Table of Contents

Market Insight: Aluminium Sheet China

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) Demand and Quality Imperatives

The global transformer manufacturing sector exhibits a pronounced and accelerating shift towards aluminum strip and foil as a core conductor material, driven by compelling economic and performance factors relative to traditional copper. While copper retains advantages in absolute conductivity, aluminum offers significant cost savings per unit volume and a critical 60% weight reduction, directly impacting transformer transportation logistics, installation complexity, and structural support requirements. This transition is particularly evident in distribution transformers (up to 500 kVA) and increasingly in larger power transformers where design optimization mitigates aluminum’s lower conductivity. Consequently, demand for high-purity, precisely engineered aluminum sheet from China has surged, positioning the nation as a dominant supplier within the global supply chain. However, this market growth is intrinsically linked to stringent quality execution; substandard material represents not merely a procurement issue but a fundamental risk to transformer reliability and lifespan.

Quality parameters for aluminum transformer strip and foil are non-negotiable engineering specifications, not mere commercial tolerances. The primary driver is electrical performance stability. Impurities exceeding 0.3% (particularly iron and silicon) drastically increase electrical resistivity, leading to elevated load losses (I²R losses) and excessive heat generation during operation. This thermal stress accelerates insulation degradation, directly causing premature transformer failure. Surface integrity is equally critical; microscopic scratches, residual rolling oils, or oxide inconsistencies compromise the essential interlaminar insulation between stacked cores. This results in interlaminar short circuits, significantly increasing no-load losses (eddy current and hysteresis losses) and creating dangerous localized hotspots. Dimensional precision, especially thickness tolerance (±0.02mm or tighter) and flatness, is vital for achieving optimal core stacking factor and magnetic flux distribution. Variations introduce air gaps, increasing magnetizing current and core losses while reducing overall efficiency.

The consequences of inadequate quality control extend far beyond initial procurement costs. Transformers incorporating inferior aluminum strip face substantially higher lifetime operational expenses due to increased energy losses (a major TCO component), reduced overload capacity, and significantly elevated failure rates necessitating costly field replacements or repairs. Regulatory pressures, particularly from energy efficiency standards like DOE 2016 (USA) and IE3/IE4 efficiency classes (global), mandate minimal core losses, making high-purity, defect-free aluminum strip essential for market access. Suppliers lacking rigorous metallurgical process control and comprehensive in-line testing cannot consistently meet these demands.

Luoyang Xinzhaohe Aluminum leverages over two decades of specialized production to address these critical quality imperatives. Our process integrates precise alloy chemistry control, advanced cold rolling with stringent surface monitoring, and comprehensive post-processing validation. The table below outlines key quality parameters where our standards exceed typical market offerings:

| Parameter | Typical Industry Requirement | Luoyang Xinzhaohe Control | Critical Impact |

|---|---|---|---|

| Purity (Al min) | 99.60% | 99.70%+ | Lower resistivity, reduced load losses |

| Fe+Si Content max | 0.35% | ≤0.25% | Minimized core loss, stable magnetism |

| Thickness Tolerance | ±0.03mm | ±0.015mm | Optimal stacking factor, lower no-load loss |

| Surface Roughness | Ra ≤ 0.8μm | Ra ≤ 0.5μm | Reliable interlaminar insulation |

| Coil Set | Moderate | Near-zero | Consistent feeding, reduced scrap |

Sourcing aluminum sheet for transformers demands a partner with deep metallurgical expertise and unwavering commitment to the exacting standards of the power industry. Quality is not a cost adder; it is the foundational requirement for transformer efficiency, reliability, and compliance in today’s demanding energy landscape. Luoyang Xinzhaohe Aluminum provides the certified material integrity essential for transformer manufacturers to meet global performance and sustainability targets.

Technical Specs: Aluminium Sheet China

Technical Specifications for Precision Aluminum Transformer Strip and Foil – Luoyang Xinzhaohe Aluminum CO., Ltd

Luoyang Xinzhaohe Aluminum CO., Ltd., with over two decades of specialized manufacturing experience, delivers high-performance aluminum sheets and strips engineered for critical applications in the transformer and electrical industries. Our aluminum transformer strip and foil products are produced under stringent quality controls to meet international standards for dimensional accuracy, surface integrity, and electrical performance. These materials are optimized for use in dry-type transformers, current collectors, and electromagnetic shielding systems where consistency and reliability are paramount.

A defining characteristic of our aluminum strip production is precision slitting, maintained within a tolerance of ±0.002 mm. This level of dimensional control ensures uniform winding performance, reduces interlayer stress in transformer coils, and enhances thermal management. Our advanced tension leveling and slitting lines utilize high-precision rotary shear technology, minimizing edge deformation and ensuring straight, parallel edges across all coil widths. Each slit edge is inspected via automated optical edge profiling to verify conformance.

Edge quality is critical in transformer applications to prevent dielectric breakdown and winding damage. Our manufacturing process guarantees burr-free edges through optimized blade clearance, real-time tool wear monitoring, and post-slitting edge cleaning. Burr height is consistently maintained below 1% of material thickness, typically measuring less than 2 µm on 0.1 mm foil. This ensures safe handling and seamless integration into automated winding equipment without risk of insulation puncture.

Electrical conductivity is a core performance metric for transformer conductors. Our aluminum strips, primarily produced from high-purity 1060, 1070, and 1350 alloys, achieve a minimum conductivity of 59.0% IACS (International Annealed Copper Standard) in the O-temper (fully annealed) condition. Conductivity is verified through four-point probe resistivity testing in accordance with ASTM B917 and IEC 60163 standards. All coils are tested batch-wise, and certified test reports are provided with shipments.

Surface finish is uniformly controlled to minimize oxidation and ensure compatibility with insulation varnishes and bonding agents. The strips exhibit a clean, oxide-limited surface, free from scratches, roll marks, and contamination. Coils are wound under controlled tension to prevent telescoping and edge buckling, ensuring smooth unwinding during customer processing.

Below are the key technical parameters for our aluminum transformer strip and foil products:

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Types | 1060, 1070, 1350 | GB/T 3190, ASTM B209 |

| Temper | O (Annealed) | GB/T 16475 |

| Thickness Range | 0.08 mm – 3.0 mm | GB/T 3194 |

| Width Range | 20 mm – 1200 mm | GB/T 3194 |

| Slitting Tolerance | ±0.002 mm | GB/T 15102 |

| Edge Burr Height | < 2 µm (typical) | Optical Profilometry |

| Surface Roughness (Ra) | ≤ 0.5 µm | ISO 4287 |

| Electrical Conductivity | ≥ 59.0% IACS | ASTM B917, IEC 60163 |

| Tensile Strength | 60–85 MPa | GB/T 228.1 |

| Elongation (min) | ≥ 35% | GB/T 228.1 |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm | Custom options |

| Packaging | Waterproof composite + Edge protectors | GB/T 3199 |

All products are traceable through batch numbering and supported by comprehensive material test certificates. Luoyang Xinzhaohe Aluminum applies continuous process improvement and in-line quality monitoring to maintain consistency across production runs.

Factory Tour: Manufacturing

Transformer Strip/Foil Production Process: Precision Engineering for Core Performance

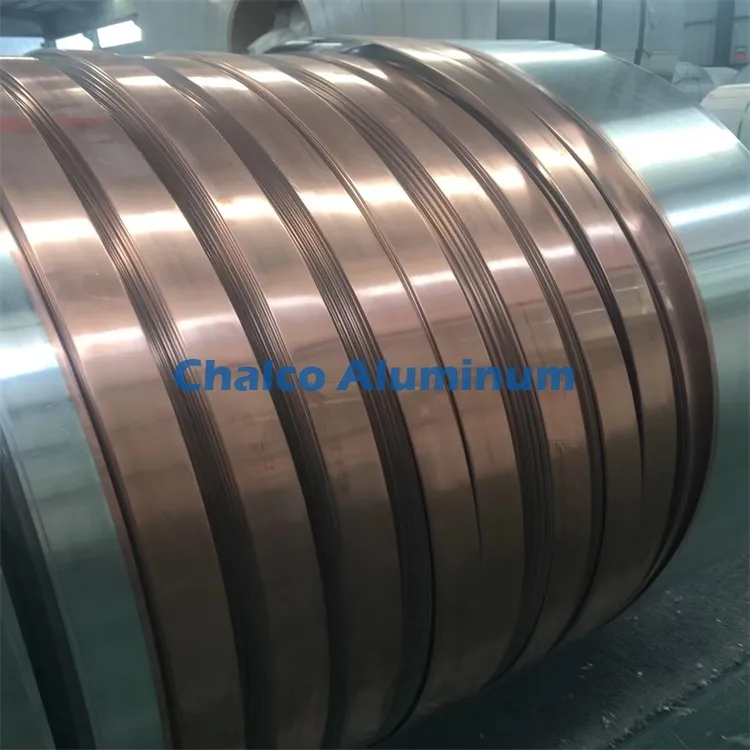

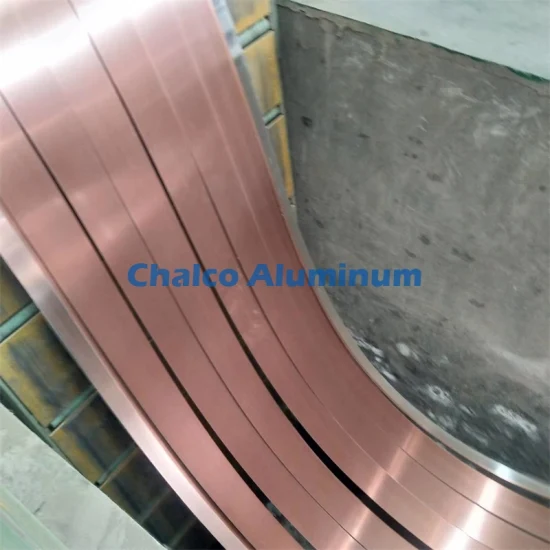

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized expertise in transformer-grade aluminum and copper strip/foil production. Our manufacturing sequence prioritizes dimensional stability, surface integrity, and edge perfection—critical for efficient core lamination and transformer efficiency. The process begins with cold rolling, where hot-rolled coils undergo multiple reduction passes at ambient temperature. This stage achieves target thicknesses ranging from 0.10mm to 0.80mm with stringent control over gauge deviation. Advanced tension leveling and precision roll grinding ensure surface roughness (Ra) remains within 0.3–0.8μm, eliminating defects that could compromise magnetic properties. A final skin-pass rolling step imparts uniform mechanical properties and optimal flatness, critical for high-speed winding operations.

Precision slitting follows, utilizing servo-driven rotary shear lines with laser-guided alignment. Coils are processed under controlled tension to maintain strip stability, achieving width tolerances of ±0.10mm for aluminum and ±0.05mm for copper. Slitter arbors are calibrated daily to prevent camber deviation exceeding 1.5mm per meter, ensuring consistent edge parallelism. This phase directly impacts yield in transformer core stacking, where even minor width variations cause air gaps and eddy current losses.

Edge conditioning is a non-negotiable final step for transformer applications. Strips undergo mechanical brushing or precision grinding to eliminate micro-burrs generated during slitting. Burr height is reduced to ≤5μm—verified via optical profilometry—to prevent insulation puncture during winding and interlaminar short circuits. Edge radii are uniformly controlled to 15–25μm, enhancing strip handling and reducing core vibration noise in operation.

Quality Verification Protocol

Every production batch undergoes multi-stage QC aligned with IEC 60404-1 and GB/T 3880 standards. Key checks include:

| Parameter | Test Method | Tolerance (Al) | Tolerance (Cu) |

|---|---|---|---|

| Thickness | Micrometer (10-point avg) | ±0.005mm | ±0.003mm |

| Width | Laser scanner | ±0.10mm | ±0.05mm |

| Tensile Strength | ASTM E8 tensile test | 80–110 MPa | 220–250 MPa |

| Edge Burr Height | Optical profilometer | ≤5μm | ≤3μm |

| Surface Defects | Visual inspection (5x) | Zero pinholes | Zero pits |

Final inspection includes 100% surface scanning via high-resolution CCD systems to detect inclusions, scratches, or roll marks. Batch traceability is maintained from ingot casting to shipment, with certified material test reports (MTRs) documenting all critical parameters. This integrated approach ensures our transformer strip/foil delivers the dimensional precision and surface quality required for high-efficiency core manufacturing, minimizing energy losses and maximizing transformer lifespan.

Packaging & Logistics

Export Packaging for Transformer Strip and Foil – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in aluminum and copper transformer strip and foil, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity throughout international transit. Our export packaging protocols are engineered to meet the stringent demands of sea freight, where exposure to humidity, mechanical stress, and prolonged handling cycles can compromise product quality if not properly mitigated.

All transformer strip and foil coils are systematically secured on high-grade wooden pallets constructed from durable, kiln-dried hardwood. These pallets are designed to ISO standards for export, ensuring structural rigidity and compatibility with global handling equipment. Each pallet is treated to ISPM 15 regulations, providing certified protection against the spread of wood-borne pests, a mandatory requirement for customs clearance in most destination countries. The load-bearing design of the pallet distributes coil weight evenly, minimizing deformation risks during stacking and transport.

Immediately following palletization, the entire coil assembly is wrapped in multi-layer moisture-proof composite film. This film consists of aluminum-laminated polyethylene barriers that offer superior resistance to water vapor transmission. A desiccant layer is integrated within the wrapping system to absorb residual ambient moisture, further safeguarding against oxidation and surface corrosion—particularly critical for thin-gauge aluminum and copper foils used in transformer windings. The sealing process employs heat-shrink technology to ensure a hermetic enclosure, preventing ingress of salt-laden air common in maritime environments.

To reinforce stability, steel strapping is applied longitudinally and transversely across the palletized unit, anchored securely to the base. This prevents lateral movement during vessel motion and port handling. Additionally, edge protectors are fitted at critical stress points to shield coil edges from impact damage. Each packaged unit is labeled with durable, weather-resistant tags indicating product specifications, batch numbers, handling instructions, and destination data, ensuring full traceability throughout the supply chain.

Our packaging methodology is validated through accelerated climate testing and real-world shipping trials across major trade routes, including trans-Pacific and Europe-Asia corridors. This ensures compliance with IEC and ASTM standards for material preservation under severe transport conditions. By integrating robust mechanical support with advanced moisture control, Luoyang Xinzhaohe Aluminum ensures that transformer strip and foil arrive at their destination with unaltered dimensional accuracy, surface finish, and electrical performance.

For international buyers, this packaging system translates into reduced risk of claims, minimized post-arrival rework, and consistent readiness for downstream processing. As a trusted exporter with extensive experience in global logistics, we align packaging design with both technical requirements and regulatory expectations, reinforcing our commitment to quality and reliability in every shipment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd for Precision Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum and copper transformer strip and foil solutions. Our vertically integrated manufacturing ecosystem, spanning from raw material sourcing to finished coil, ensures uncompromising consistency for global transformer OEMs demanding zero-defect performance. We operate dedicated production lines engineered specifically for electrical conductor applications, eliminating cross-contamination risks inherent in multi-product facilities.

Our technical differentiation begins with stringent raw material governance. Aluminum ingots undergo triple-spectrographic verification to guarantee 99.99%+ purity (Al99.99), while electrolytic tough pitch (ETP) copper meets ASTM B187 specifications with oxygen content held below 10 ppm. This foundational control enables precise tailoring of mechanical and electrical properties. Advanced cold rolling systems achieve industry-leading dimensional tolerances: ±0.003 mm for aluminum foil (0.05–0.30 mm thickness) and ±0.005 mm for copper strip (0.10–1.00 mm), critical for minimizing eddy current losses in high-efficiency transformers. Annealing processes utilize oxygen-free nitrogen atmospheres with ±2°C thermal uniformity, ensuring optimal conductivity (IACS ≥61% for Cu, ≥59% for Al) and grain structure homogeneity.

Quality assurance is embedded at every process node through automated inline monitoring. Laser micrometers track thickness variation in real-time, while eddy current testing screens for subsurface defects at production speeds up to 800 m/min. Final coils undergo 100% surface inspection via high-resolution optical systems detecting flaws as small as 10 µm. Comprehensive mechanical testing includes tensile strength, elongation, and bend tests per IEC 60404-2, with full traceability from melt batch to customer shipment via our ERP-integrated quality management system (ISO 9001:2015 and IATF 16949 certified).

Supply chain resilience is engineered into our operations. Strategic partnerships with primary metal suppliers secure priority access to low-iron content feedstock, while our 50,000-ton annual production capacity includes dedicated lines for urgent orders without disrupting standard schedules. JIT logistics support includes VMI programs, containerized sea freight coordination, and customs documentation compliance for 30+ target markets. All coils ship with certified material test reports (CMTRs) detailing chemical composition, mechanical properties, and surface quality metrics.

For transformer manufacturers requiring dimensional precision, electrical integrity, and supply continuity, Luoyang Xinzhaohe provides a technically validated partnership. Our engineering team collaborates directly with client R&D departments to optimize material specifications for specific core designs and winding processes. Initiate a technical consultation to receive application-specific data sheets and production capability analysis. Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to discuss your transformer strip or foil requirements.

| Key Production Capabilities | Aluminum Transformer Strip/Foil | Copper Transformer Strip |

|---|---|---|

| Thickness Range | 0.05–3.00 mm | 0.10–1.00 mm |

| Thickness Tolerance | ±0.003 mm (foil) / ±0.01 mm | ±0.005 mm |

| Conductivity (IACS) | ≥59% | ≥61% |

| Surface Roughness (Ra) | ≤0.4 µm | ≤0.6 µm |

| Annual Production Capacity | 30,000 tons | 20,000 tons |

| Standard Annealing Atmosphere | N₂ + H₂ (dew point ≤-40°C) | N₂ (O₂ < 10 ppm) |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium sheet china directly from China.