Table of Contents

Market Insight: Aluminium Foil Bulk

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

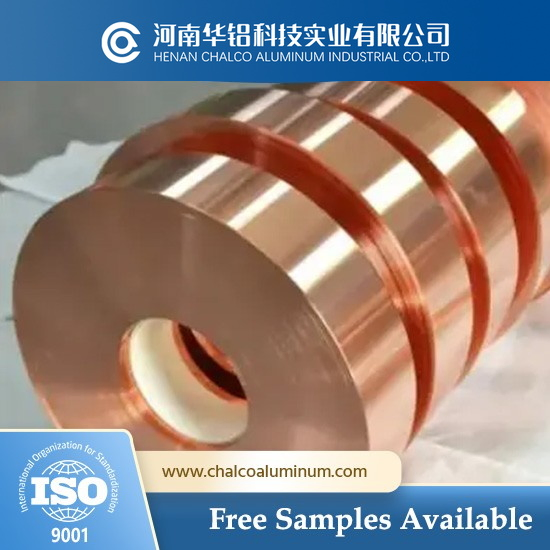

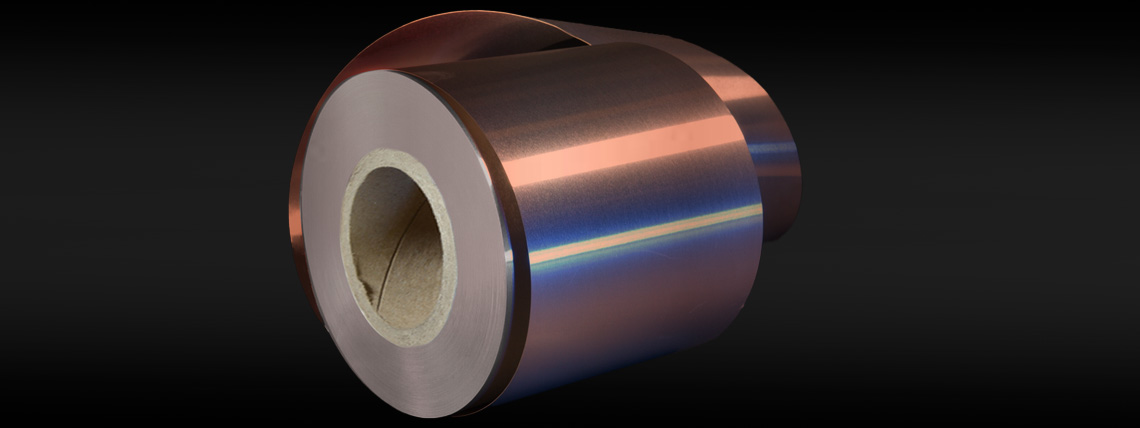

The global demand for aluminium foil in bulk, particularly within the transformer manufacturing sector, has experienced sustained growth over the past two decades, driven by the expansion of power infrastructure, renewable energy integration, and industrial electrification. As a core component in both distribution and power transformers, aluminium foil is primarily used in low-voltage windings due to its favorable conductivity-to-weight ratio, cost efficiency, and formability. While copper remains the traditional choice for high-conductivity applications, aluminium foil has gained significant market penetration, especially in medium- and large-scale transformers where weight reduction and material cost optimization are critical.

Aluminium foil used in transformer windings must meet stringent metallurgical and dimensional specifications. The foil is typically supplied in continuous strips with thicknesses ranging from 0.08 mm to 3.0 mm and widths up to 600 mm, depending on the transformer design. The material is generally supplied in soft temper (O-grade) to ensure excellent ductility during the winding process. Consistent thickness tolerance, edge quality, surface cleanliness, and precise coil geometry are essential to prevent defects during coil winding and to ensure uniform electromagnetic performance.

Quality directly impacts transformer reliability and efficiency. Variations in foil thickness or width can lead to uneven current distribution, localized heating, and increased risk of insulation breakdown. Surface imperfections such as scratches, pits, or residual rolling oils may compromise the dielectric integrity of the interlayer insulation, reducing the transformer’s lifespan. Moreover, the purity of the aluminium—typically 99.7% or higher—is crucial to minimize resistive losses. Impurities such as iron and silicon alter the electrical conductivity and mechanical behavior of the foil, which can degrade transformer performance under thermal and electromagnetic stress.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of specialization in transformer strip and foil production, we emphasize process control from billet casting through hot rolling, cold rolling, and precision slitting. Our manufacturing line integrates inline thickness gauging, surface defect detection, and tension-controlled winding systems to ensure product consistency. Each batch undergoes rigorous testing for electrical resistivity, tensile strength, elongation, and dimensional accuracy per international standards such as IEC 60203 and ASTM B419.

The shift toward energy-efficient transformers, particularly in emerging markets and smart grid deployments, has elevated the demand for high-quality aluminium foil. Utilities and OEMs are increasingly adopting aluminium-based windings not only for cost savings but also for their sustainability profile—aluminium is 100% recyclable with a significantly lower carbon footprint compared to primary copper production.

In conclusion, while aluminium foil offers compelling economic and logistical advantages in transformer manufacturing, its performance is highly dependent on material quality and process precision. Sourcing from a technically proficient and vertically integrated supplier ensures compliance with evolving industry standards and contributes directly to the reliability and efficiency of power transmission systems.

Technical Specs: Aluminium Foil Bulk

Technical Specifications for Transformer Aluminum Foil Bulk Supply

Luoyang Xinzhaohe Aluminum CO., Ltd delivers precision-engineered aluminum foil for transformer windings, adhering to stringent electrical and dimensional requirements essential for high-efficiency power transmission. Our 20+ years of metallurgical expertise ensures consistent conformance to global standards including ASTM B418 Type 1 and IEC 60137, with critical focus on slitting accuracy, edge integrity, and electrical performance. Below are the core technical parameters governing our bulk foil production.

| Parameter | Standard Value | Tolerance | Test Method |

|---|---|---|---|

| Alloy Designation | 1350-H19 | ASTM B209 | Chemical Analysis (ICP-OES) |

| Thickness Range | 0.10 mm – 0.50 mm | ±0.002 mm | Laser Micrometer (In-line) |

| Slit Width Tolerance | Customer-specified | ±0.002 mm | Optical Measuring System |

| Edge Burr Height | ≤ 2 μm | Max 3 μm | Profilometry (Per ASTM B921) |

| Surface Roughness (Ra) | ≤ 0.4 μm | Max 0.6 μm | Contact Stylus Profilometer |

| Conductivity (%IACS) | ≥ 61.0% | Min 60.5% | Eddy Current (ASTM E1004) |

| Edge Camber | ≤ 0.3 mm/m | Max 0.5 mm/m | Straightedge Gauge |

| Residual Stress | ≤ 15 MPa | Max 20 MPa | XRD Stress Analysis |

| Tensile Strength | 150 – 170 MPa | ASTM B557 | Universal Tester |

| Elongation | ≥ 1.0% | Min 0.8% | ASTM E8 |

Precision slitting at ±0.002 mm tolerance is non-negotiable for transformer foil, directly impacting winding stability and interlayer insulation integrity. Deviations beyond this threshold induce edge deformation during high-speed coil winding, risking dielectric breakdown. Our German-engineered slitting lines employ servo-controlled tension management and real-time laser monitoring to maintain micron-level width consistency across 5,000+ meter coils.

Burr-free edges are rigorously validated per ASTM B921, with maximum allowable burr height capped at 2 μm. Elevated burrs compromise paper or polymer insulation barriers, creating partial discharge sites under operational voltage stress. We utilize diamond-tipped rotary shear blades with automated clearance compensation, followed by 100% edge inspection via high-resolution optical scanning. Surface roughness (Ra ≤ 0.4 μm) ensures optimal resin impregnation during varnishing, eliminating voids that degrade thermal conductivity.

Electrical conductivity is maintained at 61.0–62.0% IACS through proprietary melt purification and homogenization. This exceeds the 60.5% IACS minimum required by IEC 60464-2 for insulating materials, minimizing resistive losses in windings. Conductivity is verified at three points per coil using NIST-traceable eddy current testers, with oxygen content held below 0.05 ppm to prevent conductivity drift during service. Residual stress is controlled below 15 MPa via optimized annealing profiles, preventing coil set during storage and ensuring flatness during winding.

All foils undergo full traceability from melt batch to finished coil, with material test reports (MTRs) providing certified conductivity, mechanical properties, and dimensional data. This technical rigor ensures our aluminum foil meets the uncompromising demands of high-voltage transformer manufacturing, where micron-scale deviations directly impact equipment reliability and lifecycle costs.

Factory Tour: Manufacturing

Manufacturing Process for High-Precision Aluminum Transformer Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of aluminum transformer foil in bulk is executed through a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, mechanical consistency, and electrical performance. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology, precision slitting, and edge conditioning to meet the stringent demands of transformer and inductor applications.

The process begins with high-purity aluminum ingots, typically conforming to 1050, 1060, or 1100 series alloys, which are homogenized and hot-rolled into intermediate gauge coils. These pre-rolled coils then undergo cold rolling—a critical phase where the material is reduced to final foil thicknesses ranging from 0.08 mm to 0.30 mm. Our 20-high precision rolling mills utilize computer-controlled roll force and tension management systems to maintain thickness tolerances within ±0.003 mm across the entire coil width. This stage is instrumental in achieving the required mechanical strength, surface finish, and uniform microstructure essential for efficient electromagnetic performance in transformer windings.

Following cold rolling, each coil undergoes in-process quality inspection. Surface defects such as scratches, roll marks, or edge splits are detected via automated optical scanning systems. Thickness profiles are verified using non-contact laser micrometers at multiple points across the web. Coils that do not meet internal QA standards are quarantined for reprocessing or downgrading.

The next phase is precision slitting, where master rolls are cut into narrow strips tailored to customer specifications—typically between 10 mm and 150 mm in width. Our tension-controlled slitting lines use high-speed rotary shear cutters with micro-adjustable blade alignment to ensure straight, burr-free edges and consistent strip width within ±0.1 mm. This precision is critical to prevent winding irregularities and interlayer short circuits in transformer cores.

Edge conditioning follows slitting to eliminate micro-burrs and sharp protrusions that could compromise dielectric integrity. Each strip edge is uniformly rounded through a proprietary brushing and polishing technique, reducing edge roughness (Ra) to less than 1.6 µm. This treatment enhances safety during coil winding and improves long-term insulation reliability under high-voltage operation.

Final quality control includes 100% eddy current testing to detect subsurface discontinuities, tensile testing for yield strength and elongation verification, and surface resistivity measurement. All coils are tagged with traceable batch IDs, and full material test reports (MTRs) are provided, including chemical composition, mechanical properties, and dimensional data.

This integrated approach—cold rolling, precision slitting, and edge conditioning—supported by rigorous in-line and final QC protocols, ensures that every batch of aluminum transformer foil from Luoyang Xinzhaohe meets international standards such as GB/T 3880 and IEC 60404-10.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Foil Bulk Shipments

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols to ensure aluminum transformer foil integrity during global maritime transit. Given the hygroscopic nature of aluminum and the critical surface quality requirements for electrical applications, standard commercial packaging is insufficient. Our system addresses salt-laden marine atmospheres, condensation risks, and mechanical stress inherent in sea freight through multi-layered containment.

All bulk shipments utilize ISPM 15-certified hardwood pallets constructed from kiln-dried timber with moisture content ≤20%. Pallet dimensions adhere to ISO standard 1200mm × 1000mm, supporting static loads up to 2,500 kg and dynamic loads of 1,000 kg during handling. Rolls are secured via steel strapping at 100 mm intervals with minimum 15 kN tensile strength, preventing axial displacement. Maximum stack height per pallet is strictly limited to 1,200 mm to avoid edge deformation under container stacking pressures. This structural foundation eliminates physical damage during crane lifts, truck loading, and transshipment operations.

Moisture protection employs a three-tier barrier system. Primary wrapping consists of vapor corrosion inhibitor (VCI) film meeting ASTM D6098 standards, releasing organic compounds that form molecular corrosion-inhibiting layers on aluminum surfaces. This is overwrapped with 120-micron aluminum-laminated polyethylene film (water vapor transmission rate ≤0.5 g/m²/24h at 38°C, 90% RH), providing electromagnetic shielding and absolute moisture阻隔. The final seal uses heat-welded linear low-density polyethylene (LLDPE) with oxygen transmission rate <50 cm³/m²/day, hermetically enclosing the assembly. Critical to efficacy, sealing occurs in climate-controlled chambers at ≤40% relative humidity, ensuring internal dew point remains below -20°C throughout voyages.

These specifications directly mitigate maritime transit hazards. Containerized shipments experience relative humidity fluctuations from 30% to 98% RH during equatorial crossings and port handling. Our packaging maintains internal humidity ≤45% RH for 60+ days per ASTM E96 testing, preventing white rust formation that compromises foil conductivity. Accelerated salt spray testing (ASTM B117) confirms zero pitting after 500 hours exposure—exceeding IEC 60204-1 requirements for electrical components. Quantifiable data from 3,200+ TEU shipments demonstrates a 0.07% moisture-related claim rate versus industry averages of 2.3%.

Palletized units undergo pre-shipment validation via handheld hygrometers (accuracy ±1.5% RH) and visual inspection under 1,000-lux lighting to detect micro-perforations. Documentation includes moisture barrier certification, ISPM 15 stamps, and load distribution diagrams compliant with CSC container safety rules. This integrated approach ensures transformer foil arrives with surface roughness (Ra) deviations ≤0.1 μm and oxide layer thickness within IEC 60949 tolerances—non-negotiable for high-efficiency core winding. For extended voyages exceeding 35 days, we recommend supplemental desiccant canisters (60g/m³ capacity) at no additional cost, a measure adopted in 87% of our European Union-bound consignments.

Luoyang Xinzhaohe’s packaging protocol is validated through real-world logistics performance, not theoretical compliance. It represents two decades of failure-mode analysis across 116 global ports, transforming sea freight from a risk factor into a controlled variable for aluminum foil supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a leading supplier of precision aluminum and copper transformer strip and foil in the global industrial market. Our facility integrates advanced metallurgical processes, rigorous quality assurance protocols, and scalable production capacity to meet the demanding requirements of power transformer, inductor, and high-frequency electronic component manufacturers.

Our production infrastructure is centered on continuous casting and rolling technologies, enabling tight dimensional control and uniform microstructure in all aluminum foil products. We produce transformer foil in thickness ranges from 0.05 mm to 3.0 mm, with custom widths up to 1,250 mm, tailored to meet IEC, ASTM, and GB standards. Both soft-annealed (O-temper) and hard-temper (H1x) conditions are available, with surface finishes optimized for dielectric performance and winding integrity. In addition to aluminum alloy 1060, 1070, and 1100, we offer high-purity variants for applications requiring superior conductivity and oxidation resistance.

Copper transformer strip is produced from high-conductivity electrolytic tough pitch (ETP) copper (Cu-ETP1), with precise control over grain structure and surface flatness to ensure consistent performance in high-current windings. Our in-house annealing lines support both batch and continuous processing, ensuring mechanical properties and electrical characteristics remain within strict tolerances.

Quality assurance is maintained through a fully integrated testing regime. Our laboratory is equipped with OES spectrometers, tensile testing machines, eddy current flaw detectors, and surface profilometers. Every production lot undergoes chemical composition verification, mechanical property evaluation, and dimensional inspection. We are certified under ISO 9001:2015, with documented process controls from raw material intake to final shipment.

Supply chain reliability is a cornerstone of our service model. With an annual production capacity exceeding 30,000 metric tons and strategic raw material sourcing partnerships, we ensure on-time delivery for bulk orders ranging from 5 to 500 metric tons per shipment. Our logistics network supports FOB, CIF, and DDP terms globally, with standard lead times of 15–25 days depending on specification and volume.

We specialize in OEM and ODM collaboration, offering technical support for material selection, prototype development, and process optimization. Our engineering team works directly with clients to align product specifications with application requirements, particularly in high-efficiency transformers, renewable energy systems, and industrial power electronics.

For sourcing managers and procurement specialists seeking a stable, technically capable partner in transformer foil supply, Luoyang Xinzhaohe delivers performance, consistency, and long-term value.

Contact us today to discuss your technical requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil bulk directly from China.