Table of Contents

Market Insight: Aluminium Foil Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for aluminum foil strip in transformer windings continues robust growth, driven by sustained expansion in electrical infrastructure, renewable energy integration, and industrial electrification. Aluminum foil strip dominates the medium and large power transformer market due to its superior strength-to-weight ratio, cost efficiency versus copper, and adequate electrical conductivity for high-voltage applications. The shift towards ultra-high-voltage (UHV) transmission systems and distributed generation networks further intensifies requirements for precision foil, demanding consistent mechanical and electrical properties across extended production runs. Copper foil retains niche use in specific high-frequency or space-constrained applications, though aluminum’s economic and density advantages make it the primary material for core winding applications globally.

Quality of aluminum foil strip is non-negotiable in transformer manufacturing, directly impacting device reliability, lifespan, and safety. Substandard foil introduces critical failure risks during transformer operation. Microscopic surface imperfections, such as pits, scratches, or excessive roughness, act as focal points for electrical field concentration, significantly increasing the probability of partial discharge initiation and eventual dielectric breakdown within the oil-immersed insulation system. Inconsistent thickness tolerance disrupts the precise layer-to-layer voltage distribution essential for stable operation, leading to localized overheating and accelerated insulation degradation. Edge burrs or poor edge conditioning cause mechanical damage to interlayer insulation paper during high-speed winding, creating immediate short-circuit pathways. Variations in metallurgical properties, including tensile strength and elongation, compromise the foil’s ability to withstand the significant mechanical stresses of the winding process and subsequent thermal cycling in service, potentially causing conductor deformation or rupture.

The consequences of foil quality deviations extend far beyond initial manufacturing yield loss. A single defective transformer core can trigger catastrophic field failures, resulting in costly grid outages, extensive equipment replacement expenses exceeding hundreds of thousands of dollars, and severe reputational damage for the transformer manufacturer. Stringent adherence to international standards such as IEC 60203 for aluminum conductors is the baseline; leading transformer producers now enforce even tighter internal specifications for surface quality, dimensional stability, and mechanical properties to mitigate these systemic risks. Material consistency batch-to-batch is equally critical, as variations necessitate production line adjustments, reduce throughput, and introduce uncontrolled variables into the transformer’s performance profile.

Aluminum vs. Copper Foil: Key Transformer Application Considerations

| Property | Aluminum Foil | Copper Foil | Practical Impact for Transformers |

|---|---|---|---|

| Conductivity (%IACS) | 61% | 100% | Aluminum requires ~56% larger cross-section for equivalent current, offset by lower density |

| Density (g/cm³) | 2.70 | 8.96 | Aluminum windings are ~50% lighter, reducing core stress and structural support costs |

| Cost (Relative) | 1.0x | ~3.3x | Aluminum offers significant material cost advantage, crucial for large units |

| Thermal Expansion | 23.1 µm/m°C | 16.5 µm/m°C | Higher expansion in Al requires careful design for thermal cycling fatigue resistance |

Suppliers must demonstrate rigorous process control from molten metal purification through cold rolling, slitting, and surface treatment to ensure foil meets the exacting demands of modern transformer design. Traceability, metallurgical certification, and proactive quality management systems are fundamental requirements, not optional extras, in this high-stakes segment. Luoyang Xinzhaohe Aluminum leverages two decades of specialized production experience to deliver foil strip where dimensional precision, surface integrity, and mechanical property consistency are engineered into every meter, directly supporting transformer manufacturers in achieving maximum operational reliability and minimizing lifecycle costs.

Technical Specs: Aluminium Foil Strip

Technical Specifications for Aluminium Foil Strip – Transformer Applications

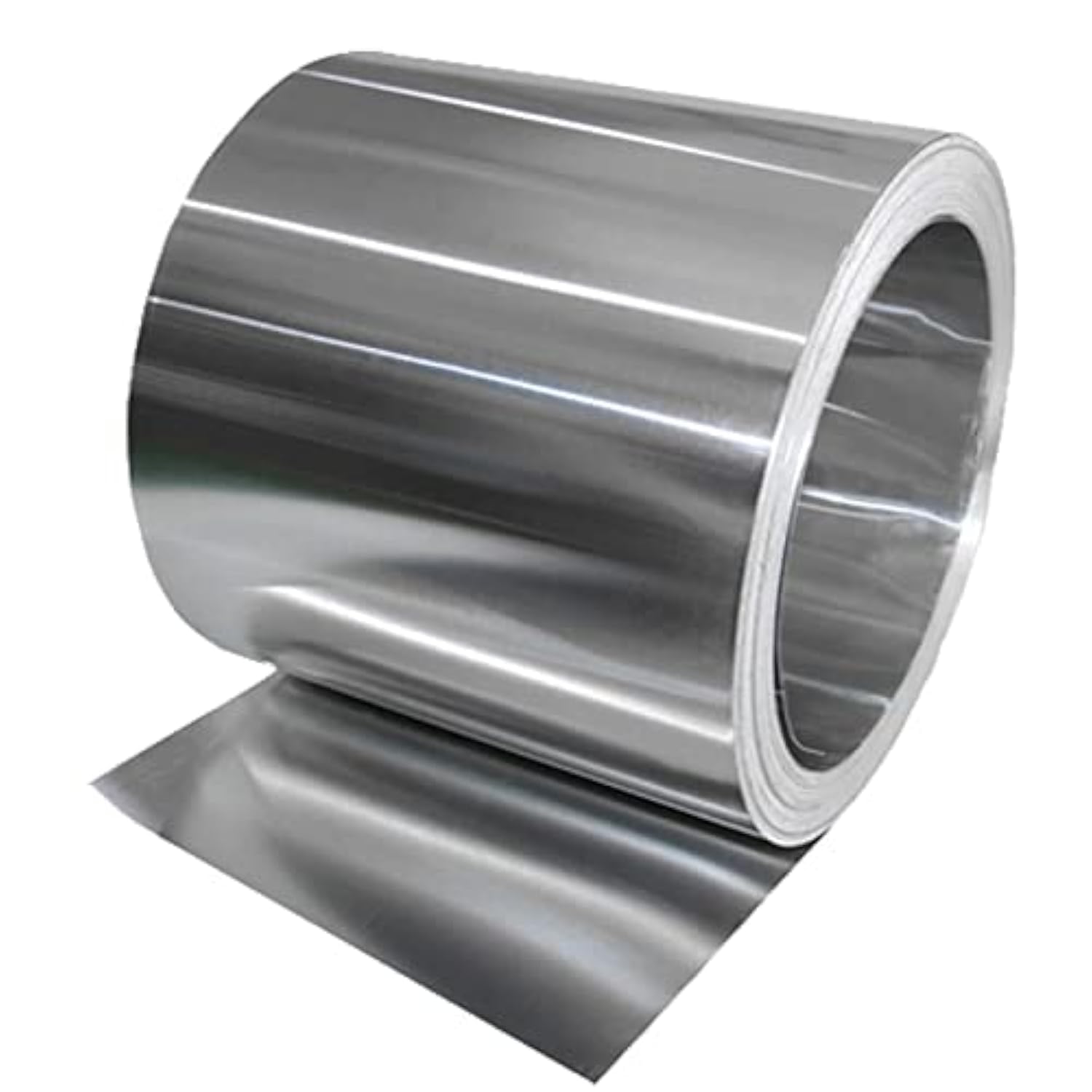

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision aluminium foil strip specifically engineered for use in transformer windings and related electrical applications. With over two decades of metallurgical and rolling process expertise, our production protocols ensure consistent dimensional accuracy, superior surface integrity, and optimal electrical performance. The following technical parameters define our standard offering for aluminium foil strip, designed to meet or exceed international quality benchmarks in the transformer industry.

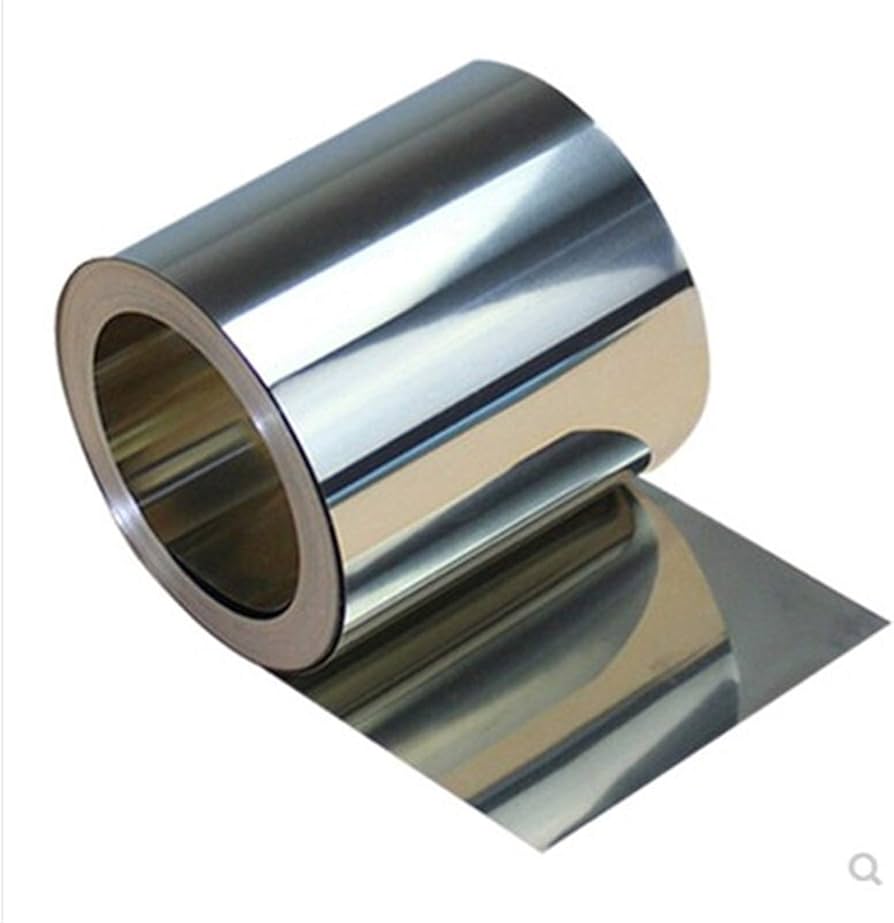

Dimensional control is critical in transformer foil applications to ensure uniform winding tension, thermal management, and dielectric stability. All aluminium foil strips are precision slit using advanced rotary shear slitting systems with automatic edge-guiding technology, achieving a slit width tolerance of ±0.002 mm. This level of precision minimizes edge misalignment during coil winding and reduces the risk of localized hotspots or insulation breakdown. Thickness tolerances are maintained within ±0.005 mm across the full coil length, with standard gauges ranging from 0.08 mm to 0.60 mm, depending on customer requirements and application load profiles.

Edge quality is a defining characteristic of our foil strip. Burr formation during slitting can compromise insulation systems and lead to partial discharge in high-voltage transformers. To eliminate this risk, all strips undergo in-line edge deburring and inspection via optical edge profiling. The result is a clean, burr-free edge with a smooth shear face, ensuring compatibility with enamel-coated and film-based insulation systems. Surface roughness (Ra) is maintained below 0.45 µm to support consistent varnish impregnation and reduce dielectric losses.

Electrical conductivity is measured in accordance with ASTM E1004 and reported as a percentage of the International Annealed Copper Standard (%IACS). Our high-purity aluminium alloy (1060, 1070, or 1350 as per ASTM B418) achieves a minimum conductivity of 61.0% IACS in the annealed (O-temper) condition. This ensures low resistive losses and high energy efficiency in transformer operation. Each production lot is tested using eddy current conductivity meters calibrated to NIST standards, with full traceability provided in the material test report.

Mechanical properties are equally critical. Tensile strength ranges from 60 to 85 MPa, with elongation exceeding 25%, enabling high-speed winding without cracking or necking. The foil is supplied in continuous coils with core diameters of 200 mm or 300 mm, and maximum coil weights up to 1,500 kg, depending on width and thickness.

| Parameter | Specification |

|---|---|

| Alloy Designation | 1060, 1070, 1350 (ASTM B418) |

| Temper | O (Annealed) |

| Thickness Range | 0.08 mm – 0.60 mm |

| Width Tolerance | ±0.002 mm |

| Thickness Tolerance | ±0.005 mm |

| Edge Quality | Burr-free, deburred, smooth shear face |

| Surface Roughness (Ra) | ≤ 0.45 µm |

| Electrical Conductivity | ≥ 61.0% IACS |

| Tensile Strength | 60 – 85 MPa |

| Elongation | ≥ 25% |

| Core Diameter | 200 mm, 300 mm |

| Max Coil Weight | 1,500 kg |

| Test Standard (Conductivity) | ASTM E1004, NIST-traceable |

All foil strips are subject to 100% eddy current inspection for subsurface defects and laminar inclusions. Packaging is moisture-resistant with protective interleafing to prevent surface oxidation during transit. Luoyang Xinzhaohe Aluminum Co., Ltd. supports full material certification, including COA and MTR documentation, ensuring compliance with ISO 9001 and IATF 16949 quality management systems.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Aluminum Foil Strip

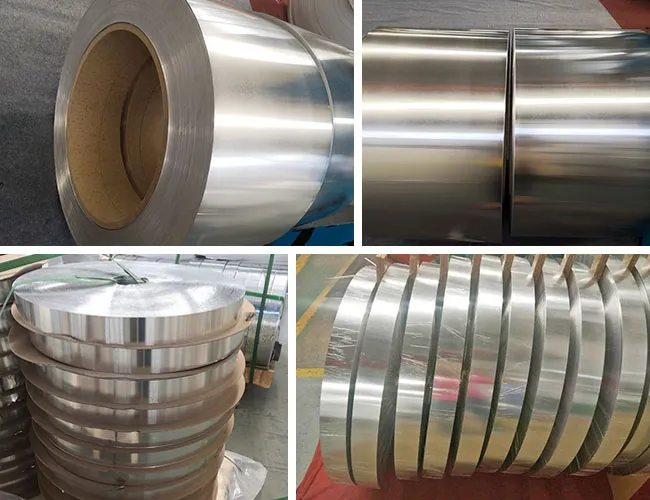

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized expertise in transformer strip production to deliver aluminum foil strip meeting stringent electrical and dimensional requirements. Our integrated manufacturing sequence begins with cold rolling, where high-purity aluminum ingots (99.7% min purity) undergo multi-pass reduction to achieve precise thickness tolerances of ±0.005 mm for gauges ranging from 0.05 mm to 0.5 mm. This stage utilizes computer-controlled rolling mills with tension leveling systems to eliminate edge waviness and ensure uniform metallurgical properties. Critical process parameters—including reduction ratio (typically 85–92% per pass), roll gap calibration, and interpass annealing—are monitored in real time via inline thickness gauges (beta-ray sensors) and surface inspection systems to detect micro-defects. Post-rolling, the strip undergoes continuous annealing in a controlled nitrogen-hydrogen atmosphere to optimize electrical conductivity (≥61% IACS) while maintaining mechanical stability for subsequent processing.

Precision slitting follows cold rolling to convert master coils into customer-specified widths, commonly between 5 mm and 300 mm for transformer applications. Our slitting lines employ servo-driven rotary shear cutters with micron-level positional accuracy (±0.02 mm) and active tension control to prevent width deviation or coil set. The process utilizes hardened tool steel blades with geometric edge profiles tailored to the aluminum alloy (typically 1060, 1070, or 1100 series), minimizing burr formation and edge deformation. Inline laser micrometers continuously validate width consistency, while eddy current sensors detect subsurface inclusions. Strips exceeding width tolerance thresholds (±0.1 mm for widths <50 mm; ±0.15 mm for wider strips) are automatically quarantined for rework.

Edge conditioning is a non-negotiable step for transformer foil strips, as sharp edges induce partial discharge and insulation degradation in windings. We implement dual-stage edge treatment: mechanical brushing with abrasive nylon wheels removes micro-burrs, followed by electrochemical deburring to achieve a controlled edge radius of 3–8 μm. This process eliminates stress concentrators that could initiate cracks during coil winding. Edge quality is verified using digital microscopy (200x magnification) and profilometry, with acceptance criteria limiting edge irregularity to ≤5 μm Ra.

Quality control is embedded at every phase through our ISO 9001-certified framework. Final inspection includes:

| Parameter | Test Method | Acceptance Criteria |

|---|---|---|

| Thickness | Micrometer (per ASTM B429) | ±0.005 mm |

| Tensile Strength | Universal Tester (ASTM E8) | 60–90 MPa |

| Elongation | Universal Tester (ASTM E8) | ≥2% |

| Surface Roughness | Profilometer (ISO 4287) | ≤0.4 μm Ra |

| Edge Radius | Optical Comparator | 3–8 μm |

All lots undergo 100% visual inspection for scratches, dents, or oxide streaks under controlled lighting. Certificates of Conformance detail chemical composition (OES analysis), mechanical properties, and dimensional data, ensuring traceability from ingot to shipment. This rigorous process guarantees foil strips with optimal winding performance, dielectric integrity, and thermal stability for high-efficiency transformers.

Packaging & Logistics

Export Packaging for Aluminum Foil Strip: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and international supply of transformer-grade aluminum and copper foil strip, we recognize that packaging is not merely a logistical necessity but a critical component of product integrity. Our export packaging protocol is engineered to withstand the rigors of sea freight, the dominant mode of global material transport, ensuring that our precision-engineered foil strips arrive at destination facilities in optimal condition.

All aluminum foil strip shipments destined for international markets are systematically secured on high-load-bearing wooden pallets. These pallets are constructed from kiln-dried, ISPM 15-compliant hardwood, providing structural stability and resistance to compression under stacked cargo conditions typical in containerized shipping. The use of wooden pallets further ensures compatibility with global handling infrastructure, including forklifts and automated warehouse systems, while minimizing the risk of deformation during loading and unloading operations.

Each coil of aluminum foil strip is first tightly wound onto a robust inner core, typically made of paper or aluminum, and then individually wrapped with multi-layer moisture-proof composite film. This film combines aluminum foil barrier layers with polyethylene substrates, offering superior resistance to water vapor transmission, saline air, and condensation—common challenges during prolonged maritime transit. The sealed envelope created around each coil prevents oxidation, surface staining, and the formation of white rust, all of which can compromise electrical performance and winding precision in transformer applications.

Following moisture sealing, the coils are firmly affixed to the wooden pallet using galvanized steel strapping and tensioned retention systems. Edge protectors are applied at critical stress points to prevent mechanical damage to coil edges during vessel motion or port handling. The entire palletized unit is then over-wrapped with UV-resistant stretch film to provide an additional layer of environmental shielding and to maintain load cohesion throughout the supply chain.

For containerized shipments, our packaging design conforms to ISO standard freight dimensions, enabling efficient stowage within 20-foot and 40-foot dry or refrigerated containers. Pallet configurations are optimized to minimize void space, reducing the potential for lateral shift during ocean transit. Furthermore, all export packages are labeled with durable, weather-resistant markings indicating product specifications, batch numbers, handling instructions, and destination data, ensuring full traceability and compliance with international customs and safety regulations.

This comprehensive packaging strategy reflects our commitment to delivering material excellence across global markets. By integrating robust materials, moisture mitigation, and structural integrity into every export shipment, Luoyang Xinzhaohe Aluminum ensures that our aluminum foil strip meets the exacting demands of transformer manufacturing, regardless of transit duration or climatic exposure.

Sourcing from Luoyang Xinzhaohe

Strategic Partnership with Luoyang Xinzhaohe Aluminum CO., Ltd

Partnering with Luoyang Xinzhaohe Aluminum CO., Ltd delivers unmatched technical assurance for critical transformer foil strip procurement. With over two decades of specialized metallurgical engineering and industrial-scale production, we provide transformer manufacturers with precision-engineered aluminum foil strips that meet the most stringent global performance and reliability standards. Our vertically integrated facility in Luoyang, China, combines deep materials science expertise with rigorous process control to eliminate supply chain vulnerabilities inherent in commodity sourcing.

Our core strength lies in metallurgical precision for electrical applications. We exclusively utilize high-purity 1xxx and 3xxx series aluminum alloys, with trace element control to ±0.01% for silicon and iron, ensuring optimal electrical conductivity (≥61.0% IACS) and thermal stability. Advanced homogenization and hot/cold rolling processes achieve micron-level dimensional consistency, critical for minimizing eddy current losses in transformer windings. Every production batch undergoes real-time X-ray fluorescence spectroscopy and mechanical property validation per ASTM E527 and IEC 60204 standards.

Manufacturing excellence is anchored in our 2,800mm-wide cold rolling mills with laser-guided thickness control systems. This enables consistent production of foil strips from 0.10mm to 3.00mm in thickness, with tolerances held to ±0.002mm. Surface integrity is maintained through proprietary cleaning and annealing protocols, achieving Ra values ≤0.25μm to prevent dielectric breakdown. Edge quality is controlled to burr heights <5μm, eliminating winding defects. The following table summarizes our technical benchmarking against industry norms

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.002mm |

| Surface Roughness (Ra) | ≤0.40μm | ≤0.25μm |

| Edge Burr Height | <10μm | <5μm |

| Tensile Strength | 70-90 MPa | 80-100 MPa |

Supply chain resilience is engineered through dual-sourcing of primary aluminum ingots from certified smelters and in-house slitting capacity exceeding 15,000 tons annually. Our ISO 9001 and IATF 16949-certified quality management system includes full material traceability via blockchain-enabled lot tracking, from raw material certification to final shipment documentation. This eliminates counterfeiting risks and ensures compliance with REACH and RoHS directives. Just-in-time logistics coordination reduces inventory holding costs for global clients, with dedicated export management for FCL/LCL shipments to major transformer hubs in Europe, North America, and Southeast Asia.

For transformer OEMs, material failure is not an option. Luoyang Xinzhaohe’s integration of metallurgical rigor, precision manufacturing, and supply chain transparency delivers foil strips that enhance transformer efficiency ratings and extend operational lifespan. We invite engineering and procurement teams to validate our capabilities through material certification packages and production facility audits. Contact Cathy Zhang, Sourcing Manager, at cathy@transformerstrip.com to initiate technical discussions or request sample reels for performance benchmarking against your specifications. Partner with us to secure a mission-critical component supplier committed to your long-term production stability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil strip directly from China.