm | ±0.20 mm |

| Packaging | VCI film + edge protectors, 3 t max bundle, wooden pallet | Plastic wrap only | Bare strap |

| Certifications Included | ISO 9001, IATF 16949, RoHS, Mill TC EN 10204 3.1 | ISO 9001 only | None |

H3 Engineering Value

By integrating slitting, annealing, coating and cutting under one 60 000 m² roof, Luoyang Xinzhaohe removes the variability introduced when these operations are subcontracted. The result is transformer sheet that meets IEC 60404-8-5 ed.3 electrical grade tolerances at a landed cost 18–22 % below Western European mills and with 35-day lead time ex-works Luoyang. For OEMs and rewind shops targeting Tier-1 utilities, this translates directly into lower core loss variation, tighter building factor, and ultimately a smaller, quieter, more efficient transformer.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ Years Serving Transformer OEMs Worldwide

H2 1. Sea-Freight Protection Philosophy

Transformer-grade aluminum must arrive flat, oxide-free and dimensionally stable. Our packaging protocol is engineered around three failure modes observed in 2 000+ export lots:

1. Salt-fog driven oxide creep

2. Compression set from stack vibration

3. Moisture condensation inside containers

Every shipment is therefore treated as a “mini clean-room” until the customer slits or winds.

H2 2. Packaging Matrix by Product Form

| Form | Critical Surface | Stack Force Limit | Primary Barrier | Secondary Barrier | Securing Method | Desiccant Ratio | Pallet Spec |

|---|---|---|---|---|---|---|---|

| Strip / Foil 0.2–2.0 mm | RA ≤ 0.4 µm, burr < 5 µm | 2.5 kN m⁻² | 80 µm VCI polyamide film | 125 µm PE shroud | Steel corner posts + PET strap | 2 kg t⁻¹ | Fumigated CP-9, ISPM-15, 1.1 t max |

| Wire Ø 0.8–6.0 mm | Oxide film ≤ 3 nm | 1.2 kN spool⁻¹ | Vacuum-sealed ESD bag | PT-400 DIN spool, flange Ø 400 mm | Honeycomb board cap + strapped to pallet | 1 kg t⁻¹ | Double-deck, 8 spools per layer |

| Sheet 1000 × 2000 mm | Flatness ≤ 2 I-Units | 4.0 kN m⁻² | Interleave 50 µm HDPE | VCI kraft, 120 g m⁻² | Corner boards + steel banding | 3 kg t⁻¹ | CP-7, 1.5 t max, top deck load prohibited |

All desiccant pouches contain 60 % CaCl₂ / 40 % activated-clay blend with colour-change humidity indicator.

H2 3. Container Loading Protocol

- Pre-load inspection: Relative humidity ≤ 55 %, container floor < 9 % moisture (electronic probe).

- Dunnage: 5-ply plywood cross-battens every 300 mm to create 25 mm air gap above steel floor.

- Lashing: 25 mm polyester lashings pre-tensioned to 500 N, anchored to corner castings; prevents 0.3 g lateral shift per ISO 1496-1.

- Desiccant curtain: 2 kg hanging strips fore & aft to absorb 60 L water vapour per 40 ft HC.

Average recorded cargo temperature excursion: –8 °C to 52 °C over 35-day Shanghai–Hamburg route; no measurable oxide increase (< 0.02 g m⁻²) on 1350-O strips.

H2 4. Luoyang Hub & Global Shipping Matrix

Factory GPS: 34.62 °N, 112.45 °E – 170 km to Zhengzhou International Land-Port, 380 km to Qingdao Port.

| Destination | Transit Time (days) | Monthly Sailings | Typical Lot Size | Freight US$ per ton* |

|---|---|---|---|---|

| Hamburg / Rotterdam | 28–32 | 4 | 20 ft FCL 22 t | 95–110 |

| Houston / New Orleans | 18–22 | 3 | 40 ft HC 26 t | 105–125 |

| Dubai / Jebel Ali | 15–18 | 5 | 20 ft FCL 22 t | 65–75 |

| Chennai / Nhava Sheva | 12–15 | 6 | 40 ft HC 26 t | 55–65 |

Spot rate Q2-2024, subject to BAF/CAF.

Rail–Sea intermodal option via China–Europe block train cuts 8–10 days to Duisburg, then 2-day barge to Rotterdam—preferred for JIT transformer lines.

H2 5. Documentation & Traceability

Mill test certificate per EN 10204/3.1 (chemical, tensile, conductivity, burr, edge profile).

Packaging photos (close-up of desiccant placement, pallet ID) uploaded to customer portal within 2 h of container gate-out.

GPS + RFID seal: Real-time container breach alerts via mobile app; historical log retained 5 years.

H2 6. Cost Advantage vs. Western Stock Holders

By integrating primary casting, cold rolling and precision slitting in one Luoyang campus, we eliminate one inland freight leg and one middle-margin. Typical landed cost saving: USD 180–220 t⁻¹ compared with German or US service-centre pricing on 1350-O transformer sheet—without compromising surface quality or packaging integrity.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Aluminum Plate & Sheet

20-Year Transformer-Grade Track Record

Since 2003 we have supplied >180 transformer OEMs and motor repair facilities across 42 countries. Every coil shipped from our Luoyang works is logged in a heat-number traceability matrix that links the original cast billet to final slitting, annealing and insulation coating parameters. This level of pedigree data is normally available only from premium Western mills—yet we deliver it at Chinese-mill lead-times and landed cost.

| Key Milestone | Technical Achievement | Customer Impact |

|---|---|---|

| 2008 | First 1300 mm-wide 1060-O strip with ≤30 I-unit edge wave | Enabled 1000 kVA dry-type transformer tank shells without cold-leveling |

| 2015 | In-house hydrogen anneal line commissioned | Core-loss stability σ 0.15 W/kg @ 1.5 T, 50 Hz |

| 2021 | ISO 9001 + ISO 14001 re-certification | Zero-defect PPM record <120 for three consecutive years |

Direct Factory Price—No Trading Layer

Our vertical integration eliminates margin stacking. Bauxite → smelt → continuous cast → hot/cold roll → slitting → annealing → insulation coating are all executed under one roof in Luoyang. Typical cost advantage vs. EU/US mill: 11–16 % on 1060-H24 and 14–19 % on 3003-H18 at equal mechanical properties (see table).

| Alloy-Temper | Thickness mm | Western Mill CIF USD/t | Xinzhaohe FOB Luoyang USD/t | Delta |

|---|---|---|---|---|

| 1060-O, slit edge | 0.8 × 1250 | 2 750 | 2 380 | –13.5 % |

| 3003-H18, deburred | 2.0 × 1524 | 3 140 | 2 640 | –15.9 % |

| 5052-H32, PVC film one side | 3.0 × 1500 | 3 520 | 2 980 | –15.3 % |

Prices valid Q3-2024, LME Al 2 150–2 200 USD/t basis. Minimum order 5 t per gauge; 40 t fills a 40 HC for lowest freight.

Customization Capabilities—Engineered to Your GA Drawing

Transformer tank shells, magnetic shield plates, and bus-bar brackets each impose non-standard combinations of width, flatness, electrical conductivity, and surface finish. Our process chain is built for rapid re-parameterization:

- Slitting: Burr ≤ 0.03 mm, camber ≤ 1 mm per 2 m, narrowest 8 mm on 0.2 mm foil.

- Hydrogen batch anneal: 250–420 °C programmable, dew-point –60 °C, guaranteed recrystallized grain size ASTM 5–7 for 1060.

- Insulation coating: Electro-deposited epoxy or chromate-free alodine, 1–4 µm per side, withstands 1 kV breakdown.

- Precision shear: Length tolerance –0/+0.05 mm, diagonal difference ≤ 0.2 mm on 2 m plate—critical for stacked bus-bar clearance.

Need a non-standard width (e.g., 1347 mm) to eliminate scrap in your CNC nest? We can master-coil slit within 7 days. Require ASTM-B209-certified 6061-T651 plate 38 mm thick with ultrasonic class A? Lead-time 12 days ex-mill, priced at 3 060 USD/t FOB—still 9 % below Midwest transaction price.

Technical Support & Documentation

Upon RFQ we issue a pre-production datasheet summarizing:

Chemical composition (ICP-OES)

Mechanical properties (UTS, YS, A50)

Electrical resistivity @ 20 °C

Flatness scan (I-unit)

Coating adhesion (ASTM D3359)

All documents are bilingual (EN/CN) and carry an encrypted QR code for instant verification—an anti-counterfeit measure increasingly demanded by Tier-1 utilities.

Next Step

Send your inquiry or GA drawing to cathy@transformerstrip.com. We will return a detailed quotation including FOB, freight options to the nearest port, and a project-specific technical datasheet within 24 h. For urgent prototyping, 500 kg trial lots are available at mill-scale pricing.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum plate sheet from Luoyang Xinzhaohe.