Table of Contents

Market Insight: Aluminum Foil Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

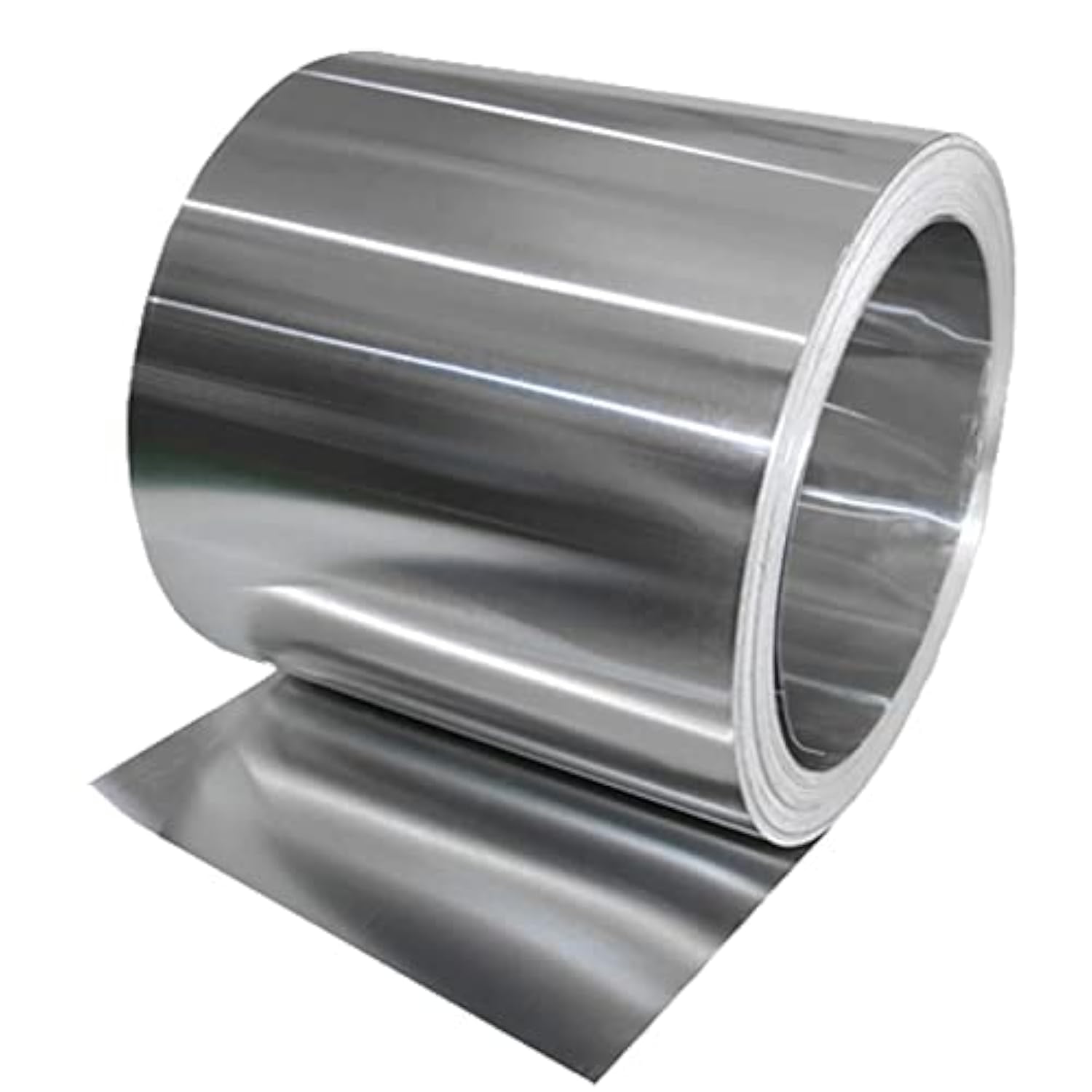

The global demand for aluminum foil strip in transformer applications continues to grow, driven by increasing electrification, energy infrastructure modernization, and the expansion of renewable energy systems. Aluminum foil strip, particularly in distribution and power transformers, serves as a critical conductor material due to its favorable combination of electrical conductivity, lightweight properties, and cost efficiency compared to copper. As utilities and industrial users seek to reduce system losses and improve energy efficiency, the role of high-purity, precisely engineered aluminum foil strip has become increasingly significant in transformer design and performance.

Aluminum foil strip is predominantly used in the fabrication of low-voltage windings in dry-type and oil-immersed transformers. Its adoption is especially prevalent in medium- and large-scale distribution transformers where weight reduction and material cost optimization are key design considerations. The electrical conductivity of aluminum—approximately 61% IACS (International Annealed Copper Standard)—is offset by its lower density, allowing for lighter transformer units without compromising current-carrying capacity. This characteristic is particularly advantageous in urban substations and renewable energy installations where transportation and installation logistics are critical.

Despite its advantages, aluminum presents unique engineering challenges in transformer applications. Its lower mechanical strength and higher coefficient of thermal expansion compared to copper necessitate precise dimensional control, consistent surface quality, and superior oxide layer management during winding and jointing processes. Poor-quality foil strip—exhibiting edge defects, thickness variation, or surface contamination—can lead to localized hot spots, increased eddy current losses, and premature insulation failure. Therefore, the reliability and longevity of a transformer are directly influenced by the metallurgical and dimensional integrity of the aluminum foil strip used.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience in transformer-grade aluminum and copper strips, we emphasize strict process control from billet sourcing through cold rolling, slitting, and quality inspection. Our aluminum foil strip is manufactured to meet international standards such as ASTM B498 and IEC 60164, ensuring consistent thickness tolerance (±0.01 mm), high surface cleanliness, and controlled mechanical properties. Each batch undergoes rigorous testing for electrical resistivity, tensile strength, and elongation to guarantee performance under continuous thermal cycling and electromagnetic stress.

The shift toward smart grids and energy-efficient transformers (e.g., amorphous metal and high-temperature insulation systems) further elevates the demand for precision-engineered aluminum strip. As transformer manufacturers aim to meet Tier 1 and Tier 2 efficiency standards, the quality of raw materials becomes a decisive factor in achieving compliance. In this context, sourcing aluminum foil strip from a technically capable and quality-focused supplier is not merely a procurement decision—it is a strategic component of transformer reliability and system efficiency.

| Parameter | Typical Specification (Al Foil Strip) |

|---|---|

| Alloy | 1060, 1070, 1350 |

| Thickness Range | 0.20 – 3.0 mm |

| Width Tolerance | ±0.2 mm |

| Thickness Tolerance | ±0.01 mm |

| Conductivity (min) | 59% IACS |

| Tensile Strength | 60 – 95 MPa |

| Elongation (min) | 25% |

In conclusion, the industrial demand for aluminum foil strip in transformers is shaped by technical performance requirements rather than mere cost considerations. High-quality material ensures optimal electromagnetic performance, thermal stability, and long-term durability—factors that directly impact the total cost of ownership for power infrastructure.

Technical Specs: Aluminum Foil Strip

Technical Specifications for Aluminum Foil Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to deliver aluminum foil strip meeting the stringent demands of transformer manufacturing. Our production processes prioritize dimensional stability, electrical performance, and surface integrity to ensure optimal core efficiency and longevity in high-voltage systems. Critical parameters are rigorously controlled through in-line metrology and adherence to international standards, with particular emphasis on precision slitting tolerances, edge quality, and conductivity. Deviations beyond specified limits risk insulation breakdown, eddy current losses, and winding instability during transformer assembly.

The following table details mandatory technical parameters for aluminum foil strip (Al 1060/1070, O-temper) supplied for transformer windings. All values represent absolute production tolerances validated via third-party certification and in-house quality assurance protocols:

| Parameter | Specification Range | Test Standard | Production Control Method |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | ASTM E29 | Laser micrometry with real-time tension control |

| Edge Burr Height | ≤5 μm (max) | ISO 1302 | SEM edge profiling at 10m intervals |

| Electrical Conductivity | 61.0–62.5 %IACS | ASTM B193 | Eddy current testing pre-slitting |

| Thickness Range | 0.20–0.80 mm | ISO 2178 | X-ray gauging with closed-loop roll gap adjustment |

| Surface Roughness (Ra) | 0.3–0.8 μm | ISO 4287 | Stylus profilometry at coil ends |

| Tensile Strength | 45–65 MPa | ASTM E8 | Universal testing machine (1 sample/2000m) |

| Elongation | ≥18% | ASTM E8 | Universal testing machine (1 sample/2000m) |

Precision slitting at ±0.002 mm is achieved through servo-driven rotary shear systems with sub-micron positional feedback, eliminating width variation that causes uneven winding tension. Edge burr control to ≤5 μm utilizes hardened tungsten carbide blades with automated clearance adjustment, verified via scanning electron microscopy to prevent insulation puncture during coil layering. Conductivity is maintained at 61.0–62.5 %IACS through strict aluminum purity control (99.70% min) and annealing homogenization, directly impacting transformer energy efficiency per IEC 60076-1. Surface roughness is optimized to 0.3–0.8 μm Ra to ensure uniform resin impregnation without compromising dielectric strength.

All coils undergo 100% width and edge inspection via non-contact optical systems, with conductivity and mechanical properties certified per batch. Traceability from molten metal to finished strip is maintained through our ISO 9001:2015-certified supply chain, including melt chemistry records and thermal processing logs. This granular control ensures dimensional conformity and electrical performance meet the zero-defect requirements of modern transformer design, reducing field failures and supporting grid reliability. Clients receive full material test reports (MTRs) aligned with EN 485-4 and customer-specific technical dossiers.

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Foil Strip for Transformer Applications

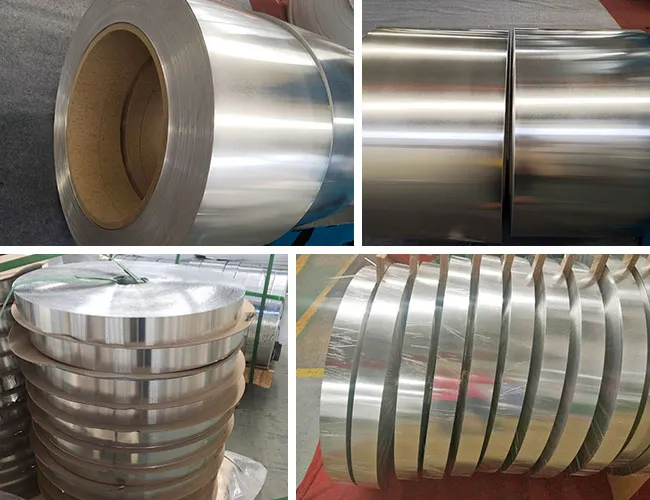

The production of high-performance aluminum foil strip for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning. This integrated manufacturing process ensures dimensional accuracy, surface integrity, and electrical performance required in advanced transformer windings.

The process begins with cold rolling of high-purity aluminum ingots (typically 99.7% Al or higher) that have undergone rigorous melt refining and continuous casting. The cast aluminum slabs are scalped, homogenized, and hot rolled to intermediate gauges before entering the cold rolling mill. Cold rolling is performed under precise tension and roll gap control to achieve target thicknesses ranging from 0.1 mm to 0.8 mm, depending on application requirements. This stage is critical for developing uniform grain structure, enhanced mechanical strength, and consistent electrical conductivity. Rolling parameters including reduction ratio, rolling speed, and interpass annealing are optimized to minimize residual stress and prevent microcracking.

Following cold rolling, the aluminum strip undergoes intermediate and final annealing in controlled atmosphere furnaces to relieve internal stresses and achieve the desired temper (commonly O-temper for full softness). The annealing cycle is precisely regulated for time, temperature, and cooling rate to maintain metallurgical homogeneity and avoid oxide formation.

The next stage is precision slitting, where wide master rolls are longitudinally cut into narrow strips of specified widths, typically ranging from 5 mm to 100 mm for transformer windings. High-tolerance rotary shear slitters with computer-controlled knife positioning ensure edge straightness within ±0.05 mm and minimal width variation. The slitting line is equipped with automatic edge guiding and tension management systems to prevent edge wave or camber, which could compromise winding integrity.

Edge conditioning is a critical post-slitting operation. The cut edges are processed through a brushing or edge rounding system to remove micro-burrs and sharp protrusions generated during slitting. This step is essential to prevent dielectric breakdown in transformer windings, where even microscopic edge defects can initiate partial discharge under high voltage stress. The conditioning process is monitored via optical edge inspection to verify smoothness and consistency.

Throughout the production flow, comprehensive quality control (QC) measures are implemented. Incoming aluminum is verified for chemical composition using optical emission spectroscopy (OES). During rolling, thickness is monitored in real time via laser micrometers. After slitting, each coil undergoes 100% surface inspection using automated vision systems to detect scratches, pits, or contamination. Final QC includes tensile testing, eddy current conductivity measurement, and dimensional verification per ASTM and IEC standards. All process data is logged for full traceability, supporting compliance with ISO 9001 and customer-specific quality requirements.

Packaging & Logistics

Export Packaging Specifications for Aluminum Foil Strip: Ensuring Integrity During Ocean Transit

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum foil strip shipments, specifically designed to counter the severe environmental challenges inherent in global maritime logistics. With over two decades of metallurgical and supply chain expertise in transformer core materials, our packaging system prioritizes absolute protection against moisture ingress, mechanical damage, and corrosion throughout extended sea voyages, safeguarding the critical surface quality and dimensional stability essential for downstream transformer winding processes.

Pallet construction forms the foundational element of our export system. All shipments utilize robust, kiln-dried hardwood pallets conforming strictly to ISPM 15 international phytosanitary standards for movement of wood packaging material. These pallets feature a minimum load-bearing capacity of 2,500 kg per unit, engineered with cross-block design to distribute coil weight evenly and prevent deformation during stacking. Surface smoothness is meticulously controlled to eliminate splinters or protrusions that could compromise the subsequent moisture barrier layers. Pallet dimensions are standardized to maximize container cube utilization while ensuring secure fitment within standard 20-foot and 40-foot dry freight containers, minimizing in-transit shifting.

The primary defense against maritime humidity and salt-laden atmospheres is our multi-layer moisture barrier system. Each aluminum foil strip coil undergoes a sequential wrapping process beginning with a high-density polyethylene inner liner, followed by a critical layer of metallized co-extruded film exhibiting a water vapor transmission rate (WVTR) below 0.5 g/m²/day. This vapor barrier is hermetically sealed using industrial heat-welding techniques meeting ISO 11607 standards, creating a continuous, impermeable enclosure. An outer layer of UV-stabilized polypropylene woven fabric provides abrasion resistance against handling impacts and container wall contact. Crucially, desiccant packs with verified moisture absorption capacity calibrated to the shipment volume and expected voyage duration are sealed within the barrier envelope.

Sea freight presents unique hazards including prolonged exposure to 70-100% relative humidity, significant temperature fluctuations causing cargo sweat, and potential salt spray penetration. Our packaging system directly mitigates these risks through the vapor barrier’s low WVTR performance and the structural integrity of the palletized unit. Coils are secured to the pallet using high-tensile steel strapping tensioned to 1,500 kgf, supplemented by edge protectors at critical stress points to prevent core collapse or foil edge damage during vessel motion. All sealed barrier packages undergo vacuum integrity testing prior to container loading to verify zero leaks.

This integrated approach, validated through accelerated salt spray and humidity chamber testing per ASTM G85 and IEC 60068-2-30 standards, ensures aluminum foil strip arrives at destination facilities with surface oxide levels and dimensional tolerances unchanged from factory release. We emphasize that adherence to these specifications is non-negotiable for maintaining material performance warranties; deviations risk interfacial corrosion, increased core losses, and winding defects. Luoyang Xinzhaohe’s packaging represents a metallurgical necessity, not merely a logistical step, in delivering transformer-grade aluminum foil strip fit for global deployment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Transformer Foil Strip Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of precision aluminum and copper foil strips engineered for transformer and electrical applications. Our deep-rooted expertise in metallurgical processing, combined with a vertically integrated production system, enables us to deliver consistently high-quality materials that meet the rigorous demands of power transmission, distribution, and industrial electronics sectors.

Our manufacturing facility is equipped with advanced cold rolling mills, continuous annealing lines, and high-precision slitting systems, ensuring tight dimensional tolerances and uniform mechanical properties across all product batches. We produce aluminum foil strip in thicknesses ranging from 0.1 mm to 6.0 mm and widths from 10 mm to 1,250 mm, customizable to meet specific customer technical requirements. Materials are processed under strict atmospheric controls to minimize oxide inclusions and surface defects, critical for dielectric performance in transformer windings.

We specialize in high-purity aluminum alloys including 1060, 1070, 1100, and 1350, all compliant with international standards such as GB/T 3880, ASTM B491, and IEC 60146. Each coil undergoes comprehensive quality verification, including tensile strength, elongation, and surface roughness testing, with full traceability from ingot to finished strip. Our in-house metallurgical laboratory supports continuous process optimization and rapid failure mode analysis, ensuring product reliability and consistency.

As a certified ISO 9001:2015 manufacturer, we maintain stringent process controls across raw material sourcing, rolling, heat treatment, and packaging. Our supply chain integrates direct access to high-grade aluminum billets, reducing lead times and enhancing cost efficiency for long-term partners. We support both small trial orders and large-volume contracts, with annual production capacity exceeding 30,000 metric tons.

Luoyang Xinzhaohe Aluminum CO., Ltd is committed to technical collaboration with transformer OEMs, winding houses, and procurement agencies seeking a dependable source for mission-critical conductive materials. Our engineering team works closely with clients to optimize foil strip specifications for improved winding efficiency, thermal management, and dielectric integrity in dry-type and oil-immersed transformer designs.

For sourcing professionals and technical buyers, partnering with us means gaining access to a stable, scalable, and technically proficient supplier with proven export experience across Asia, the Middle East, Europe, and the Americas. We provide detailed material test reports, custom packaging solutions, and responsive logistics coordination to support just-in-time manufacturing environments.

Contact us today to discuss your aluminum foil strip requirements and discover how our manufacturing excellence can enhance your product performance and supply chain resilience.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum CO., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum foil strip directly from China.