Table of Contents

Market Insight: Aluminium Foil Importer

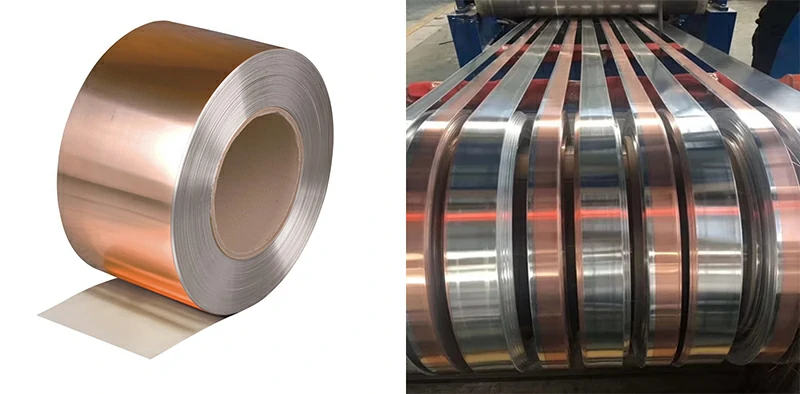

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for aluminum and copper transformer strip/foil remains robust, driven by continuous expansion and modernization of electrical infrastructure. Power distribution networks, particularly in emerging economies, require vast quantities of distribution and power transformers, where aluminum foil dominates the low-voltage winding segment due to its favorable cost-to-conductivity ratio and lighter weight compared to copper. Stringent international energy efficiency regulations (e.g., DOE 2016 in the US, Ecodesign Directive 2009/125/EC in the EU) are primary catalysts, mandating reduced no-load and load losses in new transformers. This directly increases the demand for high-purity, precisely manufactured aluminum foil, as even minor deviations in material properties significantly impact core and winding losses. Aluminum’s market share in transformer windings continues to grow, especially in distribution transformers above 250 kVA, where its 60-65% conductivity relative to copper is economically viable against its ~30% lower density and material cost.

Material quality is not merely a specification checkbox; it is a fundamental determinant of transformer reliability, efficiency, and operational lifespan. Aluminum foil for transformer windings must meet exceptionally stringent metallurgical and dimensional criteria. Electrical conductivity, directly tied to aluminum purity (typically requiring min. 99.7% Al for electrical grade), is paramount. Impurities like iron and silicon increase electrical resistivity, elevating I²R losses and reducing overall transformer efficiency. Surface integrity is equally critical; microscopic scratches, pits, or residual rolling oil contaminants act as initiation points for partial discharges under high electrical stress, potentially leading to dielectric breakdown of the insulation system and catastrophic transformer failure. Dimensional consistency—thickness tolerance (often ±2.5% or tighter), edge camber, and flatness—is non-negotiable for automated winding processes. Variations cause uneven tension, layer misalignment, and compromised insulation integrity, increasing the risk of inter-turn faults. Inadequate annealing control results in inconsistent mechanical properties, leading to foil breakage during winding or long-term dimensional instability under thermal cycling.

The consequences of substandard foil are severe and costly for end-users. Poor conductivity directly violates efficiency standards, incurring regulatory penalties and higher lifetime energy costs. Surface defects or dimensional inaccuracies accelerate insulation degradation, drastically shortening transformer service life and triggering unplanned, expensive outages. Importers sourcing foil must prioritize suppliers with proven metallurgical expertise, rigorous in-process quality control (including continuous conductivity monitoring and 100% surface inspection), and adherence to international standards like IEC 60137. Market volatility and the emergence of new, less experienced producers heighten supply chain risks; inconsistent quality from such sources translates directly into performance variability and reliability risks for transformer manufacturers. For aluminum foil importers, partnering with a supplier possessing 20+ years of specialized transformer foil production, like Luoyang Xinzhaohe Aluminum, mitigates these risks by ensuring consistent material properties essential for meeting modern grid demands and avoiding the hidden costs of premature transformer failure. The table below summarizes key comparative properties:

| Property | Aluminum Foil | Copper Foil |

|---|---|---|

| Relative Conductivity | 60-65% IACS | 100% IACS |

| Density (g/cm³) | ~2.7 | ~8.9 |

| Typical Cost Ratio | 1.0 (Reference) | ~2.5 – 3.0 |

| Primary Application | LV Windings (Dominant) | HV Windings, Specialized |

Technical Specs: Aluminium Foil Importer

Technical Specifications for Precision Transformer Strip and Foil – Aluminium

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-performance aluminium foil and strip products engineered specifically for transformer applications, where electrical efficiency, dimensional precision, and edge quality are critical. With over two decades of metallurgical and manufacturing expertise, we ensure strict adherence to international standards and customer-specific technical requirements. Our transformer-grade aluminium foils are produced from high-purity alloys, primarily 1060, 1070, and 1100 series, to maximize electrical conductivity while maintaining mechanical integrity during winding and insulation processes.

Dimensional precision is paramount in transformer foil performance. Our advanced slitting technology ensures a slit width tolerance of ±0.002 mm, enabling consistent layer alignment and minimizing interlayer stress in wound cores. This level of accuracy reduces the risk of partial discharge and enhances thermal stability under high-load conditions. The foil is processed under controlled tension and environmental conditions to prevent edge waviness, camber, or dimensional drift across extended coil lengths.

Edge quality directly influences insulation reliability and dielectric strength. All foils are slit using high-precision tungsten carbide rotary knives and undergo in-line edge inspection to guarantee burr-free edges. Burr height is maintained below 3 µm, verified through profilometric analysis. This minimizes the risk of insulation puncture and ensures compatibility with kraft paper, polymer films, and resin-impregnated insulation systems used in dry-type and oil-immersed transformers.

Electrical conductivity is a core performance metric. Our aluminium foils achieve a minimum conductivity of 59.5% IACS (International Annealed Copper Standard) in the annealed (O) temper condition, meeting or exceeding ASTM B418 and IEC 60167 requirements. Conductivity is monitored batch-wise using eddy current testing and validated via four-point probe DC resistivity measurements. Trace alloying elements such as iron and silicon are tightly controlled to below 0.25% and 0.15%, respectively, to preserve electron mobility and reduce resistive losses.

Mechanical properties are optimized for high-speed winding operations. Typical tensile strength ranges from 60 to 85 MPa with elongation of 25–35%, ensuring flexibility without cracking or necking during tight-radius coiling. Surface finish is maintained at Ra ≤ 0.4 µm to promote uniform resin wetting and adhesion in vacuum pressure impregnation (VPI) processes.

All foils are supplied in coil form, with core diameters of 200 mm, 300 mm, or 508 mm per customer request. Maximum coil weight is 3,000 kg, with outer diameter up to 1,600 mm. Each coil is protected with anti-corrosion wrapping and edge protectors to maintain integrity during international shipment.

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Series | 1060, 1070, 1100 | GB/T 3190, ASTM B209 |

| Temper | O (Annealed) | — |

| Thickness Range | 0.08 mm – 3.0 mm | GB/T 3880 |

| Slit Width Tolerance | ±0.002 mm | ISO 2174 |

| Edge Burr Height | ≤ 3 µm | ISO 8501-1 (profilometry) |

| Conductivity (min) | 59.5% IACS | ASTM E1004, IEC 60468 |

| Tensile Strength | 60–85 MPa | GB/T 228.1 |

| Elongation | 25–35% | GB/T 228.1 |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

| Core Diameter | 200 mm, 300 mm, 508 mm | Customer Specification |

| Max Coil OD | 1,600 mm | — |

| Max Coil Weight | 3,000 kg | — |

Factory Tour: Manufacturing

Transformer Foil Manufacturing Process at Luoyang Xinzhaohe Aluminum

Luoyang Xinzhaohe Aluminum CO., Ltd employs a rigorously controlled sequential manufacturing process for transformer strip and foil, ensuring the dimensional precision, surface integrity, and mechanical properties demanded by high-voltage and distribution transformer applications. Our 20+ years of metallurgical expertise is embedded within each critical stage, starting with cold rolling.

Cold rolling forms the foundational stage, where pre-annealed aluminum or copper alloy ingot is reduced to the target foil thickness, typically ranging from 0.08mm to 0.30mm for transformer windings. This process utilizes multi-stand tandem mills operating under precise tension control to achieve uniform thickness tolerance, critical for consistent dielectric performance. Simultaneously, the rolling parameters are meticulously managed to control grain structure and mechanical properties, optimizing the material for subsequent slitting and winding. Surface quality is paramount; in-line high-resolution surface inspection systems continuously monitor for defects such as scratches, dents, or inclusions, triggering automatic rejection of non-conforming sections. Thickness is verified in real-time using beta-gauge or X-ray measurement systems, with data fed back to the mill control for immediate adjustment, maintaining thickness tolerances within ±2% of nominal.

Following cold rolling, precision slitting transforms the master coil into the specific widths required by transformer manufacturers. This operation utilizes advanced slitting lines equipped with high-precision razor blades or shear cutters mounted on rigid arbors. Width tolerance is controlled to within ±0.1mm, a non-negotiable specification for ensuring tight, uniform winding layers without edge buckling or gaps. Laser micrometers continuously measure slit width across the foil web, providing instantaneous feedback to the line control system. Tension control throughout the slitting process is critical to prevent edge wave or center buckle, which could compromise downstream winding. Each slit strand undergoes continuous edge monitoring to detect any burr formation or irregularities introduced during cutting.

Edge conditioning represents a vital, often overlooked step specific to transformer foil performance. Immediately after slitting, the foil edges pass through dedicated conditioning units. These units employ precision brushing, grinding, or controlled rolling to remove micro-burrs and achieve a consistent, smooth edge radius. This process is essential to prevent damage to the delicate insulating paper or film wrapped between winding layers during transformer coil assembly. Any sharp edge or protrusion can puncture the insulation, creating a potential short-circuit path and catastrophic transformer failure. Post-conditioning, edge profile verification is performed using optical edge scanners or profilometers to confirm the absence of burrs and adherence to the specified edge radius.

Quality control is intrinsically integrated throughout the entire production flow, not confined to final inspection. Key verified parameters include:

| Parameter | Measurement Method | Target Tolerance | Criticality for Transformers |

|---|---|---|---|

| Thickness | Beta Gauge / X-ray | ±2% nominal | Uniform dielectric strength |

| Width | Laser Micrometer | ±0.1mm | Precise winding layer alignment |

| Edge Radius | Optical Profilometer | 0.02-0.05mm | Prevents insulation puncture |

| Surface Defects | High-Resolution Scanner | Zero tolerance | Avoids partial discharge initiation |

| Tensile Strength | Destructive Test (Sample) | Per ASTM B928 | Ensures winding integrity |

This integrated approach, combining advanced process control with embedded QC checkpoints, guarantees that every meter of Xinzhaohe transformer foil meets the stringent reliability requirements of global power infrastructure.

Packaging & Logistics

Export Packaging for Transformer Strip and Foil – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in manufacturing high-purity aluminum and copper transformer strips and foils, we recognize that product integrity must be preserved from production line to final delivery. This is especially critical for export shipments, where extended transit durations, fluctuating climatic conditions, and multiple handling stages increase the risk of material degradation. Our export packaging system is engineered to meet international logistics standards, ensuring that transformer-grade conductive materials arrive at their destination in optimal condition.

All transformer strip and foil coils are mounted on robust wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to support heavy loads, resist deformation during stacking, and withstand the rigors of containerized ocean freight. The structural integrity of the pallets prevents coil distortion during lifting, transport, and storage, which is essential for maintaining dimensional accuracy and flatness—key parameters for downstream processing in transformer manufacturing.

Each coil is individually wrapped with multi-layer moisture-proof composite film, featuring a metallized barrier layer that provides high resistance to water vapor transmission. This vapor barrier is critical in preventing oxidation and surface corrosion, particularly during prolonged sea voyages through tropical and humid zones. The film is heat-sealed at all seams to ensure a hermetic enclosure, further enhanced by the inclusion of desiccant packs within the packaging cavity to absorb any residual moisture.

To prevent mechanical damage, edge protectors made of high-density polyethylene are affixed to the leading edges of the coils. These protectors absorb impact energy and reduce the risk of dents or burrs during handling. Additionally, all packaged units are secured with steel or PET strapping, tensioned to industrial specifications, to prevent lateral movement or coil shift within the container.

Labeling is conducted in accordance with international shipping regulations, with each package displaying essential information including coil identification number, alloy type, temper, dimensions, net and gross weight, batch number, and handling instructions. All labels are laminated for weather resistance and affixed in multiple locations to ensure visibility post-transport.

Our packaging protocol is validated through internal quality audits and real-world performance tracking across major trade routes, including Asia-Europe, Trans-Pacific, and Middle East corridors. By integrating structural durability, environmental protection, and compliance readiness, Luoyang Xinzhaohe ensures that every shipment of transformer strip and foil meets the highest standards of reliability and safety in sea freight logistics.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Strategic Source for Precision Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise and vertically integrated manufacturing to deliver transformer strip and foil meeting the most stringent global electrical industry demands. Our 120,000 square meter facility in Luoyang, Henan Province, operates 18 dedicated cold rolling lines and 15 continuous annealing lines, providing an annual production capacity exceeding 80,000 metric tons specifically for electrical conductor applications. This scale is underpinned by rigorous process control systems ensuring consistent output critical for transformer core laminations and winding foils.

Metallurgical precision defines our core competency. We maintain strict control over grain structure, surface finish, and electrical properties through optimized homogenization, precision cold rolling, and recrystallization annealing profiles. All aluminum transformer foil (primarily 1060, 1070, 1100 alloys) undergoes 100%在线 eddy current testing for conductivity uniformity and surface defect detection, guaranteeing conductivity levels of 59.0-61.0% IACS with tolerances held to ±0.5% IACS. Copper strip production utilizes oxygen-free electrolytic tough pitch (ETP) copper, processed under controlled atmospheres to achieve conductivity ≥100% IACS and surface roughness Ra ≤0.4 µm, minimizing interlayer losses in wound components. Our in-house metallurgical laboratory, certified to ISO/IEC 17025, conducts daily microstructure analysis, tensile testing, and chemical composition verification against ASTM B498/B230 standards.

Our supply chain infrastructure is engineered for reliability and responsiveness. We source primary aluminum billets exclusively from certified smelters adhering to LME purity specifications, maintaining strategic raw material buffers to mitigate market volatility. Integrated slitting and tension leveling capabilities allow us to deliver slit widths from 10mm to 2000mm with edge camber tolerance ≤0.3mm/m, directly meeting customer coil size requirements. Logistics coordination includes dedicated container loading supervision, real-time shipment tracking, and full documentation compliance for seamless global customs clearance. This operational discipline results in a documented on-time delivery rate of 98.7% across our international client base.

Key technical specifications consistently achieved by Luoyang Xinzhaohe are summarized below:

| Material Type | Typical Thickness Range | Conductivity | Surface Roughness (Ra) | Tensile Strength | Key Standard Compliance |

|---|---|---|---|---|---|

| Aluminum Foil | 0.08mm – 0.50mm | 59.0-61.0% IACS (±0.5%) | ≤0.8 µm | 60-90 MPa | ASTM B498, IEC 60137 |

| Copper Strip | 0.10mm – 3.00mm | ≥100% IACS | ≤0.4 µm | 200-250 MPa | ASTM B230, IEC 60468 |

Partnering with Luoyang Xinzhaohe provides access to engineered material solutions backed by deep process knowledge and uncompromising quality systems. We collaborate closely with transformer manufacturers to resolve material-related performance issues and optimize specifications for specific core designs. For technical consultation on reducing core losses or improving foil handling efficiency in your production line, contact our export team. Submit your specific requirements or request a metallurgical capability dossier to Cathy at cathy@transformerstrip.com for a dedicated sourcing assessment.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil importer directly from China.