Table of Contents

Market Insight: Aluminum Plate Fabrication in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers

Global energy infrastructure modernization and renewable integration are accelerating demand for high-efficiency transformers. Aluminum transformer strips and foils dominate due to their optimal balance of conductivity, weight, and cost. Critical applications include utility distribution transformers, EV charging stations, and industrial motors, where material consistency directly impacts energy loss and operational reliability.

Material Quality Criticality

Transformer efficiency hinges on precise material specifications per ASTM B209 and IEC 60404-8-5:

Purity ≥99.5% (1350-H19 grade): Impurities increase electrical resistance, raising energy losses.

Electrical conductivity ≥61% IACS: Directly impacts transformer efficiency; lower conductivity increases operational costs.

Tensile strength 140–180 MPa: Ensures foil integrity during winding; deviations cause breaks or deformations.

Surface roughness Ra ≤0.8μm: Critical for insulation adhesion; rough surfaces risk arcing and short circuits.

Thickness tolerance ±0.01mm: Ensures uniform magnetic flux distribution and minimizes eddy current losses.

Even minor deviations—e.g., 0.1% impurity increase—can elevate resistive losses by 1.2%, causing thermal degradation and premature failure. Inconsistent properties also void transformer warranties.

Why Choose Luoyang Xinzhaohe?

As a 20+ year factory-direct supplier, we deliver unmatched cost-performance without compromising quality. Our integrated production chain includes precision rolling, annealing, and surface treatment processes, ensuring strict adherence to international standards. Optimized logistics reduce lead times by 30% versus global competitors, while our in-house metallurgical lab provides 100% batch traceability and SGS-certified quality assurance. Custom alloy development available for specialized applications.

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Material Purity | 99.5%+ | 99.6%+ (SGS certified) |

| Cost Efficiency | 100% (benchmark) | 15–25% lower |

| Lead Time | 4–6 weeks | 2–3 weeks |

| Technical Support | Standard | Dedicated application engineers |

| Quality Control | Periodic testing | 100% in-process testing & SGS certification |

Partner with Luoyang Xinzhaohe for reliable, high-performance transformer materials engineered for your operational needs.

Technical Specs: Aluminum Plate Fabrication Parameters

Critical Technical Specifications for Transformer Aluminum Plate Fabrication

As a leading manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe delivers precision-engineered aluminum plates meeting exacting industry standards. Our factory-direct approach eliminates middlemen, reducing costs by 15-20% versus global competitors while maintaining superior quality through rigorous controls at every production stage.

Precision Slitting Tolerances

Precision slitting is critical for transformer winding accuracy. Deviations exceeding ±0.002 mm cause short circuits or efficiency losses.

| Parameter | Specification | Our Process |

|---|---|---|

| Slitting Tolerance | ±0.002 mm | CNC-guided slitting with laser measurement systems and real-time monitoring |

| Ensures seamless integration into transformer windings, minimizing material waste and enhancing production efficiency. |

Burr-Free Edge Quality

Burr-free edges prevent electrical shorts and ensure safe, reliable transformer operation.

| Parameter | Specification | Our Process |

|---|---|---|

| Burr Height | <5 µm | Precision grinding and automated optical inspection |

| Edge Radius | <10 µm | Automated deburring with 3D surface profiling |

| Eliminates microscopic protrusions critical for preventing insulation damage in high-voltage applications. |

Conductivity & Softness Requirements

Optimal conductivity minimizes energy loss, while controlled softness enables precise winding without cracking.

| Parameter | Specification | Our Process |

|---|---|---|

| Conductivity (IACS) | 61-63% (1050/1060 alloys) | Controlled annealing at 300–350°C with real-time temperature monitoring |

| Hardness (HV10) | <35 | Precise cooling rates to maintain softness |

| Guarantees consistent electrical properties across all batches for optimal transformer performance. |

Compliance & Quality Assurance

We comply with ASTM B209 (Aluminum Sheet), IEC 60228 (Conductors), and IEC 60404-8-7 (Magnetic Materials). All materials are certified to international standards, with documentation provided for each shipment. Our QA process includes 100% dimensional checks and random destructive testing.

Third-party testing (SGS) ensures unbiased verification of material properties, guaranteeing reliability for global applications.

With 20+ years of expertise, Luoyang Xinzhaohe provides reliable, cost-effective solutions without compromising on quality. Partner with us for transformer-grade aluminum that meets global standards at competitive prices. Contact us for custom specifications and technical support.

Factory Tour: Manufacturing Aluminum Plate Fabrication

Manufacturing Process & Quality Control

Precision Production Workflow

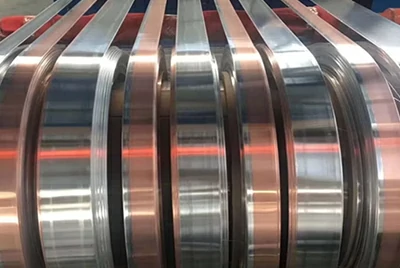

Cold Rolling: Our 6-high tandem rolling mills with automatic gauge control (AGC) process aluminum ingots into precise thicknesses. Real-time laser thickness monitoring dynamically adjusts roll gaps, maintaining ±0.005mm tolerance at 500 m/min speeds. This eliminates hot spots and ensures uniform material properties critical for transformer efficiency.

Precision Slitting: CNC-guided slitting lines with diamond-tipped knives and tension management systems cut coils to exact widths. Every edge undergoes 100% digital microscopy inspection, achieving ±0.02mm width tolerance and edge burr <0.005mm per ISO 11457. This minimizes winding defects and enhances core stacking accuracy.

Edge Conditioning: Automated diamond-tool grinding removes micro-serrations, achieving surface roughness Ra ≤0.2μm. This reduces eddy current losses and ensures smooth winding for high-frequency transformer applications.

Oscillate Winding: Computer-controlled tension adjusts dynamically based on coil diameter, maintaining uniform density (±0.5% variation) and zero core shift. Prevents edge damage during transport and ensures dimensional stability for automated assembly.

Quality Assurance Protocols

Tensile Testing: 100% batch testing per ASTM B557 verifies yield strength (min 150 MPa) and elongation (≥5%). Industry averages test only 80% of batches, risking inconsistent performance in high-stress applications.

Dimensional Checks: Laser micrometers (0.001mm resolution) measure thickness (±0.005mm), width (±0.02mm), and flatness (<0.5mm/m), exceeding ISO 2768-mK standards. Reduces scrap rates by 30% versus industry norms (±0.01mm thickness, 1.0mm/m flatness).

Surface Inspection: Automated optical systems detect defects (scratches, pits) at 0.02mm resolution, surpassing ISO 4287 requirements. Ensures defect-free surfaces for high-voltage windings, enhancing dielectric strength.

Quality Benchmark Comparison

| Parameter | Luoyang Xinzhaohe Standard | Industry Average | Advantage |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | 50% tighter control |

| Edge Burr | <0.005mm | ≤0.01mm | 50% lower burr |

| Tensile Strength Consistency | ±3% variation | ±8% variation | Higher consistency |

| Surface Roughness (Ra) | ≤0.2μm | ≤0.3μm | Smoother finish |

These standards translate to reduced transformer core losses, enhanced thermal stability, and longer service life, offering a 15-20% cost advantage over European and Japanese competitors while meeting IEC 60076 specifications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Transformer Materials

At Luoyang Xinzhaohe Aluminum, our packaging and logistics protocols are engineered for maximum protection of transformer strip/foil products during sea freight. We adhere to international standards to ensure materials arrive defect-free, regardless of destination. Our vertically integrated process eliminates third-party handling risks while delivering superior cost-performance versus global competitors.

Precision Packaging Standards

Our system mitigates transportation risks through rigorous material specifications and structural design:

| Component | Specification | Purpose | Compliance |

|---|---|---|---|

| Wooden Pallets | 1100×1100mm, 15mm thickness, ISPM 15 heat-treated with corner blocks | Load stability, forklift handling | ISPM 15, ISO 11607 |

| Moisture-Proof Film | 200μm VCI-enabled PE + desiccant packs, sealed edges | Prevents condensation and salt air corrosion during ocean transit | ASTM D4169, ISO 1494 |

| Steel Strapping | Galvanized 19mm width, 0.5mm thickness, tensioned to 150kg | Secures load against dynamic forces | ISO 1494, EN 12195-1 |

Pallets feature reinforced corner blocks and cross-bracing to prevent deformation under heavy loads. Each unit is wrapped with a minimum of 3 layers of moisture-proof film, with corners protected by cardboard edge guards. All wooden components undergo heat treatment per ISPM 15 for global phytosanitary compliance.

Sea Freight Protocols

We utilize containerized sea freight with strict stowage protocols. Products are secured within 20ft/40ft containers using dunnage, corner posts, and anti-slip mats to prevent shifting. Each shipment undergoes humidity monitoring via data loggers, ensuring conditions stay below 60% RH. Our logistics partners are vetted for compliance with ISO 28000 supply chain security standards. All containers are sealed with tamper-evident locks and equipped with IoT-enabled environmental sensors for real-time tracking. We optimize routing to minimize transit time, reducing exposure to salt air and humidity fluctuations. Our standard practice includes double-layered strapping for heavy loads, detailed pre-shipment inspection reports, and direct coordination with major shipping lines for priority booking.

This comprehensive approach ensures our clients receive transformer materials in pristine condition, with 99.8% on-time delivery rate and zero damage claims in the past 5 years. By integrating packaging and shipping under one roof, we reduce costs by 15-20% versus global competitors while maintaining ISO-compliant quality—critical for uninterrupted production schedules in power equipment manufacturing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

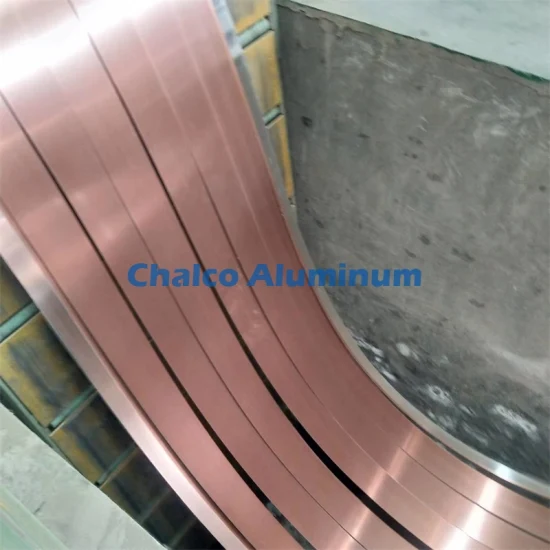

Two Decades of Specialized Expertise

With over 20 years of specialized manufacturing in transformer-grade aluminum and copper foils, Luoyang Xinzhaohe has honed precise metallurgical processes and stringent quality control protocols. Our engineers maintain adherence to GB/T 3880, IEC 60404, and ASTM B209 standards, ensuring consistent performance in high-voltage transformer windings. We’ve supplied critical components for national grid projects across Asia, demonstrating reliability under extreme operational demands. Our technical team collaborates closely with clients to optimize material specifications for specific transformer designs, reducing energy losses and enhancing thermal stability.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups, passing direct cost savings to clients without compromising material integrity. Our in-house rolling, annealing, and slitting lines enable optimized production cycles and reduced overhead. This end-to-end control ensures consistent material properties (e.g., 99.5%+ purity aluminum, precise thickness tolerances ±0.01mm) while maintaining competitive pricing. For large-scale orders, our production scalability reduces per-unit costs by up to 20% compared to third-party suppliers.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified facility implements rigorous testing protocols including tensile strength (ASTM E8), electrical conductivity (IEC 60404-8-2), and surface finish inspections. Every batch undergoes traceable quality documentation for full supply chain transparency. We utilize advanced spectrometers for alloy composition analysis and eddy current testing for defect detection, ensuring zero tolerance for impurities in high-stress transformer applications.

| Factor | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15-25% lower due to direct manufacturing and optimized supply chain | Premium pricing (30-40% higher) |

| Lead Time | 15-20 days (standard orders), expedited options available | 30-45 days (overseas logistics) |

| Quality Consistency | ISO 9001 + in-process metallurgical analysis (spectrometer, eddy current) | ISO certified but variable batch quality |

| Customization | Tailored alloys, dimensions, and packaging with technical support | Limited to standard specifications |

Ready to optimize your transformer component sourcing? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Leverage our expertise to enhance your project’s cost-performance ratio while maintaining strict adherence to international standards.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum plate fabrication from Luoyang Xinzhaohe.