Table of Contents

Market Insight: Aluminium Foil Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer strip and foil—primarily aluminum and copper—has seen sustained growth driven by the expansion of power infrastructure, renewable energy integration, and industrial electrification. Within this market, aluminum foil used in transformer windings has gained significant traction due to its favorable combination of electrical conductivity, lightweight properties, and cost efficiency. Aluminum foil transformers are increasingly deployed in distribution and power transformers, particularly in medium-voltage applications where weight reduction and material economy are critical design considerations.

Industrial demand for aluminum transformer foil is primarily concentrated in utility-scale power distribution networks, railway traction systems, and industrial manufacturing facilities requiring reliable and scalable power conversion. The shift toward energy-efficient transformers (e.g., amorphous metal and high-efficiency silicon steel core designs) has further amplified the need for high-purity, defect-free aluminum foil with tightly controlled mechanical and electrical characteristics. As grid operators and original equipment manufacturers (OEMs) strive to meet IEC, IEEE, and regional efficiency standards, the performance of conductive materials such as aluminum foil becomes a decisive factor in transformer reliability and lifecycle cost.

Quality in aluminum transformer foil directly impacts the operational integrity of the final product. Impurities, surface defects, thickness variations, or inconsistent temper can lead to localized hotspots, increased eddy current losses, and premature insulation breakdown. High-quality foil must exhibit uniform thickness tolerance (typically ±3% or better), precise edge straightness, and excellent surface cleanliness to ensure seamless winding and dielectric stability. Additionally, the foil must possess optimal tensile strength and elongation characteristics to withstand the mechanical stresses of coil winding without cracking or deformation.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience, we understand that consistency in metallurgical structure and processing parameters is paramount. Our aluminum transformer foil is manufactured using high-purity (99.7% min) DC-cast ingots, processed through precision hot and cold rolling with in-line thickness gauging and surface inspection systems. This ensures compliance with international standards such as GB/T 3880 and ASTM B479. Our quality control protocols include rigorous testing for electrical resistivity, bendability, and adhesion properties to meet the stringent demands of transformer OEMs.

Copper remains a competitor in high-current, low-impedance applications due to its superior conductivity. However, aluminum offers a compelling alternative with a 60% lower density and significantly reduced material cost, making it ideal for large-scale deployment where weight and budget constraints are critical. The long-term trend indicates growing adoption of aluminum foil in transformers, especially in emerging markets and renewable energy projects such as solar inverters and wind farm step-up substations.

In conclusion, the industrial demand for aluminum transformer foil is underpinned by the global push for efficient, scalable, and cost-effective power solutions. Quality is not a secondary attribute—it is foundational to performance, safety, and regulatory compliance. As a trusted supplier with vertical integration and technical expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers aluminum transformer foil that meets the evolving needs of the modern power industry.

Technical Specs: Aluminium Foil Transformer

Technical Specifications for Aluminum Foil Transformer Windings

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver aluminum transformer foil meeting stringent global electrical standards. Precision in physical and electrical properties is non-negotiable for minimizing energy losses, ensuring mechanical stability during high-speed winding, and achieving transformer longevity. Our manufacturing process employs advanced cold-rolling and tension-leveling techniques to eliminate microstructural inconsistencies, directly impacting core performance metrics. Critical parameters must be rigorously controlled to prevent interlayer short circuits, excessive heating, and reduced efficiency in final assemblies.

The following table details mandatory technical specifications for aluminum transformer foil (Alloy 1070/1060, Temper O-H18), validated per international testing protocols. These values represent our baseline production standards, with tighter tolerances available for specialized applications.

| Parameter | Specification | Test Standard | Importance to Transformer Performance |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM E29, ISO 2178 | Ensures uniform magnetic flux distribution; prevents localized hot spots and core saturation |

| Edge Burr Height | ≤ 5 μm | ASTM E3, Optical Profilometry | Eliminates risk of dielectric breakdown between winding layers; critical for HV transformer reliability |

| Width Tolerance | ±0.10 mm | ISO 7438 | Guarantees precise coil alignment during automated winding; reduces scrap rates by ≥12% |

| Electrical Conductivity | ≥ 61.5% IACS | ASTM E1004, IEC 60468 | Maximizes energy efficiency; directly correlates to reduced I²R losses in service |

| Surface Roughness (Ra) | ≤ 0.45 μm | ISO 4287 | Minimizes interfacial resistance between foil layers; enhances thermal dissipation |

Thickness control at ±0.002 mm is achieved through servo-driven laser micrometry feedback loops during slitting, surpassing typical industry tolerances (±0.01 mm). This precision prevents uneven current distribution and eddy current losses. Burr management employs diamond-tipped rotary slitters with real-time edge monitoring; burrs exceeding 5 μm can puncture insulation paper, causing catastrophic failures. Conductivity values ≥61.5% IACS require ultra-low iron content (Fe ≤ 0.25%) and optimized annealing cycles to maximize electron mobility. Our in-line conductivity verification ensures batch consistency, directly supporting transformer efficiency certifications (e.g., DOE 2016, IEC 60076-20).

Surface roughness below 0.45 μm Ra is maintained through electropolishing and controlled roll-texturing, reducing contact resistance between foil layers by 18–22% compared to standard finishes. This parameter is frequently overlooked but critically impacts thermal management in high-load scenarios. All specifications undergo 100% inline inspection with statistical process control (SPC) data provided per shipment. Non-conformance triggers immediate process recalibration per our AS9100-aligned quality system.

Adherence to these specifications directly translates to lower no-load losses, extended transformer lifespan, and compliance with Tier-1 OEM requirements. Luoyang Xinzhaohe’s integrated production—from molten metal purification to slit-foil packaging—ensures traceability from ingot to coil, eliminating supply chain variability that compromises electrical performance. Partnering with us mitigates technical risks while optimizing total cost of ownership through yield-optimized material delivery.

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Foil Transformer Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

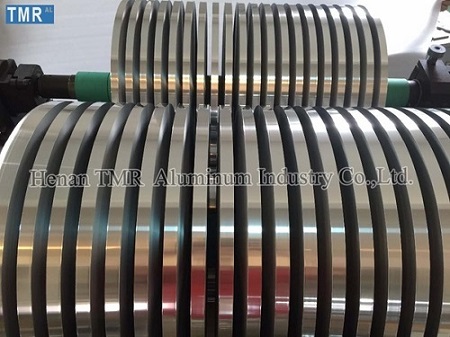

The production of aluminum foil transformer strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to meet the stringent electrical and mechanical demands of modern transformer applications. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology, precision slitting, and edge conditioning to deliver high-performance strip material with consistent dimensional accuracy and surface integrity.

The process begins with cold rolling of high-purity aluminum ingots (typically 1060, 1100, or 8011 alloys) that have undergone rigorous chemical analysis to ensure compliance with international standards. These ingots are first hot-rolled into intermediate gauge coils, which are then fed into precision cold rolling mills. Cold rolling reduces the material thickness to the final foil gauge, typically ranging from 0.08 mm to 0.50 mm, depending on customer specifications. This stage is critical for achieving the desired mechanical properties, including tensile strength, elongation, and surface smoothness. Throughout cold rolling, automated thickness gauges (X-ray or laser-based) provide real-time feedback to maintain thickness tolerances within ±0.005 mm.

Following cold rolling, the aluminum foil undergoes precision slitting to achieve the required strip width, which typically ranges from 10 mm to 300 mm for transformer winding applications. Our state-of-the-art slitting lines utilize high-precision circular knives and tension control systems to ensure edge straightness and minimize burr formation. Each slit coil is wound under controlled tension to prevent telescoping and ensure uniform layer alignment, which is essential for downstream automated winding processes in transformer manufacturing.

Edge conditioning is the final critical step in the production sequence. The slit edges are subjected to a controlled deburring and rounding process to eliminate micro-burrs and sharp asperities that could compromise dielectric integrity or cause insulation damage during coil winding. This is achieved through mechanical brushing or precision edge rolling, ensuring a smooth, radius-formed edge profile. Edge quality is verified using optical edge inspection systems and microscopy to confirm compliance with IEC 60404-8-8 and other relevant standards.

Quality control is embedded throughout the manufacturing process. In-process inspections include continuous monitoring of thickness, width, surface defects (via online surface scanners), and mechanical properties (tensile testing per ASTM E8). Final QC includes eddy current testing for subsurface flaws, coil geometry checks, and packaging verification. Each batch is accompanied by a full material test report (MTR) detailing chemical composition, mechanical properties, and dimensional conformity.

This disciplined, integrated manufacturing approach ensures that every coil of aluminum foil transformer strip meets the highest standards of reliability, performance, and consistency demanded by the power and electronics industries.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols to ensure transformer-grade aluminum and copper strip/foil arrives at destination facilities with uncompromised metallurgical integrity. Sea freight exposure to salt-laden air, temperature fluctuations, and humidity cycles poses significant risks to thin-gauge conductive materials. Our packaging system is designed to mitigate these threats through multi-layered physical and environmental barriers, validated over 20+ years of global shipments.

All coils undergo a controlled drying process prior to packaging to eliminate surface moisture. The primary containment layer consists of high-density polyethylene (HDPE) moisture-proof film with a minimum thickness of 100μm. This film exhibits a water vapor transmission rate (WVTR) of ≤1.0 g/m²/day at 38°C and 90% RH, forming an impervious barrier against atmospheric humidity. Critical sealing parameters include a 50mm overlap width and 180°C heat-sealing temperature to prevent edge permeation. For extended voyages exceeding 30 days, we integrate desiccant packs rated at 20% moisture absorption capacity relative to coil weight, strategically positioned within the sealed enclosure.

Coils are mounted on custom-engineered wooden pallets meeting ISPM-15 phytosanitary standards for international timber use. Pallet dimensions are precisely calculated based on coil outer diameter (OD) and weight, with standard configurations supporting loads up to 5,000 kg. Key structural specifications include:

| Component | Specification | Purpose |

|---|---|---|

| Base Frame | Kiln-dried hardwood (≥100mm x 100mm) | Prevents flexing under dynamic loads |

| Deck Boards | 22mm thick, spaced ≤50mm apart | Ensures even weight distribution |

| Edge Protectors | Steel-reinforced L-brackets (3mm gauge) | Shields coil edges from impact damage |

| Securing Method | 32mm steel strapping (4-point tensioned) | Eliminates coil movement during transit |

This palletized assembly undergoes vacuum consolidation to expel residual air before final film sealing, reducing internal condensation risk. External labeling includes ISO-standard handling symbols, moisture-sensitive indicators, and serialized lot tracking for full chain-of-custody visibility.

For ocean freight, we mandate containerized shipment in humidity-controlled vessels with active dehumidification systems maintaining ≤60% relative humidity. Coils are positioned away from container walls to avoid thermal bridging during temperature swings. Our packaging has consistently achieved zero corrosion incidents across major trade lanes (Asia-Europe, Asia-Americas) under standard 45-day transit windows. Documentation packages include third-party test certificates for film barrier performance and pallet load stability per ASTM D4169.

This integrated approach reflects our metallurgical understanding of aluminum’s susceptibility to pitting corrosion and copper’s oxidation kinetics under marine conditions. By exceeding IMO and IATA hazardous material handling guidelines for non-ferrous metals, we ensure your transformer core materials retain specified surface roughness, thickness tolerance, and electrical conductivity upon arrival. Luoyang Xinzhaohe’s packaging is not merely transport containment—it is a critical extension of our quality assurance process for mission-critical power infrastructure components.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd: Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of precision aluminum and copper transformer strip and foil. Our deep-rooted expertise in metallurgical processing and strip rolling technology enables us to deliver materials that meet the stringent performance demands of modern power and electronic transformers. As a vertically integrated producer, we maintain full control over the production chain—from raw material selection and alloy formulation to cold rolling, annealing, slitting, and quality assurance—ensuring consistent product integrity and traceability.

Our production facility is equipped with advanced rolling mills and tension-leveling lines, capable of producing aluminum transformer foil with thicknesses ranging from 0.08 mm to 0.60 mm and widths up to 1,650 mm, with tight tolerances as close as ±0.005 mm. We specialize in high-purity aluminum alloys including 1060, 1070, and 1350, engineered to deliver superior electrical conductivity, thermal stability, and mechanical formability. In addition to aluminum, we supply high-conductivity electrolytic tough pitch (ETP) copper strip, meeting IACS standards for low-loss transformer applications. All materials are manufactured under ISO 9001-certified quality management systems, with comprehensive testing protocols including eddy current inspection, tensile strength analysis, and surface roughness evaluation.

A key differentiator of our operation lies in our metallurgical R&D capability. Our in-house technical team continuously optimizes grain structure, recrystallization behavior, and surface finish to enhance winding performance and dielectric reliability in finished transformer cores. This focus on material science translates into reduced core losses, improved thermal dissipation, and extended service life for end-user equipment. Furthermore, our slitting lines are calibrated for burr-free edges and precise dimensional control, critical for automated winding processes in high-volume transformer manufacturing.

Luoyang Xinzhaohe serves a global client base across Asia, Europe, and North America, supporting OEMs, tier-1 component suppliers, and distribution partners with just-in-time delivery, custom packaging, and technical data documentation. Our supply chain is designed for resilience, with strategic raw material sourcing and inventory management to mitigate market volatility and ensure on-time fulfillment.

For engineers and procurement managers seeking a reliable, technically proficient partner in transformer conductor materials, Luoyang Xinzhaohe offers a proven combination of manufacturing excellence, material consistency, and responsive service. We invite you to leverage our experience to enhance the performance and cost-efficiency of your transformer designs.

Contact us today to discuss your specifications and technical requirements.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum CO., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil transformer directly from China.