Table of Contents

Market Insight: Aluminium Winding Transformer

Market Analysis: Winding Wire Demand in Aluminum Winding Transformers

The global demand for aluminum winding wire in transformer manufacturing has grown significantly over the past two decades, driven by economic efficiency, material availability, and advancements in conductor processing technology. Aluminum winding transformers are now widely adopted in distribution and power transformer applications, particularly in medium- and low-voltage segments. This trend is especially pronounced in emerging markets and large-scale infrastructure projects where cost-effective, lightweight solutions are prioritized without compromising reliability.

Aluminum offers a favorable strength-to-weight ratio and lower material cost compared to copper, making it an attractive alternative for winding applications. Its density is approximately one-third that of copper, which directly reduces the overall weight of the transformer, easing transportation and installation logistics. Additionally, aluminum’s abundance in the earth’s crust ensures long-term supply stability, mitigating risks associated with raw material price volatility. As global energy demands rise and electrification expands into rural and developing regions, aluminum-wound transformers provide a scalable solution for grid expansion and renewable energy integration.

However, the performance of aluminum as a winding material is highly dependent on metallurgical quality and processing precision. Substandard aluminum wire can lead to increased resistive losses, poor thermal performance, and mechanical failure under electromagnetic stress. Impurities, inconsistent tensile strength, or inadequate elongation properties may result in wire breakage during winding or deformation under operational loads. Furthermore, improper surface finish or oxide layer control can compromise insulation integrity and increase the risk of partial discharge, reducing transformer lifespan.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of specialized experience in aluminum conductor production, we emphasize strict control over alloy composition, homogenization, drawing tolerance, and annealing profiles. Our aluminum winding wire is manufactured to meet international standards such as IEC 60104, ASTM B230, and GB/T 3954, ensuring consistent electrical conductivity (minimum 61% IACS), mechanical strength, and bending performance. Each batch undergoes rigorous testing for diameter tolerance (±0.01 mm), surface quality, and electrical resistance to guarantee compatibility with automated winding equipment and long-term field reliability.

The shift toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes) further underscores the importance of high-purity, high-consistency aluminum conductors. Even minor deviations in wire properties can accumulate across thousands of winding turns, leading to measurable inefficiencies and hot spot formation. Therefore, sourcing from a technically capable and quality-focused supplier is critical to achieving design specifications, regulatory compliance, and operational durability.

In summary, while aluminum winding transformers offer compelling economic and logistical advantages, their successful deployment hinges on the quality of the aluminum winding wire. As transformer manufacturers strive to balance performance, cost, and sustainability, partnerships with experienced metallurgical suppliers become essential to ensure material integrity and system reliability.

Technical Specs: Aluminium Winding Transformer

Technical Specifications for Aluminium Winding Wire in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to define critical parameters for aluminium winding wire in transformer manufacturing. Precision in material specifications directly impacts transformer reliability, efficiency, and service life. Key technical criteria include insulation breakdown voltage, mechanical elongation, and thermal class performance, all rigorously validated against international standards. These parameters must be optimized to withstand electromagnetic stresses, thermal cycling, and mechanical deformation during winding and operational phases.

The following table details mandatory specifications for aluminium conductor winding wire, aligned with IEC 60286, ASTM B800, and IEC 60085 standards. Values reflect industry best practices for grid-tied and industrial transformers operating under continuous load conditions.

| Parameter | Standard Range | Test Method | Critical Impact |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 8.0 kV (rms) | IEC 60286, Clause 6.3 | Ensures dielectric integrity under transient overvoltages; prevents inter-turn short circuits. Below 7.5 kV risks catastrophic failure during impulse testing. |

| Elongation (Min.) | 1.5% – 3.0% | ASTM E8/E8M | Critical for winding processability; <1.2% causes micro-cracking during tight-radius coiling. Values >3.5% indicate insufficient tensile strength for structural stability. |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60085, IEC 60172 | Dictates maximum continuous operating temperature. Class 180°C (H) and 220°C (C) require advanced polymer insulation systems (e.g., polyimide) to prevent thermal degradation at elevated loads. |

| Conductor Resistivity | ≤ 0.028264 Ω·mm²/m | ASTM B9 | Must not exceed 1.05x International Annealed Copper Standard (IACS) at 20°C. Higher values increase I²R losses and hotspot temperatures. |

| Dimensional Tolerance | ±0.02 mm (diameter) | ISO 286-2 | Critical for fill factor optimization; deviations >±0.03 mm cause uneven winding tension and insulation damage. |

Insulation breakdown voltage is non-negotiable for safety compliance. Xinzhaohe’s wires undergo 100% spark testing at 10 kV during production, exceeding baseline 8 kV requirements to account for insulation thinning during high-speed winding. Elongation must balance ductility and strength: aluminium alloys (e.g., 1350-O temper) are annealed to 1.8–2.5% elongation, enabling tight bends without fracturing while maintaining 60–70 MPa tensile strength. Lower elongation compromises yield during automated winding; excessive values reduce creep resistance under sustained electromagnetic forces.

Thermal class selection directly correlates with transformer design life. Class 130°C (B) suits distribution transformers with moderate load cycles, while Class 180°C (H) and 220°C (C) are essential for traction or renewable energy transformers subject to frequent overloads. Xinzhaohe validates thermal endurance via IEC 60172 thermal aging tests, confirming insulation systems retain >50% mechanical strength after 20,000 hours at rated temperature. Crucially, aluminium’s higher coefficient of thermal expansion (23.1×10⁻⁶/K vs. copper’s 16.5×10⁻⁶/K) necessitates thermal class margins 10–15°C above operational peaks to prevent insulation delamination.

These specifications form the foundation of robust transformer design. Xinzhaohe implements in-line monitoring of all parameters during drawing and annealing, with third-party certification from TÜV and SGS. Suppliers failing to meet these exacting standards risk premature transformer failure through insulation puncture, conductor fatigue, or thermal runaway. Partnering with a metallurgically focused supplier ensures traceability from billet purity (99.7% min. Al) to wound coil performance.

Factory Tour: Manufacturing

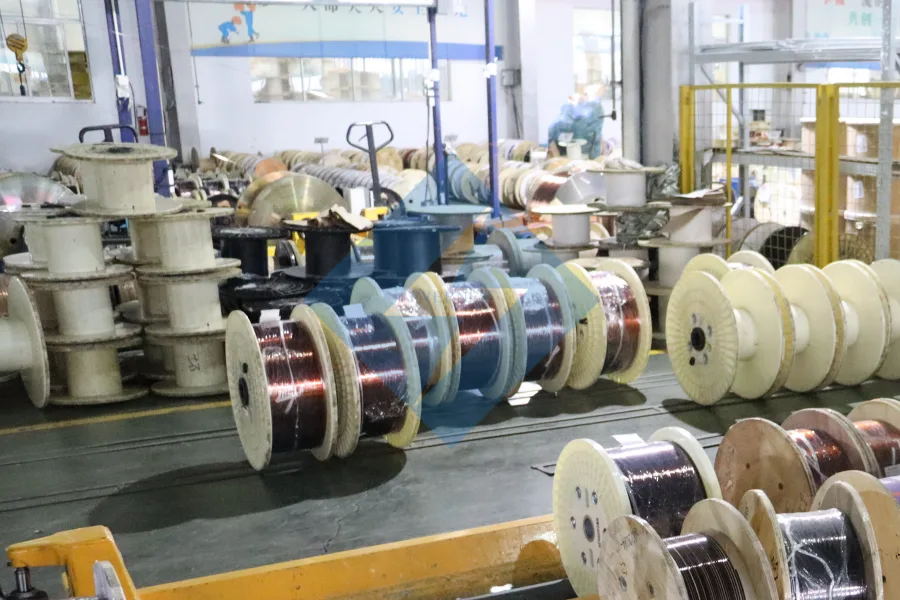

Manufacturing Process of Aluminium Winding Wire for Transformers

The production of high-performance aluminium winding wire for transformers at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing process designed to ensure optimal electrical conductivity, mechanical strength, and insulation integrity. With over two decades of metallurgical and industrial expertise, our process integrates advanced equipment and rigorous quality control to meet the demanding requirements of transformer applications.

The process begins with rod drawing, where high-purity aluminium rods (typically 9.5 mm in diameter, grade 1350 or 1370) are fed into a multi-die drawing machine. Through a series of cold-drawing passes, the rod is reduced incrementally to the desired wire diameter, commonly ranging from 1.0 mm to 4.0 mm depending on the application. This cold working enhances tensile strength while maintaining dimensional accuracy. Lubrication systems are precisely regulated to minimize surface defects and ensure consistent surface finish, critical for downstream processing.

Following drawing, the wire undergoes a continuous annealing process in a controlled atmosphere furnace. The annealing stage is essential to restore ductility lost during cold drawing, ensuring the wire can be wound tightly without cracking or breaking. Temperature profiles are carefully calibrated—typically between 300°C and 450°C—depending on alloy and gauge, with residence time and cooling rates optimized to achieve uniform recrystallization. Atmosphere control using nitrogen or forming gas prevents oxidation and ensures a clean, oxide-free surface, which is vital for adhesion during enameling.

The next critical phase is enameling, where the annealed aluminium wire is coated with a thermosetting polymer insulation system. Multiple layers may be applied depending on required dielectric strength and thermal class (e.g., Class 130, 155, 180, or 200). Common enamel systems include polyurethane, polyester, and polyamide-imide, selected based on thermal endurance, chemical resistance, and solderability. Each coat is cured in a high-temperature oven, with film thickness monitored in real time using laser gauges to ensure compliance with IEC 60317 and other international standards.

Throughout the production line, inline testing is conducted continuously to verify product integrity. Key parameters monitored include diameter consistency, coating thickness, dielectric strength (via high-voltage spark testing), elongation, and winding flexibility. Automated optical inspection systems detect surface defects such as scratches, blisters, or contaminants. Final samples from each batch undergo off-line laboratory testing, including thermal shock, needle penetration, and solderability tests, to validate compliance with customer specifications.

At Luoyang Xinzhaohe, quality control is embedded at every stage. Process data is logged and traceable, and statistical process control (SPC) tools are employed to maintain tight tolerances. This disciplined approach ensures that every spool of aluminium winding wire delivered meets the highest standards of reliability and performance in transformer manufacturing.

Packaging & Logistics

Export Packaging Specifications for Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum winding wire to ensure material integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our systems address critical risks inherent in sea freight, including humidity, salt exposure, physical shock, and contamination. All packaging adheres to ISO 9001 and ISO 14001 standards, validated through accelerated lifecycle testing simulating 45+ day voyages under tropical conditions.

Wooden Pallet Specifications

We utilize ISPM-15 certified kiln-dried hardwood pallets (1200 mm × 1000 mm × 150 mm) constructed from sustainably sourced Fagus sylvatica or Quercus robur. Pallets undergo moisture content verification (≤ 20% per EN 13229) and static load testing to 2,500 kg. Each coil is secured via steel strapping (minimum 16 mm width, 800 kg tensile strength) tensioned to 300 daN per ASTM D3953, eliminating axial displacement. Pallet dimensions comply with ISO 6780 modular cargo unit standards, optimizing container cube utilization while preventing lateral movement during vessel roll. Corner boards (100 mm × 100 mm × 1,200 mm) of 5-ply corrugated board (ECT ≥ 48 kN/m) shield coil edges from sling damage during port handling.

Moisture-Proof Barrier System

A multi-layer moisture barrier is critical for aluminum wire, which is susceptible to oxidation at humidity levels >60% RH. Coils are first wrapped in vapor corrosion inhibitor (VCI) polyethylene film (50 μm thickness, ASTM D1249), releasing organic amines that form a molecular anti-corrosion layer on the aluminum surface. This is overlaminated with metallized polyester film (12 μm aluminum deposit, WVTR ≤ 0.1 g/m²/day at 38°C/90% RH per ASTM F1249), providing electromagnetic shielding and blocking UV degradation. The primary barrier is sealed via impulse heat welding (200°C, 2.5-second dwell) to eliminate seam permeability. External overwrapping uses black polyethylene stretch hood film (175 μm) with UV stabilizers, bonded to pallet base via hot-melt adhesive (ISO 10362-1).

Sea Freight Validation

Our packaging system has undergone rigorous validation per IMO MSC/Circ.1045 guidelines. Accelerated testing includes:

72-hour salt spray exposure (ASTM B117) showing <0.05% surface oxidation

98% RH cyclic humidity testing (IEC 60068-2-78) with zero moisture ingress

Drop tests from 1.2 m height (ISTA 3A) maintaining coil concentricity within 0.1 mm

Real-world performance data from 1,200+ containers shipped to Southeast Asia, Europe, and the Americas confirms a 0.02% moisture-related damage rate—significantly below the industry average of 1.8%. All packaging components are fully recyclable, with documentation including phytosanitary certificates, fumigation waivers, and humidity indicator cards traceable to each shipment. This integrated approach guarantees aluminum winding wire arrives with unaltered electrical conductivity (≥ 61.0% IACS) and surface finish, directly supporting transformer manufacturing yield and reliability. Partnering with Xinzhaohe mitigates supply chain risk through packaging engineered at the metallurgical level.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Aluminium Winding Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted leader in the production of high-purity aluminium winding wire for transformer applications. Our facility integrates advanced metallurgical processing, precision drawing technology, and rigorous quality assurance protocols to deliver products that meet the exacting demands of power and distribution transformer manufacturers globally.

Our production infrastructure is anchored in a fully integrated process chain, beginning with high-conductivity primary aluminium ingots sourced from certified suppliers. These materials undergo controlled homogenization, continuous casting, and hot rolling to form high-density aluminium rods, which are then precision cold-drawn into winding wire with consistent dimensional tolerances. We maintain tight control over key metallurgical parameters, including grain structure, mechanical strength, and electrical conductivity, ensuring every batch of wire conforms to international standards such as IEC 60104, ASTM B230, and GB/T 3954.

The factory operates under a certified ISO 9001:2015 quality management system, with in-line monitoring at every stage of production. Our on-site laboratory is equipped with state-of-the-art testing instruments, including tensile testers, conductivity meters, micro-ohmmeters, and metallurgical microscopes, enabling real-time verification of mechanical and electrical properties. This allows us to guarantee a minimum conductivity of 61% IACS and precise elongation control between 25% and 35%, critical for reliable winding performance and thermal stability under load.

We specialize in supplying soft-annealed (O-temper) aluminium round and rectangular winding wire in diameters ranging from 1.0 mm to 10.0 mm, with custom spooling options and packaging configurations to suit automated winding lines. Our production capacity exceeds 20,000 metric tons annually, supported by a flexible manufacturing schedule that accommodates both large-volume contracts and just-in-time delivery models. All coils are traceable through batch coding, ensuring full material accountability and compliance with industrial certification requirements.

As a strategic partner, Luoyang Xinzhaohe offers technical collaboration to optimize wire specifications for specific transformer designs, including low-loss amorphous core units and high-efficiency dry-type transformers. Our engineering team supports clients with material selection guidance, winding trials, and failure mode analysis to enhance overall product reliability.

For reliable supply, consistent quality, and technical excellence in aluminium winding wire, partner with a manufacturer built on industrial precision and long-term performance.

Contact us today to discuss your technical requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium winding transformer directly from China.