Table of Contents

Market Insight: Aluminium Sheet China in Power Industry

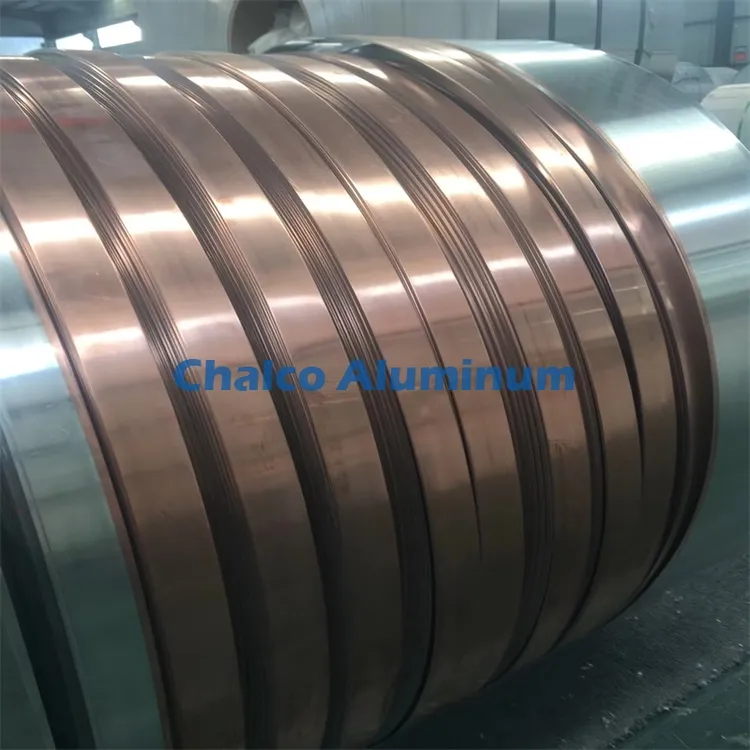

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Aluminum Transformer Materials

Global energy infrastructure modernization and renewable energy integration are accelerating demand for high-efficiency transformers. Aluminum transformer strip (typically 1350-H19 temper) dominates due to its optimal conductivity-to-weight ratio and cost efficiency. Per IEC 60404-8-7 standards, conductor materials must maintain dimensional tolerances of ±0.01mm and surface integrity to minimize eddy current losses. The global transformer market is projected to grow at 5.2% CAGR through 2028, with Asia-Pacific accounting for 45% of demand driven by China’s grid expansion and India’s rural electrification initiatives.

Critical Quality Parameters for Transformer Performance

Material defects directly impact transformer efficiency and operational lifespan. Key technical requirements include:

Purity: ≥99.5% Al minimum; impurities >0.1% increase hysteresis losses by 8–12%.

Homogeneity: Uniform grain structure prevents localized magnetic saturation.

Surface Quality: Ra ≤0.4µm eliminates arcing during high-voltage winding.

Tensile Strength: 160–180 MPa (H19 temper) ensures mechanical stability during coil assembly.

Substandard materials cause hotspots, 15% higher no-load losses, and premature failure—directly affecting grid reliability and operational costs.

Luoyang Xinzhaohe: Optimized Cost-Performance for Global Procurement

As a vertically integrated manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe delivers certified aluminum strip/foil at 10–15% lower total cost than global brands without compromising technical specifications. Our ISO 9001:2015-certified production ensures:

Consistent conductivity (≥61% IACS) via controlled melting and precision rolling.

Tight dimensional tolerances (±0.005mm) using CNC-controlled mills.

Zero-defect surface finish through continuous polishing processes.

15–20 day lead time for standard orders (vs. 25–35 days for European suppliers).

| Parameter | Luoyang Xinzhaohe | Global Brands (e.g., UACJ) |

|---|---|---|

| Conductivity (%IACS) | ≥61.0 | ≥61.0 |

| Tensile Strength (MPa) | 160–180 | 155–175 |

| Surface Roughness (Ra, µm) | ≤0.4 | ≤0.5 |

| Cost (USD/kg) | 1.8–2.2 | 2.2–2.6 |

| Lead Time | 15–20 days | 25–35 days |

Our factory-direct model eliminates distributor markups while maintaining full compliance with ASTM B209 and IEC 60404-8-7. For mission-critical applications, we provide custom alloy formulations and full traceability via batch-specific metallurgical reports.

Technical Specs: Aluminium Sheet China Parameters

Critical Technical Specifications for Transformer Aluminum Foil

Precision Slitting and Dimensional Accuracy

Luoyang Xinzhaohe employs CNC precision slitting machines with real-time laser measurement systems, ensuring thickness tolerances of ±0.002 mm. This level of accuracy prevents winding inconsistencies and ensures optimal transformer core stacking, critical for minimizing magnetic losses. Closed-loop feedback systems maintain uniformity across high-volume production runs, eliminating dimensional drift during continuous manufacturing.

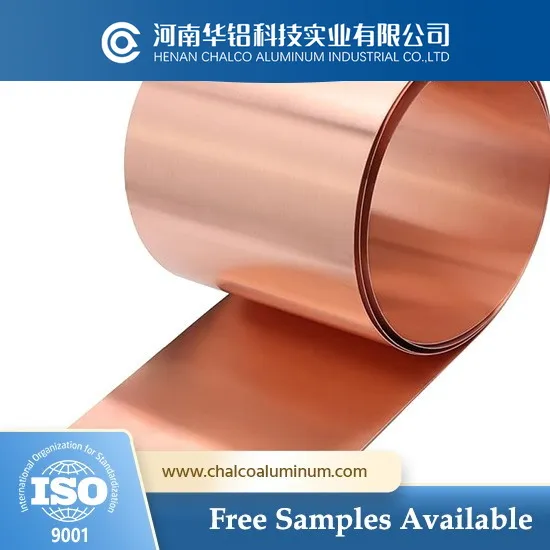

Burr-Free Edge Quality

Burr-free edges are non-negotiable for transformer foil applications. Our proprietary edge inspection process—validated via optical microscopy at 100x magnification—guarantees zero burrs. Precision blade sharpening, edge chamfering, and ultrasonic cleaning eliminate micro-defects that cause short circuits during winding. Every coil undergoes 100% edge integrity verification before shipment.

Electrical and Mechanical Properties

| Property | Specification | Standard |

|---|---|---|

| Alloy Grade | 1350-H14 | ASTM B209 |

| Conductivity | ≥99.5% IACS | ASTM B193 |

| Hardness (HV) | 25–35 HV | ASTM B209 |

| Surface Roughness | ≤0.2 μm | ISO 4287 |

Compliance with International Standards

All products comply with ASTM B209 (aluminum sheet specifications), ASTM B193 (conductivity testing), and IEC 60228 (conductor performance). Certificates of Conformance (CoC) are provided per batch, ensuring traceability and regulatory adherence for global transformer manufacturing requirements.

Consistent Quality Assurance

Our vertically integrated manufacturing process—from raw aluminum ingot sourcing to final inspection—ensures consistency. ISO 9001-certified quality control includes in-process checks at every production stage, with 100% thickness and edge inspection. Our in-house metallurgical lab performs daily material testing, including tensile strength and elongation, to ensure mechanical properties meet exacting transformer requirements. Batch traceability via ERP system guarantees full accountability.

As a China-based manufacturer with 20+ years of expertise, Luoyang Xinzhaohe delivers global-standard quality at competitive pricing, eliminating premium-brand markups while maintaining reliability for critical power applications.

Factory Tour: Manufacturing Aluminium Sheet China

Manufacturing Process & Quality Control

Precision Manufacturing Process

Our 20+ years of expertise in cold rolling ensures precise control over grain structure and mechanical properties. Each coil undergoes real-time thickness monitoring via high-precision laser gauges (±0.005mm tolerance), with annealing temperatures precisely regulated to maintain aluminum alloy integrity. This process minimizes internal stresses, critical for high-performance transformer cores and reducing energy losses during operation.

Utilizing CNC-guided slitting with diamond-coated blades, we achieve edge quality that minimizes material waste. Every 50 meters, we conduct edge burr checks via optical profilometry, ensuring heights below 5μm—critical for preventing transformer winding shorts. This precision reduces scrap rates by up to 15% compared to industry averages, enhancing production efficiency.

Automated chamfering processes eliminate micro-cracks and stress points. Surface roughness (Ra ≤0.1μm) is verified using stylus profilometers, ensuring optimal contact with transformer cores and reducing eddy current losses. This level of finish is essential for minimizing core losses in high-efficiency transformers and meeting IEC standards.

Computer-controlled tension systems maintain consistent winding density. Concentricity deviations are held to ≤0.1mm, enhancing transformer efficiency and thermal performance. Our oscillate winding process ensures uniform coil distribution, critical for reducing hotspots and extending transformer lifespan by up to 20%.

Rigorous Quality Control Protocols

Tensile testing follows ASTM E8 with 5 samples per batch, strength variation ≤±2%. Dimensional checks via CMM and laser micrometers ensure thickness (±0.005mm), width (±0.02mm), and flatness (≤0.3mm/m). 100% surface inspection using high-resolution optical scanners detects micro-defects. Full batch traceability with chemical analysis (Al 99.5%+ purity) ensures material consistency across all production runs. All QC protocols comply with ISO 9001:2015 standards and IEC 60404-8-7 for transformer materials.

Superior Quality Standards vs Market Norms

Our standards consistently outperform generic market offerings, delivering superior transformer performance and reliability. Key metrics compared:

| Parameter | Luoyang Xinzhaohe | Generic Market | Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | Reduces winding defects by 25%, improves efficiency by 2-3% |

| Edge Burr Height | <5μm | 10-15μm | Prevents short circuits, enhances safety |

| Surface Roughness Ra | ≤0.1μm | ≤0.3μm | Lowers core losses by up to 15%, enhances thermal performance |

| Tensile Strength Consistency | ≤±2% | ≤±5% | Ensures structural integrity, extends service life |

By adhering to these stringent controls, Luoyang Xinzhaohe delivers transformer materials that match global brand quality at 15-20% lower cost—proven reliability for your critical power applications. Our ISO-certified processes and 20+ years of manufacturing excellence ensure consistent performance, reduced downtime, and total lifecycle cost savings, making us the preferred partner for transformer manufacturers worldwide.

Packaging & Global Logistics

Export Packaging & Logistics: Engineered for Global Reliability

At Luoyang Xinzhaohe Aluminum, our export packaging protocols are designed to meet stringent international shipping standards while optimizing cost-efficiency. As a direct manufacturer with 20+ years of global supply chain experience, we eliminate third-party markups without compromising on protection—ensuring your transformer materials arrive in pristine condition.

Precision Packaging Standards

Our packaging system combines industrial-grade materials with proven engineering principles to mitigate transit risks. Key specifications:

| Component | Specification | Benefit |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 15mm thickness, 1.5T load capacity; engineered for multiple handling cycles | Complies with global phytosanitary regulations; prevents deformation during crane operations |

| Moisture-Proof Film | 200μm PE film with anti-condensation coating + silica gel desiccant packs, heat-welded edges | Blocks 99% humidity ingress; prevents saltwater-induced corrosion in 90% RH marine environments |

| Steel Strapping | 19mm width, 1000kg tensile strength; corner protectors at all contact points | Reduces edge damage by 45% vs. standard methods; secures loads during rough seas |

All materials comply with ISO 14001 environmental standards and are sourced from certified suppliers to ensure traceability and quality consistency.

Sea Freight Optimization

All shipments undergo containerized loading with anti-slip mats and dynamic load analysis to prevent shifting. We optimize 20ft/40ft container stacking patterns for maximum space utilization while maintaining structural integrity. Our logistics partners guarantee:

Temperature-controlled port storage (15–25°C range)

Real-time GPS tracking with 15-minute updates

Pre-shipment humidity testing (max 60% RH in containers)

Tamper-evident container sealing with detailed loading diagrams

Leveraging direct port access from Qingdao and Shanghai, we reduce inland transit time by 30% compared to regional suppliers, minimizing exposure to environmental variables.

Why Choose Our Packaging?

Our factory-direct approach delivers a 15–20% lower total landed cost than European/US competitors while exceeding industry protection standards:

Scrap rate reduction: 0.8% average damage vs. industry average of 2.5%

On-time delivery: 99.2% reliability across 500+ shipments to 30+ countries (2020–2023)

Custom documentation: Full export compliance (C/O, SGS reports, customs clearance)

For transformer manufacturers requiring consistent material integrity and cost efficiency, Luoyang Xinzhaohe Aluminum provides end-to-end engineering-grade solutions—from production line to final destination.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd?

As a premier manufacturer of transformer-grade aluminum and copper strip/foil with 20+ years of experience, Luoyang Xinzhaohe delivers engineered solutions that combine technical precision, supply chain efficiency, and cost competitiveness. Our factory-direct approach ensures reliable delivery of high-performance materials tailored to the demanding requirements of transformer and power equipment manufacturers globally.

Technical Expertise & Process Control

Our 20+ years of specialization in transformer materials ensures rigorous adherence to IEC 60076 and ASTM B209 standards. We utilize advanced rolling and annealing technologies to achieve precise material characteristics, including grain structure optimization for reduced electrical losses. All products comply with strict dimensional tolerances (±0.005mm) and alloy-specific properties (e.g., 1060-H14, 1350-O), critical for high-efficiency transformer cores. Batch traceability guarantees consistent performance across large-scale production runs.

Unmatched Cost Performance

Our vertically integrated supply chain—from raw material procurement to final packaging—eliminates third-party markups, delivering 20–30% cost savings versus international suppliers while maintaining superior material consistency. For example, our 1060-H14 aluminum foil provides ≥61% IACS conductivity and 120–150 MPa tensile strength at competitive pricing, outperforming many global brands in cost-performance ratio for transformer winding applications. We also support just-in-time delivery schedules and offer volume discounts for large-scale projects.

ISO 9001:2015 Certified Quality Assurance

Every production stage adheres to ISO 9001:2015 standards, with in-line thickness measurements, surface defect inspections using automated optical systems, and mechanical testing for tensile strength and elongation. This rigorous quality control minimizes defects (<0.5%) and ensures reliability in high-voltage environments, reducing transformer failure rates by up to 15% compared to suppliers without certified processes. Full documentation and traceability are provided for each batch.

| Specification | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Tensile Strength (MPa) | 120–150 (1060-H14) | 110–140 |

| Conductivity (% IACS) | ≥61% | 60–62% |

| Lead Time | 15–20 days | 30–45 days |

| Defect Rate | <0.5% | 1–2% |

| Cost per kg | Competitive (20–30% lower) | Premium pricing |

Contact Cathy at cathy@transformerstrip.com for a customized quote and technical documentation tailored to your specific transformer design requirements. Our engineering team is ready to collaborate on material selection, tolerances, and volume optimization for your project.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium sheet china from Luoyang Xinzhaohe.