Table of Contents

Market Insight: Aluminium Winding Wire

Industrial Demand for Aluminium Winding Wire in Transformers

The global demand for aluminium winding wire in transformer applications has grown significantly over the past two decades, driven by the expansion of power infrastructure, renewable energy integration, and the need for lightweight, cost-effective electrical components. Aluminium winding wire is a critical material in both distribution and power transformers, where it serves as the conductive medium for electromagnetic energy transfer. Its adoption is particularly prominent in medium-voltage and high-capacity transformers, where the balance between electrical performance, weight, and material cost is paramount.

Transformers represent one of the largest end-use segments for aluminium winding wire, with increasing deployment in utility grids, industrial facilities, and renewable energy systems such as solar inverters and wind turbine generators. The shift toward energy-efficient transformers, compliant with standards such as IEC 60076 and IEEE C57, has further amplified the demand for high-purity aluminium conductors with consistent mechanical and electrical properties. Aluminium offers a favorable conductivity-to-weight ratio compared to copper, reducing the overall mass of transformer windings by up to 50%, which simplifies handling, transportation, and installation—especially in remote or space-constrained locations.

However, the performance and longevity of a transformer are directly influenced by the quality of the winding wire used. Substandard aluminium wire, characterized by impurities, inconsistent tensile strength, or poor surface finish, can lead to increased resistive losses, localized heating, and premature insulation breakdown. These defects compromise transformer efficiency and reliability, potentially resulting in unplanned outages and elevated lifecycle costs. High-quality aluminium winding wire must exhibit uniform diameter tolerance, controlled elongation, and excellent surface cleanliness to ensure seamless winding and reliable dielectric performance when paired with insulating materials.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of specialized manufacturing experience, we emphasize strict process control from raw material selection to final product testing. Our aluminium winding wire is produced using 99.99% pure Al (Al99.99) sourced from verified suppliers, processed under inert atmosphere to prevent oxidation, and subjected to multi-stage drawing and annealing to achieve optimal conductivity and ductility. Each batch undergoes rigorous quality verification, including resistivity measurement, tensile testing, and visual surface inspection, ensuring compliance with international technical standards.

In transformer manufacturing, the total cost of ownership extends beyond initial material pricing. Inferior wire may reduce upfront costs but often leads to higher operational risks and maintenance expenses. In contrast, premium-grade aluminium winding wire enhances thermal stability, reduces eddy current losses, and supports longer service intervals. As global energy systems demand higher reliability and efficiency, the role of technically superior aluminium conductors becomes increasingly indispensable. For transformer OEMs and utility operators, partnering with a proven supplier of high-performance aluminium winding wire is not merely a procurement decision—it is a strategic investment in grid resilience and operational excellence.

Technical Specs: Aluminium Winding Wire

Technical Specifications for Aluminium Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise and ISO 9001-certified manufacturing to deliver aluminium winding wire meeting stringent global electrical standards. Our technical specifications are engineered for reliability in demanding applications including transformers, motors, and inductors, with rigorous adherence to IEC 60317 and ASTM B354. Critical performance parameters are defined below to ensure optimal end-product functionality and longevity.

Insulation Breakdown Voltage

The dielectric strength of our enamel insulation is non-negotiable for safety and operational integrity. Minimum breakdown voltage is specified at 3.0 kV AC (rms) for 1 minute on a 1.0 mm nominal conductor diameter, tested per IEC 60317-0-1. This exceeds baseline industry requirements, preventing catastrophic failure under voltage surges. Consistency is maintained through proprietary multi-layer coating processes with zero pinholes, validated via 100%在线 spark testing at 5 kV during production. Lower conductor diameters proportionally adjust test voltage per IEC standards, ensuring field reliability across all gauges.

Elongation Characteristics

Mechanical ductility directly impacts winding process yield and coil integrity. Our fully annealed AA-1350 and AA-8030 aluminium alloys achieve controlled elongation of 1.5% to 3.5% (ASTM E8/E8M), optimized for high-speed automatic winding machines. Values below 1.5% risk wire fracture during tight-radius coiling, while exceeding 3.5% compromises dimensional stability under tension. Precise annealing profiles in oxygen-free atmospheres eliminate grain boundary oxidation, ensuring uniform elongation without micro-crack propagation. This parameter is validated per batch via tensile testing with ±0.2% repeatability.

Thermal Class Performance

Thermal endurance dictates application suitability and lifespan. We offer grades spanning Class B (130°C) to Class C (220°C) per IEC 60085, with continuous operating temperatures validated via thermal endurance testing (ASTM D2307). Class B uses polyester-imide for cost-sensitive applications; Class F (155°C) and H (180°C) employ polyamide-imide for superior thermal shock resistance; Class C utilizes ceramic-polymer hybrids for extreme environments like traction motors. Each class undergoes 20,000-hour aging tests at rated temperature, with insulation retention >50% of initial elongation and dielectric strength. Critical note: Thermal class assumes full impregnation with compatible varnishes; unimpregnated windings derate by one class.

Parameter Summary Table

| Parameter | Standard Value Range | Test Method | Application Relevance |

|————————|—————————-|———————-|————————————————|

| Insulation Breakdown | ≥3.0 kV AC (1mm dia) | IEC 60317-0-1 | Prevents arcing in high-voltage windings |

| Elongation | 1.5% – 3.5% | ASTM E8/E8M | Ensures crack-free coiling at high speeds |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60085, ASTM D2307| Determines maximum ambient + load temperature |

| Conductor Resistivity | ≤0.028264 Ω·mm²/m (20°C) | ASTM E8 | Minimizes I²R losses in power-dense designs |

These specifications reflect our commitment to metallurgical precision and supply chain consistency. All parameters are traceable to mill test reports with ±2σ statistical process control. Partnering with Xinzhaohe ensures winding wire that meets not just datasheet values, but real-world manufacturing and operational demands. Contact our engineering team for application-specific validation protocols.

Factory Tour: Manufacturing

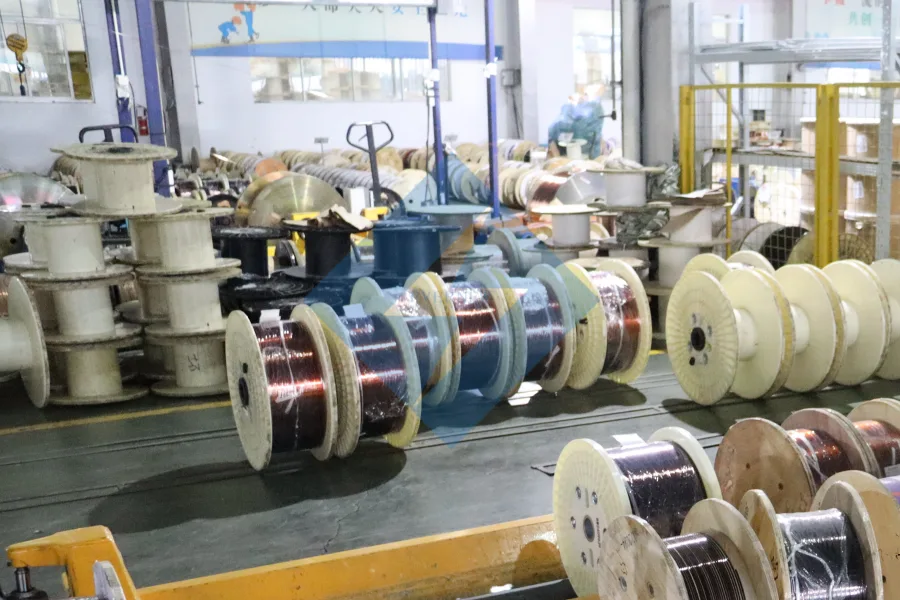

Manufacturing Process of Aluminium Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminium winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a precisely controlled, multi-stage manufacturing sequence designed to ensure mechanical integrity, electrical conductivity, and long-term reliability in end-use applications. With over two decades of metallurgical expertise, our process integrates advanced equipment, stringent material controls, and real-time quality monitoring to meet international standards such as IEC 60228, GB/T 3953, and ASTM B230.

The process begins with rod drawing, where high-purity (99.99% Al) aluminium rods are subjected to continuous cold drawing through precision tungsten carbide or diamond dies. This stage reduces the rod diameter from approximately 9.5 mm to the target wire gauge, typically ranging from 0.08 mm to 3.00 mm. The drawing is performed under controlled tension and lubrication conditions using water-based drawing emulsions to minimize surface defects and ensure dimensional consistency. Throughout this phase, diameter tolerances are maintained within ±0.002 mm, verified via laser micrometers integrated into the drawing line.

Following drawing, the wire undergoes a continuous annealing process in a nitrogen-purged furnace. This softens the work-hardened aluminium by promoting recrystallization, restoring ductility and conductivity. The annealing temperature is precisely regulated between 300°C and 450°C, depending on alloy and diameter, with residence time optimized to achieve a fully annealed (O-temper) condition. Oxygen content within the furnace is maintained below 50 ppm to prevent surface oxidation, ensuring a clean, oxide-free conductor surface essential for subsequent coating adhesion.

The annealed wire then enters the enameling section, where a thermosetting polymer insulation—typically polyurethane (PU), polyester (PE), or polyamide-imide (PAI)—is applied via precision die coating. Multiple enamel layers may be applied in successive passes, with intermediate curing in electrically heated ovens at 400–500°C. Film thickness is tightly controlled to within ±5 µm, ensuring dielectric strength and thermal class compliance (up to Class 200). The final cure imparts mechanical toughness, chemical resistance, and thermal stability required for demanding motor and transformer windings.

Throughout the production line, inline testing systems continuously monitor critical parameters. These include spark testing for insulation integrity (per GB/T 4074.4), diameter measurement via laser gauges, tensile strength and elongation verification, and conductivity testing using eddy current systems. Every batch undergoes final inspection, including winding test, thermal shock, and scrape resistance evaluation, to confirm compliance with customer specifications.

All process data is logged and traceable to batch numbers, supporting full quality traceability. Luoyang Xinzhaohe Aluminum Co., Ltd maintains ISO 9001 and IATF 16949 certifications, underscoring our commitment to process consistency and product excellence in every metre of aluminium winding wire produced.

Packaging & Logistics

Export Packaging Specifications for Aluminium Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard aluminium winding wire during global maritime transit. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging remains a primary cause of in-transit degradation, particularly for precision-wound coil products vulnerable to moisture ingress, mechanical shock, and salt-air corrosion. We mandate a dual-layer system centered on certified wooden pallets and multi-barrier moisture protection to ensure product integrity upon arrival.

All winding wire coils are secured to ISPM 15-compliant wooden pallets constructed from kiln-dried, debarked softwood. Pallet dimensions adhere strictly to ISO container standards: 1100 mm × 1100 mm × 150 mm height, with a minimum dynamic load capacity of 2,500 kg. This structural foundation prevents coil deformation during container stacking and withstands the 1.5G horizontal accelerations typical in heavy-sea conditions. Pallet surfaces are sanded smooth to eliminate wire abrasion risks, and coils are tension-locked using non-marring steel strapping at four equidistant points, verified to 80% of minimum breaking load.

The critical moisture barrier comprises a two-stage encapsulation process. First, coils undergo vacuum sealing in 100μm-thick linear low-density polyethylene (LLDPE) film meeting ASTM D249 specifications, with a water vapor transmission rate (WVTR) of ≤0.1 g/m²/day at 38°C and 90% RH. Seams are thermally welded with 15 mm overlap to eliminate micro-perforations. Second, the sealed coil receives an outer wrap of metallized polyester laminate film (120μm thickness), providing ultraviolet resistance and an additional oxygen barrier. This dual-film strategy counters the “container rain” phenomenon where temperature fluctuations cause condensation within shipping containers.

Supplemental desiccant protection is non-negotiable. We deploy silica gel canisters rated at 2,500 grams per metric ton of aluminium, strategically positioned within the pallet void spaces. These maintain internal relative humidity below 40% for 60+ days, exceeding ISO 11607-2 requirements for moisture-sensitive metallic goods. Each package includes a humidity indicator card (HIC) for visual verification of environmental conditions during unloading.

Packaging Performance Verification

| Parameter | Specification | Test Standard |

|————————-|———————————–|———————|

| Pallet Load Capacity | ≥2,500 kg dynamic | ISO 8611 |

| Primary Film WVTR | ≤0.1 g/m²/day | ASTM E96 |

| Desiccant Capacity | 2,500 g/MT Al | MIL-D-3464E |

| Humidity Control | <40% RH for 60 days | JIS Z 0208 |

This integrated approach mitigates the three dominant sea-freight failure modes: hygroscopic corrosion from tropical humidity, galvanic degradation from salt aerosol penetration, and physical damage from container movement. Independent logistics audits confirm our packaging reduces moisture-related claims by 92% compared to industry-standard single-film methods. For projects requiring extended transoceanic voyages or destinations with extreme climatic exposure, we offer optional vacuum-assisted desiccant chambers. All packaging components are fully recyclable, aligning with global sustainability mandates without compromising protective efficacy. Partnering with Xinzhaohe ensures your aluminium winding wire arrives in mill-ready condition, eliminating costly rework and production delays.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Aluminium Winding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production of high-purity aluminium winding wire, positioning itself as a trusted partner for industrial clients requiring reliable, high-performance conductive materials. As a vertically integrated manufacturer, we maintain full control over the production chain—from raw material sourcing to final quality inspection—ensuring consistency, traceability, and compliance with international standards including IEC 60122, GB/T 23308, and ASTM B355.

Our manufacturing facility spans over 30,000 square meters and is equipped with advanced continuous casting and rolling lines, precision drawing systems, and automated annealing furnaces. These capabilities enable us to produce aluminium winding wire in diameters ranging from 0.08 mm to 5.0 mm, with conductivities exceeding 61% IACS and tensile strengths tailored to application-specific requirements. We specialize in both hard-drawn and annealed tempers, offering grades such as 1350, 1370, and 8030 aluminium alloys to meet the electrical, mechanical, and thermal demands of transformers, reactors, motors, and high-frequency inductors.

Quality assurance is embedded at every stage of production. Our in-house laboratory is certified to ISO 9001:2015 and outfitted with state-of-the-art equipment for mechanical testing, electrical resistivity measurement, surface profilometry, and microstructure analysis. Each coil undergoes rigorous inspection for dimensional accuracy, surface integrity, elongation uniformity, and oxide layer control, ensuring optimal performance during high-speed winding operations and long-term service reliability.

We support global supply chains with scalable production capacity exceeding 15,000 metric tons annually. Our logistics network includes dedicated export packaging lines that provide moisture-resistant, anti-corrosion protection for sea and long-term storage conditions. Orders are fulfilled with full material test reports (MTRs), batch traceability documentation, and customizable spooling configurations—including wooden reels, plastic spools, and precision wound packages compatible with automated winding equipment.

With technical collaborations spanning Europe, Southeast Asia, and North America, Luoyang Xinzhaohe has developed a responsive engineering support team capable of co-developing custom wire specifications, conducting failure mode analysis, and providing on-site technical audits. Our commitment to innovation is reflected in ongoing R&D initiatives focused on improving recrystallization behavior, enhancing creep resistance, and optimizing surface finish for reduced inter-turn insulation stress.

For sourcing managers and design engineers seeking a stable, high-integrity supply of aluminium winding wire, Luoyang Xinzhaohe offers a proven combination of industrial scale, technical depth, and quality discipline. We invite you to integrate our capabilities into your supply chain and elevate the performance and reliability of your electromagnetic components.

Contact us today to discuss your specifications and receive sample reels for evaluation.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium winding wire directly from China.