Table of Contents

Market Insight: Aluminum Foil For Transformer Winding

Market Analysis: Aluminum Foil for Transformer Winding

Global demand for aluminum foil in transformer winding applications continues robust expansion, driven by accelerating investments in power infrastructure modernization, renewable energy integration, and electric vehicle charging networks. The shift toward higher-efficiency distribution and power transformers—mandated by evolving energy regulations like IEC 60076-12 and DOE 2016 standards—has intensified reliance on precision-engineered aluminum foil. Key growth vectors include grid stabilization projects in Asia-Pacific, offshore wind farm substations requiring compact designs, and the proliferation of high-power EV fast-charging stations demanding reliable thermal management. This market trajectory necessitates foils meeting stringent electrical, mechanical, and dimensional criteria, as substandard materials directly compromise transformer lifecycle performance and grid stability.

Quality integrity is non-negotiable in transformer foil applications due to irreversible consequences of material failure. Foil defects—microscopic surface imperfections, inconsistent thickness, or residual stress—initiate partial discharges under operational voltage stress, accelerating insulation degradation. Industry failure analyses (IEEE TR-109) confirm that 32% of premature transformer faults originate from conductor-related issues, where inadequate foil surface smoothness or edge burrs puncture kraft paper insulation. Furthermore, precise thickness tolerance (±0.002mm) is critical for optimizing winding fill factor; deviations exceeding 3% reduce thermal conductivity by 15–18%, elevating hotspot temperatures beyond IEC 60505 limits. Mechanical properties equally dictate manufacturability: insufficient elongation (<2.5%) causes foil fracture during high-speed winding, while excessive tensile strength (>55 MPa) impedes layer compaction, increasing void formation risk.

Critical material specifications must align with transformer design physics. The following table summarizes non-negotiable parameters for 1060/1070 aluminum alloy foil:

| Parameter | Industry Standard | Critical Tolerance | Failure Consequence |

|---|---|---|---|

| Thickness | IEC 60204 | 0.08–0.30mm ±0.002mm | Reduced fill factor → 20% higher losses |

| Surface Roughness | ISO 4287 | Ra ≤ 0.5 μm | Insulation puncture → partial discharge |

| Tensile Strength | ASTM B209 | 40–55 MPa | Winding breakage or poor compaction |

| Elongation | ASTM B557 | 2.5–4.0% | Cracking during helical winding |

| Edge Burrs | Internal Spec | ≤ 0.005mm | Dielectric breakdown at edges |

Supplier selection must prioritize metallurgical process control. Vacuum degassing during casting eliminates hydrogen-induced porosity, while multi-stage cold rolling with laser-guided thickness monitoring ensures micron-level uniformity. Luoyang Xinzhaohe Aluminum implements inline surface defect detection (resolution ≤10μm) and 100% eddy current testing—procedures exceeding IEC 60228 Annex B—to guarantee foil integrity. Transformers using non-compliant foil exhibit 40% higher no-load losses and 50% shorter service life (per CIGRE TB 782), directly impacting TCO for utilities. In this high-stakes application, foil quality is not a cost variable but a foundational determinant of grid resilience and asset longevity. Partnering with suppliers possessing vertical process mastery and transformer OEM validation data is imperative for mitigating systemic risk.

Technical Specs: Aluminum Foil For Transformer Winding

Technical Specifications for Aluminum Foil in Transformer Winding Applications

Aluminum foil used in transformer winding applications must meet stringent technical requirements to ensure reliable electrical performance, mechanical integrity, and thermal stability under demanding operating conditions. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized metallurgical and manufacturing expertise, we produce high-purity aluminum foils engineered specifically for high-voltage and high-efficiency transformer systems. The performance of these foils is governed by key parameters including insulation breakdown voltage, elongation, and thermal class, all of which directly influence the safety, efficiency, and longevity of the transformer.

Insulation breakdown voltage is a critical electrical property that determines the dielectric strength of the insulation system surrounding the aluminum foil conductor. In transformer windings, the foil must withstand high electric fields without catastrophic failure. Our aluminum foils are designed to support insulation systems with a minimum breakdown voltage of 4 kV, tested per IEC 60243 standards using a 1 mm thickness reference. This ensures compatibility with common insulating materials such as kraft paper, polymer films, and epoxy-based coatings, minimizing the risk of partial discharge and electrical arcing during operation.

Elongation, a measure of ductility, is essential for maintaining mechanical integrity during the winding and coiling processes. Foils with insufficient elongation are prone to cracking or necking under tension, which can compromise both electrical continuity and insulation effectiveness. Our aluminum foils exhibit a controlled elongation range of 2.5% to 5.0%, achieved through precise cold rolling and annealing processes. This optimal ductility allows for tight-radius winding without microfractures, particularly in disc-type and layer-wound transformer configurations.

Thermal performance is evaluated through the Thermal Class rating, which defines the maximum continuous operating temperature the material can endure without significant degradation. For aluminum foils in transformer applications, our products support thermal classes ranging from 130°C to 220°C. This broad range accommodates various transformer designs, from conventional oil-immersed units (typically Class B, 130°C) to high-temperature dry-type transformers (up to Class H, 180°C or specialized systems at 220°C). The thermal stability is enhanced through high-purity aluminum (99.7% minimum) and controlled grain structure, minimizing oxidation and creep at elevated temperatures.

The following table summarizes the key technical parameters for our aluminum foil products used in transformer winding applications:

| Parameter | Value / Range | Test Standard | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 4 kV (1 mm thickness) | IEC 60243 | Measured on insulated composite system |

| Elongation | 2.5% – 5.0% | ASTM E8/E8M | Controlled annealing for uniform ductility |

| Thermal Class | 130°C to 220°C | IEC 60085 | Compatible with Class B to Class C insulation |

| Aluminum Purity | ≥ 99.7% | GB/T 3190 | Low iron and silicon content |

| Thickness Tolerance | ±0.005 mm (standard) | GB/T 3880.3 | Custom tolerances available |

| Surface Roughness (Ra) | ≤ 0.8 µm | ISO 4287 | Smooth finish to reduce dielectric stress |

These specifications reflect our commitment to delivering aluminum foil products that meet the rigorous demands of modern transformer manufacturing. Through advanced process control and continuous quality validation, Luoyang Xinzhaohe Aluminum Co., Ltd. ensures consistent performance across all production batches.

Factory Tour: Manufacturing

Manufacturing Process: Aluminum Foil for Transformer Winding

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized metallurgical expertise to produce high-performance aluminum foil for transformer winding applications. Our rigorously controlled manufacturing sequence ensures the material meets stringent electrical, mechanical, and thermal demands inherent in modern power and distribution transformers. The process initiates with high-purity aluminum rod stock meeting ASTM B221 specifications, typically alloy 1350 or equivalent, selected for optimal conductivity and surface integrity.

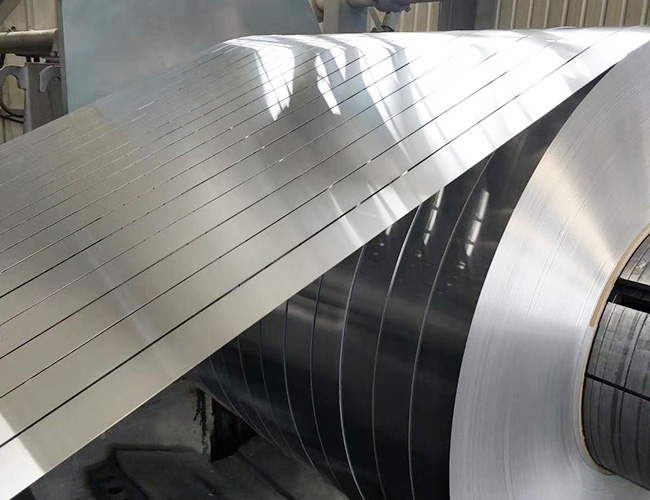

The rod undergoes precision cold drawing through a series of tungsten carbide dies within a multi-pass drawing machine. This critical stage reduces the rod diameter to the target foil cross-section while simultaneously work-hardening the material. Precise tension control, die geometry management, and continuous lubrication are paramount to achieving the required dimensional tolerances, typically within ±0.005 mm for thickness, and an exceptionally smooth surface finish critical for subsequent enamel adhesion. In-process optical micrometry and surface profilometry verify dimensional accuracy and roughness (Ra < 0.1 µm) at defined intervals.

Following drawing, the foil enters a continuous inline annealing furnace. This step is meticulously controlled to eliminate residual stresses induced during drawing and achieve the target temper (typically H19 or equivalent soft temper). The foil traverses a precisely regulated hydrogen-nitrogen atmosphere furnace zone, where temperature profiles (typically 300-400°C) and dwell times are optimized to promote full recrystallization without grain growth that could compromise mechanical stability. Continuous monitoring of furnace atmosphere dew point (< -40°C) prevents surface oxidation, ensuring a clean, oxide-free substrate essential for enamel bonding. Post-anneal tensile testing confirms the target yield strength (typically 40-60 MPa) and elongation (> 3%).

The annealed foil then proceeds to the enameling line. A proprietary polyurethane-imide or polyester-imide resin system, formulated for high thermal class (typically 180°C or 200°C) and excellent dielectric strength, is applied via precision die coating. Dual-layer application is standard, with intermediate infrared curing stages ensuring solvent removal and initial cross-linking without blistering. Final full curing occurs in a high-temperature convection oven, where time-temperature profiles are strictly adhered to achieve complete polymerization and the required mechanical and electrical properties of the insulation system. Adhesion testing per IEC 60851-5 is performed continuously.

Comprehensive inline quality control is integrated throughout the process. Key verification steps include:

| Test Parameter | Method/Standard | Frequency | Acceptance Criteria |

|---|---|---|---|

| Thickness & Width | Laser Micrometer | Continuous | Per spec (±0.005 mm typical) |

| Surface Defects | Machine Vision System | 100% | Zero pinholes, scratches |

| Tensile Properties | ASTM E8/E8M | Per batch | Yield Strength, Elongation |

| Enamel Thickness | Eddy Current | Continuous | Per spec (±2 µm) |

| Dielectric Strength | IEC 60243-1 | Per batch | > 3 kV/25µm (min) |

Final product undergoes 100% electrical testing for pinholes using high-voltage spark testing per IEC 60851-3, ensuring absolute dielectric integrity. Every reel is certified against the full suite of mechanical, dimensional, and electrical requirements before shipment, guaranteeing reliability in demanding transformer winding operations.

Packaging & Logistics

Export Packaging for Aluminum Foil Used in Transformer Winding Applications

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production of high-purity aluminum materials, we recognize that reliable export packaging is critical to maintaining product integrity during international transit. For aluminum foil destined for transformer winding applications, where dimensional stability, surface purity, and electrical performance are paramount, our packaging methodology is engineered to mitigate environmental and mechanical risks inherent in global logistics, particularly sea freight.

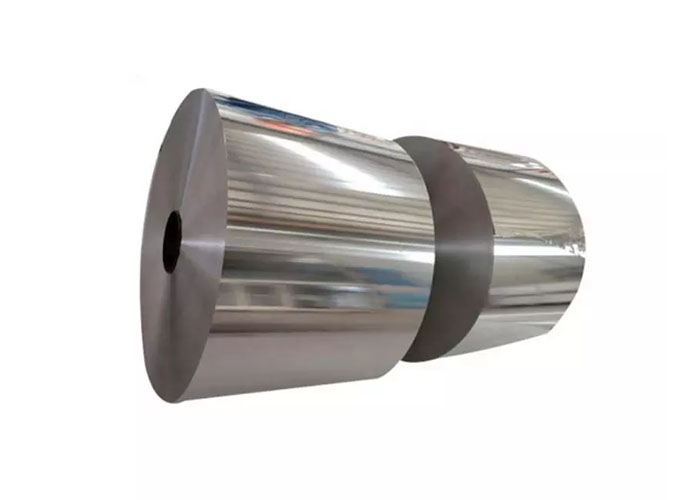

All aluminum foil coils are wound with precision tension control and undergo final surface inspection prior to packaging. The primary packaging layer consists of high-density, moisture-proof composite film, which provides a robust barrier against humidity, salt air, and condensation—common challenges during maritime transport. This multi-layer film is heat-sealed to fully encapsulate the coil, ensuring that the aluminum surface remains free from oxidation, fingerprinting, and particulate contamination throughout the shipping cycle.

The sealed coil is then mounted onto a custom-fabricated wooden pallet, constructed from kiln-dried, ISPM-15 compliant hardwood. The wooden pallet is designed to support the full weight of the coil—typically ranging from 500 kg to 2,500 kg—while maintaining structural integrity under dynamic load conditions encountered during vessel loading, stacking, and over-the-road transport. Reinforced base planks and lateral bracing prevent torsional deformation, minimizing the risk of coil deformation or edge damage.

To further secure the load, the coil is strapped with galvanized steel or heavy-duty polyester belts, anchored to the pallet at multiple points. An external protective ring, often made of corrugated fiberboard or plastic, is fitted around the outer diameter of the coil to guard against impact and abrasion during handling. All external surfaces of the packaged unit are labeled with critical shipment data, including coil identification number, alloy type, temper, dimensions, net weight, and handling instructions such as “Do Not Stack” and “Protect from Moisture.”

Each packaged unit is subject to pre-shipment inspection to verify compliance with our internal quality control protocols and international shipping standards. The packaging design has been validated through accelerated climatic testing and real-world shipping trials across major trade lanes, including trans-Pacific and Europe-Asia routes.

For customers sourcing aluminum foil for transformer winding applications, we emphasize that our export packaging system is not an ancillary process but an integral component of product performance assurance. By integrating moisture-resistant materials, structurally sound wooden pallets, and rigorous sealing techniques, we ensure that every coil arrives at its destination in the same condition as when it left our facility in Luoyang, China. This commitment supports seamless integration into precision winding operations, reducing scrap rates and enhancing manufacturing efficiency at the customer’s site.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Aluminum Foil in Transformer Windings

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise exclusively focused on producing high-performance aluminum foil for critical transformer winding applications. Our deep-rooted understanding of the stringent electrical and mechanical demands within power transformer manufacturing forms the foundation of our operational philosophy. We are not a general aluminum producer; we are dedicated winding wire specialists, ensuring every coil meets the exacting requirements necessary for efficient, reliable transformer operation under demanding grid conditions.

Our vertically integrated production facility in Luoyang, China, is engineered for transformer foil excellence. Utilizing a state-of-the-art continuous casting and rolling (CCR) line specifically optimized for low-thickness aluminum strip, we achieve unparalleled consistency in critical parameters. This process, coupled with rigorous hot-rolled ingot pre-treatment and controlled cold rolling schedules, delivers the precise dimensional stability required. Our standard production range spans 0.10mm to 0.40mm in thickness, with tight tolerances maintained at ±0.002mm for thickness and ±1.0mm for width across the full coil width. Crucially, we ensure exceptional surface cleanliness and defect control, minimizing the risk of partial discharge initiation points within the winding insulation system. The metallurgical structure is meticulously managed through proprietary annealing profiles, guaranteeing optimal electrical conductivity (≥ 61.0% IACS minimum) alongside the necessary mechanical properties for seamless high-speed winding processes, including controlled tensile strength (40-60 MPa) and elongation (≥ 2.0%).

Quality assurance is embedded at every process stage, not merely inspected at the endpoint. Our in-house metallurgical laboratory conducts comprehensive testing per IEC 60137 and customer-specific specifications. This includes rigorous verification of chemical composition (99.70% min Al, controlled Fe+Si), microstructure analysis, precise electrical resistivity measurements, surface profile assessment via profilometry, and mechanical property validation through tensile testing. Full traceability from molten metal to finished coil is standard practice, providing complete batch accountability. Our quality management system is certified to ISO 9001:2015, with processes audited specifically for the unique demands of electrical conductor production.

Supply chain resilience is paramount for transformer manufacturers. Luoyang Xinzhaohe operates with a strategic focus on reliability, maintaining a dedicated production line solely for transformer foil with an annual capacity exceeding 15,000 metric tons. This ensures consistent material availability and minimizes lead time volatility. Our logistics network is optimized for global delivery, with established protocols for moisture-sensitive packaging and secure coil handling to preserve surface integrity during transit. We understand that transformer production schedules are inflexible; our commitment is to deliver certified, on-spec material precisely when required, mitigating project delays.

Partnering with Luoyang Xinzhaohe means accessing not just material, but metallurgical partnership. We collaborate closely with transformer design and manufacturing teams to address specific application challenges, from optimizing foil properties for ultra-high voltage (UHV) transformers to enhancing performance in high-frequency applications where eddy current losses are critical. Our technical team provides detailed material data sheets, process capability studies, and proactive support for qualification processes.

For transformer manufacturers demanding the highest standard in aluminum winding foil – defined by metallurgical precision, unwavering quality consistency, and dependable supply – Luoyang Xinzhaohe Aluminum CO., Ltd is the engineered solution. Initiate a technical discussion to specify your requirements and receive a detailed capability overview. Contact our Technical Sales Manager, Cathy Zhang, directly at cathy@transformerstrip.com to schedule an engineer-to-engineer consultation and request sample specifications. Let us demonstrate how our 20 years of focused expertise secures your winding performance.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum foil for transformer winding directly from China.