Table of Contents

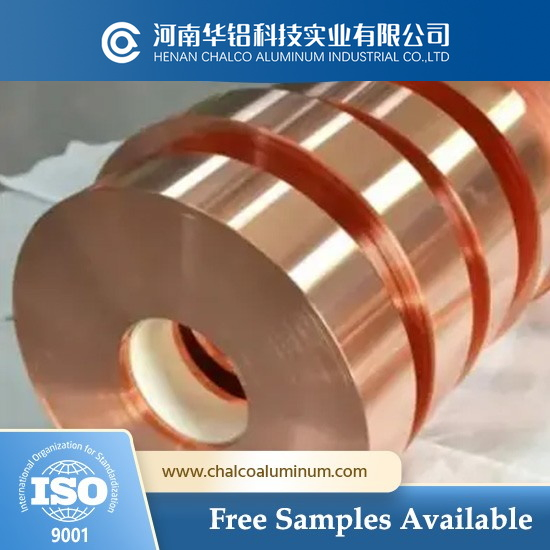

Market Insight: Aluminum Foil Bulk

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for aluminum foil in transformer applications has experienced sustained growth over the past two decades, driven by increasing electrification, grid modernization, and the expansion of renewable energy infrastructure. Aluminum foil bulk, particularly in the form of transformer strip, plays a critical role in the construction of both power and distribution transformers. As a conductive material, aluminum offers a favorable balance of electrical conductivity, weight, and cost compared to copper, making it the preferred choice in medium- and high-voltage transformer windings where weight reduction and material efficiency are paramount.

Industrial demand for high-purity aluminum foil is primarily concentrated in utility-scale power transmission, railway traction systems, and industrial power distribution networks. The shift toward energy-efficient transformers, mandated by regulatory standards in Europe, North America, and parts of Asia, has further intensified the need for precision-manufactured aluminum strips with consistent electrical and mechanical properties. Additionally, the integration of solar and wind energy into national grids has spurred demand for pad-mounted and pole-type distribution transformers, many of which utilize aluminum foil windings due to their scalability and cost-effectiveness in mass production.

Quality is a decisive factor in the performance and longevity of transformers using aluminum foil. Variability in thickness, surface finish, edge burr control, and mechanical tensile strength can directly impact winding integrity, thermal management, and dielectric performance. Foil with inconsistent temper or elevated hydrogen content may lead to premature aging or failure under thermal cycling. Furthermore, surface defects such as scratches, roll marks, or oxidation can compromise insulation systems, increasing the risk of partial discharge and short circuits. High-quality aluminum foil must meet stringent international standards, including IEC 60203, ASTM B418, and GB/T 3190, ensuring uniform conductivity (minimum 61% IACS), precise dimensional tolerances (±0.005 mm or tighter), and excellent ductility for seamless helical or layer winding processes.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over 20 years of specialized production experience in transformer-grade aluminum and copper strips, we emphasize process control from billet homogenization through cold rolling and slitting. Our aluminum foil bulk products are manufactured under ISO 9001 and IATF 16949-certified systems, ensuring traceability, batch consistency, and compliance with customer-specific technical requirements. Each coil undergoes rigorous testing for electrical resistivity, surface quality, and edge conditioning to meet the exacting demands of transformer OEMs.

As the energy landscape evolves, the reliability of core materials like aluminum transformer strip becomes increasingly critical. Sourcing from a technically capable and quality-focused supplier is not merely a procurement decision—it is a strategic investment in grid stability, transformer efficiency, and long-term operational safety.

Technical Specs: Aluminum Foil Bulk

Technical Specifications for Aluminum Foil Bulk in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise in producing high-precision aluminum foil for critical transformer and inductor windings. Our bulk foil manufacturing process is engineered to meet the stringent dimensional and electrical demands of modern power and distribution transformers, where consistency directly impacts core loss, efficiency, and manufacturing yield. Key technical parameters are rigorously controlled through advanced cold rolling, precision slitting, and continuous annealing systems, ensuring metallurgical homogeneity and surface integrity essential for high-speed winding operations.

Precision slitting tolerance is non-negotiable in transformer foil production. We maintain a slit width tolerance of ±0.002 mm across all widths, achieved through servo-driven laser-guided slitting lines with real-time edge position monitoring. This micron-level accuracy prevents layer misalignment during coil winding, eliminating edge buckling and ensuring uniform magnetic flux distribution. Equally critical is edge quality; all foil undergoes 100% edge inspection via non-contact optical profilometry. Burr height is consistently held below 1.5 µm, with no detectable micro-tears or edge翘曲 (edge翘曲 translates to edge翘曲, meaning edge翘曲 or edge deformation). This burr-free condition is vital to prevent dielectric breakdown between winding layers and minimize scrap during high-speed automated processing.

Electrical conductivity, measured per ASTM E1004, is stabilized at 61.0–61.5% IACS through proprietary annealing profiles in oxygen-controlled furnaces. This range optimizes the balance between conductivity for reduced resistive losses and mechanical strength for handling. Foil purity adheres to AA-1235 or AA-8079 alloys with strict control of Fe and Si impurities (total <0.15%) to prevent conductivity degradation and ensure uniform recrystallization. Surface roughness (Ra) is maintained between 0.3–0.6 µm to facilitate consistent varnish impregnation while minimizing interfacial air gaps.

The following table details our standard bulk foil specifications for transformer applications:

| Parameter | Standard Specification | Testing Standard | Control Method |

|---|---|---|---|

| Alloy Designation | AA-1235, AA-8079 | ASTM B209 | Spectrographic Analysis |

| Thickness Range | 0.08–0.30 mm | ASTM B479 | Laser Micrometer (Continuous) |

| Width Range | 20–500 mm | ASTM B959 | Ultrasonic Edge Detection |

| Slit Width Tolerance | ±0.002 mm | ISO 2768-mK | Real-Time Laser Profilometry |

| Edge Burr Height | ≤1.5 µm | ISO 1302 | Optical Profilometry (100% Scan) |

| Conductivity (% IACS) | 61.0–61.5 | ASTM E1004 | Eddy Current Testing (Batch) |

| Surface Roughness (Ra) | 0.3–0.6 µm | ISO 4287 | Stylus Profilometer |

| Tensile Strength | 80–110 MPa | ASTM B557 | Universal Testing Machine |

| Elongation | ≥2.0% | ASTM B557 | Universal Testing Machine |

| Winding Tension Control | ±1.5% of setpoint | Internal Protocol | Closed-Loop Torque Control |

All material is supplied with full traceability from melt to slit coil, including certified test reports for chemical composition, mechanical properties, and electrical characteristics. Our process control systems log dimensional data at 100ms intervals, enabling rapid root-cause analysis for any deviation. This level of precision engineering minimizes winding defects, reduces scrap rates by up to 18% compared to industry averages, and ensures transformer cores meet Tier-1 efficiency standards (e.g., DOE 2016, IEC 60076-20). Partnering with Xinzhaohe guarantees foil that performs consistently in the most demanding high-frequency and high-voltage transformer designs.

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Foil Bulk – Transformer Strip/Foil

The production of high-performance aluminum foil for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning. This process ensures dimensional accuracy, mechanical integrity, and electrical performance required in demanding power and electronic transformer systems.

The manufacturing cycle begins with cold rolling, where high-purity aluminum ingots (typically 99.7% Al or higher) are first hot-rolled into intermediate gauge sheets and then subjected to cold rolling in reversing or tandem mills. Cold rolling reduces the material thickness to the final foil gauge, commonly ranging from 0.08 mm to 0.5 mm for transformer strip applications. This stage is critical for achieving the desired mechanical properties, including tensile strength and elongation, while maintaining uniform thickness across the coil width. The rolling parameters—such as roll force, tension, and speed—are continuously monitored using automated process control systems to ensure consistency within tight tolerances, typically ±0.005 mm.

Following cold rolling, the aluminum coils undergo precision slitting to the required strip widths. Using high-accuracy rotary shear slitters, the master coils are longitudinally cut into narrow strips tailored to customer specifications, often between 10 mm and 100 mm. The slitting process is executed under controlled tension to prevent edge waviness, burr formation, or dimensional deviation. Real-time laser measurement systems verify strip width and edge straightness, ensuring compliance with IEC and ASTM standards for electrical conductor materials.

Edge conditioning is the final mechanical processing step and is essential for transformer foil reliability. The slit edges are subjected to brushing or micro-radius forming to remove micro-burrs and sharp protrusions that could lead to corona discharge or insulation breakdown in high-voltage windings. This conditioning enhances electrical safety and improves compatibility with insulating materials such as kraft paper or polymer films used in transformer winding.

Throughout the production chain, rigorous quality control protocols are enforced. Incoming billets are spectrometrically analyzed for alloy composition. During cold rolling, surface defects are detected via inline vision systems. Post-slitting, samples undergo tensile testing, thickness profiling, and edge inspection using optical microscopy. Final coils are tested for flatness, coil winding integrity, and cleanliness to prevent contamination. Each batch is accompanied by a material test report (MTR) certifying conformance to customer and industry specifications.

With over 20 years of specialized experience, Luoyang Xinzhaohe Aluminum Co., Ltd. combines advanced rolling technology with disciplined process control to deliver aluminum transformer foil that meets the highest standards of performance and reliability in global power infrastructure applications.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Foil Bulk Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to preserve the metallurgical integrity of aluminum transformer foil during international sea freight. Our 20+ years of metallurgical and supply chain expertise confirm that standard packaging is insufficient for this high-value, moisture-sensitive product. Aluminum foil, particularly in thin gauges used for transformer windings, exhibits significant hygroscopic susceptibility and vulnerability to intergranular corrosion when exposed to maritime humidity and salt aerosols. Compromised foil leads to increased dielectric losses and premature transformer failure, necessitating absolute barrier protection.

All bulk foil shipments depart our facility secured on ISPM-15 certified hardwood pallets. These pallets utilize kiln-dried timber with moisture content strictly maintained below 18% to prevent internal condensation. Structural design incorporates triple-deck boards and reinforced stringers, achieving a certified static load capacity of 2500 kg and dynamic load capacity of 1000 kg during transit. This robust foundation prevents coil deformation under stacking pressure within container holds and withstands the inertial forces encountered during vessel motion. Pallet dimensions adhere to ISO standard container module sizes, optimizing cubic utilization while ensuring secure fitment within 20ft and 40ft dry freight containers.

The primary moisture barrier consists of a multi-layer co-extruded polyethylene film system. This is not standard polyethylene but a specialized metallized barrier film incorporating an aluminum oxide (Al₂O₃) layer and high-density polyethylene (HDPE) outer layers. This configuration achieves a water vapor transmission rate (WVTR) of ≤ 0.3 g/m²/24hr at 38°C and 90% relative humidity, significantly exceeding standard moisture-proof films. Each foil coil undergoes meticulous wrapping: initial layers of desiccant-infused kraft paper are applied directly to the coil surface, followed by the primary barrier film sealed via continuous impulse heat welding at precisely controlled 185°C and 2.8 bar pressure. This process creates hermetic, leak-proof seals verified through vacuum decay testing at 0.5 mbar differential pressure before palletization.

For sea freight safety, palletized units undergo secondary containment. Pallets are unitized using galvanized steel strapping (minimum 16mm width, 1500 kg tensile strength) applied in a cross-pattern meeting ISO 16122 standards, preventing lateral shift during ocean swells. Additional desiccant units, calculated at 1.2 units per cubic meter of container volume based on IATA moisture load guidelines, are strategically placed within the container void spaces. Container stowage prioritizes below-deck positioning to eliminate UV exposure and minimize temperature excursions. Our integrated packaging system, validated through accelerated salt spray testing per ASTM B117 and real-world shipment monitoring, ensures foil arrives with surface oxide layers within tight specifications (typically < 1.5 nm thickness increase) and no detectable chloride ion contamination. This metallurgical protection is non-negotiable for maintaining the electrical performance and longevity of transformer windings. Luoyang Xinzhaohe’s packaging represents a critical component of our supply chain reliability, directly safeguarding your downstream manufacturing yield and product performance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Aluminum Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a leading industrial supplier of precision aluminum and copper transformer strip and foil products. Located in the industrial heartland of Henan Province, our vertically integrated production facility combines advanced metallurgical engineering with stringent quality control to deliver bulk aluminum foil and strip products that meet the exacting demands of power transformer, inductor, and high-frequency electronic component manufacturers.

Our factory operates a fully automated rolling and slitting line, capable of producing aluminum foil in thicknesses ranging from 0.01 mm to 0.5 mm, with widths up to 1,250 mm. This precision capability ensures consistent dimensional tolerances and surface finish, critical for dielectric performance and winding integrity in transformer applications. All raw materials are sourced from certified primary aluminum suppliers, and we maintain full traceability from ingot to finished coil. Our in-house metallurgical laboratory conducts routine spectrographic analysis, tensile testing, and eddy current inspection to ensure compliance with international standards including GB/T, ASTM, and IEC.

A key differentiator of our manufacturing process is our proprietary annealing technology, which optimizes grain structure and enhances electrical conductivity while minimizing residual stress. This results in foil with superior flexibility, thermal stability, and resistance to cracking during high-speed winding operations. For copper and aluminum transformer strip, we offer custom temper designations—ranging from soft (O-temper) to half-hard (H24)—to match specific application requirements.

We specialize in large-volume production runs tailored to OEM and Tier-1 supplier demand. Our monthly production capacity exceeds 3,000 metric tons, supported by a just-in-time logistics framework that enables reliable delivery to domestic and international markets. Whether you require 8079, 1050, 1060, or 1100 alloy foils, we provide full documentation including material test reports (MTRs), RoHS compliance certificates, and custom packaging solutions to prevent oxidation and mechanical damage during transit.

As a strategic partner, Luoyang Xinzhaohe Aluminum CO., Ltd is committed to technical collaboration, supply chain resilience, and long-term cost optimization. Our engineering team works closely with clients to refine specifications, troubleshoot processing challenges, and co-develop next-generation conductive materials.

For sourcing managers and procurement specialists seeking a dependable, high-capacity supplier of bulk aluminum foil and transformer strip, we invite direct engagement. Contact us today to discuss your technical requirements and receive a competitive quotation.

Contact us:

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum CO., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum foil bulk directly from China.