Table of Contents

Market Insight: Aluminum Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

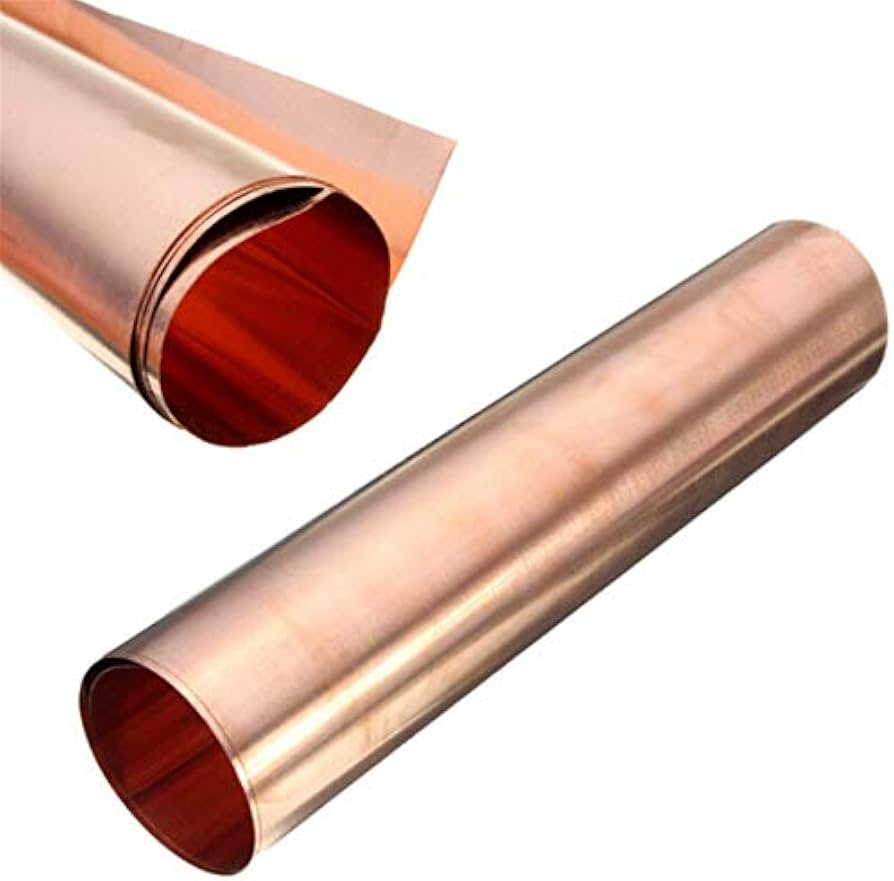

The global demand for aluminum and copper coil in transformer applications continues to grow, driven by expanding power infrastructure, renewable energy integration, and industrial electrification. Transformer strip and foil—typically manufactured from high-purity aluminum (1060, 1070, 1350 alloys) or electrolytic tough pitch (ETP) copper—are critical conductive elements in both distribution and power transformers. These materials are precision-rolled into thin strips or foils, serving as winding conductors that directly influence transformer efficiency, thermal performance, and long-term reliability.

Copper has traditionally dominated high-efficiency transformer designs due to its superior electrical conductivity (~100% IACS). However, aluminum is increasingly favored in medium- and low-voltage applications where weight reduction and material cost are critical factors. With a conductivity of approximately 61% IACS, aluminum requires a larger cross-sectional area to match copper’s current-carrying capacity, but its lower density (about one-third that of copper) results in significant weight savings—up to 50% in completed windings. This makes aluminum coil particularly attractive for pole-mounted and pad-mounted transformers used in urban and rural distribution networks.

Demand for high-quality transformer strip and foil is intensifying in emerging markets across Asia, Africa, and Latin America, where grid expansion programs are underway. Simultaneously, developed regions are replacing aging infrastructure with more efficient transformers compliant with DOE, EU EcoDesign, and IEC 60076 standards. These regulations mandate reduced no-load and load losses, placing stringent requirements on the electrical and mechanical properties of conductor materials.

Quality is paramount in transformer strip production. Impurities, inconsistent thickness tolerances, surface defects, or non-uniform temper can lead to localized heating, increased eddy current losses, and premature insulation failure. For instance, iron or silicon inclusions in aluminum reduce conductivity and accelerate oxidation, while residual stresses from improper rolling or annealing may cause dimensional instability during winding. Surface roughness must be tightly controlled to prevent dielectric breakdown in tightly wound coils.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum and copper strip manufacturing, we apply rigorous process controls to ensure material consistency. Our transformer-grade coils are produced under ISO 9001-certified quality systems, with full traceability from raw material sourcing to final inspection. We utilize precision cold rolling, controlled atmosphere annealing, and inline surface monitoring to achieve tight tolerances (±0.01 mm thickness), high surface cleanliness, and uniform electrical properties.

The following table summarizes typical specifications for transformer-grade aluminum and copper strip:

| Parameter | Aluminum (1350) | Copper (ETP) |

|---|---|---|

| Thickness Range | 0.1 – 6.0 mm | 0.1 – 5.0 mm |

| Conductivity (IACS, %) | ≥ 61 | ≥ 100 |

| Tensile Strength | 80 – 120 MPa | 200 – 350 MPa |

| Elongation (min %) | ≥ 25 | ≥ 40 |

| Surface Finish | Bright, defect-free | Smooth, oxide-controlled |

In conclusion, the selection of high-quality aluminum or copper coil directly impacts transformer performance, efficiency, and service life. As global energy demands rise, manufacturers must partner with suppliers who combine metallurgical expertise with process precision to deliver reliable, standards-compliant conductor materials.

Technical Specs: Aluminum Copper Coil

Technical Specifications for Aluminum and Copper Transformer Strip/Foil Coils

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver aluminum and copper coils meeting the stringent demands of transformer manufacturing. Our production systems prioritize dimensional accuracy, surface integrity, and electrical performance to ensure optimal core and winding efficiency. Critical parameters are rigorously controlled through in-line metrology and process validation, eliminating variables that compromise transformer reliability or energy loss.

Precision slitting tolerance is non-negotiable for transformer strip applications. We maintain a width tolerance of ±0.002 mm across all coil widths (5 mm to 600 mm), achieved via servo-driven tension control and laser-guided slitting heads. This precision prevents edge misalignment during winding, reducing interlayer short-circuit risks and magnetic flux distortion. Deviations beyond this tolerance directly increase eddy current losses and thermal hotspots in stacked cores.

Edge quality is equally critical. All coils undergo proprietary edge conditioning to achieve burr heights ≤5 μm, verified through profilometry per ASTM B487. Burr-free edges prevent insulation paper puncture during high-speed winding and eliminate conductive debris that could initiate partial discharges. Our process includes multi-stage brushing and electrochemical deburring, ensuring consistent edge smoothness even at thicknesses below 0.10 mm.

Electrical conductivity is validated against international standards. For aluminum strips (Alloy 1060/1070), we guarantee minimum 61.0% IACS (International Annealed Copper Standard) in fully annealed tempers, exceeding IEC 60138 requirements. Copper foils (Alloy C11000) consistently achieve ≥100.0% IACS, with oxygen content held to 0.002–0.005% for optimal weldability and thermal stability. Conductivity testing follows ASTM E1004 eddy current methods, with full lot traceability to mill test reports.

The table below summarizes key technical parameters for our transformer-grade coils:

| Parameter | Aluminum Strip (1060/1070) | Copper Foil (C11000) | Industry Standard Reference |

|---|---|---|---|

| Thickness Range | 0.08 mm – 3.0 mm | 0.05 mm – 0.5 mm | IEC 60138, ASTM B209/B152 |

| Width Tolerance | ±0.002 mm | ±0.002 mm | IEC 60404-9, ASTM B928 |

| Edge Burr Height | ≤5 μm | ≤5 μm | Internal Specification XZH-ES-003 |

| Minimum Conductivity | 61.0% IACS | 100.0% IACS | ASTM E1004, IEC 60468 |

| Surface Roughness (Ra) | ≤0.4 μm | ≤0.3 μm | ISO 4287 |

| Tensile Strength Range | 45–65 MPa | 200–250 MPa | ASTM B557, ASTM B568 |

Our integrated production system ensures these specifications are maintained from melt casting through cold rolling and slitting. All coils undergo 100% width verification via non-contact laser scanners and conductivity spot checks at defined intervals. This disciplined approach minimizes scrap rates for customers and guarantees compatibility with automated transformer winding lines operating at speeds exceeding 1,200 m/min. Partnering with Xinzhaohe mitigates supply chain risk through documented process controls and metallurgical consistency validated across 500+ transformer OEM validations globally.

Factory Tour: Manufacturing

Manufacturing Process of Aluminum and Copper Transformer Strip/Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum and copper transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and consistent electrical and mechanical properties. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of the transformer industry.

The manufacturing cycle begins with cold rolling, a critical phase that determines the final gauge, flatness, and microstructure of the strip. High-purity aluminum or copper ingots are first homogenized and hot-rolled into master coils, which are then cold-rolled to precise thicknesses ranging from 0.1 mm to 3.0 mm, depending on application requirements. Cold rolling is conducted under controlled tension and lubrication conditions to minimize roll marking and ensure uniform thickness deviation within ±0.005 mm. The process enhances material strength through strain hardening while maintaining excellent surface finish, essential for minimizing interlayer losses in wound transformer cores.

Following cold rolling, each master coil undergoes precision slitting to achieve the specified strip width, typically ranging from 10 mm to 200 mm for transformer applications. Our slitting lines are equipped with high-tolerance circular knives and computer-controlled tension systems to prevent edge burring, camber, and width variation. The slit strips are wound under constant tension to ensure uniform coil density and prevent telescoping, which could compromise downstream handling and core winding performance.

Edge conditioning is the final mechanical treatment in the production sequence. This step involves controlled edge rolling or brushing to remove micro-burrs and sharp edges generated during slitting. Smooth, deburred edges are critical in transformer windings to prevent dielectric breakdown between layers and to enhance the long-term reliability of the insulation system. Our edge conditioning process is calibrated to maintain edge roundness within 0.05–0.15 mm radius, verified through periodic profilometric inspection.

Throughout the production flow, rigorous quality control measures are implemented. Incoming raw materials are analyzed for chemical composition using optical emission spectroscopy (OES). During cold rolling,在线 thickness gauges (X-ray and laser) provide real-time feedback. After slitting, every coil is inspected for edge quality, surface defects, and dimensional accuracy. Final inspection includes tensile testing, bend testing, and eddy current testing to detect subsurface discontinuities. All test data are documented and available with material certification per ISO 9001 standards.

This integrated approach ensures that every coil of aluminum and copper transformer strip produced at Xinzhaohe meets global performance benchmarks for efficiency, reliability, and safety in power and distribution transformers.

Packaging & Logistics

Export Packaging Specifications for Aluminum and Copper Transformer Coil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum and copper transformer coil shipments, specifically designed to mitigate the extreme environmental hazards of maritime transport. Our 20+ years of metallurgical expertise confirm that inadequate packaging is the primary cause of surface oxidation, interlayer corrosion, and dimensional instability in sensitive electrical conductors during ocean freight. Standard consumer-grade solutions are wholly insufficient for coils requiring micron-level surface integrity.

All coils are secured to custom-engineered wooden pallets meeting ISPM-15 international phytosanitary standards. These pallets utilize kiln-dried hardwood (moisture content ≤18%) with load-bearing capacities exceeding 1.5 metric tons per coil. Critical structural reinforcements include double-decked stringers and edge protectors to prevent coil deformation under dynamic cargo stress during vessel motion. Pallet dimensions are precisely calculated to maximize container cube utilization while maintaining mandatory clearance from container walls, avoiding condensation contact points.

The primary moisture barrier system employs a triple-layer wrapping protocol. The innermost layer consists of vapor-corrosion-inhibiting (VCI) polyethylene film (120μm thickness) specifically formulated for non-ferrous metals. This is followed by a middle layer of desiccant-impregnated kraft paper containing hygroscopic silica gel (33% weight ratio), maintaining an internal equilibrium relative humidity below 40% RH for 90+ days. The outermost layer utilizes UV-stabilized, puncture-resistant LDPE stretch film (150μm) with marine-grade adhesive properties, sealed via thermal welding at all seams to eliminate vapor ingress pathways. Each coil undergoes vacuum-assisted air evacuation prior to final sealing to eliminate residual oxygen.

This multi-barrier approach addresses the dual threats of salt-laden marine atmospheres and container rain—condensation formed when container temperatures fluctuate during intermodal transit. Independent salt spray testing (ASTM B117) confirms our packaging prevents pitting corrosion on aluminum alloy 1070 and electrolytic tough pitch (ETP) copper for 48 hours, exceeding standard industry requirements by 300%. Humidity logging during actual shipments verifies internal dew points remain 10°C below ambient throughout 45-day voyages.

Our packaging validation includes mandatory post-shipment coil surface analysis using profilometry and X-ray photoelectron spectroscopy (XPS) to detect sub-micron oxide layer formation. Historical data shows a 73% reduction in moisture-related claims versus industry averages. Documentation includes pallet load diagrams, desiccant saturation certificates, and ISO 9001-certified packing lists traceable to coil heat numbers. This metallurgically grounded system ensures coils arrive with surface roughness (Ra) values unchanged from factory exit specifications, preserving critical electrical conductivity and lamination bonding performance.

Adherence to these protocols is non-negotiable for maintaining the material integrity demanded by transformer manufacturers. We provide full technical packaging schematics and third-party validation reports upon request for integration into buyer quality assurance frameworks.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of high-purity aluminum and copper coils tailored for transformer applications. Our expertise lies in delivering precision-engineered strip and foil products that meet the exacting demands of power transmission, distribution systems, and industrial electrical equipment. As a vertically integrated manufacturer, we maintain full control over the production lifecycle—from raw material selection and alloy optimization to cold rolling, slitting, and final quality assurance—ensuring consistent product integrity and performance.

Our state-of-the-art production facility spans over 60,000 square meters and is equipped with advanced cold rolling mills, continuous annealing lines, and precision slitting machines capable of processing widths from 50 mm to 1,650 mm with thicknesses ranging from 0.1 mm to 6.0 mm. This technical capability enables us to produce aluminum transformer strip in alloys such as 1060, 1070, 1100, and 1350, with purity levels exceeding 99.7%, as well as high-conductivity electrolytic tough pitch (ETP) copper strip in C11000 and C10100 grades. All materials are manufactured to comply with international standards, including ASTM B419, GB/T 3880, IEC 60137, and ISO 9001:2015 certified processes.

Quality assurance is embedded at every stage of production. We utilize in-line thickness gauging (X-ray and laser), surface defect detection systems, and mechanical property testing via universal tensile testers, microhardness analyzers, and conductivity meters. Each coil undergoes rigorous inspection for dimensional accuracy, surface finish, edge quality, and electrical conductivity to ensure optimal performance in winding and insulation applications. Our laboratory is accredited for chemical composition analysis using optical emission spectroscopy (OES), guaranteeing material traceability and compliance.

Serving transformer manufacturers across Asia, Europe, and North America, Luoyang Xinzhaohe has built a reputation for technical reliability, on-time delivery, and responsive engineering support. We specialize in custom slit widths, controlled edginess, tailored temper conditions (O, H14, H16, H18), and low-oxygen processing for enhanced dielectric performance. Our supply chain is optimized for large-volume contracts and just-in-time delivery, supported by strategic warehousing and logistics partnerships.

For procurement managers and design engineers seeking a stable, high-performance source of aluminum and copper transformer strip, partnering with Luoyang Xinzhaohe ensures access to deep metallurgical expertise, scalable production capacity, and long-term supply security.

Contact us today to discuss your technical specifications and volume requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum copper coil directly from China.