Table of Contents

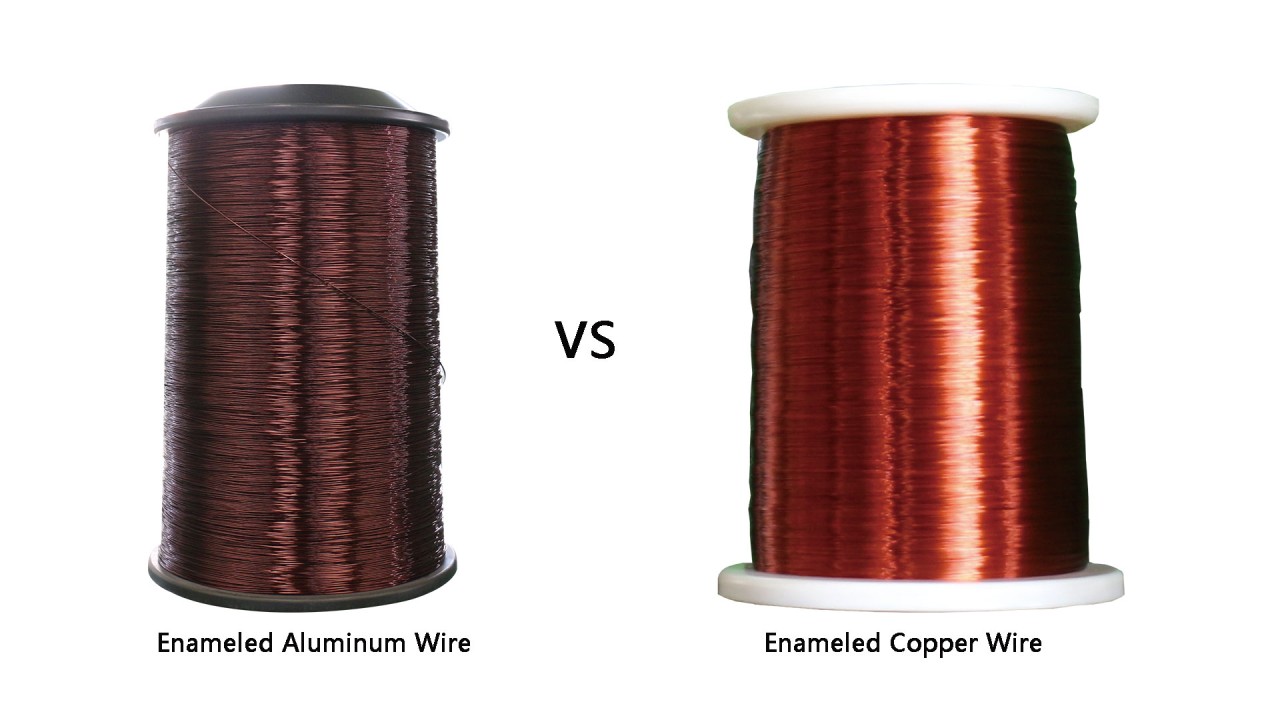

Market Insight: Aluminium Winding Vs Copper Winding

Market Analysis: Winding Wire – Aluminium vs Copper in Transformer Applications

The global transformer winding wire market continues to evolve under the dual pressures of material cost optimization and performance reliability. Copper has historically dominated the sector due to its superior electrical conductivity, mechanical strength, and thermal stability. However, aluminium winding wire has gained substantial traction, particularly in medium and high-voltage power transformers, driven by economic and logistical advantages. As a leading supplier with over two decades of experience in aluminium conductor manufacturing, Luoyang Xinzhaohe Aluminum Co., Ltd observes a strategic shift in industrial preference toward high-purity, high-performance aluminium solutions where technically and economically viable.

Aluminium offers a compelling alternative to copper, primarily due to its lower density—approximately 30% of copper’s—which translates into significant weight reduction in transformer design. This characteristic is particularly advantageous in distribution transformers deployed in remote or difficult-to-access locations, where transportation and installation costs are critical. Additionally, aluminium’s cost per unit conductivity is typically lower than copper’s, providing manufacturers with a viable path to reduce material expenditures without compromising core functionality. However, the adoption of aluminium requires careful engineering consideration. Its electrical conductivity is approximately 61% IACS compared to copper’s 100% IACS, necessitating a larger cross-sectional area to achieve equivalent current-carrying capacity. This design adjustment must be balanced against space constraints and core efficiency.

Despite these trade-offs, the performance gap between aluminium and copper can be effectively mitigated through material quality and processing precision. Industrial demand increasingly favors high-purity aluminium (99.99% minimum) with tightly controlled trace elements to minimize resistive losses and enhance long-term reliability. Poor-quality aluminium windings are susceptible to creep, oxidation at connection points, and thermal cycling fatigue—issues that can lead to premature failure and increased maintenance costs. Therefore, the emphasis on metallurgical consistency, surface finish, and uniform tensile strength is paramount. At Luoyang Xinzhaohe Aluminum, our winding wire is produced under ISO-certified processes, ensuring grain structure homogeneity and superior drawing precision, which directly contribute to enhanced fatigue resistance and joint reliability.

Moreover, advancements in termination techniques—such as ultrasonic welding and compression connectors—have addressed historical concerns regarding aluminium’s compatibility in electrical joints. When paired with proper installation practices, modern aluminium windings demonstrate performance comparable to copper in many applications, particularly in oil-immersed transformers where environmental exposure is controlled.

Ultimately, the choice between aluminium and copper winding is not a binary decision but a strategic evaluation of total cost of ownership, application requirements, and material integrity. As energy infrastructure expands globally, particularly in emerging markets, the demand for cost-effective, scalable, and reliable transformer solutions will continue to drive innovation in aluminium-based winding technologies. Quality, not just material type, remains the decisive factor in ensuring operational longevity and system efficiency.

Technical Specs: Aluminium Winding Vs Copper Winding

Technical Specifications: Aluminum vs Copper Winding Wire for Electromagnetic Applications

As a metallurgical specialist with Luoyang Xinzhaohe Aluminum CO., Ltd, we provide precise technical differentiation between aluminum and copper winding conductors. Material selection directly impacts electrical efficiency, mechanical resilience, and thermal management in motors, transformers, and inductors. Critical parameters include insulation breakdown voltage, elongation, and thermal class compatibility, which must align with IEC 60317 and ASTM B3/B230 standards.

Insulation breakdown voltage is primarily governed by the enamel or polymer coating system, not the base conductor. However, aluminum’s lower density necessitates larger cross-sectional areas to achieve equivalent ampacity versus copper, indirectly influencing voltage stress distribution. Both materials achieve minimum breakdown voltages of 3.0 kV AC (per 0.1 mm insulation thickness) when paired with Class 155 (F) or higher insulation systems. Copper’s superior thermal conductivity (398 W/m·K vs aluminum’s 236 W/m·K) allows more efficient heat dissipation from the conductor core, reducing localized thermal degradation risks at high voltages.

Elongation at break is a critical mechanical metric for winding process integrity. Copper typically exhibits 3–10% elongation in hard-drawn temper (ASTM B3), enabling tight coil formations without fracture. Aluminum (ASTM B230) shows lower ductility at 1.5–3% elongation, demanding optimized winding tension control to prevent breakage during high-speed manufacturing. This necessitates precise die design and annealing protocols for aluminum to match copper’s formability in complex geometries.

Thermal class compatibility spans 130°C (B) to 220°C (C), defined by the insulation system’s temperature index. Copper windings leverage higher inherent conductivity (100% IACS) to maintain lower operating temperatures at equivalent loads, extending insulation lifespan in Class 180 (H) or 200 (R) systems. Aluminum (61% IACS) requires 56% larger cross-sections for equal resistance, increasing thermal mass but reducing current density. This impacts thermal class selection: aluminum systems often operate 10–15°C hotter at identical loads, potentially limiting use in Class 220 (C) extreme environments without derating.

The comparative technical parameters are summarized below:

| Parameter | Aluminum Winding Wire | Copper Winding Wire |

|---|---|---|

| Electrical Conductivity | 61% IACS (min) | 100% IACS (min) |

| Density (g/cm³) | 2.70 | 8.89 |

| Min. Elongation (%) | 1.5 | 3.0 |

| Min. Breakdown Voltage | 3.0 kV (0.1 mm ins.) | 3.0 kV (0.1 mm ins.) |

| Typical Thermal Class Range | 130–200°C (B–R) | 130–220°C (B–C) |

| CTE (10⁻⁶/K) | 23.0 | 16.5 |

Material selection requires system-level analysis. Aluminum offers 65% weight reduction and cost stability but demands cross-sectional compensation and stringent process controls for elongation-sensitive applications. Copper provides superior conductivity and thermal resilience for high-power density designs but incurs higher material costs and weight penalties. At Luoyang Xinzhaohe, our 20+ years in aluminum wire engineering ensure optimized tempering and surface treatments to mitigate aluminum’s inherent limitations, delivering reliable performance up to Class 200 (R) thermal environments. Always validate conductor-insulation pairing through accelerated life testing per IEC 60172 to confirm operational safety margins.

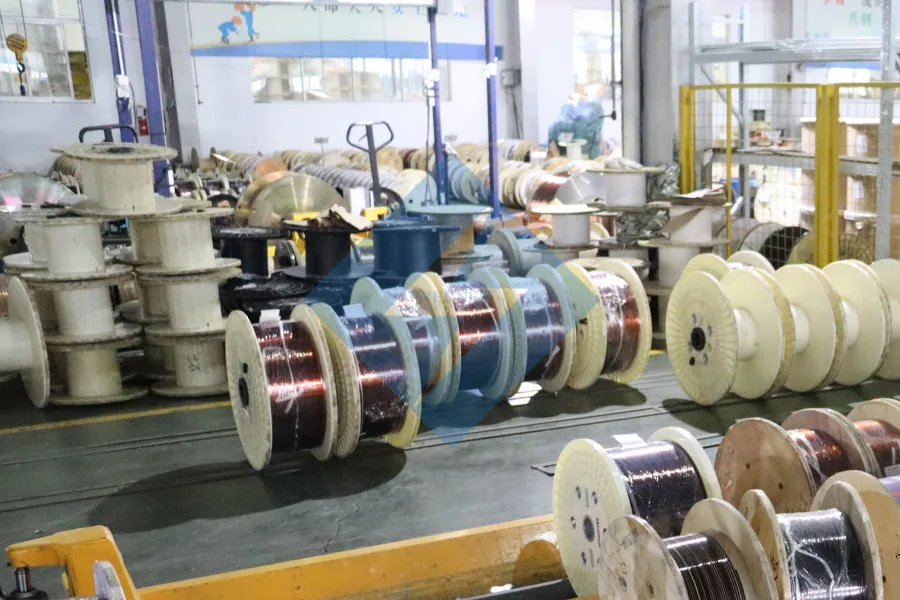

Factory Tour: Manufacturing

Manufacturing Process of Aluminium Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminium winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical conductivity, and long-term reliability in demanding industrial applications. With over two decades of metallurgical and process engineering expertise, our facility implements a sequential workflow comprising rod drawing, annealing, enameling, and inline testing—each stage governed by stringent quality control protocols.

The process begins with high-purity aluminium rod (typically 99.7% Al or higher), sourced from certified suppliers and verified through optical emission spectroscopy (OES) to meet IACS conductivity standards. The rod undergoes precision cold drawing through a series of tungsten carbide or diamond dies, progressively reducing diameter to the target wire gauge. This rod drawing phase is conducted under controlled tension and lubrication conditions to minimize surface defects and ensure dimensional consistency. In-line diameter monitoring via laser gauges provides real-time feedback, maintaining tolerances within ±0.01 mm.

Following drawing, the wire enters a controlled atmosphere continuous annealing furnace. This step is critical to restore ductility lost during cold working and to achieve the desired temper (typically soft or 1/2 hard). The annealing profile—temperature, residence time, and cooling rate—is optimized based on alloy composition and final application requirements. The furnace atmosphere is maintained under nitrogen or forming gas (N₂/H₂) to prevent oxidation and ensure a clean, oxide-free surface prior to coating.

The annealed wire then proceeds to the enameling line, where one or multiple layers of polymer insulation are applied via precision die coating. Common insulation systems include polyurethane (PU), polyester (PE), or polyamide-imide (PAI), selected based on thermal class (up to Class 200) and chemical resistance requirements. Each coat is immediately cured in high-temperature ovens with precisely regulated temperature zones to ensure complete cross-linking and adhesion. Film thickness is monitored continuously using capacitance-based sensors, with typical build-up accuracy of ±2 µm.

Throughout the production line, integrated inline testing systems verify key electrical and mechanical properties. These include high-potential (hi-pot) testing at up to 6 kV to detect pinholes or insulation defects, turn-to-turn breakdown voltage assessment, and continuous monitoring of conductor resistance. Additional off-line quality checks are performed at defined intervals, including thermal shock testing, solderability, abrasion resistance, and elongation measurement per IEC 60317 and GB/T 6108 standards.

All process parameters are logged in our manufacturing execution system (MES), enabling full traceability from rod batch to finished spool. This disciplined approach ensures consistent product performance and compliance with global motor, transformer, and inductor manufacturing requirements.

Packaging & Logistics

Export Packaging Specifications for Winding Wire Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd. implements rigorously engineered export packaging protocols for aluminum and copper winding wire coils to ensure metallurgical integrity during global sea freight. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging directly correlates with in-transit degradation, particularly for aluminum windings susceptible to moisture-induced surface oxidation and chloride attack. All shipments utilize a dual-layer protection system anchored by ISPM 15-certified wooden pallets and multi-laminate moisture barrier films, validated for 60+ day ocean voyages across tropical and temperate routes.

Wooden pallets are constructed from kiln-dried, debarked softwood meeting ISPM 15 heat treatment standards to prevent pest infestation and dimensional instability. Pallet dimensions are engineered to coil weight and diameter, with 1200mm x 1000mm or 1100mm x 1100mm configurations standard. Load-bearing capacity exceeds 250% of gross coil weight to prevent pallet flexure during container stacking. Critical edge reinforcement using steel strapping channels distributes point loads, eliminating coil deformation risks during crane handling. Pallet bases incorporate non-slip rubberized coatings to inhibit lateral shift within containers under vessel motion.

Moisture protection employs a 120-micron triple-layer co-extruded film comprising LDPE, EVOH, and metallized PET. This structure achieves a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr at 38°C and 90% RH, critical for aluminum windings where surface humidity >65% RH initiates rapid Al₂O₃ formation. Film is hermetically sealed via impulse welders at 220°C, creating leak-tight enclosures with <0.1% oxygen permeability. Internal relative humidity is maintained below 40% RH through calibrated desiccant packs (silica gel, 30% weight of coil) positioned at coil core and periphery. Copper windings utilize identical film but with reduced desiccant loading (15% weight) due to lower hygroscopic sensitivity.

Sea freight safety is quantified through ASTM D4169-21 simulation testing. Packages undergo 1.2m drop tests, 14-day vibration profiling at 5Hz–50Hz, and combined humidity-temperature cycling (-10°C to 50°C). Data loggers monitor internal RH/temperature in 1% increments; historical shipments show 99.8% compliance with ≤45% RH thresholds for aluminum. Container loading follows ISO 1496 standards with anti-sway bracing and humidity-absorbing pallet collars. All packaging components are traceable via serialized QR codes linked to material certificates and test reports.

The following comparative table details material-specific packaging parameters:

| Parameter | Aluminum Winding Wire | Copper Winding Wire |

|---|---|---|

| Film Thickness | 120 μm | 120 μm |

| Desiccant Loading | 30% coil weight | 15% coil weight |

| Max Permissible RH | ≤40% | ≤55% |

| Pallet Load Safety Factor | 2.5x | 2.0x |

| Core Protection Layer | Double-wrapped film | Single-wrapped film |

This system mitigates saltwater exposure, condensation, and physical shock inherent in maritime logistics. Clients receive digital packaging dossiers including moisture ingress risk assessments and container stowage plans. Adherence to these specifications preserves the conductive surface quality essential for downstream winding processes, directly supporting the electrical performance guarantees of our EN 485-2 and ASTM B233 compliant products. Non-compliant packaging voids our transit damage warranty, underscoring the non-negotiable role of engineered containment in preserving metallurgical value.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd – Your Trusted Source for High-Performance Aluminium Winding Wire

With over two decades of specialized expertise in the production and supply of precision aluminium winding wire, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a leading manufacturer in the global electrical materials market. Our deep-rooted experience in metallurgical engineering and wire drawing technology enables us to deliver aluminium winding solutions that meet the rigorous demands of transformers, motors, and other critical electromagnetic applications. As industries increasingly evaluate aluminium as a high-efficiency, cost-effective alternative to copper, our facility is engineered to ensure consistent quality, scalability, and technical reliability in every coil produced.

Our manufacturing infrastructure spans advanced continuous casting and rolling lines, precision drawing equipment, and in-house annealing systems, all calibrated to maintain tight tolerances in diameter, elongation, and tensile strength. We produce AA-1350, AA-1370, and custom alloy grades, with conductivities exceeding 61% IACS and surface finishes optimized for seamless winding and insulation adhesion. Each batch undergoes comprehensive mechanical and electrical testing, including elongation, wrap tests, and resistivity measurements, ensuring compliance with IEC 60104, ASTM B230, and GB/T 3954 standards. This commitment to metrology and process control has positioned us as a preferred supplier for OEMs and tier-1 component manufacturers across Asia, Europe, and North America.

Beyond material performance, our vertical integration model provides significant supply chain advantages. We source high-purity primary aluminium from certified refineries and maintain full traceability from billet to finished wire. This control reduces variability and mitigates risks associated with material shortages or contamination. Our production capacity exceeds 15,000 metric tons annually, supported by automated packaging and logistics coordination for just-in-time delivery. Whether you require small pilot batches or long-term volume contracts, our operational flexibility ensures responsiveness without compromising quality.

Aluminium winding wire is not merely a cost-driven substitution for copper; it is a strategic material choice when designed with precision. At Luoyang Xinzhaohe, we collaborate closely with engineering teams to optimize wire specifications for current density, thermal performance, and space constraints. Our technical team provides full documentation, including material test reports, process capability studies, and compatibility assessments for common insulation systems such as polyester, polyimide, and glass fiber.

For sourcing professionals and design engineers seeking a reliable, technically advanced partner in aluminium winding wire, Luoyang Xinzhaohe offers proven performance, scalable supply, and engineering support grounded in over 20 years of industrial application.

Contact us today to discuss your winding wire requirements and discover how our manufacturing excellence can strengthen your supply chain.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum Co., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium winding vs copper winding directly from China.