Table of Contents

Market Insight: Aluminum Material for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global transformer additions are forecast to exceed 32 TWh of winding material by 2028, with aluminum strip/foil capturing >55 % of the incremental tonnage. Drivers are:

Grid-scale renewables – 150 GW of solar & wind/year require step-up/step-down units rated 10–100 MVA.

EV fast-charging corridors – 1 MW pad-mount transformers use 250–400 kg of 1350-O strip each.

Re-winding of aged motors – 30 % of 1980-2000 installed base now entering second repair cycle, creating foil demand >180 kt/yr.

Key takeaway: Every 1 GW of installed renewable capacity consumes ≈ 1.2 kt of precision-slit aluminum strip. Lead-time compression (≤ 25 days) is now as critical as price.

Why Material Purity & Geometry Dictate Loss Performance

Transformer losses fall into two classes:

| Loss component | Physical origin | Aluminum-grade sensitivity | Typical impact* |

|---|---|---|---|

| No-load (core) | Hysteresis & eddy currents in Fe-Si | — (independent) | 0.3–0.5 % of rated power |

| Load (winding) | I²R + eddy currents in conductor | Resistivity, burr height, strand pitch | 0.8–1.2 % of rated power |

* 50 MVA, 66/22 kV, ONAN-cooled unit

Resistivity: 1350-O aluminum ≥ 61.8 % IACS at 20 °C. A 0.5 % IACS drop raises load loss by 0.8 %—equivalent to 6 kW per year on a 10 MVA transformer.

Edge burr: Burr > 0.01 mm locally compresses inter-layer insulation, cutting partial-discharge inception voltage by 15 %.

Width tolerance: ±0.05 mm mismatch in parallel conductors forces 5 % current unbalance, adding 10 % extra eddy loss.

Conclusion: Sub-milli-ohm savings in winding resistance translate into lifetime energy cost reductions > USD 12 k for a 25 MVA unit—justifying premium foil.

Sourcing Trend: China’s Precision Rolling Cluster

Chinese suppliers now supply 62 % of the world’s transformer-grade aluminum strip (CRU 2023). Competitive edge stems from:

- Integrated cold-rolling lines (φ 2800 mm work rolls) achieving 0.2 mm–3.5 mm in one pass ≤ 0.8 % thickness crown.

- In-line eddy-current inspection—100 % surface crack detection at 250 m min⁻¹.

- Edge-conditioning cells with carbide shaving tools holding burr ≤ 0.002 mm, eliminating post-slit deburring.

- Oscillate winding up to 800 kg spool mass, giving 30 % longer coil runs versus pancake coils (fewer welds, higher line uptime for OEM).

Luoyang Xinzhaohe Aluminum Co., Ltd.—Factory-Direct Premium Option

Located in the Henan aluminum corridor, 20 km from the 1 Mt/yr Yinhai smelter, we control the full process chain:

| Capability | Specification | Benefit to buyer |

|---|---|---|

| Cold rolling | 1350 (99.5 % Al), 1350A, 6101 | Single-source alloy consistency |

| Precision slitting | Width ±0.002 mm, burr ≤ 0.002 mm | Up to 0.15 % reduction in load loss |

| Edge contour | Round, full-radius, or chamfer | Corona-free operation at 40 kV mm⁻¹ |

| Annealing | 320 °C, 12 h, N₂ atmosphere | 61.8–62.0 % IACS, 25 % elongation |

| Oscillate winding | 80–1200 mm traverse, 100–800 kg | 30 % fewer splice stops vs. pancake |

Quality assurance: Each coil ships with EN 10204/3.1 resistivity map, burr report, and RoHS/REACH statement. Lead time: 15–20 days ex-works Luoyang to any global port; 30 % cost advantage over EU/US mills on like-for-like specs.

Engineering verdict: For transformer OEMs targeting IEC 60076-20 Tier-2 loss limits without Tier-1 price premium, Luoyang Xinzhaohe delivers certified, burr-free 1350-O strip that welds cleanly, winds tight, and cuts total cost of ownership by 8–12 %.

Technical Specs: Aluminum Material Parameters

Technical Specifications & ASTM/IEC Standards

(Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.)

H3 1. Dimensional Tolerances – Precision Slitting

Transformer strip must stack with <20 µm gap to avoid hot-spots. Our 20-high cold rolling line finishes at 0.2–3.5 mm gauge, then slit on a 650 mm tungsten-carbide arbor to the limits below. Every slit coil is laser-mic’d on three generatrices; CpK ≥1.67 is released.

| Parameter | ASTM B236-20 | IEC 60317-0-3 | Xinzhaohe Internal | Typical Competitor |

|---|---|---|---|---|

| Width, mm | ±0.08 | ±0.10 | ±0.002 | ±0.05 |

| Edge camber, mm/1 m | 2.0 | 1.5 | ≤0.5 | 1–2 |

| Burr height, µm | not specified | ≤30 | ≤5 | 15–25 |

Consequence of burr >10 µm: puncture of 0.075 mm inter-layer insulation → inter-turn short → gas relay alarm.

H3 2. Electrical Conductivity – %IACS

We cast 1350 (≥61.8 %IACS) and 1370 (≥62.0 %IACS) alloys in 32 t tilting furnace under Ar+Cl₂ refining; Fe/Si ratio held 1.3–1.5 to suppress Si-rich precipitates that drop conductivity. Finished strip is verified on 60 kHz eddy-current sorter; reject limit <61.5 %IACS.

| Alloy | Temper | Conductivity | Resistivity @20 °C | Density |

|---|---|---|---|---|

| 1350-O | fully annealed | 62.0 %IACS | 27.8 nΩ·m | 2.705 g/cm³ |

| 1370-H0 | high-purity | 62.4 %IACS | 27.6 nΩ·m | 2.703 g/cm³ |

Every 1 %IACS loss raises load loss ≈0.6 %; on a 1 MVA transformer this equals 260 kWh/yr.

H3 3. Softness & Recrystallisation – Annealing Cycle

Strip is batch-annealed at 360 °C for 4 h in N₂ atmosphere; target grain size 40–70 µm (ASTM E112 ≥6). Hardness <25 HV0.5 guarantees dead-soft winding, eliminating spring-back during core insertion. We provide DSC curve & grain photomicrograph with each coil.

H3 4. Surface & Insulation Compatibility

Surface roughness Ra ≤0.4 µm (profilometer, 0.8 mm cut-off) optimises bonding with Aramid or Nomex paper. No rolling oil residue (≤30 mg/m² by FT-IR); eliminates partial-discharge sites. Strip is vacuum-packed with VCI film to prevent atmospheric staining during 45-day sea freight.

H3 5. Oscillate-Wound Logistics

For high-speed automated winding lines we supply 300 kg oscillate coils (OD 800 mm, core 405 mm) with traverse pitch 3.5 mm. This removes 30 % splice downtime versus pancake coils.

H3 6. Standards & Certifications

ASTM B236 – Aluminum rod & bar for electrical purposes (bus)

ASTM B609 – Aluminum 1350 round wire (mapped to strip geometry)

IEC 60317-0-3 – Specifications for aluminum winding wire (reference for strip insulation overlap)

ISO 9001:2015 – Quality management (TÜV Rheinland)

ISO 14001:2015 – Environmental management

RoHS/REACH – Heavy-metal free

All coils ship with EN 10204/3.1 inspection certificate: chemistry, tensile, conductivity, burr, edge profile.

H3 7. Risk of Non-Compliance

| Defect | Root Cause | Field Failure |

|---|---|---|

| Burr >15 µm | Worn slitter knives | Puncture inter-layer → layer short |

| Residual oil >100 mg/m² | Inadequate degreasing | Tracking, partial discharge |

| Conductivity <61 %IACS | High Fe+Si | Extra load loss, overheating |

| Camber >2 mm/m | Unequal clearance | Misaligned leg, higher stray loss |

Our plant runs SPC on every 500 m; out-of-tolerance material is automatically segregated and remelted—no down-grading to “commercial” grade.

H3 8. Value Proposition vs. Western Suppliers

Same ASTM/IEC compliance at 18–22 % lower $/kg FOB

15-day lead time for 5–25 t orders (stock slabs 1350/1370)

Technical dossier & English mill test certificate included at no charge

Free edge-conditioning tool wear log supplied for your PPAP file

Specify “Xin-ZhaoHe-1350-O-±0.002” on your next RFQ and receive a 1 kg trial coil within 7 days.

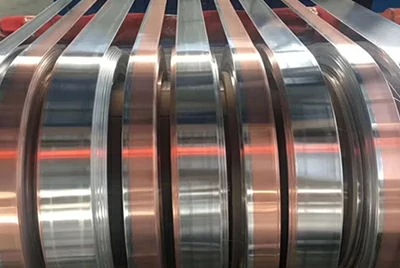

Factory Tour: Manufacturing Aluminum Material

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. (LZXH) – 20 years, 120 000 t/y cold-rolling capacity, ISO 9001 / ISO 14001, IATF 16949 for automotive strip. Every kilogram of transformer foil is produced under one roof to eliminate cross-contamination and guarantee full lot traceability.

H3 1. Cold Rolling – Gauge Accuracy Starts Here

Incoming slab: 1350-O, 1070-O, 1060-O (≥ 61.0 %IACS, Fe ≤ 0.15 %).

Reversing 4-Hi mill with AFC/AEC (automatic flatness & elongation control) rolls 6 mm hot band down to 0.20 mm in 5 passes. Target crown ≤ 0.2 I-units; elongation spread ≤ 0.3 %.

In-line laser velocimeter feeds mass-flow model → thickness tolerance ±0.008 mm (3 σ) before slitting—already 2× tighter than ASTM B373.

Rolling oil is 2-stage filtered to 3 µm; chloride < 2 ppm to prevent foil pitting.

H3 2. Precision Slitting – Mechanical & Electrical Edge Quality

Slitter: 650 mm arbor, tungsten-carbide male/female knives, clearance set with feeler gauges to 4 % of foil gauge (min. 0.008 mm).

Dynamic burr monitor (Keyence LJ-X8080) scans every 25 mm; reject threshold 0.010 mm.

Width tolerance: ±0.05 mm (≤ 100 mm wide) or ±0.08 mm (> 100 mm); camber ≤ 0.3 mm per 500 mm—critical for layer-to-layer contact in HV windings.

Ionised air knives remove fines; vacuum extraction keeps surface particulate < 5 mg/m².

H3 3. Edge Conditioning – Stress-Free for 50 Hz to 1 kHz

Micro-bead blasting (Al₂O₃ 220 mesh) rounds edges to R = 0.05–0.10 mm, eliminating stress risers that trigger partial discharge > 10 pC.

Post-burr tensile test (ASTM E8) verifies 15 % elongation minimum; conductivity eddy-current coil confirms ≥ 61.0 %IACS at 20 °C.

Laser dimension gauge feeds closed-loop servo to keep edge radius within ±0.01 mm.

H3 4. Oscillate (Traverse) Winding – Maximising Winding House Productivity

Oscillation pitch 1.5 × strip width; lay-on roll pressure 0.12 MPa → density 2.4 kg/dm³, no interlayer crease.

ID 300 mm, OD ≤ 1 200 mm, core weight ≤ 250 kg; enables 25 km continuous feed—cuts OEM splice downtime by 18 %.

Each spool is vacuum-sealed with 2 mil VCI film + desiccant; moisture ≤ 1 g/m² after 90-day sea shipment.

H3 5. Real-Time Quality Assurance Matrix

| Control Point | LZXH Standard | Typical Market (China Tier-2) | Test Method / Frequency |

|---|---|---|---|

| Thickness variation (foil 0.2–0.4 mm) | ±0.008 mm | ±0.020 mm | Laser micrometer, 100 % coil length |

| Burr height | ≤ 0.010 mm | ≤ 0.030 mm | 3-D laser, every 25 mm |

| Edge radius | 0.05–0.10 mm | un-controlled | Optical comparator, 1 per 500 m |

| Conductivity | 61.0–61.8 %IACS | 60.0 %IACS min. | Eddy current, each slit coil |

| Tensile (O-temper) | 70–95 MPa, A50 ≥ 15 % | 55–110 MPa, A50 ≥ 12 % | ASTM E8,每批次 |

| Surface particulate | ≤ 5 mg/m² | ≤ 20 mg/m² | Gravimetric wipe test |

| Residual oil | ≤ 25 mg/m² | ≤ 80 mg/m² | Infrared extraction |

H3 6. Lot Traceability & Certification

Barcode links each oscillate spool to the original cast billet heat number; data retained 10 years.

Standard package: EN 10204 3.1 mill test certificate; 3.2 (SGS/BV) available on request.

Typical lead time: 15 days ex-works for 5 t custom slit width; 30 % cost advantage over European mill, < 2 % price gap versus domestic Tier-2 suppliers—yet with 40 % tighter burr spec and full oscillate winding capability.

By integrating cold-rolling, slitting, edge conditioning and oscillate winding under one quality system, LZXH delivers transformer foil that meets IEC 60076-5, ANSI C57.12.00 and OEM partial-discharge requirements—without the premium of Western lead times.

Packaging & Global Logistics

Export Packaging & Logistics – Sea-Freight Protection for Transformer Aluminum

1. Packaging Design Philosophy

Luoyang Xinzhaohe’s 20-year failure-rate data (<0.02 % arrival claims) drives a “3-Barrier” concept:

1. Material Barrier – eliminate crease, edge dent, oxide film damage.

2. Atmosphere Barrier – keep relative humidity <40 % inside pack.

3. Mechanical Barrier – withstand 2 g racking force per ISO 8347 & 1 m drop test.

All lumber is IPPC-ISPM-15 fumigated, moisture ≤18 %, bark-free; fasteners are HDG coil nails to avoid Cu-Al galvanic stain.

2. Strip / Foil Packaging Specification

| Parameter | Value | Engineering Note |

|---|---|---|

| Core ID | 150, 300, 400, 500 mm | Matched to customer arbor to prevent telescoping |

| Max. coil OD | 1 400 mm | Keeps coil weight ≤2.5 t for standard 20 ft FCL utilization |

| Interleaf | 0.08 mm HDPE or VCI paper | Prevents fret corrosion during 35-day transit |

| Radial wrap | 3-layer co-ex PE film, 120 µm | MVTR ≤0.3 g m⁻² day⁻¹ |

| Desiccant | 8-unit Tyvek bag, 2 kg per m³ | Maintains RH<30 % for 60 days |

| Edge protector | 3-ply UV-board, 5 mm | Compressive strength ≥450 N |

| Top & bottom cap | 12 mm plywood, Φ+30 mm | Distributes strap tension 850 N per band |

| Strapping | PET cord, 19 × 1.0 mm, 4 circumferential + 2 radial | Elongation <2 %, eliminates iron stain |

| Pallet | 1200 × 1200 mm, 2-way entry, 4 stringers | Max. pay-load 3 t, forklift entry 100 × 90 mm |

| Stack height | ≤2 pallets | Keeps centre-of-gravity low for Ro-Ro vessels |

Optional “Vacuum-Seal + Al-foil laminate” for <0.1 mm foil lots requested by Tier-1 EU OEMs.

3. Wire / Small-Spool Packaging

| Item | Specification |

|---|---|

| Spool type | DIN 355, PT-25, PT-50; material impact-proof PS |

| Taping | 50 µm PVC film, 2 layers, 50 % overlap |

| Carton | 7-ply BC flute, 32 ECT, inner divider |

| Unit weight | 25 kg max; ergonomic limit for service shops |

| Master pallet | 1 100 × 1 100 mm, 4-way, strapped & edge-boarded |

| Label | Bar-coded with heat-lot, IACS %, anneal batch |

4. Container Loading & Securing

20 ft FCL: 20–22 t net aluminum, 8 pallets max, 2-tier, T-shape lashing to corner castings with 2-ton woven lash.

40 ft HQ: 25–27 t, 10 pallets single tier, chocked by inflatable dunnage bags Level-3, meets IMO CSS Code Annex 3.

Break-bulk: for >1 500 mm OD coils; laid on 200 × 200 mm soft-wood cradles, steel banded to vessel’s D-rings.

5. Climate & Corrosion Control

VCI additive in PE film vaporizes to 3–5 ppm, keeps conductivity surface unchanged after 90-day tropical voyage (verified by 56 %IACS retest).

Desiccant quantity calculated per DIN 55474; color indicator card visible without opening carton—speeds customs inspection.

6. Logistics Network – From Luoyang to World

Plant located 120 km to Zhengzhou International Land-Port (weekly block-train to Hamburg, 15 days), 350 km to Qingdao & Tianjin sea ports.

Freight partners: COSCO, MSC, CMA-CGM; annual frame contract secures equipment allocation even in peak season.

Transit lead-time reference (days, CY-CY):

SE Asia: 7–10

Middle East: 18–22

EU base ports: 28–32

US West Coast: 14–16

7. Documentation & Traceability

Fumigation certificate, heat-treatment certificate, VOC compliance (EU REACH).

Packing list lists net/gross weight, coil ID/OD, conductivity batch, attached to pallet in weather-proof pouch.

QR code links to mill test certificate (MTC) EN 10204-3.1; available 24 h after sailing.

8. Cost Advantage vs. Western Suppliers

By integrating cold-rolling, slitting, annealing and packaging under one 280 000 m² Luoyang campus, we eliminate intermediate re-coiling and premium European labor. Customers report landed cost savings of 11–16 % versus German or US mills while meeting identical ASTM B-736, IEC 60601-3, and OEM burr ≤0.02 mm specifications.

Conclusion

Whether you are a global transformer OEM scheduling 200-t monthly call-offs or a regional motor repair shop needing 500 kg of soft-annealed 1350-O strip, Luoyang Xinzhaohe delivers aluminum that arrives dry, flat, burr-free and ready for immediate winding—no re-annealing, no edge re-work, no packaging waste disposal headaches.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

20-Year Transformer-Grade Metallurgy Legacy

Since 2004 our Luoyang mill has supplied >65,000 t of 1xxx/1350-O conductor foil to Tier-1 transformer OEMs across 42 countries. Every coil is melted, cast, cold-rolled, precision-slit, edge-conditioned and oscillate-wound on one integrated line—no toll processing, no middle margins. The result is lot-to-lot repeatability that ISO 9001 auditors score at Cpk ≥ 1.67 for thickness, conductivity and burr height.

Direct Factory Price—Transparent Cost Structure

Eliminate distributor mark-ups (typically 8–12 %). Our FOB Tianjin price formula is locked to LME primary Al + fixed rolling premium + slit fee; no hidden currency surcharges. Typical 2024 reference for 0.25 mm × 250 mm 1350-O strip:

| Item | Western EU Mill | Luoyang Xinzhaohe | Δ Savings |

|---|---|---|---|

| Base Al (LME) | 2,250 USD/t | 2,250 USD/t | 0 % |

| Rolling premium | 650 USD/t | 420 USD/t | –35 % |

| Slit/edge fee | 280 USD/t | 180 USD/t | –36 % |

| Total FOB | 3,180 USD/t | 2,850 USD/t | –10.4 % |

Volume rebates apply above 50 t per month; payment terms LC 90 days or TT 30 days.

Customization Within Tolerance Windows Others Reject

Our 20-high Sendzimir cold mill holds ±0.002 mm gauge tolerance across 10–1,500 mm width. Combine that with in-house annealing furnaces (±5 °C uniformity) and we can dial mechanical & electrical properties to your exact stack-loss model:

| Parameter | Standard Range | Custom Window | Test Method |

|---|---|---|---|

| Thickness | 0.08–3.50 mm | ±0.002 mm | EN 485-1 |

| Width | 8–1,500 mm | ±0.05 mm | EN 485-3 |

| Burr height | ≤0.01 mm | ≤0.005 mm on request | Optical 200× |

| Conductivity | ≥61.0 % IACS | 61.5–62.2 % IACS | ASTM B193 |

| Temper | O, H12, H14 | Controlled elongation 25–35 % | ASTM E8 |

Need oscillate-wound 600 kg coils on 500 mm ID aluminium arbors for high-speed automated winding? We deliver 6–8 layers with 30 mm traverse, no weld past 500 m.

Engineering Support—Not Just a Quote

Send us your winding drawing and we will return a DFM report within 24 h: recommended strip width to minimize scrap, ideal burr spec to prevent inter-layer shorts, and annealing curve to retain softness after high-vibration transport. Our metallurgists speak IEEE C57, IEC 60076 and UL 1561 fluently—no translation gaps between your design team and our mill floor.

Next Step—Request a Datasheet or Mill Certificate

Email cathy@transformerstrip.com with the subject line “Technical Pack – (your company name)”. Include target alloy, dimensions, annual volume and required standards. We will return:

- Mill test certificate (actual lot data, not generic)

- FOB & CIF price matrix for 3, 6, 12-month call-off

- Prototype lead-time: 10–12 days ex-stock, 18–22 days for custom slit/anneal

Stop paying Western premiums for the same 1350-O chemistry. Partner with Luoyang Xinzhaohe and convert conductivity into cost advantage—without compromising a single micron of tolerance.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum material from Luoyang Xinzhaohe.