Table of Contents

Market Insight: Aluminium Sheet

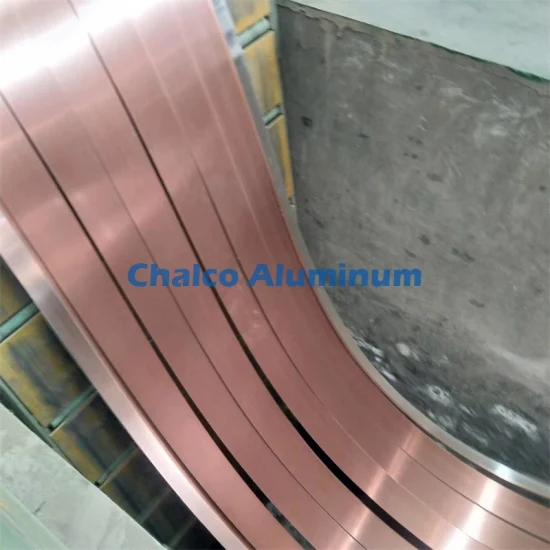

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for aluminum transformer strip and foil continues robust growth, driven primarily by the expansion and modernization of electrical infrastructure. Distribution transformers represent the largest application segment, where aluminum strip (typically 0.2mm to 3.0mm thickness) is the dominant conductor material due to its superior conductivity-to-weight ratio and cost-effectiveness compared to copper, especially in medium and low-voltage applications. This trend is amplified by volatile copper prices and strategic efforts to reduce material costs in grid infrastructure projects worldwide. Aluminum foil (sub-0.2mm thickness) is critical in capacitor windings within power factor correction units and certain high-frequency transformer designs, demanding exceptional surface integrity and dimensional precision. The renewable energy sector, particularly solar and wind farm substations, further accelerates demand for reliable, high-efficiency transformers utilizing these aluminum products. Stringent global energy efficiency regulations (e.g., DOE 2016 in the US, Ecodesign Directive 2009/125/EC in the EU) mandate lower no-load and load losses, placing increased emphasis on the core and winding materials’ electrical properties, directly impacting strip and foil specifications.

Quality is non-negotiable in transformer conductor materials, as microscopic defects or property deviations directly compromise transformer reliability, efficiency, and lifespan. Aluminum strip must exhibit precisely controlled electrical conductivity (minimum 61.0% IACS for EC-grade alloys), achieved through stringent purity management (99.7% min Al) and optimized annealing processes to ensure consistent recrystallization. Thickness tolerance is critical; variations exceeding ±2% cause uneven winding tension, leading to mechanical stress, increased eddy current losses, and potential hotspots during operation. Surface quality is equally vital; scratches, pits, or residual rolling lubricants create initiation points for interfacial oxidation between conductor layers, degrading dielectric strength and accelerating insulation aging under thermal cycling. Foil used in capacitors requires near-perfect surface smoothness (Ra < 0.3µm) and absence of pinholes to prevent dielectric breakdown at high electric fields. Contaminants like iron or silicon particles exceeding ppm thresholds act as recombination centers, increasing resistive losses. Luoyang Xinzhaohe Aluminum leverages 20+ years of specialized production expertise to consistently meet these exacting parameters, ensuring the metallurgical homogeneity and surface perfection required for transformers operating reliably under decades of thermal and electromagnetic stress. Compliance with international standards such as IEC 60137 and ASTM B418 is fundamental, but leading manufacturers exceed baseline requirements through advanced process control to deliver the ultra-stable material properties essential for next-generation efficient power systems. Failure to adhere to these quality benchmarks inevitably results in premature field failures, costly grid disruptions, and significant warranty liabilities for transformer manufacturers.

Technical Specs: Aluminium Sheet

Technical Specifications for Precision Aluminum Sheet – Transformer Strip/Foil Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-purity aluminum sheets specifically engineered for transformer strip and foil applications, where dimensional accuracy, edge quality, and electrical performance are critical. With over two decades of metallurgical expertise and advanced rolling and slitting technologies, our aluminum sheets meet the stringent demands of power transmission and electronic component manufacturing. The following technical parameters define the performance benchmarks of our aluminum sheet products.

Dimensional precision is paramount in transformer applications to ensure consistent winding behavior and minimize interlayer stress. Our aluminum sheets are precision slit to tight tolerances, with a width tolerance of ±0.002 mm, achieved through servo-controlled slitting lines equipped with laser-guided edge detection systems. This level of accuracy ensures uniform coil build-up and reduces the risk of edge wave or telescoping during high-speed winding operations. The thickness range is available from 0.10 mm to 1.50 mm, with thickness tolerance maintained within ±0.005 mm for foils and ±0.01 mm for thicker strips, depending on alloy and temper.

Edge quality directly influences handling performance and dielectric integrity in transformer windings. Our production process incorporates high-precision shear slitting with optimized blade clearance and burr suppression technology, resulting in burr-free edges with a maximum burr height of ≤0.005 mm. This eliminates the risk of insulation puncture and ensures compatibility with thin polymer-based insulation systems used in modern dry-type transformers. Edge straightness is maintained within 0.3 mm per meter, minimizing skew during coil winding.

Electrical conductivity is a key performance indicator for transformer efficiency. Our aluminum sheets are produced from high-purity 1060, 1070, or 1350 alloys, with a minimum conductivity of 59.0% IACS (International Annealed Copper Standard), as measured per ASTM E1004. Consistent grain structure and controlled annealing cycles ensure uniform conductivity across the strip length and width, reducing eddy current losses and improving thermal stability under load. The material is supplied in O (annealed) temper, providing optimal formability and softness for tight-radius winding.

Surface finish is controlled to minimize friction and prevent insulation abrasion. A uniform roughness average (Ra) of 0.4–0.8 µm is maintained through precision roll finishing and cleaning processes that eliminate residual oils or particulates. All sheets are tested for surface defects using automated optical inspection systems.

The table below summarizes the core technical parameters:

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy | 1060, 1070, 1350 | GB/T 3190 |

| Temper | O (Annealed) | GB/T 16865 |

| Thickness Range | 0.10 – 1.50 mm | GB/T 3880.3 |

| Thickness Tolerance | ±0.005 mm (foil), ±0.01 mm (strip) | GB/T 3880.3 |

| Slit Width Tolerance | ±0.002 mm | Custom Measurement |

| Edge Burr Height | ≤0.005 mm | Optical Profilometry |

| Electrical Conductivity | ≥59.0% IACS | ASTM E1004 |

| Surface Roughness (Ra) | 0.4 – 0.8 µm | ISO 4287 |

| Edge Straightness | ≤0.3 mm/m | Laser Measurement |

These specifications reflect Luoyang Xinzhaohe Aluminum’s commitment to delivering technically superior aluminum sheet products tailored for high-reliability transformer and foil applications.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in producing high-integrity aluminum and copper transformer strip and foil. Our manufacturing sequence is meticulously engineered to meet the stringent dimensional, surface, and edge quality demands critical for efficient transformer core performance and winding reliability. The core process flow encompasses Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating rigorous quality control protocols.

The Cold Rolling process forms the foundational step, transforming pre-annealed cast and homogenized ingot or continuous cast coil into the target gauge with precise metallurgical properties. Utilizing state-of-the-art 4-high or 6-high rolling mills, controlled reduction ratios and interstand tension management are paramount. This stage dictates the final grain structure, mechanical properties (yield strength, elongation), and surface finish. Critical parameters such as roll force, rolling speed, coolant lubrication, and strip tension are continuously monitored and adjusted in real-time using automated gauge control (AGC) systems. In-process quality control includes continuous laser micrometer measurement for thickness profile (crown, wedge) and width, coupled with surface inspection systems detecting defects like scratches, inclusions, or roll marks. Material chemistry, verified via OES spectroscopy on representative samples, ensures compliance with alloy standards like 1060 or 1100 for aluminum strip, with strict control over iron and silicon content to optimize magnetic properties.

Following cold rolling and intermediate annealing if required, Precision Slitting subdivides the master coil into the exact widths demanded by transformer lamination or winding specifications. This operation employs high-precision slitting lines featuring hardened rotary knives, precision knife arbors, and sophisticated tension control systems to maintain strip flatness and prevent edge wave or center buckle. Maintaining consistent slit width tolerance, typically within ±0.1 mm or tighter for critical applications, is essential for uniform core stacking factor. Real-time laser width scanners continuously verify slit dimensions across the web, while edge quality is monitored for knife streaks or minor burrs. Tension control throughout the slitting process is vital to minimize coil set and ensure stable handling for downstream processing.

The final critical stage is Edge Conditioning, specifically designed to eliminate micro-burrs and achieve a smooth, radius-controlled edge profile. Unconditioned edges pose significant risks in transformer cores, potentially causing interlaminar short circuits, reducing insulation effectiveness, and increasing core losses. Our process utilizes precision brushing, edge rolling, or controlled abrasive techniques calibrated to the specific material gauge and alloy. This step is non-negotiable for high-efficiency transformer production. Post-conditioning, edge profile is rigorously verified using optical comparators or high-magnification edge inspection systems to confirm the absence of sharp protrusions and adherence to specified edge radius.

Throughout this integrated manufacturing sequence, Luoyang Xinzhaohe implements a comprehensive quality management system aligned with ISO standards. Key process parameters and critical quality characteristics are documented and traceable for every production lot. The table below summarizes critical in-process QC checkpoints:

| Process Stage | Critical Parameter | Measurement Method | Target Tolerance |

|---|---|---|---|

| Cold Rolling | Thickness Profile | Laser Micrometer (Online) | ±0.005 mm (Typical) |

| Surface Defects | Automated Vision System | Zero Critical Defects | |

| Precision Slitting | Slit Width | Laser Width Scanner (Online) | ±0.10 mm (or tighter) |

| Edge Wave/Flatness | Tension/Flatness Sensors | Per Customer Spec | |

| Edge Conditioning | Edge Radius/Burr Presence | Optical Comparator/Microscope | Zero Sharp Burrs |

This disciplined approach to Cold Rolling, Precision Slitting, and Edge Conditioning, underpinned by embedded quality control at every phase, ensures the transformer strip and foil supplied by Luoyang Xinzhaohe Aluminum CO., Ltd delivers the dimensional accuracy, surface integrity, and edge perfection required for optimal transformer efficiency, longevity, and safety in demanding power applications.

Packaging & Logistics

Export Packaging for Aluminum Transformer Strip and Foil – Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in the production and global supply of aluminum and copper transformer strip and foil, we maintain rigorous standards in export packaging to ensure product integrity during international transit. Given the hygroscopic nature of aluminum and the dimensional precision required in transformer applications, our packaging methodology is engineered to mitigate risks associated with moisture, mechanical stress, and prolonged sea exposure.

All aluminum transformer strip and foil shipments are systematically secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support coil weights ranging from several hundred kilograms to multiple metric tons, ensuring structural stability during containerized ocean freight. The use of treated timber prevents fungal growth and pest infestation, complying with international phytosanitary regulations for cross-border shipments.

Each coil is first wrapped in a multi-layer moisture-proof composite film, consisting of aluminum foil laminate and polyethylene barrier layers. This vapor-resistant wrapping acts as a primary defense against humidity, salt air, and condensation—common challenges in marine transport, particularly in tropical and coastal regions. The sealed envelope is heat-welded circumferentially to eliminate permeability, creating a hermetic barrier that preserves surface finish and prevents oxidation during voyages that may span several weeks.

Following film encapsulation, the coil is affixed to the wooden pallet using high-tensile steel strapping, tensioned and sealed to industrial specifications. Edge protectors made from laminated cardboard or steel are applied at critical contact points to prevent deformation of the coil’s outer wraps during handling and stacking. For added security, especially in high-vibration transit environments, optional corner braces and top covers fabricated from marine-grade plywood are employed to shield against physical impact and top-load compression in container stacks.

External labeling includes UV-resistant, tamper-evident tags with serialized batch identifiers, alloy designation, temper, dimensions, net weight, and handling instructions compliant with IMDG and IATA freight guidelines. Critical orientation markers such as “THIS SIDE UP” and “DO NOT INVERT” are prominently displayed to guide port logistics personnel.

Our packaging protocol is validated through internal accelerated aging tests and real-world performance tracking across key trade lanes, including Asia-Europe, Trans-Pacific, and Middle East routes. This data-driven approach ensures continuous improvement in moisture resistance and load integrity under dynamic climatic conditions.

By integrating robust materials, precision sealing techniques, and international regulatory compliance, Luoyang Xinzhaohe Aluminum CO., Ltd guarantees that every shipment of transformer strip and foil arrives at its destination with uncompromised metallurgical and dimensional quality, ready for immediate integration into high-efficiency electrical systems.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Transformer Strip & Foil Manufacturer

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise to deliver transformer strip and foil meeting the most stringent global electrical industry standards. Our vertically integrated production ecosystem, engineered specifically for aluminum and copper electromagnetic materials, ensures unparalleled consistency from raw material sourcing to finished coil. This deep-rooted specialization translates into reduced supply chain volatility and guaranteed performance for critical power infrastructure components.

Our core strength lies in advanced metallurgical process control. We utilize proprietary homogenization and annealing kinetics protocols to achieve optimal electrical conductivity (exceeding 61.0% IACS for 1070/1350 alloys) while maintaining precise mechanical properties. Rigorous elemental analysis and grain structure refinement guarantee uniform magnetic permeability and minimal hysteresis loss—critical for high-efficiency transformer cores. Every production batch undergoes statistical process monitoring, with full traceability from ingot to shipment, ensuring compliance with IEC 60137, ASTM B209, and customer-specific technical dossiers.

Production capacity is anchored by state-of-the-art continuous casting and cold rolling lines, supported by in-house annealing and slitting facilities. This integration eliminates third-party dependencies, enabling strict control over surface finish (Ra ≤ 0.35 µm), edge quality, and dimensional tolerances. Our technical capabilities are summarized below:

| Parameter | Aluminum Transformer Strip | Copper Transformer Foil |

|---|---|---|

| Thickness Range | 0.15 mm – 3.0 mm | 0.05 mm – 0.5 mm |

| Width Range | 50 mm – 1650 mm | 50 mm – 1200 mm |

| Conductivity | ≥ 61.0% IACS (min) | ≥ 98.0% IACS (min) |

| Tolerance Control | ±0.005 mm (thickness) | ±0.002 mm (thickness) |

| Surface Roughness | Ra ≤ 0.35 µm | Ra ≤ 0.25 µm |

Supply chain resilience is engineered into our operational DNA. We maintain strategic raw material reserves of 99.70%+ purity aluminum and oxygen-free copper, coupled with dual-sourced energy contracts to mitigate market fluctuations. Our lean logistics framework—certified to ISO 9001 and IATF 16949—delivers on-time shipment rates exceeding 99.2% globally, with JIT and VMI options tailored for OEM production schedules. Dedicated metallurgical support teams collaborate with clients during prototyping to resolve material interaction challenges, such as interfacial oxidation or winding tension optimization, before volume production.

Partnering with Luoyang Xinzhaohe means securing a supplier whose technical rigor matches your engineering specifications. We transform metallurgical precision into supply chain certainty for transformer manufacturers worldwide. Contact our technical sourcing team to discuss your next project’s material requirements and receive a customized production feasibility assessment.

Initiate your precision supply chain solution: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium sheet directly from China.