Table of Contents

Market Insight: Aluminium Sheet Fabrication

Market Analysis Transformer Strip Foil Aluminum Copper

Global transformer manufacturing exhibits robust demand for precision aluminum and copper strip/foil, driven by expanding power infrastructure and stringent energy efficiency regulations. Aluminum strip, particularly in the 0.1mm to 3.0mm thickness range, has gained significant market share against copper due to its superior weight-to-conductivity ratio and cost-effectiveness, especially in distribution and large power transformers. Regional dynamics vary; Asia-Pacific leads consumption growth fueled by grid modernization and renewable energy integration, while mature markets in Europe and North America prioritize replacements meeting Tier 2/Tier 3 efficiency standards like DOE 2016 and EU Ecodesign Lot 10. Annual global consumption of transformer aluminum strip exceeds 800,000 metric tons, with compound annual growth projected at 4.5% through 2030, primarily from aluminum’s role in reducing transformer weight and material costs without compromising core performance in well-designed units.

Quality in aluminum strip fabrication is non-negotiable for transformer reliability and lifecycle cost. Substandard material directly impacts critical performance parameters. Impurities exceeding 99.7% minimum purity (Al 1060/1070) increase electrical resistivity, elevating I²R losses and reducing efficiency. Surface defects—scratches, pits, or residual rolling oil—compromise insulation integrity during winding, potentially causing partial discharges or catastrophic insulation failure under operational stress. Dimensional inconsistencies, particularly thickness tolerance deviations beyond ±2% and edge burrs, disrupt precise coil layering, increasing localized eddy current losses and thermal hotspots. Grain structure homogeneity is equally vital; improper annealing leads to inconsistent mechanical properties during winding, causing deformation or tension variations that degrade magnetic performance. Luoyang Xinzhaohe Aluminum’s two-decade focus on transformer-grade material implements rigorous hydrogen degassing, precision cold rolling with laser thickness control, and proprietary surface cleaning protocols to eliminate these failure modes, ensuring compliance with IEC 60137 and ASTM B209 standards.

The following table summarizes key comparative attributes influencing material selection:

| Parameter | Aluminum Strip | Copper Strip | Critical Impact on Transformer Performance |

|---|---|---|---|

| Conductivity (%IACS) | 58-61% | 100% | Higher resistivity in Al requires larger cross-section but lower weight |

| Density (g/cm³) | 2.70 | 8.96 | Significant weight reduction (≈60%) with aluminum |

| Material Cost | Lower (≈35-40% of Cu) | Higher | Direct impact on transformer Bill of Materials |

| Surface Quality | Critical for insulation adhesion | Critical for insulation adhesion | Defects cause partial discharge, insulation failure |

| Dimensional Tolerance | Must be ≤ ±0.005mm for foil | Must be ≤ ±0.005mm for foil | Ensures uniform winding tension, minimizes eddy losses |

Transformer manufacturers increasingly recognize that initial material cost savings from substandard strip are eclipsed by field failure risks and efficiency penalties over a 30+ year operational lifespan. Precision aluminum strip fabrication, adhering to strict metallurgical and dimensional specifications, is fundamental to achieving mandated efficiency levels, ensuring grid reliability, and minimizing total cost of ownership. Luoyang Xinzhaohe Aluminum’s integrated quality control—from molten metal treatment to final slitting—provides the consistency demanded by Tier-1 transformer OEMs for mission-critical applications.

Technical Specs: Aluminium Sheet Fabrication

Technical Specifications for Aluminium Sheet Fabrication – Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-precision aluminium sheet fabrication tailored for critical electrical applications, particularly transformer strip and foil. With over two decades of metallurgical and industrial processing expertise, our manufacturing protocols ensure dimensional accuracy, edge integrity, and optimal electrical performance. The following technical specifications define our standard for aluminium sheet products used in high-efficiency transformer windings and conductive components.

Precision slitting is a core competency in our fabrication process, ensuring consistent width control across high-volume production runs. All slit edges are maintained within a tolerance of ±0.002 mm, achieved through computer-controlled tension management and high-precision rotary shear slitting systems. This level of accuracy is essential for minimizing interlayer stresses in wound transformer cores and ensuring uniform current distribution in parallel conductors. Our slitting lines are calibrated daily and monitored in real-time using laser micrometry, guaranteeing compliance across all production batches.

Edge quality is rigorously controlled to eliminate burrs, micro-tears, and deformation that could compromise insulation integrity or cause localized current crowding. Burr-free edges are achieved through optimized blade geometry, clearance settings, and post-slitting edge inspection via optical profilometry. Each coil undergoes edge scanning to confirm surface roughness (Ra) remains below 0.8 µm, ensuring compatibility with thin polymer and pressboard insulation systems used in modern transformer design.

Electrical conductivity is a critical performance parameter for transformer-grade aluminium. Our alloys, primarily 1060, 1070, and 1350 series, are refined to achieve a minimum conductivity of 61.0% IACS (International Annealed Copper Standard) in the annealed (O) temper. This exceeds the ASTM B418 and IEC 60164 standards for electrical conductor aluminium. Conductivity is verified through four-point probe resistivity measurements on sample strips from each heat lot, with traceability maintained through our quality management system.

Mechanical properties are controlled to balance formability and structural stability. Tensile strength ranges from 65 to 95 MPa with elongation of at least 35%, enabling tight winding radii without cracking or delamination. Coil consistency is ensured through uniform thickness profiles, with thickness variation across the width held to within ±0.005 mm.

All material is supplied in clean, dry conditions with anti-corrosion paper interleave and moisture-resistant packaging to prevent oxidation during transit and storage.

| Parameter | Specification | Test Standard |

|---|---|---|

| Width Tolerance | ±0.002 mm | ISO 21748 |

| Thickness Range | 0.10 – 3.00 mm | ASTM E29 |

| Thickness Uniformity | ±0.005 mm across width | ISO 15897 |

| Edge Burr Height | < 5 µm | ISO 8501-1 (Modified) |

| Surface Roughness (Ra) | ≤ 0.8 µm | ISO 4287 |

| Electrical Conductivity | ≥ 61.0% IACS | ASTM B193 |

| Tensile Strength | 65 – 95 MPa | ASTM E8 |

| Elongation (min) | 35% | ASTM E8 |

| Temper | O (Annealed) | ASTM B209 |

| Coil ID / OD | 508 mm / up to 1800 mm | Customizable |

These specifications reflect our commitment to delivering transformer strip and foil that meets the highest benchmarks in electrical efficiency, mechanical reliability, and dimensional precision.

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Transformer Strip and Foil

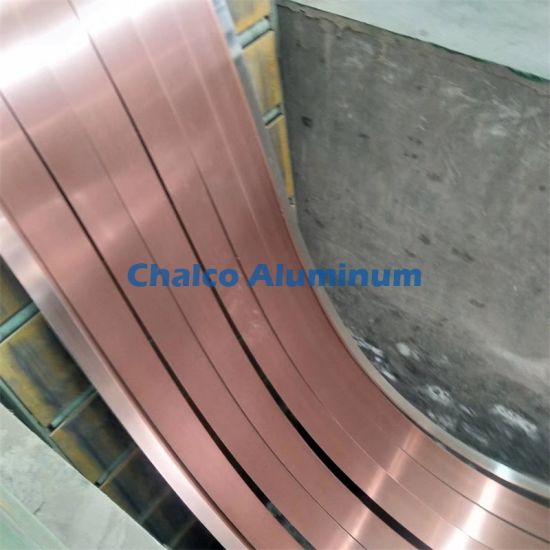

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in producing aluminum and copper transformer strip and foil to exacting electrical industry standards. Our integrated manufacturing sequence ensures optimal electromagnetic performance, dimensional precision, and surface integrity critical to transformer efficiency and reliability. The core process flow comprises Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating rigorous quality control.

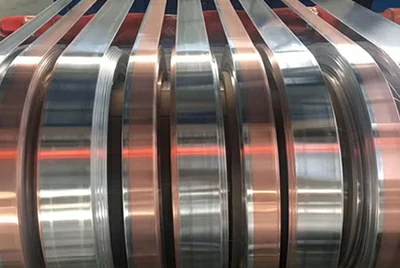

Cold Rolling forms the foundational step, transforming cast and homogenized ingot or continuous cast slab into precise strip gauges. Utilizing state-of-the-art 4-high or 6-high tandem mills under precisely controlled tension and temperature, we achieve significant reductions while maintaining strict metallurgical homogeneity. Critical parameters include roll surface finish, interstand tension, and lubrication regime, directly influencing final surface roughness (Ra) and residual stress levels. This stage is paramount for achieving the required thickness tolerance and ensuring minimal cross-thickness variation essential for uniform magnetic flux distribution in wound cores. Continuous在线 thickness monitoring via beta-gauges provides real-time feedback for immediate process correction. Post-rolling, the strip undergoes tension leveling to eliminate edge wave or center buckle, guaranteeing flatness suitable for high-speed winding.

Precision Slitting follows, where the master coil is longitudinally divided into narrow strips matching the specific core lamination width. This operation demands exceptional knife geometry, concentricity, and alignment. We employ precision-guided razor slitting or shear slitting systems with micron-level adjustment capabilities. The slit edge quality is non-negotiable; excessive burr formation or edge deformation directly impacts core loss and can damage insulation during winding. Slitting parameters – including knife overlap, clearance, and strip tension – are meticulously optimized for each alloy and gauge to minimize burr height and edge pull-down. Continuous visual and tactile edge inspection occurs throughout the slitting run.

Edge Conditioning is a critical, often overlooked, step specific to high-performance electrical applications. Immediately after slitting, the strip edges undergo controlled mechanical or chemical deburring and edge rounding. This process eliminates microscopic burrs and sharp asperities created during slitting, which are primary initiators of electrical shorts between laminations and contribute to increased core loss. Our proprietary edge conditioning systems ensure a consistent, smooth edge profile without inducing surface defects or dimensional changes to the strip body.

Quality control is embedded at every phase. Key verification points include:

Cold Rolled Coil: Thickness profile (±0.005mm typical), width tolerance (±0.1mm), flatness (I-Unit < 15), surface roughness (Ra 0.3-0.8µm), macro/micro cleanliness.

Slit Strip: Burr height measurement (< 2% of material thickness), edge straightness, slit width consistency, visual surface inspection for handling marks.

Final Product: Comprehensive dimensional certification, eddy current testing for subsurface defects, chemical composition verification (OES), mechanical properties (tensile, yield strength, elongation), and dedicated core loss testing per IEC 60404-3 on representative samples.

This disciplined, QC-integrated manufacturing sequence ensures our aluminum and copper transformer strip and foil consistently meets the stringent demands of modern power and distribution transformer manufacturing, directly contributing to reduced no-load losses and enhanced product longevity for our customers. Our process capability data demonstrates consistent adherence to the tightest industry specifications.

| Critical Parameter | Typical Target Tolerance | Measurement Standard |

|---|---|---|

| Thickness | ±0.005 mm | Beta Gauge, Micrometer |

| Width | ±0.10 mm | Laser Scanner |

| Edge Burr Height | < 2% Material Thickness | Optical Profilometer |

| Surface Roughness (Ra) | 0.3 – 0.8 µm | Stylus Profilometer |

| Core Loss (P1.5/50) | Customer Specific | Epstein Frame IEC 60404-2 |

Packaging & Logistics

Export Packaging for Aluminum and Copper Transformer Strip: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in precision aluminum and copper strip manufacturing for transformer applications, we recognize that packaging is not merely a logistical necessity but a critical component of product integrity. Our export packaging protocols are engineered to withstand the rigorous demands of international sea freight, where prolonged exposure to humidity, temperature fluctuations, and mechanical stress can compromise material performance.

All transformer strips—whether aluminum or copper—are systematically secured on high-grade wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets provide structural stability and are designed to support the weight distribution of tightly wound coils or stacked sheet packs without deformation during transit. Each pallet is treated to resist fungal growth and insect infestation, ensuring compliance with global phytosanitary standards and preventing customs delays.

Immediately following final inspection and quality verification, the material is wrapped in multi-layer moisture-proof composite film. This film incorporates a metallized polyethylene barrier that provides a vapor transmission rate of less than 0.1 g/m²·24hr, effectively isolating the metal surface from ambient humidity. The wrapping process is performed in a climate-controlled environment to minimize initial moisture exposure, and all seams are heat-sealed to form a hermetic enclosure. This protective barrier is essential for preventing oxidation, surface staining, and interlayer corrosion—particularly critical for thin-gauge strips used in high-efficiency transformers.

Additional protection is achieved through the integration of desiccant packs placed strategically within the sealed package. These silica gel units maintain an internal relative humidity below 40% throughout transit, even under extreme external conditions. For shipments exceeding 30 days, we implement a dual desiccant system with humidity indicators to allow for post-arrival verification of internal environmental conditions.

Each packaged unit is labeled with durable, weather-resistant markings indicating product specifications, batch numbers, handling instructions, and orientation arrows to prevent inversion. Load securing on containers is performed using steel strapping and anti-slip mats to minimize lateral movement during ocean transport. Our packaging design has been validated through accelerated salt spray testing and real-world shipment monitoring across major trade routes, including trans-Pacific and Europe-Asia corridors.

By combining robust wooden palletization with advanced moisture barrier technology, Luoyang Xinzhaohe ensures that transformer strip materials arrive at their destination with preserved surface finish, dimensional accuracy, and electrical performance. This systematic approach to export packaging reflects our commitment to delivering not only high-quality materials but also a fully secured supply chain for global transformer manufacturers.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized expertise in aluminum and copper transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd delivers engineered solutions meeting the exacting demands of power transmission and distribution systems. Our vertically integrated facility in Luoyang, China, combines advanced metallurgical processes with stringent quality control to produce transformer strip and foil renowned for dimensional stability, superior electrical conductivity, and surface integrity. We focus exclusively on high-performance conductive materials, ensuring every coil adheres to global standards including IEC 60404-6, ASTM B209, and GB/T 3880, while supporting custom specifications for niche applications.

Our production capabilities span critical technical parameters essential for efficient transformer cores. We manufacture aluminum transformer strip from 0.006 mm to 3.0 mm in thickness and widths up to 2,200 mm, with tolerances maintained within ±0.001 mm for ultra-thin foil. Copper strip production covers 0.05 mm to 3.0 mm thickness and widths to 1,250 mm. This precision is achieved through state-of-the-art cold rolling mills, continuous annealing lines, and proprietary tension-leveling systems that eliminate coil memory and ensure flatness deviations below 5 I-Units. Metallurgical refinement includes controlled grain structure development via homogenization and intermediate annealing cycles, optimizing magnetic properties and minimizing core losses in final assemblies.

Quality assurance is embedded at every process stage. In-house laboratories utilize OES spectrometry for real-time alloy composition verification, laser micrometry for thickness profiling, and universal testing machines for mechanical property validation. Surface defect detection employs high-resolution optical scanning to identify imperfections as small as 10 microns, critical for preventing dielectric breakdown in laminated cores. All batches undergo rigorous electrical resistivity testing, with aluminum foil consistently achieving ≥61% IACS and copper strip meeting ≥100% IACS per ASTM B3. Comprehensive traceability is maintained from ingot casting through slitting, with mill test reports documenting chemical, mechanical, and dimensional data for full compliance auditing.

Supply chain resilience is engineered into our operations. Strategic partnerships with primary aluminum smelters secure consistent high-purity feedstock (99.7%+ Al), while our 50,000-ton annual production capacity and JIT inventory management ensure on-time delivery for global clients. Dedicated export logistics teams manage containerized shipments with climate-controlled packaging to prevent oxidation, supported by ISO 9001 and IATF 16949 certified processes. Our technical team provides collaborative support from material selection through prototyping, including finite element analysis for lamination stack design optimization.

Partner with Luoyang Xinzhaohe to eliminate supply chain volatility in your transformer manufacturing. We transform metallurgical precision into your competitive advantage through scientifically validated materials and responsive engineering partnership. Contact Cathy Zhang, International Sales Director, to specify your requirements and receive a tailored production schedule: cathy@transformerstrip.com. Ensure your next transformer core generation achieves peak efficiency with foil and strip engineered for uncompromised performance.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium sheet fabrication directly from China.