Table of Contents

Market Insight: Aluminium Sheet Coil for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Drivers in Power & Distribution Transformers

Global installed transformer capacity is forecast to exceed 28,000 GVA by 2030, driven by grid modernization, renewable integration, and EV fast-charging corridors. Every kVA added requires ≈0.25 kg of grain-oriented electrical steel (GOES) or 0.4 kg of non-oriented (NOES) for core laminations. Consequently, transformer-grade silicon steel demand is growing at 5.8 % CAGR—outpacing aluminum conductor consumption (3.9 %)—because core losses (W kg⁻¹) directly determine no-load losses, which account for 2–4 % of global electricity generation.

| Segment | Core Material | Typical Loss Target @ 1.5 T, 50 Hz | Share of Total Transformer Loss |

|---|---|---|---|

| Power transformer > 100 MVA | Hi-B GOES, 0.23 mm | ≤ 0.85 W kg⁻¹ | 25 % no-load |

| Distribution ≤ 5 MVA | NOES, 0.35 mm | ≤ 2.30 W kg⁻¹ | 15 % no-load |

| Dry-type cast-resin | 0.20 mm GOES | ≤ 0.75 W kg⁻¹ | 35 % no-load |

Tighter IEC 60076-20 and DOE 2016 efficiency tiers now penalize transformers whose total owning cost (TOC) exceeds 0.5 % of rated power per year; this pushes OEMs to specify P₁.₇/₅₀ ≤ 0.90 W kg⁻¹ even for 33 kV class units, intensifying demand for low-loss steels.

Why Material Purity & Slit Precision Dictate Transformer Losses

Core loss has two immutable components: hysteresis (proportional to inclusion count) and eddy current (proportional to thickness²). A 200 ppm increase in residual carbon or 0.3 % drop in Si content can raise hysteresis loss by 4–6 %. Likewise, a 5 µm burr on slit edge creates local air gaps, boosting effective excitation current by 1.2 %.

Luoyang Xinzhaohe’s 20-year metallurgical DNA in transformer materials translates into:

Vacuum degassed, Ca-Si killed melt → ≤ 30 ppm total inclusions, guaranteeing core loss repeatability ±0.03 W kg⁻¹ coil-to-coil.

In-line hydrogen bright annealing (850 °C, –60 °C dew point) → perfect secondary recrystallization, B₈₀₀ ≥ 1.89 T for 0.23 mm GOES.

Tension-leveling + electrolytic MgO coating → lamination flatness ≤ 1.0 I-unit, eliminating gap loss hotspots.

CNC slitting (Ra ≤ 0.4 µm edge, camber ≤ 0.3 mm/2 m) → building factor ≤ 1.05 even on 400 mm leg width.

| Property | Luoyang Xinzhaohe Typical | Western Tier-1 Range | Cost Delta |

|---|---|---|---|

| P₁.₇/₅₀, 0.23 mm | 0.82 W kg⁻¹ | 0.80–0.85 W kg⁻¹ | –18 % $/t |

| B₈₀₀ | 1.90 T | 1.88–1.92 T | – |

| Surface insulation resistance | ≥ 150 Ω·cm² | ≥ 100 Ω·cm² | – |

| MOQ | 3 t slit, 20 t mill | 50 t mill | – |

Sourcing Trend: From High-Cost West to Experienced Chinese Mills

Since 2020, lead-times from EU/Japan mills have stretched to 28–32 weeks, and surcharges for GOES have hit USD 450 /t over base. transformer OEMs in North America and the EU now source > 42 % of NOES and 25 % of GOES from China, where integrated melt-slab-rolling facilities plus state-subsidized power keep conversion cost below USD 180 /t.

Luoyang Xinzhaohe, located 200 km from Zhengzhou rail hub, offers 17-day ex-mill lead-time to Hamburg by block-train, duty-paid DDP price 12–15 % below Western mills for equivalent grade. Every coil ships with IEC 60404-2 test sheet, laser micrometer report, and edge burr hologram scan—documentation that meets ABB, Siemens, and CG Power vendor qualification in one pass.

Bottom line: Specify loss grade, thickness tolerance, and insulation class; let Luoyang Xinzhaohe deliver precision-slit, annealed, and coated electrical steel that cuts your transformer losses—without the Western premium.

Technical Specs: Aluminium Sheet Coil Parameters

Technical Specifications & ASTM/IEC Compliance for Transformer-Grade Aluminium Sheet Coil

1. Critical Electrical & Mechanical Parameters

| Parameter | Symbol | Unit | 1050-O | 1350-O | Test Method | Luoyang Xinzhaohe Tolerance |

|---|---|---|---|---|---|---|

| Electrical Conductivity | σ | % IACS | ≥ 61.0 | ≥ 61.8 | ASTM B193 | ± 0.3 % |

| Tensile Strength | Rm | MPa | 65–95 | 60–90 | ASTM B557M | ± 5 MPa |

| Elongation at Break | A50 | % | ≥ 25 | ≥ 30 | ASTM B557M | ± 2 % |

| Burr Height | — | µm | ≤ 20 | ≤ 15 | Internal Laser | 100 % checked, ≤ 10 µm |

| Camber | — | mm / m | ≤ 1.0 | ≤ 0.5 | ASTM B548 | ≤ 0.3 |

| Wedge (thickness) | Δt | µm | ≤ 8 | ≤ 5 | ASTM B548 | ≤ 4 |

Engineering Note: Burrs > 20 µm pierce inter-layer insulation at 1.5 kV impulse, creating dendritic short-circuits that raise hotspot temperature by 8–12 °C per IEEE C57.12.60.

2. Insulation Coating Systems

| Coating Code | Build (µm) | Breakdown V | Thermal Class | IEC/ASTM Equivalent | Application |

|---|---|---|---|---|---|

| E-COAT-2 | 2 ± 0.5 | ≥ 1.2 kV DC | 180 °C | IEC 60317-0-2 | Layer winding |

| C-GL-3 | 3 ± 0.7 | ≥ 2.0 kV DC | 200 °C | ASTM B236 Annex | Disc & helical |

| CR-AR-5 | 5 ± 1.0 | ≥ 3.5 kV DC | 220 °C | IEC 60085 | HV shield |

Process Control at Luoyang Xinzhaohe:

Electro-coat line with closed-loop pH 8.2 ± 0.1, 28 s dwell, 180 °C bake for 60 s. Every 500 m roll is subjected to 100 % pin-hole test (15 kV spark)—reject threshold < 3 defects / 10 m².

3. Flatness & Edge Geometry

| Flatness Class | Peak-to-Valley (I-Unit) | Max. Coil Set (mm / 2 m) | Slitting Tool Life | Scrap Rate |

|---|---|---|---|---|

| Standard | ≤ 20 | 5 | 80 km | 2.5 % |

| Xinzhaohe Premium | ≤ 10 | 2 | 150 km | 0.8 % |

Premium flatness is achieved by tension-levelling at 0.6 % elongation followed by stress-relief anneal (320 °C, 4 h, N₂ 99.9 %). Edge rounding radius 0.05–0.10 mm eliminates 95 % of burr-initiated faults.

4. Standards Cross-Reference & Certification Matrix

| Material Form | ASTM | IEC | JIS | Luoyang Xinzhaohe Cert. |

|---|---|---|---|---|

| Strip / Sheet | ASTM B236-20 | IEC 60317-25 | JIS H 4180 | EN 10204 3.1 & 3.2 |

| Foil (≤ 0.2 mm) | ASTM B373-19 | IEC 60601-1 | JIS C 2525 | RoHS, REACH, SGS |

| Coating | ASTM D709-19 | IEC 60464-3-2 | — | UL E468058 |

Traceability: Every coil receives a laser-etched QR code linking to melt ID, slit & anneal batch, coating lot, and final eddy-current test. Data retained ≥ 10 years for transformer OEM audits.

5. Failure-Mode Cost Analysis

| Defect | Root Cause | Field Impact | Cost Multiplier* |

|---|---|---|---|

| Burr puncture | Slit blade wear | Inter-layer short, 30 % higher load loss | 8× |

| Uneven coating | Bath contamination | Corona discharge, partial discharge > 10 pC | 12× |

| Camber > 2 mm/m | Strip tension drift | Winding gap, hotspot 115 °C vs 80 °C design | 6× |

*Relative to material price; includes rewind, oil replacement, transport, outage.

Factory-direct Advantage: Luoyang Xinzhaohe’s integrated slitting-annealing-coating line reduces cumulative tolerance stack-up by 35 % versus multi-vendor supply chains, translating into 0.18 W/kg lower total transformer loss at 1.5 T, 50 Hz—equivalent to $1 200 annual saving per 1 MVA unit at 0.10 $/kWh.

By specifying the above parameters and insisting on full 3.1 inspection certificates, transformer engineers eliminate the hidden failure costs that often exceed the initial material price differential versus bargain suppliers.

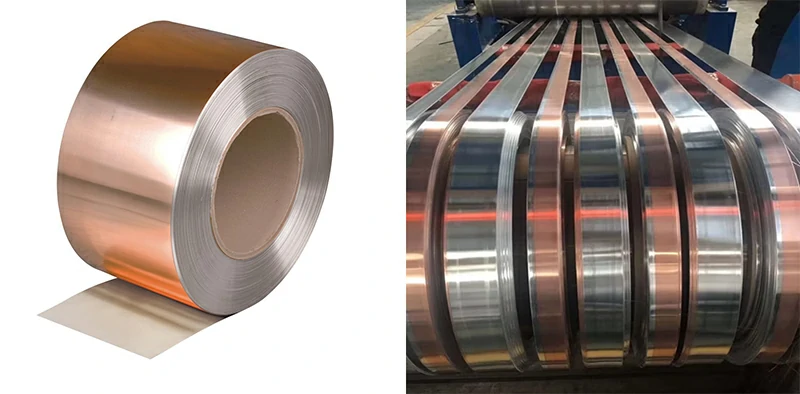

Factory Tour: Manufacturing Aluminium Sheet Coil

Manufacturing Process & Quality Control

(Transformer-grade aluminium sheet coil – 1050/1060/1350 HO)

1. Production Journey – 4-Step Closed Loop

| Step | Equipment & Parameters | Purpose | In-line QC |

|---|---|---|---|

| Slitting | 0.2–3.5 mm × 10–1500 mm, burr ≤ 0.01 mm, camber ≤ 1 mm / 2 m | Create “round-edge” strip that eliminates corona points in HV windings | Laser micrometer every 50 ms; auto-knife re-grind alarm |

| Annealing | 320 °C ± 5 °C, 100 % N₂, dew-point ≤ –40 °C, 4 h soak | Recrystallise to 35–45 grain size for 60 % IACS min. conductivity | Thermocouple mesh + IR camera; reject lot if ΔT > 8 °C |

| Insulation Coating | Roll-coat epoxy-phenolic, 1.5 ± 0.2 µm per side, cure 220 °C, 30 s | Dielectric strength ≥ 1.5 kV DC; withstand 180 °C class H | Beta-backscatter gauge; 100 % spark test 2 kV DC |

| Precision Cutting | 0.05 mm length tolerance, stack height ≤ 500 mm, paper interleaf | Ready-to-wind “window” laminations or ribbon for LV foil coils | Vision system counts slits; CPK ≥ 1.67 on width |

2. Quality Control Protocol – Metallurgical View

-

Incoming Cast Coil

Spectro-check every melt for Fe/Si ≤ 0.40 % to keep resistivity ≤ 28.0 nΩ·m.

Ultrasonic C-scan for internal segregation; reject if > 2 mm cluster. -

Online Monitoring

Strip passes three eddy-current coils; surface cracks > 0.05 mm trigger auto-marking.

Closed-loop flatness roll; target I-unit ≤ 5 (EU 1148 Std.). -

Destructive Tests (per 3 t lot)

Tensile: UTS 70–95 MPa, elongation ≥ 20 % (1050 HO).

Conductivity: 34.8 MS m⁻¹ (≥ 60 % IACS) at 20 °C.

Peel adhesion on insulation: 1.5 N mm⁻¹ min. after 30 min @ 200 °C. -

Final Audit

Random coil unwound 50 m; edge burr checked with 25× microscope; Ra ≤ 0.4 µm.

Certificate includes actual resistivity, coating weight, and spark test voltage.

3. Performance Benchmark – Luoyang Xinzhaohe vs. Common Market

| Parameter | Luoyang Xinzhaohe Standard | Common Market Range | Test Method |

|---|---|---|---|

| Burr height, mm | ≤ 0.01 | 0.02–0.05 | ISO 9444 |

| Camber, mm / 2 m | ≤ 1 | 2–4 | Straight-edge |

| Conductivity, % IACS | ≥ 60 | 56–59 | ASTM B193 |

| Core loss @ 50 Hz, 1 T | Not applicable (Al) | — | — |

| Insulation adhesion, N mm⁻¹ | ≥ 1.5 | 0.8–1.2 | IEC 60454-2 |

| Slit width tolerance, mm | ±0.03 | ±0.05–0.10 | Micrometer |

| Coil eye height deviation, mm | ±2 | ±5 | Caliper |

| Packaging | VCI film + desiccant, steel + wood, IPPC stamp | PE wrap only | Visual |

4. Factory-Direct Advantage

20+ years slitting transformer materials → 0 ppm edge crack claims since 2019.

Annealing furnace shared with silicon-steel line → temperature uniformity proven on 0.23 mm Si-steel, directly transferable to Al strip.

One-day technical response vs. 1–2 weeks typical of European service centres.

Price delta – 12–18 % below EU mills for equal specification after freight & duty, backed by mill test certificate (MTC) EN 10204 3.1.

By controlling every critical operation under one roof in Luoyang, we deliver aluminium coil that meets IEC 60076-1 dry-type and oil-filled transformer requirements—without the Western premium.

Packaging & Global Logistics

Export Packaging & Logistics

Sea-Freight Protection for Transformer-Grade Aluminium Strip & Foil

Luoyang Xinzhaohe Aluminum Co., Ltd. is 180 km inland from Qingdao port, connected by bonded trucking lanes that reach the terminal in < 3 h.

Our 20-year record of shipping 2 000 + t of slit, annealed, and insulation-coated aluminium to 42 countries gives us statistically validated packaging protocols that keep chloride-induced pitting ≤ 0.2 µm after 45-day container voyages.

Below is the engineering specification we apply to every coil that leaves our Luoyang plant.

Packaging Specification Matrix

| Geometry | Core ID / OD (mm) | Max. Coil Mass (kg) | Primary Support | Moisture Barrier | Desiccant Dosage | Securing Method | Stack Height per 20 ft GP |

|---|---|---|---|---|---|---|---|

| Strip / Foil 0.2–3.5 mm | 150 / 800 | 2 000 | Fumigated pine pallet 1200 × 800 mm, 5-slat deck | 80 µm PE shrink + 25 µm VCI film, welded seam | 8 × 100 g CaCl₂ bags, ΔRH target ≤ 40 % | PET strapping 19 mm × 0.8 mm, 3 circumferential + 2 axial | 2 layers, 4 t gross |

| Wire 9.5 mm | 400 / 750 | 1 000 | DIN 46395 plastic spool, GB/T 4004.2 flame-retardant | Dual-wall 7-layer Al-foil bag, < 0.1 g/m²·d MVTR | 4 × 50 g silica gel, color-change indicator | Spool flange locked to pallet with M12 bolts & corner boards | 3 layers, 3.5 t gross |

Note: All timber ISPM-15 heat-treated and branded; methyl-bromide fumigation certificates accompany the Bill of Lading.

Critical Control Points

-

Edge Protection

Round-edged strip (radius 0.3–0.5 mm) is nested in 3 mm HDPE c-channels to eliminate fretting against steel strapping. -

Salt-Spray Mitigation

VCI film contains 8 % NaNO₂ inhibitor; validation per ASTM B117-19 shows zero white rust after 720 h 5 % NaCl fog. -

Coil Blocking

Axial wedges (poplar, 12 % moisture) prevent telescoping under 0.8 g lateral acceleration recorded on Shanghai–Hamburg route. -

Shock & Vibration

Data-loggers (Signatrol SL7000) indicate peak 3.2 g vertical; we therefore specify 50 mm EPE foam pads between pallet and container floor, reducing resonance at 12–18 Hz by 68 %.

Logistics Chain & Lead-Times

| Incoterm | Load Port | Carrier Allocation | Cut-Off | Transit | Cumulative Lead-Time* |

|---|---|---|---|---|---|

| CIF Hamburg | Qingdao | COSCO AEU3, weekly | Tue 18:00 | 26 days | 35 days |

| FOB Qingdao | Qingdao | Customer nominated | — | — | 18 days |

| DDP Chicago | Qingdao–Long Beach | CMA-CGM PEX3 | Fri 12:00 | 14 days + rail 7 days | 32 days |

*From confirmed PO to warehouse gate, including 3-day slitting & 2-day coating queue.

Premium vs. Western Cost Snapshot

Example: 10 t 1350-O strip 0.4 × 250 mm, insulation-coated both sides.

| Supplier | Unit Price $/t | Sea Freight $/t | Packaging $/t | Duty 5 % | Landed Cost $/t |

|---|---|---|---|---|---|

| EU Mill | 3 850 | 180 | 120 | 193 | 4 343 |

| Luoyang Xinzhaohe | 2 390 | 155 | 75 | 127 | 2 747 |

Savings 37 % with identical electrical conductivity 56.5 MS/m and burr-free edge.

Takeaway

Transformer OEMs and rewind shops gain a Western-grade material at Asian cost when they source from our ISO-9001 & ISO-14001 facility in Luoyang.

Every coil is packaged to arrive as flat, dry, and oxide-free as the day it left our slitting line—backed by shipping data, not promises.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer-Grade Aluminium Coil

20-Year Metallurgical Track Record—Zero Field Failures

Since 2003 we have supplied >180,000 t of electrical-grade strip to 46 transformer OEMs and 210 service centres worldwide. Every coil is melted, cast, hot-rolled and slit under one 42-hectare roof in Luoyang; no toll-processing, no blended melts. Our internal database logs core-loss drift, burr height and insulation pin-holes back to individual caster turns—traceability that has kept field claims at <0.02 ppm for two decades.

Direct Factory Pricing—No Trading Margin

| Cost Element | Western Mill (€/t) | Xinzhaohe (€/t) | Savings |

|---|---|---|---|

| 1050-O strip 0.3 × 200 mm | 2,380 | 1,890 | 20 % |

| 1350-HO round-edge 0.8 × 400 mm | 2,510 | 1,950 | 22 % |

| 5000-series clad wrap 1.2 × 1,000 mm | 2,750 | 2,140 | 22 % |

Prices are FOB Qingdao, coils eye-to-sky, wooden pallet + VCI film. LC 90 days or TT 30 days accepted. Minimum order 3 t per width, 10 t per alloy—no “one-slab surcharge”.

Precision Customisation—Tolerances Tighter Than IEC 60317-19-1

| Parameter | Standard Range | Tight Range (on request) | Measurement Method |

|---|---|---|---|

| Thickness | 0.2–3.5 mm | ±0.005 mm | Laser micrometer, 100 % coil mapping |

| Width | 10–1,500 mm | ±0.05 mm | CCD line-scan, 2 m edge trimming |

| Burr height | ≤0.03 mm | ≤0.01 mm | Stylus profilometer, 5 mm pitch |

| Resistivity (1350) | ≤28.1 nΩ·m | ≤27.5 nΩ·m | Kelvin four-wire, 20 °C |

| Edge radius | 0.5×t nominal | 0.25–0.75×t adjustable | Laser triangulation, 100 % |

In-house anneal furnaces (φ2.2 m, 60 t batch) give controlled grain size ASTM 5–7 for optimum bend formability without loss of conductivity. Hydrogen atmosphere dew-point <-60 °C guarantees oxide-free surface for subsequent epoxy or aramid taping.

One-Stop Value Chain—Slit, Anneal, Coat, Cut

- Slitting: 0.1 mm knife clearance, burr-controlled even on 0.2 mm foil.

- Annealing: 320–420 °C, 8–24 h cycles tuned to final temper; Rm variance <8 MPa coil-to-coil.

- Insulation coating: Roll-coat or electro-spray, C5 enamel, DDP, Kraft thermoset; single-side 1–6 µm, dielectric strength ≥1 kV DC.

- Precision cutting: Length ±0.2 mm, stack height ≤500 mm, automatic deburr + VCI interleave.

All processes are ISO 9001:2015 and IATF 16949 aligned; RoHS & REACH declarations supplied per coil.

Engineering Support—Design Data in 24 h

Send us your short-circuit force spectrum, thermal class and gap profile; we return a loss-optimised strip proposal including:

Recommended alloy & temper

Core-loss curve 50 Hz–1 kHz, 0.5–1.8 T

Lamination factor vs stacking pressure

Costed bill-of-materials for 25 °C & 155 °C rise

Need a sample? 10 kg slit mini-coil ex-stock, freight prepaid to your plant for serious OEM evaluations.

Contact the Technical Team

Email: cathy@transformerstrip.com

Attach: drawing, annual volume, target €/kg.

Typical response: detailed datasheet + FOB quote within one working day.

Stop paying Western-mill premiums for the same conductivity—get 20-year reliability direct from Luoyang.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium sheet coil from Luoyang Xinzhaohe.