Table of Contents

Market Insight: Aluminium Winding

Market Analysis: Winding Wire – Industrial Demand for Aluminium Winding in Transformers

The global demand for aluminium winding wire in power and distribution transformers has grown significantly over the past two decades, driven by the need for cost-effective, lightweight, and efficient electrical infrastructure. As transmission and distribution networks expand—particularly in emerging economies—aluminium has emerged as a strategic alternative to copper in transformer windings. This shift is supported by advancements in alloy development, conductor processing, and winding techniques that have enhanced the performance and reliability of aluminium-based systems.

Aluminium winding wire offers a compelling value proposition in transformer manufacturing. With approximately one-third the density of copper, aluminium reduces the overall weight of transformer assemblies, simplifying transportation and installation logistics, especially in rural or remote grid applications. Additionally, aluminium’s lower material cost contributes to reduced manufacturing expenses, a critical factor in large-scale infrastructure projects where capital efficiency is paramount. These economic and mechanical advantages have positioned aluminium as the conductor of choice in distribution transformers rated up to 35 kV, as well as in certain power transformer designs where weight and cost constraints are decisive.

Despite these benefits, the performance of aluminium winding wire is highly dependent on material quality and manufacturing precision. Impurities, inconsistent tensile strength, or inadequate elongation properties can lead to winding deformation, increased resistance, or mechanical failure under thermal cycling and short-circuit stresses. Poor surface finish or oxide inclusion may compromise insulation integrity, accelerating dielectric breakdown. Therefore, adherence to international standards—such as IEC 60104, ASTM B230, and GB/T 3954—is essential to ensure electrical conductivity, mechanical stability, and long-term reliability.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of specialized production experience, we emphasize metallurgical purity and process control in every batch of aluminium winding wire. Our conductors are produced from high-purity 1350 or 1370 aluminium alloy, processed through precision rod casting, continuous casting-conducting (CC), and multi-stage wire drawing under controlled atmospheres to minimize hydrogen content and oxide formation. Each coil undergoes rigorous testing for diameter tolerance, DC resistance, tensile strength, and bend performance to meet or exceed industry benchmarks.

The increasing adoption of aluminium in smart grids, renewable energy integration, and energy-efficient transformer designs further underscores the importance of consistent quality. As utilities and OEMs pursue higher efficiency classes (e.g., DOE 2016, IEC 60076-20), the electrical and mechanical properties of the winding material directly influence core losses, loadability, and lifecycle costs. Inferior-grade aluminium wire may lead to premature aging, increased maintenance, and unplanned outages—risks that far outweigh initial material savings.

In conclusion, while aluminium winding wire delivers substantial economic and logistical advantages in transformer applications, its successful implementation hinges on stringent quality control and adherence to engineering specifications. For industrial buyers, selecting a proven supplier with technical depth and process consistency is critical to ensuring system reliability and performance over decades of service.

Technical Specs: Aluminium Winding

Technical Specifications for Aluminium Winding Wire

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages two decades of metallurgical expertise to deliver aluminium winding wire meeting stringent industrial demands. Our specifications prioritize electrical integrity, mechanical resilience, and thermal stability for reliable performance in transformers, motors, and reactors. Critical parameters are rigorously controlled through in-line monitoring and third-party validation per IEC 60317 and ASTM B230 standards.

Insulation breakdown voltage defines dielectric safety margins under operational stress. Our enameled aluminium wire achieves minimum 3.5 kV AC breakdown at 0.1 mm insulation thickness, tested per IEC 60851-5. This exceeds baseline requirements for Class 130–155 applications, mitigating risks of partial discharge in high-voltage windings. Humidity resistance is validated via 168-hour salt fog testing (ASTM B117), ensuring consistent performance in corrosive environments.

Elongation directly impacts winding process yield and fatigue resistance. Aluminium’s inherent lower ductility versus copper necessitates precise temper control. Our wire maintains 1.5–2.5% elongation (ASTM E8) at 0.8–3.0 mm diameters, verified through tensile testing per IEC 60851-3. This range prevents micro-cracking during tight-radius coiling while accommodating thermal cycling stresses. Values below 1.2% risk brittle fracture during automated winding; exceeding 3.0% compromises tensile strength.

Thermal class dictates operational longevity under heat aging. We supply grades from Class 130 (B) to Class 220 (C), with thermal indices validated per IEC 60216. Critical thresholds include:

| Parameter | Specification Range | Test Standard | Critical Notes |

|---|---|---|---|

| Thermal Class | 130°C to 220°C | IEC 60216 | Class 180+ requires ceramic-filled polyimide |

| Thermal Index (TI) | ≥130°C (Class B) | IEC 60216-2 | Minimum 10,000-hour life at rated temperature |

| Hot Deformation | ≤30% at 200°C | IEC 60851-6 | Measures insulation flow under load/heat |

| Thermal Shock | Pass at -65°C | IEC 60851-4 | Ensures crack resistance during thermal cycling |

Class 200–220 wires utilize dual-layer polyamide-imide/polyesterimide coatings, sustaining 20,000+ hours at 200°C without >50% tensile strength loss. For Class 155 (F) and below, single-layer polyesterimide suffices. All grades undergo thermal aging at 20°C increments above rated class to establish safety margins.

Metallurgical purity (99.7% min Al) and grain structure control per ASTM E527 ensure uniform conductivity (61% IACS) and prevent intergranular corrosion. Dimensional tolerance adheres to ±0.005 mm for diameters ≤1.0 mm (IEC 60122), critical for fill factor optimization in tight stator slots. Adhesion strength exceeds 4 N/mm² (IEC 60851-7), eliminating delamination during thermal transients.

These specifications reflect our commitment to zero-defect supply for mission-critical applications. Partner with Xinzhaohe for traceable material certification and application-specific validation testing.

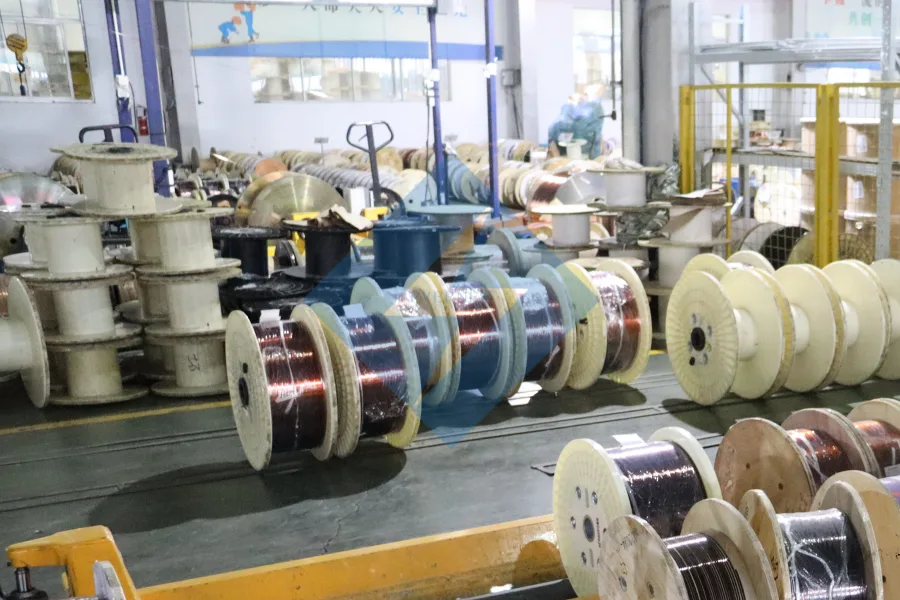

Factory Tour: Manufacturing

Manufacturing Process of Aluminium Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminium winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled sequence of metallurgical and coating processes designed to ensure mechanical integrity, electrical efficiency, and long-term reliability in demanding industrial applications. With over two decades of expertise in non-ferrous metal processing, our manufacturing workflow integrates precision engineering with advanced quality control at every stage, beginning with rod drawing and culminating in fully tested, enamel-coated conductors ready for deployment in motors, transformers, and other electromagnetic equipment.

The process initiates with high-purity aluminium rod material, typically conforming to ASTM B233 or equivalent international standards, which undergoes rod drawing to achieve the target wire diameter. Utilizing multi-die drawing blocks and precision capstans, the rod is progressively reduced under controlled tension and lubrication conditions to minimize work hardening and surface defects. This cold working stage is critical for establishing dimensional accuracy and enhancing tensile strength, while maintaining the required electrical conductivity. Throughout drawing, real-time diameter monitoring via laser gauges ensures tight tolerance control, typically within ±0.01 mm.

Following drawing, the wire enters a continuous annealing system where it is subjected to a precisely regulated thermal cycle in a nitrogen-purged inert atmosphere. This softening treatment restores ductility lost during cold drawing, ensuring the wire meets the required temper specifications—typically soft (O-temper) for winding applications. Temperature uniformity and residence time are tightly controlled to prevent over-annealing or oxidation, preserving both metallurgical homogeneity and surface quality.

The annealed wire then proceeds to the enameling section, where one or multiple layers of polymer insulation are applied via a vacuum die coating system. Common insulation systems include polyesterimide (PEI), polyamide-imide (PAI), or dual-layer combinations to meet thermal class requirements up to 220°C. Each coat is immediately cured in a series of high-efficiency infrared and convection ovens, with dwell time and temperature profiles optimized for cross-linking density and dielectric strength. Film thickness is monitored in real time using non-contact capacitance sensors to maintain consistency across batches.

Inline testing is integral to the production line. Every meter of finished wire undergoes high-voltage breakdown testing (typically 3–10 kV depending on gauge and insulation class), spark testing for pinhole defects, and continuous diameter and ovality verification. Additional periodic checks include elongation, springback, thermal shock, and solvent resistance tests performed in accordance with IEC 60317 and GB/T 4074 standards.

Final quality assurance includes batch sampling for adhesion, thermal endurance, and conductivity measurement. Only wire lots passing all criteria are approved for spooling, packaging, and shipment, ensuring consistent performance for our global industrial clients.

Packaging & Logistics

Export Packaging Specifications for Aluminium Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols to ensure aluminium winding wire integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our packaging system addresses critical risks inherent in sea freight: moisture exposure, mechanical shock, and atmospheric corrosion. This methodology directly safeguards coil geometry, surface finish, and electrical properties—key performance indicators for downstream wire drawing and winding processes.

Wooden Pallet Structural Requirements

All export shipments utilize ISPM-15 certified heat-treated wooden pallets constructed from kiln-dried hardwood. Pallet dimensions strictly adhere to ISO 13356 standards (1200mm × 1000mm or 1100mm × 1100mm) with a minimum load-bearing capacity of 2,500 kg. Each pallet incorporates double-deck boards with cross-support stringers to distribute coil weight evenly, preventing deformation under stack loads. Coils are secured via steel strapping (minimum 19mm width, 15 kN tensile strength) tensioned to 25% of breaking load, anchored to pallet perimeter blocks. This configuration eliminates lateral movement during vessel roll or container handling, mitigating edge damage and core collapse risks.

Moisture Barrier System

Aluminium’s hygroscopic nature necessitates multi-layer moisture protection. Coils undergo vacuum-sealing in 120-micron metallized polyethylene film with integrated vapour corrosion inhibitors (VCI). This primary barrier is overlaminated with 0.2mm thick polypropylene moisture-proof film, heat-welded at all seams to achieve <0.1 g/m²/24hr water vapour transmission rate (ASTM F1249). Desiccant packs (minimum 30% weight ratio to coil mass) are placed within the sealed envelope, maintaining internal relative humidity below 40% throughout typical 45-day ocean voyages. External pallet wrapping uses UV-stabilized stretch film (500% elongation) applied at 30% overlap to resist salt-laden air penetration.

Sea Freight Validation Protocol

We subject packaged coils to accelerated salt-spray testing (ASTM B117) simulating 90 days’ marine exposure. Real-time validation occurs via humidity dataloggers embedded in 5% of export shipments, tracking internal conditions across Shanghai-Rotterdam routes. Historical data confirms <0.02% corrosion-related claims over the past decade—attributable to our packaging’s ability to withstand temperature fluctuations (-25°C to 60°C) and humidity spikes (up to 98% RH). Crucially, this system prevents interlayer oxidation that compromises wire drawing lubricity and increases breakage rates by up to 18% in suboptimally protected shipments.

Quality Assurance Integration

Final packaging verification includes torque testing of strapping anchors, seal integrity pressure checks, and visual inspection for film punctures. Documentation provides ISPM-15 certification, desiccant quantity logs, and humidity test reports. This end-to-end control reduces total landed cost by eliminating rework, production delays, and material write-offs—proving that precision packaging is not a cost center but a value-preserving supply chain imperative for aluminium winding wire.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Aluminium Winding Solutions

With over two decades of specialized experience in the production of high-purity aluminium materials, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of aluminium winding wire. Our facility in Luoyang, China, is engineered for precision, consistency, and scalability, serving demanding industries such as power transmission, electric motors, transformers, and renewable energy systems. As a vertically integrated manufacturer, we maintain full control over the production chain—from molten metal refining to final wire drawing—ensuring uncompromising quality and traceability.

Our production infrastructure is anchored in advanced continuous casting and rolling lines, enabling the manufacture of aluminium rod with purity levels exceeding 99.70% Al, conforming to GB/T 8732 and IEC 60122 standards. This high-purity input is critical for achieving optimal electrical conductivity and mechanical performance in winding applications. The rods are then processed through precision wire drawing systems equipped with closed-loop tension control and inline diameter monitoring, supporting wire diameters from 1.0 mm to 6.0 mm with tight tolerances of ±0.02 mm. We specialize in soft-annealed (O-temper) and hard-drawn (H18/H19) tempers, tailored to customer specifications for elongation, tensile strength, and bendability.

Quality assurance is embedded at every stage of production. Our in-house laboratory is outfitted with OES spectrometers, universal testing machines, and eddy current inspection systems to verify chemical composition, mechanical properties, and surface integrity. Each coil undergoes 100% visual and electrical testing to detect surface defects and ensure consistent conductivity. All batches are supplied with full material test reports (MTRs) and comply with ISO 9001:2015 quality management protocols.

Logistical efficiency is a cornerstone of our service model. With an annual production capacity exceeding 30,000 metric tons and direct access to major rail and port networks, we support both large-volume OEM contracts and just-in-time delivery programs. Packaging is customized to prevent oxidation and mechanical damage during transit, with options including wooden reels, steel spools, and moisture-resistant wrapping.

For engineers and procurement managers seeking a reliable, technically proficient partner in aluminium winding wire, Luoyang Xinzhaohe offers a proven track record of performance, consistency, and responsive collaboration. Our technical team is available to support material selection, process optimization, and custom specification development.

Contact us today to discuss your requirements

Cathy Zhang

Sales Manager, Winding Wire Division

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium winding directly from China.