Table of Contents

Market Insight: Aluminum Plate Fabrication

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for transformer strip and foil, particularly aluminum-based solutions, continues robust growth driven by critical infrastructure investments. Rising electricity consumption, grid modernization initiatives, and the rapid expansion of renewable energy integration necessitate higher-efficiency power transformers. Aluminum strip and foil have gained significant traction against traditional copper alternatives due to compelling advantages in weight reduction (approximately 50% lighter than copper for equivalent conductivity) and material cost stability. This shift is especially pronounced in distribution transformers and emerging applications like high-frequency transformers for renewable inverters and electric vehicle charging infrastructure, where aluminum’s favorable strength-to-weight ratio and thermal conductivity offer tangible system-level benefits. However, the inherent electrical conductivity of aluminum is lower than copper, demanding exceptionally precise fabrication to minimize resistive losses and ensure competitive performance.

The technical requirements for transformer strip and foil fabrication are exceptionally stringent, making material quality non-negotiable. Aluminum strip used in transformer windings must achieve ultra-high purity levels, typically 99.85% minimum, to maximize electrical conductivity and minimize joule heating. Surface finish is equally critical; microscopic imperfections or residual oxides act as nucleation sites for partial discharges under high voltage stress, accelerating insulation degradation and risking catastrophic transformer failure. Dimensional tolerances, particularly thickness consistency across the coil width and length (often ±0.01mm or tighter), directly impact winding precision, magnetic flux distribution, and ultimately, core loss characteristics. Any deviation introduces parasitic eddy currents and hysteresis losses, degrading transformer efficiency and increasing operational costs over its 30+ year lifespan. Contamination control during rolling, slitting, and handling is paramount, as even trace metallic or non-metallic inclusions can create localized hot spots.

Consequences of substandard aluminum plate fabrication are severe and costly. Inconsistent thickness leads to uneven current distribution and increased I²R losses. Surface defects compromise the integrity of insulating varnishes or papers applied during winding, creating weak points prone to electrical breakdown. Impurities directly reduce bulk conductivity, forcing designers to use more material to compensate, negating aluminum’s weight and cost advantages. These factors collectively elevate no-load and load losses, pushing transformers outside mandated efficiency standards (e.g., DOE 2016, IE4/IE5). Failed units incur not only replacement costs but also significant downtime penalties for utilities and industrial users. The total cost of ownership is dominated by operational energy losses over decades, making initial material quality a decisive factor in lifecycle economics.

For procurement professionals, sourcing transformer-grade aluminum strip demands rigorous supplier qualification beyond basic price considerations. Vendors must demonstrate certified metallurgical control processes, advanced rolling mill capabilities for micron-level tolerances, and stringent in-line surface inspection systems. Traceability from smelter ingot to finished coil is essential. Luoyang Xinzhaohe Aluminum leverages two decades of specialized experience in transformer materials, implementing multi-stage quality gates including laser surface profiling, eddy current testing for subsurface flaws, and certified laboratory analysis for purity and mechanical properties. Partnering with a supplier possessing deep technical understanding of the interplay between aluminum fabrication parameters and transformer electromagnetic performance is fundamental to securing reliable, high-efficiency power infrastructure. Quality here is not a premium feature; it is the baseline requirement for functional, compliant, and economically viable transformers.

Technical Specs: Aluminum Plate Fabrication

Technical Specifications for Aluminum Plate Fabrication – Precision Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-performance aluminum plate fabrication solutions tailored for transformer strip and foil applications. With over two decades of metallurgical and manufacturing expertise, our processes are engineered to meet the most stringent industry standards for electrical conductivity, dimensional accuracy, and edge quality. Precision in fabrication is critical in transformer components, where even minor deviations can lead to inefficiencies, increased losses, or premature failure. Our advanced slitting lines, coupled with proprietary deburring and surface treatment technologies, ensure that each aluminum strip meets exacting specifications for performance and reliability in high-demand electrical systems.

A core element of our fabrication capability is precision slitting, performed under controlled tension and alignment conditions to achieve a tolerance of ±0.002 mm. This level of accuracy ensures uniform winding in transformer cores and coils, minimizing air gaps and enhancing magnetic flux efficiency. The slitting process is monitored in real time using laser-based measurement systems, allowing for dynamic corrections and consistent width control across production batches. Each coil is subjected to post-slitting inspection using high-resolution optical edge profiling to verify dimensional conformity.

Edge quality is paramount in transformer applications. Burrs or micro-tears can initiate electrical discharge, increase localized heating, and compromise dielectric integrity. Our fabrication process incorporates multi-stage mechanical and electrochemical deburring techniques, ensuring completely burr-free edges. Surface roughness is maintained below 0.4 µm Ra, contributing to smooth layer-to-layer contact during coil winding. Additionally, edge contour analysis is performed using scanning electron microscopy (SEM) on sample batches to validate edge integrity.

Electrical conductivity is optimized through precise alloy selection and thermal processing. Our standard aluminum strips are produced from high-purity 1060, 1070, or 1350 alloys, achieving a minimum conductivity of 59.5% IACS (International Annealed Copper Standard). Conductivity is verified through four-point probe resistivity testing in accordance with ASTM B209 and IEC 60164 standards. All material is fully annealed to achieve a soft temper (O-temper), ensuring maximum ductility for winding operations while maintaining stable electrical performance.

All fabrication parameters are documented and traceable, with material certifications (MTCs) provided per EN 10204 3.1 requirements. Environmental controls during processing prevent oxidation and contamination, preserving surface integrity and conductivity.

The following table summarizes the key technical parameters for our aluminum plate fabrication service:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Alloy | 1060, 1070, 1350 (Al ≥ 99.6%) | GB/T 3880, ASTM B209 |

| Thickness Range | 0.10 mm – 3.0 mm | ISO 11566 |

| Slitting Tolerance | ±0.002 mm | ISO 9001:2015, internal QA |

| Edge Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

| Burr Height | < 1% of material thickness, typically < 5 µm | SEM inspection, internal SOP |

| Electrical Conductivity | ≥ 59.5% IACS | ASTM E1004, IEC 60462 |

| Temper | O (Fully Annealed) | ASTM B660 |

| Surface Condition | Clean, oxide-controlled, no scratches | Visual & optical inspection |

| Tensile Strength | 65 – 95 MPa | ASTM E8 |

| Elongation (min) | ≥ 35% | ASTM E8 |

These specifications reflect our commitment to delivering aluminum transformer strips that combine dimensional precision, electrical efficiency, and mechanical reliability. Luoyang Xinzhaohe Aluminum Co., Ltd. supports global OEMs and tier-1 suppliers with consistent, high-quality material solutions for power and distribution transformers.

Factory Tour: Manufacturing

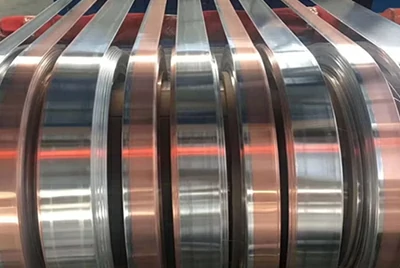

Manufacturing Process for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to deliver precision transformer strip and foil through a rigorously controlled three-stage production sequence. This process ensures optimal electromagnetic performance, dimensional stability, and compatibility with high-speed winding operations critical to transformer core efficiency.

Cold rolling forms the foundational stage, where hot-rolled aluminum or copper coils undergo multi-stand reduction to achieve target thicknesses ranging from 0.1 mm to 3.0 mm. Our 20-high cluster mills apply precise interstand tension control and roll gap adjustments, maintaining thickness tolerances within ±0.005 mm for foil grades (<0.2 mm) and ±0.01 mm for strip grades (0.2–3.0 mm). Critical parameters—including roll surface roughness (Ra 0.1–0.3 µm), rolling speed (150–600 m/min), and interstand lubrication—are dynamically monitored via inline sensors to prevent surface defects and ensure uniform microstructure. This stage directly influences core loss characteristics; excessive residual stress or uneven deformation would elevate hysteresis losses in the final transformer.

Precision slitting follows, converting master rolls into narrow strips meeting exact width specifications. Utilizing razor-sharp rotary knives with automatic lateral positioning, we achieve width tolerances of ±0.05 mm for strips below 50 mm width and ±0.1 mm for wider formats. Key to this phase is burr minimization: edge protrusions exceeding 2% of material thickness are rejected, as they cause insulation damage during core stacking. Our slitters integrate real-time laser micrometers that trigger immediate knife recalibration if deviations exceed 0.02 mm, ensuring consistent edge squareness (90° ± 0.5°).

Edge conditioning completes the sequence, eliminating micro-burrs and stress concentrations through either mechanical brushing or controlled edge rolling. For aluminum transformer foil (0.1–0.5 mm), we employ ceramic abrasive brushes at 1,200 RPM to produce a smooth, oxide-free edge with surface roughness below Ra 0.8 µm. Copper strip (0.5–3.0 mm) undergoes edge rolling using hardened steel rollers to compress edge fibers, reducing susceptibility to cracking during winding. This step is non-negotiable for preventing interlaminar short circuits in stacked cores.

Quality control is embedded at every phase. During cold rolling, X-ray fluorescence verifies alloy composition, while ultrasonic testers screen for subsurface inclusions. Slitting outputs undergo 100% inline surface scanning (detecting defects >0.1 mm) and periodic tensile testing (yield strength ±10 MPa tolerance). Final inspection includes:

| Parameter | Foil (0.1–0.5 mm) | Strip (0.5–3.0 mm) |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Width Tolerance | ±0.05 mm | ±0.1 mm |

| Edge Burr Max | 2 µm | 5 µm |

| Surface Defects | None >0.1 mm | None >0.3 mm |

All batches receive certification per ASTM B209/B317 standards, with core loss validation data available upon request. This integrated approach—combining metallurgical precision with closed-loop process control—guarantees material that maximizes transformer efficiency and minimizes field failure risks. Partnering with Xinzhaohe ensures your supply chain receives not just material, but engineered performance.

Packaging & Logistics

Export Packaging for Aluminum and Copper Transformer Strip/Foil – Technical Specification

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of aluminum and copper transformer strip and foil, we maintain rigorous standards for export packaging to ensure product integrity during international transit. Our packaging protocols are specifically engineered to meet the demands of sea freight, the most common and cost-effective mode of transport for bulk industrial materials, while mitigating risks associated with moisture, mechanical stress, and prolonged exposure to variable climatic conditions.

All transformer-grade aluminum and copper strips and foils are systematically prepared for export on robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to ISO 13355:2011 standards for load-bearing capacity and dimensional stability, ensuring compatibility with global container handling systems. Each pallet is treated to ISPM 15 regulations, undergoing thermal treatment to eliminate biological contaminants, and is stamped accordingly for customs compliance across international jurisdictions. The structural design incorporates reinforced stringers and deck boards to uniformly distribute load weight, minimizing the risk of deformation during stacking and marine transport.

Prior to palletization, each coil or sheet pack is wrapped in multiple layers of industrial-grade moisture-proof polyethylene film with a minimum thickness of 125 microns. This vapor barrier film exhibits low water vapor transmission rates (WVTR <5 g/m²·24h), effectively shielding the metal surfaces from humidity, salt-laden air, and condensation commonly encountered in maritime environments. The film is hermetically sealed using heat-welded seams and overlapped by no less than 150 mm to prevent capillary ingress. Additionally, desiccant packs are strategically placed within the sealed envelope to absorb any residual moisture and maintain a controlled microclimate during extended voyages.

For enhanced protection, especially in high-humidity trade routes, an optional vapor corrosion inhibitor (VCI) layer can be integrated beneath the moisture-proof film. VCI technology actively releases corrosion-inhibiting molecules that form a protective molecular layer on the metal surface, providing long-term safeguarding against oxidation without altering the material’s surface properties or downstream processing characteristics.

All packaged units are secured with high-tensile steel or PET strapping, applied in a cross-pattern configuration to prevent lateral shift during handling and transit. Load stability is verified through standardized tilt and vibration testing simulating container ship conditions. Markings on each pallet include product identification, batch number, net and gross weight, handling instructions, and orientation indicators, all printed in UV-resistant ink for legibility after prolonged exposure.

Our export packaging system is validated through accelerated aging and real-world shipment monitoring, confirming its efficacy over transit durations exceeding 45 days. This comprehensive approach ensures that transformer strip and foil materials arrive at their destination with preserved surface quality, dimensional accuracy, and electrical performance—critical for downstream winding and insulation processes in transformer manufacturing.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd for Precision Transformer Strip and Foil

With over two decades of specialized metallurgical engineering and manufacturing expertise, Luoyang Xinzhaohe Aluminum CO.,Ltd stands as a strategic partner for global transformer manufacturers demanding uncompromising quality in aluminum and copper strip and foil. Our core competency lies in the precise production of critical electrical materials where dimensional stability, surface integrity, and consistent metallurgical properties are non-negotiable for efficient transformer performance and longevity. We understand that deviations in foil thickness, surface defects, or inconsistent annealing profiles directly impact core losses, winding integrity, and ultimately, the operational efficiency of your transformers. Our facility is engineered from the ground up to eliminate these risks, serving as a reliable extension of your supply chain for mission-critical components.

Our technical strength originates in advanced, vertically integrated production capabilities. We operate state-of-the-art tandem cold rolling mills specifically calibrated for transformer-grade materials, achieving exceptional thickness tolerances down to ±0.005mm for aluminum foil (0.10mm – 0.50mm) and stringent profiles for copper strip. Critical to electrical performance, our controlled atmosphere continuous annealing lines ensure precise temper (H18, O-temper) with uniform microstructure and optimal electrical conductivity, consistently meeting or exceeding IEC 60137 and ASTM B209/B3. Rigorous in-line surface inspection systems, including laser scanning and AI-assisted defect detection, guarantee surface roughness (Ra) remains ≤0.25μm for aluminum and ≤0.20μm for copper, eliminating particles or imperfections that could compromise dielectric strength. Every coil undergoes comprehensive metallurgical verification, including tensile testing, grain structure analysis, and eddy current flaw detection, ensuring batch-to-batch repeatability essential for automated winding processes.

Beyond metallurgical precision, our supply chain infrastructure provides tangible operational advantages. Strategically located in Luoyang with direct access to major rail and road networks, we maintain a significant buffer stock of 5,000+ metric tons across standard aluminum alloy 1060, 1070, 1350, and ETP copper grades. This substantial inventory, coupled with our dedicated JIT logistics management, enables reliable delivery within 15-20 days globally, mitigating raw material volatility and production line stoppages. Our integrated quality management system, certified to ISO 9001:2015 and IATF 16949, governs every process from melt chemistry control through slitting and packaging, ensuring traceability and compliance with the most stringent international electrical standards. We function not merely as a supplier, but as a technical collaborator, offering metallurgical support and process optimization insights to enhance your transformer design and manufacturing efficiency.

Partnering with Luoyang Xinzhaohe means securing a foundation of material excellence for your transformer cores. We deliver the dimensional precision, surface perfection, and metallurgical consistency required to minimize core losses and maximize product reliability. To initiate a technical consultation and receive our detailed material specifications and production capability dossier, contact our Chief Supply Chain Officer directly at cathy@transformerstrip.com. Let us demonstrate how our engineered aluminum and copper strip/foil solutions can enhance your transformer performance and supply chain resilience.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum plate fabrication directly from China.