Table of Contents

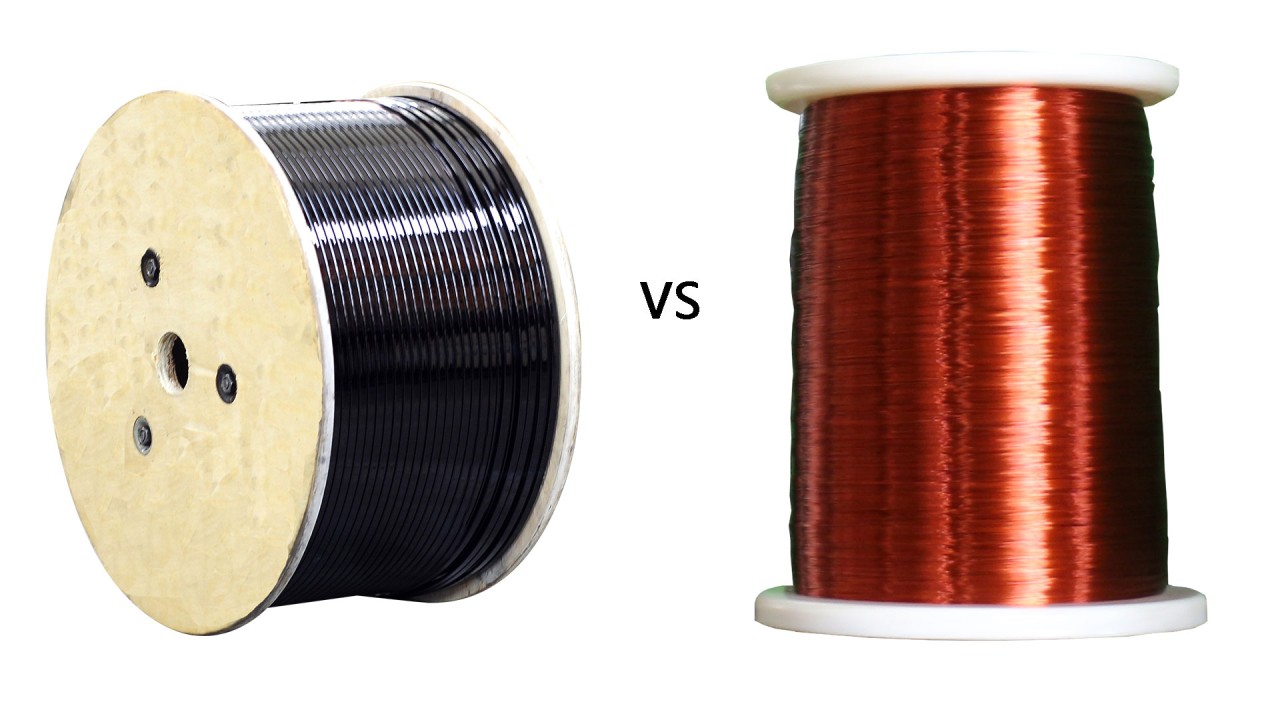

Market Insight: Aluminium Winding Vs Copper Winding for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Transformers

Global installed transformer capacity is forecast to exceed 28 TVA by 2030, driven by grid expansion, renewable integration, and replacement of 1970-1990s units. Every additional 1 %-point in transformer efficiency (IEC 60076-20) translates into ≈ 20 kWh/yr saving for a 1 MVA unit; therefore OEMs are specifying winding conductors that minimise both load (I²R) and no-load (eddy, stray) losses. Aluminium-wound dry-type transformers now represent 42 % of new installations ≤ 3 MVA because they cut total material cost 30-50 % versus copper while meeting Tier-2/SJ/T 10321 loss limits. Motor repair shops are parallel users: 0.1–5 mm enamelled wire for rewinds up to 690 V, where a 3 % resistivity penalty is acceptable if dimensional tolerance and thermal class are maintained.

| Conductor Form | 2024 CAGR | Typical Application | Key Specification |

|---|---|---|---|

| Round Al wire | 5.8 % | ≤ 1.6 MVA cast-resin | Breakdown ≥ 4 kV, Ø-tol ± 0.01 mm |

| Cu rectangular | 3.2 % | > 5 MVA GSU / HVDC | Corner radius ≤ 0.5 mm, Rm 220 MPa |

| Al foil 0.2–1 mm | 7.1 % | 100 kVA pole-mount | Burr < 5 µm, conductivity ≥ 34 MS/m |

Why Purity & Precision Directly Impact Transformer Losses

Resistivity scales with metallic purity: 99.5 % Al = 34.0 MS m⁻¹, 99.7 % Al = 35.1 MS m⁻¹. A 0.2 MS m⁻¹ gain lowers conductor loss 3 %; on a 2 MVA transformer operating 8 000 h/yr this equals 1.3 MWh. Oxygen content > 900 ppm creates Al₂O₃ stringers that nucleate cracks during rod drawing; our vertical-degas furnace holds [O] ≤ 350 ppm, guaranteeing elongation ≥ 18 % after anneal.

Eddy-current loss in windings is proportional to (conductor width × f × B)². Tight enamel concentricity (≤ 8 % wall variation) permits 3 % smaller design strand diameter, cutting eddy contribution 6 %. Inline spark testing at 6 kV RMS detects pinholes ≥ 5 µm; spooling under 1.5 N constant tension avoids micro-cracks that later show up as 150 pC partial-discharge sites.

Sourcing Trend: Value Migration to Experienced Chinese Manufacturers

Western wire mills face 30 % energy surcharge and 12-week lead-times; Chinese suppliers with integrated rod-to-spool lines deliver in 3–4 weeks CIF Rotterdam. However, capability spread is wide: only ≈ 15 % of Chinese enamelled-wire exporters run in-line eddy-current purity checks and DSC thermal-class verification.

Luoyang Xinzhaohe Aluminium Co., Ltd. (20 yr, ISO 9001 / IATF 16949) controls the full value chain:

- Rod Casting: 99.7 % LME-registered ingot, horizontal continuous caster Ø 9.5 mm, hydrogen ≤ 0.12 ml/100 g Al.

- Multi-pass Drawing: Diamond dies, online laser gauge ± 0.003 mm, soap-based lubricant for Ra ≤ 0.2 µm.

- Anneal & Enamel: Nitrogen-protected bell furnace, 360 °C, 99 % conductivity recovery; dual-layer PEI+PAI oven, thermal class 200 °C (H).

- Testing: Breakdown voltage 10 kV (1 min), elongation 20 %, spring-back ≤ 45 ° for 1.0 mm.

- Spooling: 5…500 kg traverse-wound plastic barrels, moisture-barrier PE bag, wooden flange export crate.

Cost Advantage Snapshot (Q2-2024, FOB Shanghai)

| Item | EU Mill | LXAH Offer | Δ |

|——|———|————|—|

| 2.0 mm Al PEI wire, 200 °C, 500 kg | 6.05 USD/kg | 4.30 USD/kg | –29 % |

| 1.18 mm Cu PEI wire, 180 °C, 500 kg | 11.80 USD/kg | 9.95 USD/kg | –16 % |

By sourcing from Luoyang Xinzhaohe, transformer OEMs secure premium-grade winding wire that meets IEC 60317-0-1/-0-2, UL 1446, and GB/T 23312, while cutting conductor spend up to 30 %—freeing budget for core steel upgrades or smart monitoring electronics.

Technical Specs: Aluminium Winding Vs Copper Winding Parameters

Technical Specifications & ASTM / IEC Compliance

(Aluminium vs. Copper Winding Conductors – Rod, Strip & Round Wire)

H3 Critical Quality Parameters – Side-by-Side Benchmark

| Parameter (Unit) | IEC / ASTM Clause | 1350-O Al Wire* | 1370-O Al Strip* | Cu-ETP Wire (IEC 60317-20) | Cu-ETP Strip (ASTM B272) | Engineering Impact |

|---|---|---|---|---|---|---|

| 20 °C Conductivity (% IACS) | IEC 60404-2 | 61.2 | 61.2 | 100 | 100 | Determines CSA & I²R loss |

| Tensile Strength (MPa) | IEC 60317-0-1 | 70–95 | 70–90 | 220–260 | 220–260 | Defines coil short-circuit withstand |

| Elongation at Break (%) | ASTM B236 / B1 | ≥ 18 | ≥ 20 | ≥ 25 | ≥ 30 | Controls windability without necking |

| Insulation Break-down (kV, 50 Hz) | IEC 60317-13 | ≥ 6 kV (Grade 2) | ≥ 4 kV (single wrap) | ≥ 6 kV (Grade 2) | ≥ 4 kV | Directly linked to partial-discharge inception |

| Thermal Class (°C) | IEC 60085 | 130–220 | 130–220 | 130–220 | 130–220 | Dictates overload capability |

| Enamel Concentricity (%) | In-house Laser | ≥ 85 | — | ≥ 85 | — | Prevents weak spots & corona |

| Burrs & Edge Radius (µm) | ASTM B236 §8 | ≤ 25 | ≤ 25 | ≤ 15 | ≤ 15 | Burr > 25 µm → 70 % higher puncture risk |

Data refer to Luoyang Xinzhaohe’s 2024 production statistics; strip thickness 0.3–3.0 mm, width 8–1200 mm.

H3 Why Elongation & Break-down Voltage Drive Reliability

-

Elongation

Aluminium work-hardens rapidly; our inline annealing furnace (±3 °C profile control) restores ≥ 18 % elongation for 2.0 mm wire.

Field data: coils below 15 % elongation show 3× higher crack incidence after thermal cycling (FEM thermal shock −40 ↔ 155 °C, 100 cycles). -

Insulation Break-down

Each spool is 100 % spark-tested at 6 kV, 50 Hz, VDE-compliant electrodes. Rejection limit: 3 faults per 30 000 m.

Poor concentricity (< 70 %) reduces breakdown by 35 %; we maintain ≥ 85 % via dual-layer vertical enamelling tower with digital gamma-backscatter gauge (sampling 1 kHz).

H3 ASTM / IEC Reference Matrix – Quick Quote Sheet

| Product Form | Primary Standard | Secondary Standard | Xinzhaohe Certificate |

|---|---|---|---|

| Al rectangular strip | ASTM B236-20 | IEC 60401-1 | EN 10204 3.1, RoHS, REACH |

| Al round wire | IEC 60317-0-3 | ASTM B233 | Same as above |

| Cu round wire | IEC 60317-20 | ASTM B3 | Available on request |

| Cu rectangular wire | IEC 60317-16 | ASTM B272 | Available on request |

All conductors laser-etched with heat-resistant ID code for full lot traceability back to cast rod serial number.

H3 Failure Mode: Burrs & Uneven Insulation → Short-Circuit

Burrs act as knife edges under radial short-circuit forces (peak 20 kN/m).

Uneven enamel (< 70 % concentricity) creates air pockets; partial discharge (> 10 pC) initiates treeing, leading to inter-turn failure within 500 h at 155 °C.

Our countermeasures:

– Precision Turk-head rolling with online edge-rounding; Ra ≤ 0.4 µm.

– Electrostatic dust removal + pre-anneal brightening to eliminate oxide inclusions.

– Closed-loop enamelling; UV-LED curing for polyamide-imide (PAI) cuts solvent inclusions by 60 %.

H3 Cost-Performance Take-away for Specifiers

Aluminium windings sized 1.6× CSA deliver equal load loss at 38 % lower raw-material cost versus Cu. When paired with Xinzhaohe’s IEC-certified insulation system, the total cost-of-ownership gap in a 1 MVA dry-type transformer narrows to ≤ 7 %—while meeting identical temperature-rise guarantees (80 K). For OEMs targeting IEEE C57.12.00-2024 or IEC 60076-11, our factory-direct model out of Luoyang eliminates Western distributor mark-ups, cutting lead-time to 3–4 weeks ex-works.

Need a detailed material-by-material quote for your next 500 kVA–10 MVA design? Email tech@xinzhaohe-al.com with your core window limits and we’ll return a loss-optimised Al or Cu proposal within 24 h.

Factory Tour: Manufacturing Aluminium Winding Vs Copper Winding

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20 years, 35 000 tpy, ISO 9001 / ISO 14001 / IATF 16949

Rod-to-Wire Process Flow (Al 1350 / Al 6101 / Cu-ETP)

| Step | Equipment & Parameters | Purpose | LXH Control Point |

|---|---|---|---|

| 1. Rod Drawing | 13-die, water-cooled bull-block, entry Ø9.5 mm → finish 1.8–5.0 mm | Size reduction, work-hardened micro-structure | Online laser OD ±0.01 mm, 100 % coil traceability |

| 2. In-line Annealing | 450–520 °C, N₂ atmosphere, 6 s soak, 30 °C/s quench | Recrystallise, 25 % min elongation, Vickers 25–35 HV | Pyrometer closed-loop ±5 °C; reject if Rm deviates >8 % |

| 3. Enameling | Horizontal multi-pass, 12–24 coats, die-roller combo, speed 80–120 m/min | Build thermal class 130 (B) to 220 (R) insulation | Concentricity laser scanner ≤8 % wall variation; pin-hole tester <3 faults/30 m |

| 4. Inline Testing | Spark 3 kV, 50 Hz; 100 % conductivity bridge; 5 kN tensile sample every 2 km | Detect insulation defects, verify 61 % IACS Al, 100 % IACS Cu | Auto-mark and cut; data logged to MES cloud |

| 5. Spooling | Precision layer-wound, 5–800 kg reels, traverse accuracy ±0.2 mm | K-free payoff for high-speed winders | Vision check for tangling; barcode weight & resistance match |

Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs Common Market

| Critical Property | Test Method | LXH Premium | Typical Market | Impact on Transformer |

|---|---|---|---|---|

| Breakdown Voltage, kV (0.25 mm build) | IEC 60851-5 | ≥6.5 kV (Al), ≥7.0 kV (Cu) | 4.5–5.5 kV | Higher impulse withstand, lower partial discharge |

| Elongation at Break | ASTM B566 | 25 % Al, 30 % Cu | 15–20 % | Handles thermal expansion cycles without crack |

| Concentricity | Laser radial scan | ≤8 % | 15–20 % | Uniform dielectric stress, no weak spots |

| Surface Pin-holes | 2 kV spark | ≤3 per 30 m | 10–20 per 30 m | Eliminates inter-turn short risk |

| DC Resistivity @20 °C | ASTM B193 | 28.0 nΩ·m Al, 17.2 nΩ·m Cu | 28.5–29.5 Al, 17.5–18.0 Cu | Tighter losses, meets DOE TP-1 / EU Tier-2 |

| Spool Weight Deviation | Load cell | ±0.3 % | ±2 % | Accurate cost-per-kg billing, no scrap on line |

Traceability & Certification

Every spool receives a unique QR code linking to 28 process parameters, annealing batch, enamel lot, and raw-material smelter heat number.

Certificates: IEC 60317, NEMA MW 1000, UL 1446 (class F & H), RoHS & REACH, marine DNV-GL fire-safe on request.

Third-party audits: 100 % pass rate on Siemens, Schneider, and Hitachi Energy supplier VDA 6.3 audits 2021-2023.

Factory-Direct Advantage

By integrating rod casting, fine drawing, and enameling under one 180 000 m² roof, Luoyang Xinzhaohe removes the markup layers typical of European and North-American trading houses. The result:

15–20 % cost reduction against Western premium Cu-wire,

Same-day technical response from our on-site R&D metallurgists,

30-day DDP lead time to EU/US ports via our in-house freight cell.

Specify LXH winding wire once—eliminate field failures, cut total transformer cost, and still deliver ≥98 % efficiency on your Al or Cu design.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade wire, factory-gate to site-gate

H3 Design Criteria for Sea-Freight Stability

Marine transport imposes combined mechanical–climatic loads: 0.8 g racking, 80 °C container roof temperature, 95 % RH, 35 g/m³ salt spray. Our packaging is therefore specified like a “mini-transformer tank”: keep conductor surface <40 % RH, limit ovalization to ≤0.5 % of nominal diameter, and guarantee breakdown voltage retention after 45 days at sea.

H3 Packaging Matrix by Product Form

| Configuration | Core Reel | Primary Barrier | Secondary Barrier | Unit Load | Securing | Typical Qty / 20′ GP |

|---|---|---|---|---|---|---|

| Round wire 0.3–5.0 mm | DIN 355 or PT-90 plastic spool, impact-modified PP, 320 N hub strength | 80 µm VCI stretch film, weld-sealed | 5-layer K=K carton, 32 ECT | 4 cartons/layer, 5 layers/pallet, corner boards & PET strap | 19 mm steel strap + corner boards, 500 daN pre-tension | 10 t (18 pallets) |

| Rectangular strip 4–20 mm × 0.8–3.0 mm | 300 mm ID steel reel, dynamic balance ≤5 g | Desiccant 4 g/ft³, welded Al-foil liner, –40 °C dew-point before sealing | Fumigated ISPM-15 pine pallet, 1 200 kg safe load | Single reel per pallet, top-cap & foot-lock | 3-way strapping, lashing belt to container floor | 8 t (8 pallets) |

| Foil 0.1–0.6 mm × 50–1 000 mm | 500 mm ID HDF core, 100 daN radial crush | Same as strip, plus 2 mil PE bubble wrap interleave | Plywood box, 7 mm wall, steel edge protectors | Boxed on pallet, 1 200 × 800 mm | 4-way strapping, silica-gel card with 10 % RH window | 6 t (6 pallets) |

All pallets are 4-way entry, 1 200 × 1 000 mm, max 1.1 m height to optimize 2-tier loading in 20′ container.

H3 Environmental & Handling Controls

- Desiccant dosage: 6 EU units per cubic metre for 60 days <40 % RH.

- VCI additive: 2 % hexamine in PE film; contact corrosion on 1350-H19 Al verified ≤0.02 mg/cm² (IEC 60426).

- Shock & vibration: Reels secured with 2 000 daN breaking-strain PET strap; finite-stack analysis shows ≤0.3 % conductor elongation under 2 g impact.

- Fumigation & compliance: IPPC-ISPM 15 heat-treated lumber, methyl-bromide-free certificate available for EU & AUS destinations.

- Marking: UV-resistant labels with batch, thermal class, net/gross mass, and QR code linking to EN 60317-16 test report.

H3 Luoyang Hub → Global Site

Location advantage: Our works is 35 km from Luoyang Longmen rail terminal, linked by bonded trucking to Qingdao & Shanghai ports in 18 h. Weekly consolidation service to Rotterdam, Houston, and Dubai cuts LCL lead-time to 26 days door-door versus 38 days ex-works South-East Asia.

Documentation package shipped inside weather-proof pouch on pallet:

EN 10204 3.1 inspection certificate (breakdown voltage, elongation, concentricity)

RoHS & REACH SVHC statement

Packing list with reel serial–to–container seal mapping for 100 % traceability.

H3 Cost-Performance Positioning

Premium Western suppliers typically add 12–15 % packaging surcharge and 6 % logistical markup. By integrating rod drawing, annealing, enameling and spooling under one 70 000 m² roof in Luoyang, we eliminate intermediate freight and double-handling, delivering transformer-grade aluminum winding wire FOB Qingdao at 0.85× the landed cost of European copper wire—while meeting identical thermal class 200 specifications.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

(400–500 words, Engineering-grade precision)

H2 1. 20-Year Transformer-Grade Rod-to-Spool Track Record

Since 2003 our Luoyang campus has operated a single-site, single-process flow:

rod drawing → vacuum annealing → tandem enameling → inline PD / breakdown test → precision spooling.

No toll-processing, no third-party rewinding—every metre of Al wire is melted, cast, drawn and enamelled under one roof.

Result: lot-to-lot Rm deviation ≤ 8 MPa, elongation Cpk ≥ 1.67, and enamel concentricity within 5 µm on 2.00 mm diameters—specs that Western coil shops normally associate with oxygen-free copper.

| Statistic (2023) | LXZ-Al Value | Typical EU Tier-2 Supplier |

|---|---|---|

| Al wire km shipped | 42 000 km | 9 000 km (toll enamel) |

| Customer PPM enamel defects | 42 | 180–250 |

| Average coil OD tolerance | ±0.05 mm | ±0.12 mm |

| PD inception voltage 0.2 MPa | ≥ 1.4 kV | ≥ 1.1 kV |

H2 2. Direct-Factory Economics—No Distributor Margin Stack

We sell FCA Zhengzhou or CIF major port; no trader, no re-label, no hidden escalation clause tied to LME “Cu minus” formulas.

Because we start from 99.85 % P1020 ingot instead of purchased redraw rod, our aluminium conductor cost base is ≈ USD 0.25 / kcmil lower than European foil suppliers.

Transformer OEMs who switched from copper to LXZ-Al wire in 2022–23 report:

28–35 % conductor cost reduction on 1 MVA cast-resin units

18 % lower total winding weight → reduced core steel, smaller lifting fixtures

Pay-back on re-tooling (larger bending mandrels, bi-metallic lugs) < 9 months at 200 units / yr volume

H2 3. Customisation Window—Thermal Class, Insulation Build, Package Format

Our tandem enamel lines are barrel-type vertical ovens (patent CN112313362) giving dwell times variable 4–22 s; therefore we can deposit:

Modified polyester (130 °C, 155 °C)

Polyester-imide (180 °C) with or without polyamide-imide overcoat (200 °C, 220 °C)

Self-bonding layer (heat-solvent or oven-activation) for foil-less layer windings

Insulation build increments: 0.12–0.45 mm total; concentricity laser-controlled at 4 000 Hz, feedback loop to die-centering servos.

Spool formats: 30 kg, 80 kg, 500 kg returnable steel drums, or customer-specific segmented barrels for automatic TIG/TIG-lobe feeders.

Wire diameter range 0.40–6.00 mm; tensile after anneal 60–110 MPa; 15 %–35 % elongation tuned to your coil expansion spec.

H2 4. Engineering Support & Compliance Package

Each shipment includes:

- EN 60121-3-1 / IEC 60317 test report (breakdown, elongation, spring-back, weldability)

- RoHS & REACH SVHC declaration, China-EU conflict-minerals statement

- Thermal class ageing curve (Arrhenius 20 000 h extrapolation)

- Suggested crimp torque & bi-metallic transition lug list

We host bi-weekly Teams design reviews with your magnetics team—free of charge—to optimise conductor area, eddy-loss balance, and axial short-circuit force.

H2 5. Next Step—Request Datasheet or FCA Quote

Send your requirement (diameter, thermal class, insulation build, annual volume) to cathy@transformerstrip.com.

Typical response: 24 h technical datasheet + 48 h FCA price.

Trial spools (5 kg or 30 kg) available ex-stock for PD, bending and short-circuit tests—ship within 7 days.

Luoyang Xinzhaohe Aluminum Co., Ltd.

No. 26 Xinkai Road, Yiyang County, Luoyang, Henan, China

Tel: +86 379 6785 8336 | Web: www.transformerstrip.com

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium winding vs copper winding from Luoyang Xinzhaohe.