Table of Contents

Market Insight: Aluminium Foil For Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

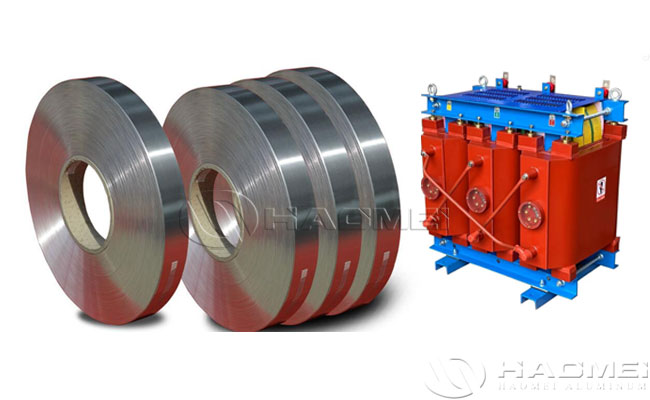

Global demand for aluminum transformer foil is intrinsically linked to the expansion and modernization of electrical infrastructure, driven by rising energy consumption, renewable energy integration, and stringent efficiency regulations. Transformers represent a critical component in power transmission and distribution networks, where aluminum foil serves as the primary conductor material in windings for medium and large power transformers due to its favorable conductivity-to-weight ratio and cost-effectiveness compared to copper. The shift towards higher efficiency standards, such as DOE 2016 in the US and EU Ecodesign Directive Lot 20, necessitates reduced no-load and load losses, directly increasing the demand for ultra-high-purity, dimensionally precise aluminum foil. This trend is amplified by the global push for grid resilience and the deployment of transformers in solar/wind farm substations, where aluminum’s lighter weight offers significant logistical and installation advantages over copper alternatives. Current market analysis indicates sustained growth, particularly in Asia-Pacific, fueled by China’s ongoing grid upgrades and new renewable energy projects requiring millions of new transformers annually.

The criticality of foil quality cannot be overstated, as it directly dictates transformer performance, longevity, and safety. Aluminum foil for transformer windings must meet exceptionally rigorous metallurgical and dimensional specifications. Minimum 99.99% Al purity is essential to minimize electrical resistivity and prevent accelerated aging caused by impurity-induced hotspots. Surface quality is paramount; microscopic scratches, pits, or residual rolling oils create initiation points for partial discharges under high voltage stress, leading to catastrophic insulation failure. Precise thickness tolerance (typically ±2% or tighter) and consistent edge straightness are non-negotiable to ensure uniform winding tension, prevent inter-layer short circuits, and avoid mechanical damage during the complex coil-winding process. Furthermore, controlled annealing is vital to achieve the optimal balance of electrical conductivity and mechanical formability without inducing grain coarsening or hydrogen-related porosity, which compromises dielectric integrity. Any deviation in these parameters risks localized overheating, reduced thermal stability, and premature transformer failure, incurring substantial replacement costs and grid downtime.

Consequences of substandard foil manifest in operational failures with severe financial and safety implications. Inadequate surface finish accelerates oil degradation in oil-immersed transformers, generating combustible gases. Thickness variations cause uneven current distribution, elevating hot-spot temperatures beyond design limits and degrading solid insulation. Impurities act as catalytic sites for sludge formation within the insulating oil, further impairing heat transfer. These factors collectively shorten transformer lifespan, increase maintenance frequency, and elevate the risk of unplanned outages or fire hazards. Given transformers often operate for 30+ years under continuous electrical and thermal stress, the initial material quality is a fundamental determinant of asset reliability. Suppliers lacking deep metallurgical process control and stringent in-line quality assurance protocols cannot consistently deliver foil meeting IEC 60137 and IEEE C57.12.00 standards. Luoyang Xinzhaohe Aluminum leverages two decades of specialized production experience, advanced rolling and annealing technologies, and comprehensive material testing to ensure every foil shipment meets the exacting demands of modern, high-efficiency transformer manufacturing, safeguarding grid stability and customer return on investment.

Technical Specs: Aluminium Foil For Transformer

Technical Specifications for Aluminium Foil in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision aluminium foil specifically engineered for use in transformer windings, where electrical performance, dimensional accuracy, and surface integrity are critical. The foil serves as a key conductive element in low-voltage (LV) windings of dry-type and oil-immersed transformers, demanding strict adherence to metallurgical and geometric specifications. Our production process integrates advanced cold rolling, precision slitting, and edge conditioning technologies to ensure compliance with international standards such as IEC 60137, GB/T 3190, and ASTM B209.

Dimensional control is paramount in transformer foil applications to ensure uniform winding tension, minimize interlayer stresses, and prevent dielectric breakdown. Our aluminium foil is slit to precise widths with a tolerance of ±0.002 mm, achieved through servo-controlled slitting lines equipped with laser-guided edge detection systems. This level of precision ensures consistent coil geometry and reduces the risk of localized hotspots during transformer operation. Foil thickness ranges from 0.08 mm to 3.0 mm, with standard tolerances maintained within ±0.005 mm for thickness variation across the strip length.

Edge quality directly influences winding integrity and safety. All foils are processed through a burr-free slitting technique utilizing high-precision tungsten carbide knives and optimized blade clearance settings. This results in clean, smooth edges with no micro-tearing or protrusions, reducing the risk of insulation puncture during coil winding. Surface roughness is controlled to Ra ≤ 0.4 µm, ensuring optimal adhesion with insulating paper or film and minimizing partial discharge risks.

Electrical conductivity is a fundamental performance metric. Our transformer-grade aluminium foil is produced from high-purity 1060 or 1070 alloys (Al ≥ 99.6%), achieving a minimum conductivity of 59% IACS (International Annealed Copper Standard) in the annealed (O) temper condition. This ensures low resistive losses and high energy efficiency in transformer operation. Conductivity is verified through four-point probe resistivity measurements calibrated to national standards.

Mechanical properties are tailored to balance formability and structural stability. Typical tensile strength ranges from 60 to 95 MPa, with elongation exceeding 25%, enabling tight-radius winding without cracking or necking. The foil exhibits excellent flatness, with a maximum edge wave of ≤ 0.5%, ensuring smooth feeding through automated winding machines.

All material batches undergo 100% inline eddy current testing and periodic metallurgical analysis to verify homogeneity, absence of inclusions, and compliance with RoHS and REACH regulations.

| Parameter | Specification |

|---|---|

| Alloy Grade | 1060, 1070 (Al ≥ 99.6%) |

| Temper | O (Annealed) |

| Thickness Range | 0.08 – 3.0 mm |

| Thickness Tolerance | ±0.005 mm |

| Width Range | 10 – 500 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, no micro-tears |

| Surface Roughness (Ra) | ≤ 0.4 µm |

| Electrical Conductivity | ≥ 59% IACS |

| Tensile Strength | 60 – 95 MPa |

| Elongation | ≥ 25% |

| Flatness (Edge Wave) | ≤ 0.5% |

| Insulation Compatibility | Compatible with kraft paper, NOMEX, PE |

| Testing Standard | IEC 60137, GB/T 3190, ASTM B209 |

Factory Tour: Manufacturing

Manufacturing Process for Transformer Aluminum Foil

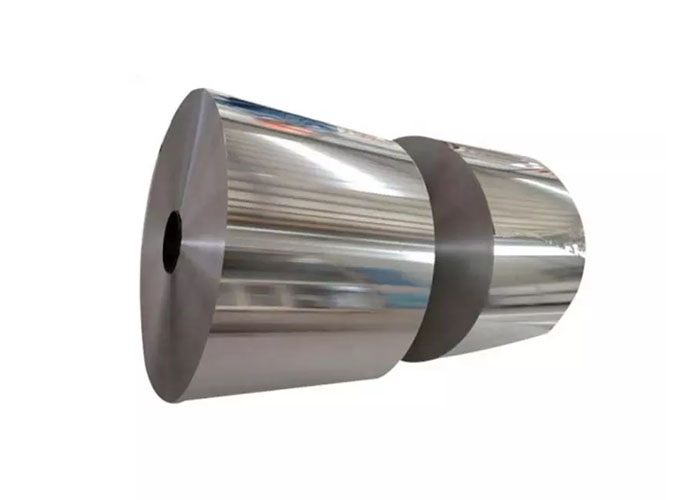

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized metallurgical expertise to produce transformer aluminum foil meeting stringent electrical and mechanical demands. Our process begins with cold rolling high-purity aluminum ingot (99.99% min Al) sourced from verified suppliers. This critical stage reduces material thickness to the precise foil gauge required, typically ranging from 0.08mm to 0.30mm for transformer applications. Advanced tension control systems and precision roll grinding ensure exceptional thickness uniformity, maintaining tolerances within ±0.002mm across the entire coil width. Surface integrity is paramount; our rolling mills operate under strictly controlled atmosphere conditions to prevent oxidation and achieve the requisite smooth, defect-free finish essential for dielectric performance. All cold-rolled coils undergo rigorous initial inspection per ASTM B209 standards, verifying dimensions, surface quality, and mechanical properties.

Precision slitting follows cold rolling, transforming master coils into narrow strips conforming to specific transformer winding dimensions. Our state-of-the-art slitting lines utilize computer-controlled servo systems and hardened tungsten carbide knives to achieve edge straightness deviations of less than 0.1mm per meter. Laser-guided tracking ensures consistent strip width within ±0.1mm tolerance, critical for uniform winding tension and core assembly. This stage meticulously avoids edge burrs or micro-tears which could compromise insulation integrity or cause partial discharges in the final transformer. Each slit coil is continuously monitored for edge quality and dimensional accuracy during the operation.

Edge conditioning represents a vital, often overlooked step where Xinzhaohe applies significant process control. Slit edges undergo multi-stage mechanical brushing and deburring to eliminate microscopic imperfections and residual stresses induced during slitting. This proprietary process ensures edges are perfectly smooth and free from micro-burrs, preventing damage to interlayer insulation paper during winding and eliminating potential sites for electrical field concentration. The conditioned edges significantly enhance the foil’s long-term reliability under high electrical stress and thermal cycling.

Comprehensive quality control is integrated throughout production. Key verification steps include:

In-line laser micrometry for real-time thickness monitoring during cold rolling and slitting

Surface profilometry to quantify roughness (Ra typically maintained below 0.4μm)

Tensile testing per ASTM E8 to confirm yield strength (typically 80-120 MPa) and elongation

100% eddy current testing on slit and conditioned foil to detect subsurface flaws

Visual inspection under controlled lighting for surface defects

Final dimensional certification for every production lot

Our integrated QC protocol guarantees consistent delivery of foil meeting the most demanding transformer specifications. The table below summarizes critical dimensional tolerances we consistently achieve.

| Parameter | Typical Tolerance | Measurement Standard |

|---|---|---|

| Thickness | ±0.002 mm | ASTM E29, E344 |

| Width | ±0.10 mm | ASTM B955 |

| Edge Straightness | ≤ 0.10 mm/m | Internal Method XZH-TF-07 |

| Surface Roughness (Ra) | ≤ 0.40 μm | ISO 4287 |

This disciplined approach from raw material to finished slit coil ensures Xinzhaohe’s aluminum foil provides the dimensional precision, surface perfection, and edge integrity required for high-efficiency, reliable power and distribution transformers.

Packaging & Logistics

Export Packaging for Aluminum Foil Used in Transformer Applications

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in transformer-grade aluminum and copper strip and foil, we recognize that packaging is not merely a logistical necessity but a critical component of product integrity—especially in international shipments. Our export packaging system is engineered to meet the stringent demands of global supply chains, ensuring that our high-purity aluminum foils arrive at their destination in optimal condition, fully compliant with industrial processing requirements.

All aluminum foil coils designated for export are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to withstand the mechanical stresses of containerized sea freight, including stacking loads, lateral shifts during vessel movement, and handling via forklift or crane. The structural integrity of the pallet is reinforced with cross-bracing and load-bearing base blocks, minimizing the risk of coil deformation during transit. Each coil is securely fastened to the pallet using corrosion-resistant steel strapping, tensioned to industry-standard specifications to prevent axial or radial displacement.

To combat the primary environmental hazard in maritime transport—moisture—each palletized coil is fully encased in a multi-layer moisture-proof barrier. This includes an inner wrapping of vapor-corrosion inhibiting (VCI) film, which actively suppresses oxidation by releasing protective molecules into the enclosed atmosphere. The VCI layer is then sealed within a high-density polyethylene (HDPE) outer wrap, providing a robust, waterproof shield against humidity, salt spray, and condensation. All sealing is performed under controlled ambient conditions to prevent entrapment of moisture during packaging.

The entire wrapped unit is further protected by a rigid wooden crate or pallet cover, depending on the coil dimensions and destination climate profile. This outer shell prevents physical damage from handling, container wall contact, and potential impact during intermodal transfer. Critical handling information, including coil identification, weight, direction of winding, and moisture-sensitive indicators, is affixed to the exterior in both Chinese and English, ensuring clarity across international logistics networks.

Our packaging protocol is validated through accelerated climate testing and real-world performance tracking across major trade routes, including trans-Pacific and trans-Indian Ocean shipments. This data-driven approach confirms that internal relative humidity within the sealed package remains below 40% throughout journeys exceeding 45 days—a critical threshold for preventing surface oxidation on high-conductivity aluminum alloys (e.g., 1060, 1070, and 1350 series).

For transformer manufacturers relying on precise dielectric properties and surface cleanliness, any compromise in foil condition can lead to insulation failure or winding defects. By integrating structural resilience with advanced moisture control, Luoyang Xinzhaohe ensures that our aluminum foil products maintain their metallurgical and dimensional specifications from factory to fabrication line—delivering reliability at every stage of the supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Aluminum Foil Source for Critical Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver aluminum transformer strip and foil meeting the most stringent performance demands. Our factory is engineered specifically for the production of high-purity, ultra-precision aluminum materials essential for modern transformer windings, where electrical efficiency, thermal management, and long-term reliability are non-negotiable. We understand that dimensional consistency, surface integrity, and metallurgical homogeneity directly impact core losses, thermal runaway resistance, and the operational lifespan of your transformers. Our integrated production ecosystem begins with rigorous raw material selection and proprietary melt purification processes, ensuring base metal purity exceeding 99.99% Al (Fe+Si < 0.025%). This foundational control enables precise management of recrystallization behavior and grain structure during subsequent cold rolling and annealing, critical for achieving the required mechanical properties and electrical conductivity without compromising formability.

Our manufacturing infrastructure centers on state-of-the-art continuous casting and rolling lines dedicated exclusively to transformer-grade products. These lines incorporate advanced tension leveling and precision thickness control systems capable of consistently producing foil within tolerances of ±0.002 mm for thicknesses ranging from 0.10 mm to 0.80 mm. Full-hard temper production is standard, with optional intermediate tempers available based on specific winding process requirements. All slit edges undergo proprietary deburring and surface conditioning to eliminate micro-notches that could initiate failure under high electrical stress or thermal cycling. Comprehensive in-line monitoring tracks key parameters including thickness profile, strip flatness (I-units), and surface defects in real-time, ensuring every coil meets the dimensional stability specifications demanded by automated winding equipment.

Quality assurance is embedded at every process stage through our ISO 9001 and IATF 16949 certified systems. Every production lot undergoes rigorous offline testing per IEC 60137 and ASTM B209 standards, including:

Tensile strength and elongation verification

Electrical resistivity measurement

Surface roughness analysis (Ra)

Chemical composition validation via OES

Microstructural examination

This granular quality data, coupled with full traceability from melt to shipment, provides the confidence your engineering and procurement teams require. Our vertically integrated supply chain, controlling the process from billet production through final slitting, guarantees supply continuity and minimizes lead time volatility. Strategically located in Henan Province with direct access to major logistics hubs, we ensure reliable just-in-time delivery to global transformer manufacturers. Partnering with Luoyang Xinzhaohe means securing a supplier whose metallurgical depth and process discipline directly translate to enhanced transformer performance and reduced total cost of ownership for your end products. Initiate a technical consultation to discuss your specific foil requirements and receive sample reels for qualification. Contact our Chief Technical Officer Cathy Wang directly at cathy@transformerstrip.com to optimize your transformer material sourcing strategy.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil for transformer directly from China.