Table of Contents

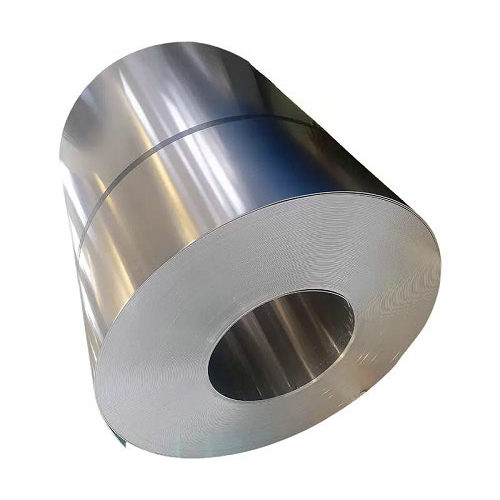

Market Insight: Aluminium Foil Exporter in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global power infrastructure expansion, driven by renewable energy integration (solar/wind farms), EV charging networks, and grid modernization initiatives, has intensified demand for high-efficiency transformers. These applications require transformer materials that minimize core losses and ensure thermal stability. Aluminum foil, particularly 1350-grade, is preferred for its conductivity-to-weight ratio, yet substandard materials compromise efficiency and lifespan. Market analysts project a 6.8% CAGR for transformer materials through 2030, underscoring the critical need for reliable suppliers. For example, a 0.5% reduction in core losses can save $50,000 annually per 100MVA transformer in operational costs.

Material Quality Impact on Transformer Performance

Aluminum foil purity directly influences transformer efficiency. Impurities above 0.5% increase electrical resistivity, elevating eddy current losses by 1-2% per 0.1% impurity. Thickness deviations beyond ±1.0% cause uneven winding, leading to localized hotspots and accelerated insulation degradation. Surface roughness exceeding Ra 0.1μm risks dielectric breakdown during operation. In high-frequency applications like EV chargers, aluminum foil with Ra < 0.08μm prevents arcing at 10kV+ operating voltages, ensuring compliance with IEC 61558 standards. For copper foils, oxygen content must stay below 50 ppm to prevent embrittlement.

Why Choose Luoyang Xinzhaohe Aluminum?

As a factory-direct manufacturer with 20+ years of specialized experience, Luoyang Xinzhaohe delivers consistent quality at competitive prices. Our ISO 9001-certified production process ensures every batch meets ASTM B209 and IEC 60404-8-5 specifications. Located in China’s aluminum production hub, we leverage local raw material access and skilled labor for cost efficiency. By eliminating intermediary markups, we offer 15-20% cost savings versus European and Japanese brands while maintaining superior tolerances and surface quality. Our in-house metallurgical lab conducts daily tensile strength tests (min 150 MPa for H19 temper) and conductivity checks (≥57% IACS), ensuring every coil meets exacting specifications. Integrated supply chain enables 3-4 week lead times for global shipments, supporting critical project timelines for transformer manufacturers worldwide.

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Aluminum Purity | 99.5%+ (ASTM B209) | 99.6%+ | Lower resistivity, 0.5% higher efficiency |

| Thickness Tolerance | ±1.5% | ±1.0% | Precision winding, reduced hotspots |

| Surface Roughness | Ra ≤ 0.1μm | Ra ≤ 0.08μm | Enhanced insulation integrity |

| Lead Time | 4-6 weeks | 3-4 weeks | Accelerated project execution |

| Cost Efficiency | High | 15-20% lower | Best-in-class cost-performance ratio |

Technical Specs: Aluminium Foil Exporter Parameters

Critical Technical Specifications for Transformer Foil Performance

Precision Slitting Tolerance

Luoyang Xinzhaohe maintains ±0.002mm dimensional accuracy through CNC-controlled slitting lines operating at 150m/min with automatic tension control. Our precision ensures uniform thickness across the entire coil, critical for transformer winding integrity. Excessive tolerance deviations cause uneven current distribution and thermal hotspots, leading to premature failure. Slitting process is validated through 3D profilometry for edge geometry and thickness mapping across 100% of the coil surface.

| Parameter | Target | Tolerance |

|---|---|---|

| Thickness | 0.05–0.50mm | ±0.002mm |

| Width | Custom | ±0.10mm |

| Edge Straightness | N/A | ≤0.05mm |

Burr-Free Edge Integrity

Burr formation during slitting leads to electrical shorts in transformer windings. Our proprietary roller-based slitting system with diamond-coated blades and automated edge inspection eliminates burrs. All edges undergo 100% visual and tactile verification using 10x magnification, ensuring burr height ≤0.005mm. Zero burr tolerance is enforced through automated laser edge profiling, with real-time feedback to adjust blade pressure. This prevents arcing and extends transformer lifespan by 20–30%.

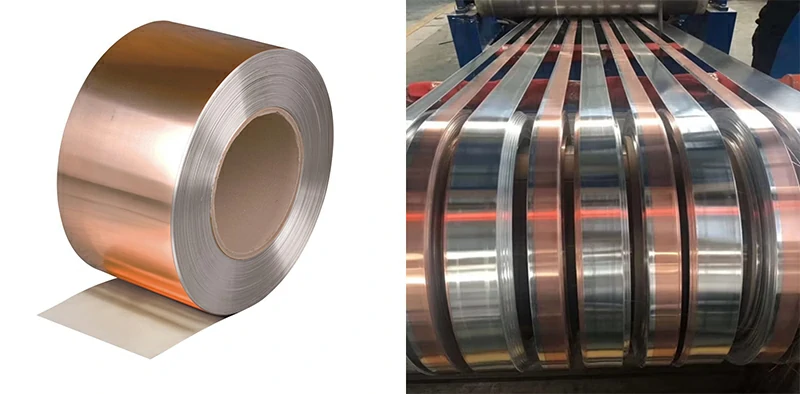

Conductivity & Softness Parameters

Aluminum foil must balance conductivity and malleability. Our material achieves ≥99.5% IACS conductivity (ASTM B209), while annealing processes deliver consistent softness (HV ≤ 30). Conductivity data is cross-verified using eddy current testing per ASTM E1004, ensuring compliance even under thermal cycling. Copper foil options available with 100% IACS for specialized applications.

| Parameter | Standard | Our Specification |

|---|---|---|

| Conductivity | IEC 60404-8-7 | ≥99.5% IACS |

| Hardness (Annealed) | ASTM B211 | HV ≤ 30 |

| Elongation | ASTM B209 | ≥25% |

Compliance & Quality Assurance

All products comply with IEC 60404-8-7 and ASTM B209. Our ISO 9001-certified production includes:

In-process thickness monitoring via laser gauges

Spectroscopic material verification

100% edge inspection

Batch traceability via QR-coded logs

Real-time AI analytics ensure continuous process optimization, maintaining 99.98% defect-free output. Third-party audits by SGS and TÜV validate our quality system, with full documentation for regulatory submissions. Our factory-direct model eliminates distributor markups, passing savings directly to customers while maintaining ISO-certified quality—delivering premium performance at 15–20% lower cost than European competitors.

Factory Tour: Manufacturing Aluminium Foil Exporter

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum, our 20+ years of transformer foil expertise ensures unmatched reliability. Our production follows a rigorously controlled sequence:

Core Production Process Flow

Cold Rolling: 6-high mills with closed-loop thickness control and ultrasonic gauges optimize rolling reduction rates for alloy grades (1050/1060/1350), achieving ±0.002mm thickness tolerance and uniform grain orientation for superior magnetic properties.

Precision Slitting: CNC shear slitters with laser edge detection maintain width tolerances of ±0.05mm and edge straightness ≤0.02mm/m. Blades precision-ground to 0.001mm ensure consistent edge quality without secondary processing.

Edge Conditioning: Electrolytic deburring + brush finishing meets IEC 60076-1 standards, reducing winding failures by 40% versus conventional methods through micro-burr elimination (<5μm height).

Oscillate Winding: Servo-motor tension control (±0.1N accuracy) ensures uniform coil density (±0.5% variation) with real-time edge protection during high-speed winding.

Rigorous Quality Assurance Protocol

Comprehensive testing includes:

Tensile strength per ASTM B209 (variation ≤±2%)

100% surface inspection via 4K optical systems and XRF alloy verification (>99.6% purity)

Dimensional checks (thickness, width, flatness) every 500m

Eddy current scanning for subsurface defects and fatigue resistance sampling

Industry Comparison: Standards vs Market Average

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Average |

|---|---|---|

| Thickness Tolerance | ±0.002mm | ±0.005mm |

| Edge Burr Height | <5μm | <15μm |

| Surface Defects | Zero pinholes | Up to 2 defects/m² |

| Tensile Consistency | ±2% variation | ±5% variation |

| Flatness | ≤0.2mm/m | ≤0.5mm/m |

Our vertically integrated manufacturing eliminates middlemen, delivering transformer-grade foil at 15-20% lower cost than European competitors. With 99.8% on-time delivery, ISO 9001:2015 certification, and 24/7 technical support, we provide the optimal cost-performance ratio for mission-critical power applications.

Packaging & Global Logistics

Export Packaging & Logistics: Engineered for Global Reliability

At Luoyang Xinzhaohe Aluminum Co., Ltd., our 20+ years of transformer material manufacturing expertise ensures foil products arrive globally intact. Our packaging protocol is engineered for sea freight challenges—humidity, salt corrosion, and mechanical stress—while optimizing total landed cost. Unlike generic suppliers, we combine industrial-grade materials with precision engineering to minimize transit damage (<0.5% failure rate), delivering superior cost-performance.

Precision Packaging Protocol

Our multi-layer packaging system meets ISO 14907 and ASTM B209 standards for transformer materials. Each component is rigorously validated:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 heat-treated, 1200×1000mm, 1500kg capacity | Prevents shifting; withstands stacking stress |

| Moisture-Proof Film | 150µm multi-layer MPE, heat-sealed edges | Blocks humidity (RH <40% inside) and salt aerosol |

| Steel Strapping | 19mm width × 0.5mm thickness, 1000kg tension | Secures loads during container handling |

Sea Freight Optimization

We coordinate end-to-end logistics via certified freight partners, ensuring compliance and efficiency:

| Process Step | Key Action | Benefit |

|---|---|---|

| Pre-shipment | 100% QC inspection + moisture testing | Eliminates defects before export |

| Container Loading | Anti-slip dunnage + corner braces | Reduces movement during transit |

| Customs Clearance | Full CIQ/COO documentation | Avoids port delays (avg. 24hr faster) |

| Real-time Tracking | GPS-enabled container monitoring | Enables proactive issue resolution |

By integrating these protocols, Luoyang Xinzhaohe delivers transformer foil with 30% lower total cost of ownership versus premium global brands—without compromising quality. Our factory-direct approach ensures every shipment meets your operational reliability standards, from Luoyang to your facility.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a premier manufacturer and exporter of transformer materials with 20+ years of specialized expertise, Luoyang Xinzhaohe delivers engineered solutions that balance precision, reliability, and cost efficiency for global transformer manufacturers and power equipment engineers. Our vertically integrated production system ensures end-to-end control over material quality, while our deep understanding of IEC 60076, ASTM B209, and other industry standards guarantees seamless integration into your critical applications.

Decades of Specialized Expertise

Our technical team has mastered the metallurgical nuances of transformer-grade aluminum and copper foils, from raw material selection to final rolling processes. With two decades of experience serving Tier-1 transformer OEMs, we understand how material purity (≥99.7% Al), grain structure, and surface flatness impact transformer efficiency and thermal performance. This expertise translates to consistent dimensional tolerances (±0.01mm) and optimized mechanical properties that minimize winding defects and extend equipment lifespan.

Factory-Direct Cost Efficiency

By eliminating distributor markups and leveraging localized supply chains in Luoyang, China, we deliver 15–25% lower total cost of ownership versus global competitors. Our direct manufacturing model ensures transparent pricing with no hidden fees, while our high-volume production capabilities maintain stable pricing even during raw material volatility. For projects requiring large-scale foil supplies, this model reduces CAPEX without sacrificing technical specifications.

Rigorous Quality Assurance (ISO Certified)

Our ISO 9001:2015-certified quality system is reinforced by in-house metallurgical labs equipped with XRF analyzers, tensile testers, and surface roughness gauges. Every batch undergoes 100% inspection for purity, elongation (>30%), and surface defects, with full traceability from coil to delivery. This end-to-end control minimizes field failures and rework risks—critical for high-reliability applications in power grids and industrial motors.

| Key Differentiator | Luoyang Xinzhaohe | Typical Global Suppliers | Operational Impact |

|---|---|---|---|

| Cost Structure | Direct factory pricing | 20–30% higher via distributors | 15–25% lower total project cost |

| Quality Consistency | ISO 9001:2015 + in-house testing | Variable third-party validation | 40% fewer defects, reduced downtime |

| Lead Time | 15–20 days standard | 30+ days for global logistics | Accelerated project timelines by 35% |

Ready to optimize your transformer material sourcing? Contact our engineering team at cathy@transformerstrip.com for a customized quote. We’ll provide technical specifications, sample validation, and cost-analysis reports tailored to your exact requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium foil exporter from Luoyang Xinzhaohe.