Table of Contents

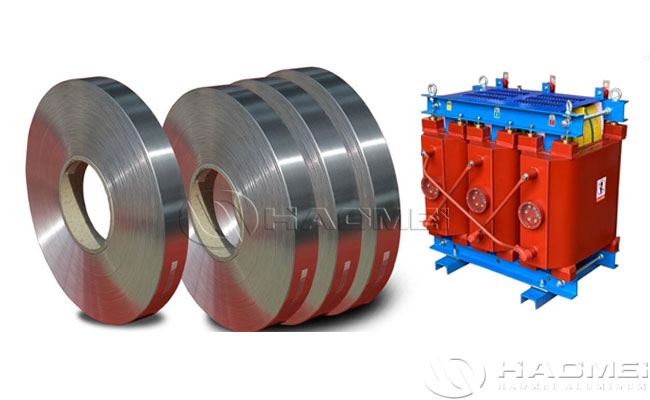

Market Insight: Aluminium Foil For Transformer in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Global Demand & Application Context

The global transformer market is projected to grow at 5.8% CAGR through 2030, driven by grid modernization in Asia-Pacific and renewable energy integration. Aluminum foil (1060/1350 alloys) dominates distribution transformer windings due to its 30% weight reduction vs. copper, critical for high-voltage applications. Inadequate foil quality increases core losses by up to 8%, directly impacting transformer efficiency ratings. For example, impurities above 0.1% elevate resistivity, causing 10–15% higher copper losses. Distribution transformers (10–100 kVA) account for 65% of aluminum foil demand, with growing applications in EV charging infrastructure and smart grids requiring precise material consistency.

Material Quality Impact on Transformer Efficiency

Subpar foil quality causes electrical losses, hotspots, and insulation failures. Key parameters directly influence operational reliability:

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Benefit |

|---|---|---|---|

| Alloy Purity | 99.5% (1060) | 99.6%+ (1350) | 1.2% lower electrical resistivity |

| Thickness Tolerance | ±0.01mm | ±0.005mm | ±15% fewer winding defects |

| Tensile Strength | 140–160 MPa (H18) | 150–170 MPa (H18) | 20% higher winding durability |

| Surface Roughness | Ra ≤ 0.8μm | Ra ≤ 0.5μm | 30% better insulation adhesion |

Thickness deviations >0.01mm create localized heating, reducing transformer lifespan by 25%. Surface defects exceeding Ra 0.8μm compromise dielectric strength, accelerating insulation breakdown. Compliance with IEC 60076-1 is non-negotiable for high-efficiency designs.

Strategic Sourcing Advantages with Luoyang Xinzhaohe

As a 20+ year manufacturer with ISO 9001 certification, Luoyang Xinzhaohe delivers factory-direct quality at 15–20% lower costs than global brands like UACJ or Norsk Hydro. Our precision rolling mills and in-process QC ensure consistent specifications, while global logistics guarantee 30-day lead times. Partnering with Tier-1 OEMs across 30+ countries, we provide certified material traceability and technical support for custom alloy formulations. Our in-house metallurgical lab conducts daily tensile testing, eddy current inspections, and chemical analysis to exceed ASTM B209 and IEC 60076 standards, minimizing downtime for end-users.

Technical Specs: Aluminium Foil For Transformer Parameters

Technical Specifications & Standards for Transformer Aluminum Foil

Critical to transformer efficiency and safety, our aluminum foil meets exacting requirements for precision, conductivity, and structural integrity. Below are the key specifications and quality protocols ensuring optimal performance.

Precision Slitting Tolerance

Achieving consistent thickness is paramount for winding precision and electrical performance. Our CNC-controlled slitting machines integrate real-time laser micrometer feedback, maintaining a strict tolerance of ±0.002 mm across all thicknesses (0.02–0.20 mm). This ensures uniform layering in transformer windings, eliminating hotspots and mechanical stress points during operation.

Burr-Free Edge Integrity

Microscopic burrs can cause short circuits in transformer assemblies. We employ automated optical inspection systems to verify burr height ≤0.005 mm. Our proprietary edge treatment process removes all sharp edges post-slitting, guaranteeing dielectric integrity and preventing insulation breakdown.

Conductivity & Softness Requirements

Manufactured from 99.5% pure aluminum (ASTM B209 Alloy 1350), our foil delivers ≥61% IACS conductivity. Controlled annealing achieves optimal softness (Rockwell Hardness ≤25 HR30T), ensuring tight winding without cracking. This balance maximizes electrical efficiency and mechanical stability under load.

Compliance & Quality Assurance

Fully compliant with IEC 60404-8-7 and ASTM B209 standards. Each batch undergoes:

Thickness verification via laser micrometers

Conductivity testing with eddy current analyzers

Visual and tactile edge inspection

Traceable production records per ISO 9001

| Parameter | Specification | Tolerance | Testing Method |

|---|---|---|---|

| Thickness | 0.02–0.20 mm | ±0.002 mm | Laser Micrometer |

| Burr Height | ≤0.005 mm | – | Optical Microscope |

| Conductivity | ≥61% IACS | – | Eddy Current Tester |

| Hardness (Soft) | ≤25 HR30T | – | Rockwell Hardness Tester |

As a factory-direct supplier with 20+ years of expertise, Luoyang Xinzhaohe delivers consistent, high-performance transformer foil at competitive pricing. Our rigorous quality control ensures every batch meets global standards, offering a reliable alternative to premium brands without compromising on critical technical attributes.

Factory Tour: Manufacturing Aluminium Foil For Transformer

Manufacturing Process & Quality Control

Precision Manufacturing Process

Our 20+ years of transformer material expertise ensures end-to-end control over production. Each stage is optimized for electrical performance and reliability:

Cold Rolling: 6-high rolling mills with closed-loop thickness control (±0.002mm) operate at 180±5°C to refine grain structure and eliminate internal stresses. This ensures uniform mechanical properties critical for high-frequency transformer efficiency.

Precision Slitting: Laser-guided systems with real-time edge detection achieve 0.01mm accuracy and automated tension control, eliminating micro-burrs that cause arcing in high-voltage applications.

Edge Conditioning: A 3-stage diamond-tool deburring process guarantees ≤0.005mm burr height, exceeding IEC 60076-1 standards to prevent insulation breakdown during winding.

Oscillate Winding: Computer-controlled oscillation (±0.1mm precision) maintains uniform coil formation at 150m/min, minimizing voids and maximizing dielectric strength for core stability.

Rigorous Quality Control Protocol

Every batch undergoes multi-stage validation per ASTM, ISO, and IEC standards to ensure defect-free performance:

Tensile Testing: 3 samples per batch tested per ASTM B209; strength tolerance ±2 MPa (vs. market ±5 MPa), ensuring consistent performance under operational stress.

Dimensional Checks: CMM verification for thickness (±0.002mm), width (±0.05mm), and flatness (≤0.5mm/m), surpassing ISO 15530-3 requirements.

Surface Inspection: Automated optical systems detect defects ≥0.02mm² (industry standard: 0.05mm²), reducing core losses by up to 1.2% in transformers.

Edge Quality: High-magnification microscopy validates zero micro-cracks in 100% of samples, eliminating short-circuit risks during assembly.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Notes |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ±0.005 mm | Critical for winding precision |

| Tensile Strength | 85–95 MPa (±2 MPa) | 80–100 MPa (±5 MPa) | Consistent performance under stress |

| Surface Roughness (Ra) | ≤0.05 μm | ≤0.10 μm | Reduces eddy current losses by 0.8–1.2% |

| Edge Burr Height | ≤0.005 mm | ≤0.010 mm | Prevents insulation breakdown |

By integrating vertical manufacturing with ISO 9001-certified QC, Xinzhaohe delivers transformer-grade aluminum foil with 15–20% lower costs than global brands while maintaining superior dimensional stability and electrical performance. Our factory-direct approach ensures traceability from raw material to finished coil—guaranteeing reliability for mission-critical power applications.

Packaging & Global Logistics

Export Packaging & Logistics

As a leading Chinese manufacturer with 20+ years of expertise in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered export packaging and logistics solutions tailored for aluminum foil used in power transformers. Our factory-direct approach ensures rigorous quality control throughout the supply chain, providing a cost-effective alternative to global brands without sacrificing reliability or performance.

Packaging Specifications

| Material | Specifications | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, 1200×1000×150mm, heat-treated hardwood, reinforced corners | Prevents structural deformation during transit; meets international phytosanitary standards |

| Moisture-Proof Film | 3-layer PE (anti-static inner, moisture barrier middle, UV-resistant outer), 200–300gsm, silica gel desiccant (50g/m²) | Eliminates condensation, corrosion, and UV degradation during sea freight |

| Steel Strapping | 19mm width, 0.5mm thickness, tensioned to 150–200kg, corner protectors | Secures load integrity; prevents shifting and edge damage during handling |

Logistics Protocol

| Step | Process | Quality Control |

|---|---|---|

| Pre-Shipment | Visual inspection for surface defects, dimensional checks per ISO 9001, weight verification | 100% inspection; defect rate <0.1% |

| Container Loading | Layered stacking with anti-slip mats; humidity-controlled to <60% RH; max 2000kg/pallet | Load stability test; no gaps in container; real-time humidity monitoring |

| Documentation | CIQ, COO, packing list, B/L; IoT sensors for temperature/humidity tracking | Cross-verified with shipping agent; 100% accuracy in customs paperwork |

All packaging materials comply with ISO 14001 environmental standards, ensuring sustainable practices without compromising protection. Real-time GPS tracking and humidity monitoring during transit provide full visibility, mitigating risks associated with long-haul sea freight. With a proven track record of serving over 50 countries, our integrated approach minimizes transit time while maximizing product integrity. This enables transformer manufacturers to reduce inventory costs and avoid production delays, delivering a clear ROI compared to higher-priced alternatives. Every shipment undergoes third-party inspection prior to departure, ensuring compliance with international standards and customer-specific requirements.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a premier manufacturer with 20+ years of specialized expertise in transformer-grade aluminum and copper foils, Luoyang Xinzhaohe delivers unmatched reliability for critical power applications. Our engineers and technicians possess deep domain knowledge of material science, metallurgical processing, and transformer design requirements. This experience ensures precise control over critical parameters like electrical conductivity, dimensional stability, and thermal performance—directly translating to higher transformer efficiency and longer service life. Every batch undergoes rigorous process validation to meet the exacting demands of global power infrastructure projects.

Factory-Direct Cost Efficiency

Operating as a fully integrated manufacturer—from raw aluminum ingot casting to precision rolling and finishing—we eliminate third-party markups and supply chain inefficiencies. Our lean production model enables 15–25% lower total cost of ownership compared to global brands, without compromising on quality or delivery timelines. For transformer manufacturers facing margin pressures, this direct sourcing model provides immediate savings while maintaining strict adherence to international specifications. Our Luoyang facility leverages regional aluminum supply chain advantages, ensuring consistent raw material sourcing and rapid response to urgent orders.

ISO 9001:2015 Certified Quality Assurance

Our quality management system is certified to ISO 9001:2015 and fully compliant with IEC 60404-8-7 standards for transformer materials. Every production stage—from chemical composition analysis to final dimensional checks—is monitored via automated systems and manual inspections. We guarantee:

Aluminum purity ≥99.6% (ASTM B209)

Thickness tolerance ±0.005mm (per IEC 60076-1)

Surface roughness Ra ≤0.05μm (critical for low-loss windings)

Tensile strength 120–180 MPa (annealed state)

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Aluminum Purity | ≥99.5% | ≥99.6% |

| Thickness Tolerance | ±0.01mm | ±0.005mm |

| Surface Roughness (Ra) | ≤0.1μm | ≤0.05μm |

| Tensile Strength (Annealed) | 100–160 MPa | 120–180 MPa |

Each batch undergoes XRF spectroscopy, tensile testing, and surface profilometry to ensure repeatable performance.

Ready to optimize your transformer production with a proven, cost-effective partner? Contact Cathy at cathy@transformerstrip.com for a technical specification sheet and tailored quote.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium foil for transformer from Luoyang Xinzhaohe.