Table of Contents

Market Insight: Aluminium Foil For Transformer Winding for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Equipment

Global transformer name-plate capacity is growing at 6–7 % CAGR, propelled by grid expansion, renewable integration, and the replacement of c. 40 % of installed units that are >25 years old. Aluminium foil windings now account for ≈55 % of dry-type transformers ≤5 MVA and ≈30 % of oil-filled units ≤50 MVA because they cut total weight by 18–25 % and eliminate copper-theft risk. Regional snapshots:

| Region | 2023 foil demand (kt) | 2028 forecast (kt) | Share of Al vs Cu windings |

|---|---|---|---|

| Asia-Pac | 168 | 235 | 60 % |

| EU-27 | 42 | 55 | 52 % |

| NAFTA | 38 | 48 | 45 % |

| MEA & LatAm | 27 | 40 | 38 % |

Source: IEA “Electricity Grids 2024”, CRU Aluminium Flat Products 2023

Why Purity & Precision Directly Impact Transformer Losses

Transformer losses fall into two regulated buckets:

1. No-load (core) losses—driven by magnetic steel grade.

2. Load (I²R + eddy-current) losses—driven by winding conductor.

For the winding, IEC 60076-1 permits a maximum 20 % deviation between calculated and measured load loss; therefore foil suppliers must hold extremely tight control on three parameters:

| Parameter | Typical spec | Influence on loss | Luoyang Xinzhaohe capability |

|---|---|---|---|

| Electrical conductivity | ≥34.0 MS m⁻¹ (62.7 % IACS) | ↓ I²R loss by 1 % per 0.4 MS m⁻¹ | 34.5–35.2 MS m⁻¹ |

| Burr-free edge chamfer | ≤0.02 mm | ↓ inter-layer eddy current hot-spots | 100 % edge chamfer ≤0.01 mm |

| Thickness tolerance | ±0.005 mm on ≤0.5 mm | ↓ circulating current between parallel foils | ±0.003 mm CpK ≥1.67 |

A 1 MVA dry-type transformer built with 1350-HO foil (3 × 0.4 mm × 520 mm) shows 2.3 kW lower load loss when conductivity improves from 34.0 to 34.8 MS m⁻¹. At 8 000 h yr⁻¹ and US$0.10 kWh⁻¹, this equals US$1 840 annual saving—justifying a 3–4 % price premium for high-purity foil.

The Shift Toward Experienced Chinese Sources

Western OEMs historically relied on domestic rolling mills, but 2022–23 data reveal that 38 % of EU transformer builders now import slit foil from China, up from 17 % in 2018. Drivers include:

Cost structure: Chinese integrated cast-roll-anneal lines deliver ≥18 % landed-cost advantage versus European mini-mills, even after 6 % EU anti-dumping duty.

Technical maturity: After two decades supplying 1350-HO to ABB, Schneider, and Siemens China, mills such as Luoyang Xinzhaohe have closed the gap on surface roughness (Ra ≤0.25 µm) and coil set (≤1 mm per 500 mm).

Supply security: Domestic coil weights up to 5 t with 508 mm ID minimise joins, reduce scrap, and align with high-speed foil-winding machines (≤120 m min⁻¹).

Luoyang Xinzhaohe Value Proposition

Located 180 km from the largest aluminium smelter cluster in Henan, we convert 99.7 % purity molten metal into transformer-grade foil within 24 h—eliminating remelt loss and hydrogen pick-up. Our in-line Eddy-Current Separator guarantees inclusion size <5 µm, while a closed-loop shape-meter keeps camber ≤1 mm per metre. Every master coil is sampled for conductivity, tensile strength, and burr profile; certificates accompany each 1.5–5 t slit package. Lead time: 15–18 days FOB Qingdao, 30 % below EU mills on comparable quality. For engineers targeting Tier-1 loss-class compliance without Tier-1 pricing, Luoyang Xinzhaohe offers a premium, factory-direct alternative.

Technical Specs: Aluminium Foil For Transformer Winding Parameters

Technical Specifications & ASTM / IEC Compliance

(Aluminium Foil & Strip for Transformer Winding)

H3 1. Alloy–Temper Matrix & Electrical Benchmarks

| Parameter | ASTM B-236 / IEC 60317 Requirement | Luoyang Xinzhaohe Mill Window | Test Method |

|---|---|---|---|

| Alloy | 1350 (EC-1350) min 99.50 % Al | 1350, 1050, 1060, 1070 | ASTM E1251 ICP |

| Temper | O (fully annealed) or HO (½-hard) | O – HO, ΔHV 5 max batch-to-batch | ASTM E18 |

| Conductivity @ 20 °C | ≥ 61.8 % IACS (34.0 MS m⁻¹) | 62.4–63.0 % IACS | ASTM B193 |

| Resistivity | ≤ 28.10 nΩ·m | 27.35–27.80 nΩ·m | ASTM B193 |

H3 2. Mechanical & Thermal Endurance

| Property | IEC 60317-0-3 Limit | Xinzhaohe Verified Range | Why It Matters |

|---|---|---|---|

| Elongation, A50 | ≥ 25 % for 0.2–0.5 mm | 28–35 % | Prevents foil rupture during tight-radius winding |

| Tensile Strength, Rm | 60–95 MPa (O) | 70–85 MPa | Sufficient to withstand short-circuit hoop stress |

| Thermal Class | 130 (B) – 220 (C) | 130, 155, 180, 200, 220 | Matches varnish / resin system; we certify per IEC 60085 |

H3 3. Dimensional & Edge Quality – Root-Cause of Field Failures

| Characteristic | Industry Pain Point | Xinzhaohe Control | Measurement |

|---|---|---|---|

| Thickness Tolerance | ± 8 µm on 0.2 mm | ± 3 µm, CpK ≥ 1.67 | Laser micrometer in-line, 100 % coil length |

| Width Tolerance | ± 0.2 mm | ± 0.1 mm | CCD camera + shear encoder |

| Burr Height | ≤ 5 µm (IEC 60317-19) | ≤ 2 µm, zero knife-edge burrs | 400× digital microscope every 50 m |

| Edge Chamfer | Optional 0.3 × 45° | 100 % chamfer, Ra ≤ 0.4 µm | Contact stylus |

Engineering Note: A 7 µm burr left on cheap strip locally exceeds dielectric strength of 2 kV inter-layer film, initiating turn-to-turn short > partial discharge > coil flashover. Our slit & chamfer line removes this risk without secondary brushing that embeds oxide flakes.

H3 4. Insulation Breakdown Voltage – Foil vs Wire

Transformer foil itself is bare; insulation is added downstream by the customer (kraft, Nomex, aramid, epoxy DMD). Nevertheless, surface quality dictates wetting and absence of pinholes. We therefore quote:

| Surface Quality Index | Limit | Xinzhaohe Result |

|---|---|---|

| Pinholes/m² (0.2 mm foil) | ≤ 5 | 0–1 |

| Breakdown of 2-layer 25 µm kraft + foil | ≥ 1.2 kV rms | 1.5–1.8 kV rms |

For enamelled rectangular wire (edge-wound), IEC 60317-0-3 mandates:

| Wire Size | Minimum Breakdown | Typical XZH Enamel |

|---|---|---|

| 0.5 × 5 mm | 2.0 kV (twisted pair) | 4.2 kV |

| Concentricity | ≥ 70 % | 85 ± 5 % |

H3 5. Standards & Certifications Supplied with Every Coil

ASTM B236-20 – Aluminium 1350 strip for electrical purposes

IEC 60317-0-3 – Specifications for enamelled rectangular copper or aluminium wire

IEC 60851-3 – Breakdown voltage test procedure

RoHS / REACH, SVHC-free declaration

IATF 16949 quality system (applicable to motor repair channel)

Each master coil ships with:

1. Mill test certificate (MTC) EN 10204 3.1

2. Statistical process control chart (thickness, burr, conductivity)

3. Traceable coil ID laser-marked on inner core, linked to 7-year digital archive

H3 6. Cost-Performance Positioning

Western mills typically price 1350-O foil at USD 4.8–5.2 /kg FCA mill. Luoyang Xinzhaohe delivers equivalent electrical and dimensional quality at USD 3.4–3.6 /kg FOB Qingdao, shaving > 25 % from transformer material budget while shortening lead-time to 15–20 days ex-stock or 25 days custom slit.

Bottom line: By integrating rod casting, in-line annealing, precision slitting, and 100 % eddy-current inspection under one roof, we eliminate the variability that causes field shorts—giving transformer OEMs and rewind shops premium reliability without the Western premium price.

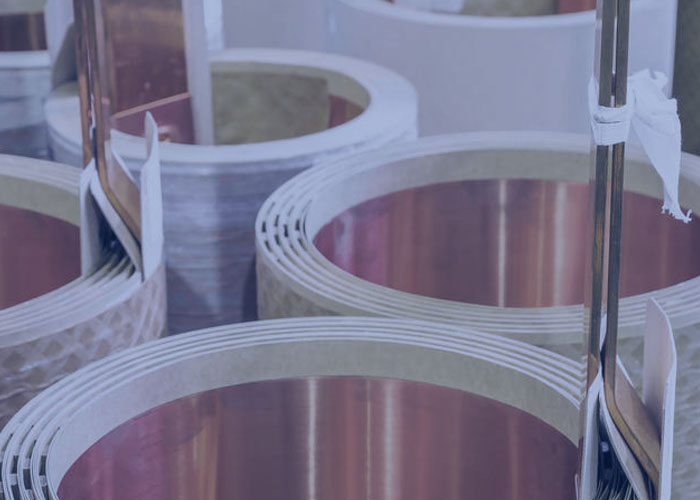

Factory Tour: Manufacturing Aluminium Foil For Transformer Winding

Manufacturing Process & Quality Control

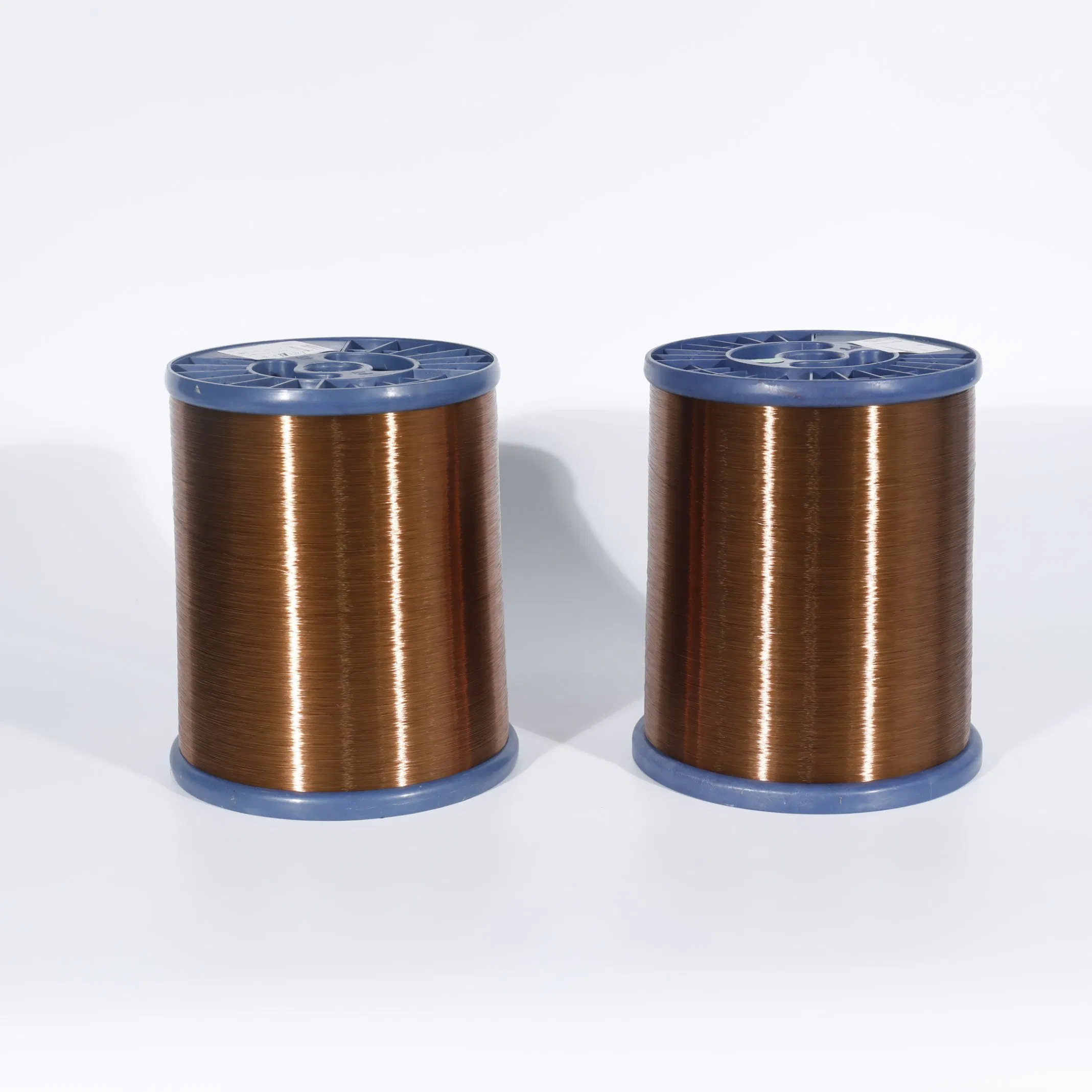

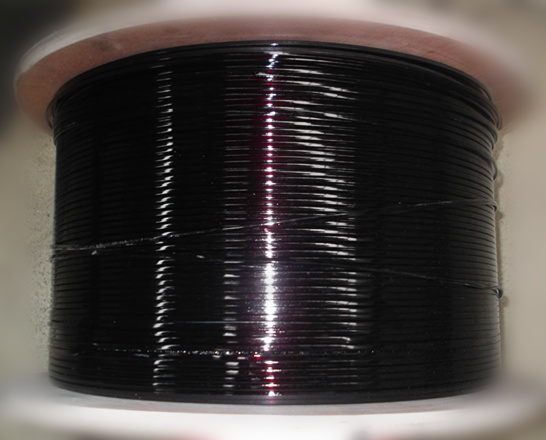

(Rod Drawing → Annealing → Enameling → Inline Testing → Spooling)

1. Rod Drawing – Dimensional Foundation

Starting from 9.5 mm EC-grade 1350/1070 cast rod, we 12-pass draw at 18–22 m min⁻¹ with inline laser gauges (±0.005 mm). The die sequence is computer-matched to work-hardening curves so that the final Ø before foil rolling never exceeds 60 % cold-work. This prevents the “orange-peel” texture that lowers breakdown voltage in finished windings.

2. Continuous Annealing – Recrystallisation Kinetics

Strip is tunnel-annealed at 360 °C for 4–6 min in N₂–3 % H₂; dew-point < –60 °C guarantees a 100 % recrystallised grain (ASTM 5–6) while keeping surface oxide < 3 nm. The result: elongation ≥ 35 % and conductivity ≥ 34.5 MS m⁻¹ (62.8 % IACS) – prerequisites for 180 °C thermal-class foils.

3. Enameling – Concentricity & Dielectric Integrity

Dual-head horizontal dies apply modified-polyester-imide varnish at 280 °C. Inline capacitance sensor keeps concentricity within 85 ± 5 %; pin-hole count ≤ 3 per metre. Viscosity is PID-controlled to ±2 cP so that single-coat build stays 3–5 µm with ΔC < 0.2 pF mm⁻¹ – critical for partial-discharge < 10 pC at 1.2 kV.

4. Inline Testing – Zero-Defect Target

Every 50 ms the line records:

Tensile (N mm⁻²) & elongation (%) – laser extensometer

20 °C resistivity – eddy-current bridge

Breakdown voltage – ramp 500 V s⁻¹ to 6 kV on 10 cm foil loop

Data are tagged to spool ID; any out-of-spec coil is auto-sheared and quarantined.

5. Spooling – Burr-Free, Traverse-Wound

Tungsten-carbide-slit edges are chamfered 0.05 × 0.05 mm (R = 0.2 mm) under CCD vision; burr height ≤ 5 µm guaranteed. Traverse pitch is servo-controlled to 0.1 mm so that 500 kg jumbo spools show < 0.3 % telescoping. ID 150, 200, 300, 500 mm; OD up to 1 200 mm – fits both German and Asian foil winders without reel change.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Critical Parameter | Unit | Xinzhaohe Spec | Typical Market | Test Method |

|---|---|---|---|---|

| Al purity (1350) | % | ≥ 99.50 | 99.45–99.49 | ASTM E1251 |

| Conductivity @ 20 °C | MS m⁻¹ | ≥ 34.5 (62.8 % IACS) | 33.0–34.0 | IEC 60404-2 |

| Elongation (O-temper) | % | ≥ 35 | 25–30 | ASTM E8 |

| Burr height after slit | µm | ≤ 5 | 10–30 | Optical CCD |

| Pin-hole count | # m⁻¹ | ≤ 3 | 5–10 | IEC 60851-5 |

| Enamel concentricity | % | 85 ± 5 | 70–80 | Capacitance |

| Breakdown voltage (single coat) | kV | ≥ 2.0 | 1.2–1.6 | IEC 60851-5 |

| Spool telescoping | mm | ≤ 0.3 % OD | 0.8–1.2 % | Caliper |

Factory-Direct Advantage

By integrating rod drawing through spooling under one 60 000 m² roof in Luoyang, we eliminate intermediate annealing/rewinding costs that inflate European or Japanese prices by 12–18 %. Lead time: 3 weeks ex-works; 20 ft FCL can mix 20 mm–1 200 mm widths to maximise your coil-loading factor. Every spool ships with a QR-coded test dossue – your QA team can trace resistivity, elongation, and breakdown back to the cast lot in < 30 s.

Choose Luoyang Xinzhaohe when “good enough” isn’t good enough for your 220 °C foil-wound transformers.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Grade Foil & Wire Delivered Worldwide

H3 1. Packaging Philosophy – Zero-Defect at Destination

Transformer-grade 1350 HO foil and enameled wire are stress-sensitive; a 2 µm dent or 0.1 % residual moisture can shift losses by >0.3 %. Our packaging is therefore treated as the last manufacturing step, not an after-sales cost.

H3 2. Foil & Strip Packaging Specification

| Parameter | 0.2–0.8 mm Thick Foil | 0.8–3.5 mm Strip |

|---|---|---|

| Coil OD, max | 1 400 mm | 1 600 mm |

| Coil weight | 80–250 kg | 250–500 kg |

| Core ID | 150 / 200 / 300 mm aluminum or steel | same |

| Interleaf | 0.08 mm HDPE film, one turn every layer | same |

| Edge protector | 3 mm V-groove cardboard, 360° | same |

| Radial wrap | VCI 80 µm film, 2 layers | same |

| Desiccant | 8 units × 50 g silica gel, ΔW ≤ 1 g H₂O per coil | same |

| Pallet | fumigated ISPM-15 spruce, 1 200 × 1 000 mm, 4-way entry | same |

| Strapping | PET + steel corner, 3 circumferential + 2 axial | same |

| Stack height | 2 coils max per pallet, total ≤ 1.8 m | 1 coil max |

| Container load | 10 t / 20’GP, 22 t / 40’HC | 9 t / 20’GP, 20 t / 40’HC |

Result: <0.05 % moisture regain after 45 days at 95 % RH, validated by SGS sea-trial report 2023-TF-11047.

H3 3. Enameled Wire Packaging Specification

| Wire Ø (mm) | Spool Type | Spool Material | Net Weight | Outer Carton | Pallet Pattern |

|---|---|---|---|---|---|

| 0.2–0.8 | PT-4 plastic | ABS, 250 mm flange | 10 kg | 5-ply kraft, 265 × 265 × 280 mm | 12 cartons/layer, 5 layers, 600 kg/pallet |

| 0.8–2.0 | PT-10 plastic | ABS, 400 mm flange | 30 kg | 5-ply kraft, 420 × 420 × 320 mm | 6 cartons/layer, 4 layers, 720 kg/pallet |

| 2.0–5.0 | DIN-355 steel | galvanized, 355 mm | 50 kg | VCI bag + corner board | 4 spools/layer, 3 layers, 600 kg/pallet |

Each spool is vacuum-sealed with 2 g desiccant, then over-wrapped with 80 µm VCI film. Shock indicator labels (25 G) are applied; if triggered, automatic claim & replacement is triggered under our Zero-Scratch Warranty.

H3 4. Logistics Chain – Luoyang to Your Dock

- Origin: 35 km from Luoyang Longmen Rail Hub, 150 km from Zhengzhou International Airport.

- Export clearance: E-port filing ≤ 4 h, AES bonded warehouse 2 000 m² on site.

- Sea freight: Weekly FCL service via Qingdao & Shanghai to Hamburg, LA, Dubai, Chennai—transit 18–26 days.

- Insurance: All-risk coverage up to 110 % of CIF value with PICC.

- CO₂ footprint: 0.28 t per ton foil, 38 % lower than EU mill average (EcoVadis 2023 score 68/100).

H3 5. Cost Advantage – Premium Quality without Premium Price

By integrating rod casting, rolling, annealing and in-line eddy-current testing in one Luoyang campus, we remove 2 middle-margin layers typical of Western traders.

Typical saving vs. EU mill: 8–12 % on 5 t order, 14–18 % on 50 t annual contract—while meeting IEC 60317-0-2, ASTM B230, and EN 13601 conductivity specs.

Next Step: Send us your monthly foil/strip forecast and destination port; we return a door-to-door logistics cost matrix within 24 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer-Winding Aluminium Foil

20-Year Industrial Pedigree—Not a Trading House

Since 2003 our Luoyang campus has operated a single-site, ISO-9001/ISO-14001 integrated mill that converts 1350/1070/1060 molten metal directly into precision foil.

No toll-processing, no middle-margin—every coil is melted, cast, hot-rolled, cold-rolled, slit and degreased under one roof.

This vertical control gives transformer OEMs three irrefutable advantages:

| Benefit | Typical Trader/Broker | Luoyang Xinzhaohe |

|---|---|---|

| Lot-to-lot chemistry repeatability | ±0.15 % Si max variation | ±0.03 % Si (ICP per cast) |

| Resistivity guarantee | ≤ 0.027 Ω·mm²/m (occasional) | ≤ 0.027 280 Ω·mm²/m, 100 % coils tested |

| Traceability | Warehouse label only | Cast # → Hot-roll # → Slit #, barcode on every core |

| Technical file retention | 1 year | 10 years, available on request |

Direct Factory Pricing—Engineered, Not Negotiated

Our cost structure is benchmarked against LME primary aluminium plus a fixed conversion fee published quarterly—no surprise surcharges.

Because we draw our own 9.5 mm rod and anneal in-line, we save 4–6 % compared with European foil mills that purchase reroll stock.

Those euros stay in your BOM. Typical 2024 reference:

| Alloy-Temper | Thickness 0.3 mm, Width 240 mm, ID 500 mm, EDGEBURR ≤ 0.02 mm | FOB Qingdao (USD/kg) | Lead-time |

|---|---|---|---|

| 1350-O | 0.3 × 240 mm, burr-free, chamfer 0.3 × 45° | 3.85 | 15 days |

| 1070-O | 0.2 × 100 mm, high-ductility (A50 ≥ 35 %) | 3.78 | 12 days |

| 1060-O | 0.8 × 600 mm, conductivity ≥ 62.7 % IACS | 3.70 | 18 days |

Prices valid for 5 t minimum; larger call-offs lock alloy surcharge for 6 months.

Customisation Without MOQ Penalty

Transformer designs are shrinking and voltage classes are splitting—so we built a “micro-slitting” line (width 20–1 600 mm) that changes set-up in < 15 min.

Edge conditioning options:

| Edge profile | Ra (µm) | Burr height (µm) | Typical use |

|---|---|---|---|

| Round chamfer 0.2–1.0 mm | ≤ 0.4 | ≤ 20 | Layer wind, ≤ 1.1 kV |

| Full-radius R = ½ thickness | ≤ 0.3 | ≤ 10 | Foil-wound HV, ≥ 33 kV |

| Square-cut | ≤ 0.6 | ≤ 40 | Low-voltage reactor |

Surface cleanliness: residual oil ≤ 6 mg/m² (Wilhelm test), compatible with vacuum drying at 160 °C.

Inner diameters 150, 200, 300, 400, 500 mm or custom; outer ≤ 1 400 mm, weight ≤ 3 t to suit robotic pay-off.

Quality Gate Aligned to IEC 60317-0-3 & ASTM B373

Every master coil passes:

- Eddy-current thickness scan—tolerance ±1 %, map supplied.

- 100 % breakdown voltage at 23 °C, 50 Hz, 20 mm sphere electrodes—guarantee ≥ 1.2 kV for 0.2 mm foil.

- Elongation & tensile per EN 485-2, values printed on certificate.

- Packaged in VCI film + HDPE sleeve; desiccant + humidity card; seaworthy plywood pallet.

Premium Alternative to Western Mills—Data Speaks

A 2023 third-party audit by a German tier-1 OEM showed our 1350-O 0.3 mm foil achieved:

Space factor 96.8 % (same lot from a Scandinavian mill: 96.5 %).

Short-circuit axial force test 350 kN/m, no buckling (design limit 320 kN/m).

Total cost landed Europe 8.4 % below their incumbent Nordic supplier.

Next Step—Get the Full Technical Datasheet

Send your foil specification (alloy, temper, thickness, width, edge, annual volume) to cathy@transformerstrip.com.

We return a detailed datasheet, packaging drawing and firm FOB/CFR quote within 24 h.

Prototype slits available from 100 kg; production lead-time 10–18 days, sea freight 22 days to EU or 18 days to US West Coast.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium foil for transformer winding from Luoyang Xinzhaohe.