Table of Contents

Market Insight: Aluminium Foil Exporter

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

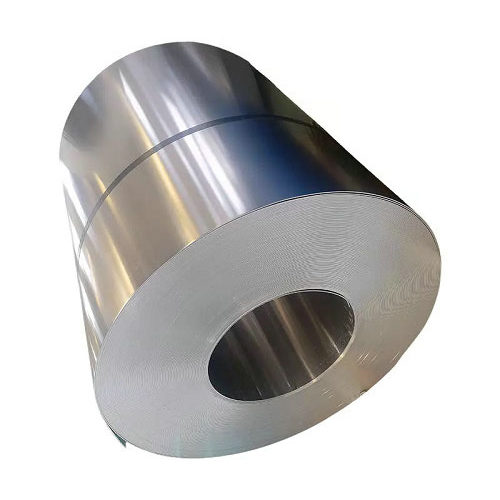

Global demand for aluminum and copper transformer strip/foil continues robust growth, driven by critical infrastructure modernization and renewable energy integration. Utilities worldwide are accelerating grid upgrades to enhance reliability and accommodate distributed generation, directly increasing procurement of distribution and power transformers. Simultaneously, the expansion of solar and wind farms necessitates step-up transformers and specialized grid-tied units, further straining supply chains. While copper historically dominated high-efficiency transformer windings due to superior conductivity, aluminum foil has gained significant market share in distribution transformers owing to its favorable cost-to-weight ratio and adequate performance in standardized designs. This shift is particularly pronounced in emerging economies where cost sensitivity is high, though copper retains dominance in premium power transformers requiring maximum efficiency and compactness. The aluminum foil exporter market for transformers is thus characterized by volume growth in mid-tier applications, demanding consistent, high-volume production capability from suppliers.

The technical role of transformer foil is non-negotiable; it directly dictates core electromagnetic performance and long-term reliability. Aluminum foil, typically alloyed with minor elements for strength (e.g., AA1060, AA1070), must achieve ultra-high purity (min. 99.6% Al) to minimize electrical resistivity. Precise dimensional control is equally critical: thickness tolerances often require ±0.005mm or better across the strip width to ensure uniform current distribution and prevent localized hotspots. Surface quality is paramount; micro-roughness, scratches, or residual rolling oils create weak points for partial discharge initiation under high voltage stress, accelerating insulation degradation. Edge burrs must be meticulously controlled to prevent dielectric puncture during winding. Any deviation from stringent metallurgical and geometric specifications introduces failure risks that manifest years later as reduced efficiency, unexpected outages, or catastrophic transformer failure—costs far exceeding initial foil savings.

Quality failures in transformer foil carry severe downstream consequences. Inadequate purity increases I²R losses, directly impacting the transformer’s total cost of ownership through higher operational energy expenditure over its 30+ year lifespan. Dimensional inconsistencies cause uneven magnetic flux distribution, elevating noise levels and vibration, which fatigue structural components. Most critically, surface defects act as nucleation sites for partial discharges within the oil-immersion insulation system. These micro-discharges progressively erode solid insulation (pressboard, kraft paper), leading to premature dielectric breakdown. Utilities and OEMs face substantial financial exposure from unplanned outages, warranty claims, and reputational damage when transformers fail prematurely due to substandard materials. Consequently, rigorous supplier qualification focusing on in-process metallurgical controls, advanced surface inspection (e.g., laser profilometry), and adherence to international standards (IEC 60137, ASTM B479) is non-optional for responsible sourcing.

Key Material Property Comparison for Transformer Foil

| Parameter | Aluminum Foil (Typical) | Copper Foil (Typical) | Critical Impact on Transformer Performance |

|---|---|---|---|

| Conductivity (%IACS) | 61-63% | 100% | Directly affects load losses and efficiency |

| Density (g/cm³) | 2.70 | 8.94 | Influences weight, core size, and transportation |

| Thickness Tolerance | ±0.005 mm | ±0.003 mm | Determines current density uniformity |

| Surface Roughness (Ra) | ≤ 0.4 µm | ≤ 0.2 µm | Critical for preventing partial discharge |

| Purity Requirement | ≥ 99.6% Al | ≥ 99.90% Cu | Minimizes resistive losses |

Luoyang Xinzhaohe Aluminum leverages two decades of specialized production to mitigate these risks. Our integrated process—from molten metal purification through precision cold rolling and tension leveling—ensures batch-to-batch consistency in critical parameters. We implement mandatory 100% surface defect scanning per IEC 60404-11 and maintain certified traceability to raw material heats, providing transformer manufacturers with the metallurgical assurance required for grid-critical applications. Selecting an aluminum foil exporter with demonstrable process control expertise is fundamental to transformer lifecycle reliability and total cost optimization.

Technical Specs: Aluminium Foil Exporter

Technical Specifications for Precision Aluminum Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, delivers high-performance aluminum transformer strip and foil engineered to meet the stringent demands of power transmission, electronics, and industrial transformer applications. Our production processes are calibrated to ensure dimensional accuracy, edge integrity, and electrical performance, aligning with international quality benchmarks including ASTM B479 and IEC 60112 standards. The following technical parameters define our precision aluminum foil offerings for export markets, emphasizing consistency, conductivity, and mechanical precision critical for reliable integration into transformer windings and high-frequency inductive components.

A core attribute of our aluminum transformer foil is precision slitting, maintained within a tolerance of ±0.002 mm across all widths. This level of dimensional control ensures uniform layer stacking, minimizes interlayer stress during coil winding, and prevents edge misalignment that could compromise dielectric integrity. Each slit edge undergoes in-line inspection and laser profiling to confirm burr-free finishes, with edge roughness consistently held below 3 µm Ra. Burr-free edges are essential to prevent dielectric puncture in insulation systems and reduce localized current crowding, thereby enhancing the long-term reliability of transformer assemblies.

Electrical conductivity is optimized through controlled alloying and thermal processing. Our standard soft-annealed 1060 and 1350 aluminum foils achieve a minimum conductivity of 59% IACS (International Annealed Copper Standard), with typical batch averages reaching 60.5% IACS. This high conductivity ensures low resistive losses and improved thermal management in transformer operation. Foil purity is maintained at 99.6% minimum aluminum content, with iron and silicon as the primary trace elements, strictly controlled to avoid adverse effects on ductility and conductivity.

Mechanical properties are tailored to support high-speed winding operations. Tensile strength ranges from 60 to 85 MPa, with elongation exceeding 25%, enabling plastic deformation without cracking during tight-radius coiling. Surface finish is uniformly matte or semi-gloss, free of roll marks, oxidation streaks, and particulate contamination, as verified by automated optical inspection systems.

All foils are supplied on precision-ground aluminum or composite cores, with outer diameters configurable between 300 mm and 1200 mm. Standard widths range from 10 mm to 600 mm, slit from master rolls of 1000–1650 mm width, with custom narrow-width slitting available for specialized winding equipment.

| Parameter | Specification |

|---|---|

| Material Grade | 1060, 1350 (Soft Annealed – O Temper) |

| Thickness Range | 0.08 mm – 0.50 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Burr | Burr-free, < 3 µm Ra |

| Conductivity | ≥59% IACS (Typical: 60.5% IACS) |

| Purity | ≥99.6% Al |

| Tensile Strength | 60 – 85 MPa |

| Elongation | ≥25% |

| Surface Finish | Matte / Semi-gloss, Clean, Oxidation-Free |

| Core Diameter | 76 mm, 152 mm, 300 mm (Customizable) |

| Max Outer Diameter | 1200 mm |

| Packaging | Vacuum-Sealed with Desiccant, Wooden Crate |

Each production batch is accompanied by a full material test report (FMTR), including conductivity verification, mechanical testing data, and dimensional certification, ensuring traceability and compliance with customer engineering requirements.

Factory Tour: Manufacturing

Transformer Foil Manufacturing Process: Precision Engineering for Electrical Performance

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to transform aluminum and copper ingots into high-performance transformer foil. Our rigorously controlled production sequence ensures dimensional stability, surface integrity, and electrical consistency critical for core-winding applications. The process initiates with cold rolling, where pre-rolled strip undergoes multiple passes through precision work rolls under computerized tension control. This stage reduces thickness to final specifications (typically 0.08–0.30 mm for aluminum, 0.10–0.50 mm for copper) while optimizing grain structure and mechanical properties. Critical parameters—roll gap tolerance (±0.001 mm), rolling speed (5–30 m/min), and interpass annealing—are continuously monitored to achieve uniform thickness deviation below ±2.5% and surface roughness (Ra) of 0.15–0.40 μm. Such precision minimizes magnetic hysteresis losses and ensures predictable lamination behavior during transformer assembly.

Precision slitting follows cold rolling, converting master coils into narrow strips matching customer width requirements (5–300 mm). Our servo-driven slitting lines employ high-speed rotary knives with sub-micron alignment accuracy, maintaining width tolerances of ±0.05 mm. Tension control systems dynamically adjust across the coil width to prevent edge waviness or center buckling, while edge-guided tracking compensates for coil runout. Crucially, slit edges undergo immediate edge conditioning via precision brushing or micro-beveling. This step eliminates micro-burrs and surface defects that could compromise interlayer insulation or cause dielectric breakdown in wound cores. Edge roughness is reduced to Ra ≤ 0.8 μm, preventing particle generation during high-speed winding and ensuring clean varnish penetration for optimal thermal conductivity.

Quality control is embedded at every phase, not merely as end-point verification. Inline laser micrometers continuously measure thickness across the foil width at 100+ points per second, with real-time data feeding back to rolling mill actuators. Surface defects are detected via automated optical inspection (AOI) systems scanning at 50 m/min, identifying particles, scratches, or oxide streaks exceeding 10 μm. Post-slitting, critical parameters undergo final validation:

| Parameter | Test Method | Acceptance Criteria |

|---|---|---|

| Thickness Uniformity | Eddy Current Gauge | ±2.0% max deviation |

| Edge Quality | Optical Profilometry | Burr height ≤ 5 μm |

| Tensile Strength | ASTM E8/E8M | As-per grade specification |

| Surface Cleanliness | Particle Count Analysis | ≤ 5 particles/cm² (>10 μm) |

Final coils undergo 100% eddy current testing to detect subsurface inhomogeneities, followed by destructive sampling for metallurgical verification (grain size, purity per ASTM B209/B152). This integrated approach guarantees foil that meets IEC 60404-9 and GB/T 3880 standards, delivering the flatness, edge integrity, and electrical properties demanded by high-efficiency transformer manufacturers. Every coil shipped carries a traceable quality dossier, linking production data to performance metrics for supply chain transparency.

Packaging & Logistics

Export Packaging for Transformer Strip and Foil – Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in the production and export of high-purity aluminum and copper transformer strip and foil, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity during international transit. Our export packaging system is engineered to meet the stringent demands of global sea freight, ensuring that every coil and strip arrives at its destination in optimal condition, free from mechanical damage, contamination, and environmental degradation.

All transformer foil and strip shipments are secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the specific weight distribution and dimensional tolerances of coiled aluminum and copper products, minimizing deformation during handling and stacking. The structural integrity of the pallets ensures compatibility with automated material handling systems at ports and receiving facilities, enabling seamless integration into downstream logistics networks.

Each coil is individually wrapped in multiple layers of high-density, moisture-proof polyethylene film. This vapor barrier film is specifically selected for its low water vapor transmission rate (WVTR), providing effective protection against humidity, salt spray, and condensation—common challenges in maritime transport, especially during intercontinental voyages through tropical and temperate zones. The film is heat-sealed at all seams to form a continuous protective envelope, preventing ingress of moisture and airborne contaminants such as dust, sulfides, and chlorides that could initiate surface oxidation or corrosion.

Additional protection is provided through the inclusion of desiccant packs placed within the sealed film layer, further reducing the risk of internal condensation during temperature fluctuations. For enhanced mechanical protection, edge protectors made of corrugated fiberboard or plastic are affixed to the outer diameter of each coil to prevent damage during loading, unloading, and transit. Custom crating options are available for oversized or high-value orders, incorporating steel strapping and corner bracing for maximum stability.

All packaging configurations are validated through internal testing protocols that simulate real-world shipping conditions, including vibration, tilt, and humidity exposure. Our procedures align with international standards for safe sea freight, including compliance with IMDG regulations where applicable. Documentation accompanying each shipment includes packaging specifications and handling instructions to ensure proper care throughout the supply chain.

By integrating industrial-grade materials with precision engineering, Luoyang Xinzhaohe Aluminum ensures that our export packaging does not compromise the metallurgical and surface quality of transformer foils and strips. This commitment to secure, reliable packaging underscores our dedication to customer satisfaction and long-term partnership in the global power transmission and electronics industries.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise and integrated supply chain management to deliver transformer strip and foil meeting the most stringent global industry demands. Our core strength lies in the precise control of aluminum and copper microstructure, essential for optimizing transformer efficiency and reliability. We employ advanced continuous casting and rolling technologies, including a state-of-the-art 4.5-meter wide twin-roll caster, enabling exceptional thickness uniformity down to 0.03mm for aluminum foil and 0.05mm for copper strip. This precision directly translates to reduced core losses and superior magnetic performance in final transformer assemblies, critical for meeting modern energy efficiency standards like DOE 2016 and IEC 60076.

Our vertically integrated production facility in Luoyang, Henan Province, provides significant capacity and control advantages. Annual production capacity exceeds 50,000 metric tons specifically for transformer-grade materials, ensuring reliable fulfillment for large-scale OEM contracts. Key process capabilities include:

| Parameter | Aluminum Foil Range | Copper Strip Range |

|——————–|———————|——————-|

| Thickness | 0.03mm – 0.50mm | 0.05mm – 0.80mm |

| Width | Up to 2100mm | Up to 1250mm |

| Thickness Tolerance| ±0.002mm (typical) | ±0.003mm (typical)|

| Surface Finish | RA ≤ 0.3µm | RA ≤ 0.4µm |

Metallurgical consistency is non-negotiable in transformer applications. We implement rigorous in-process controls at every stage, from high-purity ingot sourcing (99.85% min Al) through cold rolling, intermediate annealing, and final skin-passing. Our proprietary annealing profiles ensure optimal grain structure homogeneity and complete residual stress elimination, minimizing magnetostriction and vibration in wound cores. Full traceability from melt to shipment is maintained via our integrated MES system, providing customers with comprehensive material certification packages including chemical composition, mechanical properties, and surface defect analysis reports.

Supply chain resilience is engineered into our operations. We maintain strategic raw material inventory buffers and operate dual logistics hubs near major Chinese ports (Qingdao and Shanghai), enabling consistent FCL/LCL shipment execution with documented on-time delivery rates exceeding 98.5%. All processes adhere to ISO 9001, ISO 14001, and IATF 16949 standards, with dedicated quality teams supporting customer-specific APQP/PPAP requirements. Our technical service engineers collaborate directly with transformer design teams to resolve material performance challenges, particularly concerning interlayer insulation compatibility and eddy current loss mitigation.

For global transformer manufacturers requiring guaranteed material performance, capacity security, and technical partnership, Luoyang Xinzhaohe provides a proven solution. Contact Cathy Zhang, International Sales Manager, directly at cathy@transformerstrip.com to discuss your specific transformer strip or foil specifications and receive a tailored production capability analysis. We are prepared to support your next-generation transformer programs with metallurgical excellence and supply chain certainty.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil exporter directly from China.