Table of Contents

Market Insight: Aluminum Plate

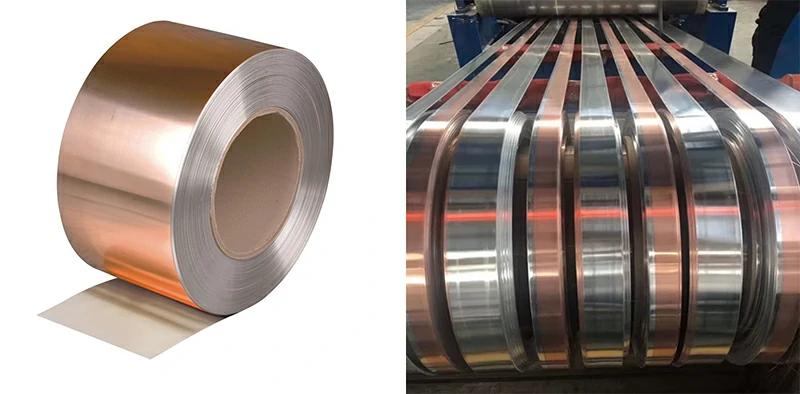

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for aluminum plate and strip in transformer windings continues robust growth, driven by fundamental economic and technical advantages over copper, particularly in distribution transformers. While copper maintains higher conductivity, aluminum offers a superior weight-to-conductivity ratio critical for large-scale installations and grid infrastructure projects. The shift toward aluminum is pronounced in emerging markets and for units above 500 kVA, where material cost savings (typically 30-50% lower base metal cost) and reduced structural support requirements significantly impact total lifecycle economics. Key demand drivers include accelerating grid modernization worldwide to integrate renewable energy sources, stringent energy efficiency regulations (e.g., DOE 2016 in the US, IE4/IE5 standards globally), and the ongoing substitution of copper in new transformer designs where weight and cost are paramount. Aluminum’s lower density (2.7 g/cm³ vs. copper’s 8.96 g/cm³) directly translates to lighter transformer cores, simplifying transportation and installation logistics, especially in remote or urban settings with access constraints.

Material quality is non-negotiable in transformer strip/foil applications, directly impacting core performance, reliability, and service life. Impurities, even at trace levels, drastically reduce electrical conductivity. For instance, iron content exceeding 0.15% can depress conductivity below the critical 61% IACS minimum required for efficient operation, increasing I²R losses and operational temperature. Precise control of grain structure through tailored annealing processes is essential to achieve the optimal balance of ductility for tight winding and sufficient tensile strength to withstand electromagnetic forces during fault conditions. Surface integrity is equally critical; microscopic defects, scratches, or residual oxides act as initiation points for insulation breakdown under high voltage stress, leading to premature transformer failure. Consistent dimensional tolerances (thickness, width) are mandatory for automated winding processes and uniform magnetic flux distribution within the core. Industry standards like ASTM B209 and IEC 60138 define stringent requirements for conductivity, mechanical properties, surface quality, and dimensional accuracy, which reputable suppliers rigorously adhere to.

The following comparison highlights critical material properties influencing transformer design and performance:

| Property | Aluminum (1350-H19) | Copper (ETP) | Significance for Transformers |

|---|---|---|---|

| Electrical Conductivity | 61.0% IACS min | 100% IACS | Directly impacts load losses & efficiency |

| Density (g/cm³) | 2.70 | 8.96 | Determines unit weight & structural requirements |

| Tensile Strength (MPa) | 150-185 | 200-250 | Affects winding integrity under electromagnetic stress |

| Relative Material Cost | 1.0 (Base) | 3.0-3.5 | Major factor in total transformer cost of ownership |

Substandard aluminum strip introduces severe supply chain risks. Inconsistent conductivity necessitates oversized conductors, negating weight/cost benefits. Poor surface quality increases scrap rates during winding and causes field failures, incurring high warranty costs and reputational damage. Variability in mechanical properties disrupts high-speed manufacturing lines. Luoyang Xinzhaohe Aluminum leverages two decades of specialized production expertise, employing advanced melt purification (flux injection, dual-stage filtration), continuous casting for homogeneous microstructure, and precision cold rolling with laser-guided thickness control to ensure every coil meets or exceeds the most demanding transformer OEM specifications. This unwavering commitment to metallurgical precision and process control is fundamental to delivering the reliability the global power infrastructure requires.

Technical Specs: Aluminum Plate

Technical Specifications for Aluminum Plate – Transformer Strip/Foil Application

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision aluminum plates specifically engineered for transformer strip and foil applications, where dimensional accuracy, edge quality, and electrical performance are critical. With over two decades of metallurgical expertise, our production processes are optimized to meet the stringent demands of power transmission and electronic component manufacturing. The following technical specifications define the performance parameters of our aluminum plate products, ensuring consistency, reliability, and compliance with international standards.

Dimensional precision is paramount in transformer applications to ensure uniform winding and minimize losses. Our aluminum plates are produced with a slitting tolerance of ±0.002 mm, achieved through state-of-the-art precision slitting lines equipped with laser-guided edge control systems. This tight tolerance ensures uniform strip width across large production runs, reducing variability during coil winding and improving overall transformer efficiency. The slit edges are processed using high-precision rotary shear technology, eliminating micro-tearing and ensuring burr-free edges. Burr height is consistently maintained below 1% of material thickness, preventing dielectric breakdown and enhancing insulation integrity in wound components.

Edge quality is further verified through optical inspection and tactile profilometry, with each batch subjected to edge smoothness testing. Surface roughness (Ra) is controlled within 0.4–0.8 µm, depending on alloy and temper, to optimize adhesion in laminated insulation systems and reduce interlayer friction during winding operations.

Electrical conductivity is a key performance metric for transformer-grade aluminum. Our plates, typically produced in 1060, 1070, and 1350 alloys, achieve a minimum conductivity of 59.0% IACS (International Annealed Copper Standard) in the annealed (O) temper. This high conductivity ensures low resistive losses and improved energy efficiency in transformer operation. Conductivity is validated through four-point probe resistivity measurements calibrated to ASTM B209 and IEC 60169-3 standards.

Mechanical properties are tailored to balance formability and strength. Typical yield strength ranges from 35–55 MPa in the O temper, with elongation exceeding 30%, enabling deep drawing and tight-radius bending without cracking. All material is supplied free of surface defects, including pits, scratches, and oxide streaks, as per ISO 6892-1 surface quality Class A.

Below is a summary of key technical parameters:

| Parameter | Specification |

|---|---|

| Alloy Grades | 1060, 1070, 1350 |

| Temper | O (Annealed) |

| Thickness Range | 0.10–3.00 mm |

| Width Tolerance (Slitting) | ±0.002 mm |

| Edge Quality | Burr-free, Burr Height <1% of thickness |

| Surface Roughness (Ra) | 0.4–0.8 µm |

| Electrical Conductivity | ≥59.0% IACS |

| Yield Strength | 35–55 MPa |

| Elongation | ≥30% |

| Surface Quality Standard | ISO 6892-1 Class A |

| Test Standards | ASTM B209, IEC 60169-3, GB/T 3880 |

All aluminum plates undergo full batch traceability, with certified mill test reports (MTRs) provided for chemical composition, mechanical properties, and electrical conductivity. Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to ISO 9001:2015 quality management protocols to ensure product consistency and customer reliability in high-performance transformer applications.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd employs a rigorously controlled sequence for producing high-performance aluminum transformer strip and foil, critical for efficient core lamination stacks. This process ensures dimensional stability, surface integrity, and magnetic properties essential for minimizing core losses. The core sequence begins with Cold Rolling, where pre-annealed hot band undergoes significant reduction in thickness under precisely managed rolling parameters. Our 20-roll Sendzimir mills provide exceptional control over flatness, surface finish, and gauge uniformity. Critical parameters including roll force, interstand tension, and coolant lubrication are continuously optimized to achieve target thicknesses ranging from 0.10 mm to 3.0 mm while maintaining tight tolerances and suppressing residual stresses. Thickness deviation is maintained within ±0.002 mm across the strip width through real-time laser micrometer feedback loops integrated into the mill control system.

Following cold rolling, the coil undergoes Precision Slitting. This stage utilizes high-precision slitting lines equipped with advanced tension leveling systems operating at 15-25% of the material’s yield strength. The primary objective is to achieve exact strip widths with exceptional edge straightness and minimal edge waviness, critical for uniform stacking in transformer cores. Slitting knives are maintained under strict calibration schedules, and edge guidance systems ensure positional accuracy within ±0.05 mm. The process simultaneously removes edge defects from prior operations and produces multiple narrow strips from a single master coil, optimizing material yield for specific customer lamination patterns.

The final critical stage is Edge Conditioning. Raw slit edges inevitably contain micro-burrs and surface irregularities that can cause interlamination shorts and increased eddy current losses in the transformer core. Our proprietary edge conditioning process employs controlled mechanical brushing and precision deburring techniques. This step meticulously removes burrs to a height of ≤ 5 μm while simultaneously work-hardening the immediate edge zone to enhance stacking stability. The process is validated through continuous microscopic edge inspection and surface profilometry to ensure consistent edge squareness and absence of detrimental surface defects.

Integrated Quality Control Verification

Quality control is embedded throughout the manufacturing sequence, not as discrete checkpoints but as continuous process validation. Key parameters and verification methods are summarized below:

| Process Stage | Critical Parameter | Measurement Method | Target Tolerance |

|---|---|---|---|

| Cold Rolling | Thickness Uniformity | Laser Micrometer (100% inline) | ±0.002 mm |

| Surface Roughness (Ra) | Contact Profilometer (per coil) | 0.4 – 0.8 μm | |

| Precision Slitting | Edge Straightness | Optical Edge Scanner (100% inline) | ≤ 0.15 mm/m |

| Width Tolerance | Laser Width Gauge (100% inline) | ±0.05 mm | |

| Edge Conditioning | Burr Height | Optical Microscopy (per 500m) | ≤ 5 μm |

| Edge Squareness | Precision Calipers & Optical Comparator | ≤ 0.05 mm/m |

This integrated approach, combining advanced metallurgical processing with real-time metrology, guarantees the dimensional precision, edge quality, and surface characteristics demanded by high-efficiency transformer manufacturing. Our decades of experience ensure consistent delivery of strip and foil meeting the most stringent global standards for core loss performance.

Packaging & Logistics

Export Packaging Standards for Aluminum Plate – Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of experience in the production and international distribution of high-precision aluminum and copper transformer strips and foils, we maintain rigorous export packaging protocols to ensure product integrity during global logistics, particularly sea freight. Our packaging system is engineered to address the dual challenges of mechanical stress and environmental exposure inherent in maritime transport.

All aluminum plate shipments are secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to meet international phytosanitary standards, ensuring customs clearance across major trade corridors without delay. Each pallet is structurally reinforced to support the full weight load of stacked aluminum plates, minimizing deformation or shifting during handling and transit. The use of wooden pallets provides superior load stability compared to alternative materials, especially under the dynamic conditions of containerized shipping.

Immediately after final quality inspection and surface verification, aluminum plates are wrapped in multi-layer moisture-proof composite film. This film incorporates a high-barrier aluminum foil interlayer bonded between polyethylene sheets, providing an effective vapor transmission rate of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. This specification ensures protection against salt-laden marine atmospheres, which are prevalent in sea freight environments. The film is heat-sealed at all edges to form a hermetic enclosure, preventing ingress of moisture, dust, and corrosive agents throughout the shipment duration.

To further enhance protection, desiccant packs are strategically placed within the sealed film envelope. These silica gel units maintain a controlled microclimate inside the wrapping, absorbing any residual or infiltrated humidity. Additionally, edge protectors made of high-density polyethylene are applied to the leading edges of each plate stack to mitigate mechanical damage during loading, unloading, and intermodal transfers.

All packaged units are labeled with durable, weather-resistant tags indicating product grade, batch number, dimensions, net weight, and handling instructions in accordance with ISO 780 and ISTA 3A standards. Critical orientation markers such as “This Side Up” and “Do Not Stack” are clearly displayed to prevent inversion or improper storage.

Our packaging methodology has been validated through accelerated aging tests and real-world shipment monitoring across routes including China to Southeast Asia, the Middle East, Europe, and South America. These trials confirm that our system effectively prevents white rust formation, surface oxidation, and physical deformation—common failure modes in improperly packaged aluminum products.

By integrating structural robustness with advanced moisture mitigation, Luoyang Xinzhaohe Aluminum ensures that every aluminum plate arrives at its destination in as-manufactured condition, meeting the exacting demands of transformer and electrical equipment manufacturers worldwide.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Transformer Strip and Foil Excellence

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver mission-critical aluminum and copper transformer strip and foil. Our vertically integrated facility in Luoyang, China, is engineered for precision, consistency, and scalability, directly addressing the stringent demands of global transformer and inductor manufacturers. Partnering with us provides access to deep process knowledge and robust infrastructure designed to mitigate supply chain volatility while ensuring material performance.

Our core strength lies in advanced metallurgical process control. We operate state-of-the-art continuous casting and rolling lines dedicated exclusively to transformer-grade conductors. This specialization enables precise management of alloy composition, particularly for high-purity aluminum (99.99% minimum) and oxygen-free copper, critical for minimizing electrical losses and maximizing thermal stability in core components. Rigorous in-line monitoring of grain structure, surface finish, and mechanical properties occurs throughout production. We consistently achieve tight thickness tolerances down to ±0.005mm for foils and maintain exceptional flatness essential for high-speed winding operations, directly contributing to your end-product efficiency and reliability.

Quality assurance is embedded within our operational DNA, not treated as a final checkpoint. Our ISO 9001 certified quality management system integrates comprehensive testing protocols at every stage. This includes real-time eddy current testing for conductivity and defect detection, alongside laboratory verification of chemical composition, tensile strength, elongation, and surface roughness per IEC 60137 and customer-specific standards. Full traceability from raw material batch to finished coil is standard, providing auditable data for your quality documentation and failure analysis requirements.

Supply chain resilience is a strategic priority. Our 200,000+ metric ton annual production capacity across multiple dedicated lines ensures reliable fulfillment for large-volume contracts without compromising lead times. We maintain strategic raw material inventory buffers and operate under strict lean manufacturing principles to optimize throughput and minimize waste. Our logistics network is optimized for global export, featuring containerized shipping solutions with protective packaging designed specifically for sensitive strip and foil products to prevent transit damage. This integrated approach guarantees on-time delivery performance exceeding 98%.

Partnering with Luoyang Xinzhaohe means aligning with an engineering-driven supplier focused on solving your technical and supply chain challenges. We understand that transformer efficiency and longevity start with the fundamental properties of the conductor material. Our commitment to metallurgical precision, unwavering quality, and dependable supply provides the foundation for your competitive advantage.

Key Production Capabilities Summary

| Parameter | Aluminum Transformer Strip/Foil | Copper Transformer Strip/Foil |

|---|---|---|

| Typical Thickness | 0.10mm – 3.00mm | 0.15mm – 2.50mm |

| Width Range | 50mm – 1600mm | 50mm – 1200mm |

| Key Alloys | 1070, 1060, 1350 | C10100, C10200, C11000 |

| Min. Purity | 99.99% Al | 99.99% Cu |

| Annual Capacity | 120,000+ MT | 80,000+ MT |

Initiate a technical consultation to discuss your specific transformer core material requirements and secure capacity allocation. Contact Cathy Zhang directly at cathy@transformerstrip.com to receive detailed material specifications, production schedules, and quality assurance documentation tailored to your project.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum plate directly from China.