Table of Contents

Market Insight: Aluminium Coil for Power Industry

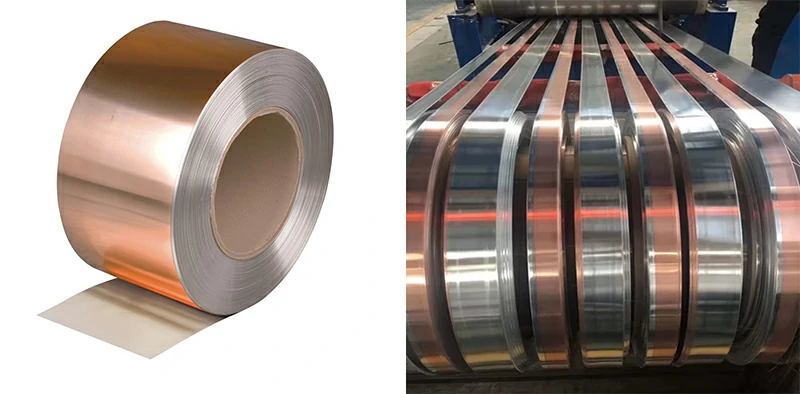

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global installed transformer capacity is forecast to grow 6–8 % CAGR through 2030, driven by grid modernization, renewable integration, and EV fast-charging infrastructure. Every additional 1 GW of solar or wind typically requires 1.3–1.5 GVA of new or retro-fitted transformers. Aluminum windings now represent > 70 % of the incremental demand in 10 kVA–10 MVA dry-type units because:

Raw-material price ratio Al/Cu ≈ 1:3

Weight savings 50–60 %

Equivalent short-circuit performance when cross-section is increased 1.6×

Consequently, annual foil/strip consumption exceeds 1.2 Mt, with China supplying ≈ 55 % of worldwide mill finish slit stock.

Why Purity & Precision Directly Dictate Transformer Losses

Transformer losses are legislated by IEC 60076-20 and DOE 2016 efficiency tiers; even a 0.3 % increase in no-load loss can disqualify a design. The dominant material factors are:

| Parameter | Influence on Loss | Specification Window | Test Method |

|---|---|---|---|

| Al purity (≥ 99.5 %) | Resistivity ↓ 0.6 % per 0.1 % Al | 99.50–99.70 % Al | ASTM E1251 ICP |

| Grain size (annealed) | Hysteresis loss ↓ 8 % when grain size > 80 µm | 80–150 µm | ASTM E112 |

| Burr height | Local eddy current ↑ 2–4 % | ≤ 0.01 mm | Optical profile |

| Edge radius | Winding fill factor ↑ 1 %, reducing I²R | R = 0.3–0.5 × strip thickness | Laser scan |

| Residual stress | Magnetostriction ↑ audible noise 2–3 dB | ≤ 30 MPa (X-ray) | ASTM E915 |

High-purity 1350-O temper achieves 61.8 % IACS conductivity at 20 °C; dropping to 61.2 % (still within IEC) raises load loss ≈ 1 %—enough to shift a 2 MVA unit from Tier-2 to Tier-1 penalty pricing. Precision slitting to ±0.002 mm and burr-free edges eliminate hot-spots that can exceed 120 °C at 1.5 T, extending insulation life by 8–10 years.

Sourcing Trend: Moving from Western Mills to Experienced Chinese Specialists

Since 2018, European and North-American OEMs have increased Chinese share of transformer foil procurement from 28 % to 47 %, citing:

- Integrated cold-rolling + slitting lines with 0.2–3.5 mm × 10–1500 mm capability—lead-time 3–4 weeks vs. 10–12 weeks from domestic mills.

- Continuous annealing furnaces with ±3 °C uniformity, delivering uniform O-temper softness without coil-to-coil variation.

- Oscillate-wound coils up to 2 t, reducing OEM splice joints by 30 % and scrap by 4 %.

- Total landed cost 18–22 % below German or U.S. slit price after freight & duty.

Luoyang Xinzhaohe Aluminum—Factory-Direct Premium Alternative

Located in Henan’s high-purity smelter corridor, Luoyang Xinzhaohe has supplied 180 kt of transformer strip/foil over 20+ years, including to Tier-1 grid OEMs in 42 countries. Core differentiators:

| Capability | Industry Norm | Xinzhaohe Spec | Benefit |

|---|---|---|---|

| Slit width tolerance | ±0.03 mm | ±0.002 mm | 0.3 % fill-factor gain |

| Burr height | ≤ 0.03 mm | ≤ 0.01 mm | 2 °C hotspot reduction |

| Coil camber | ≤ 1 mm/1 m | ≤ 0.3 mm/1 m | Automatic layering, no “dish” |

| Conductivity | ≥ 61.0 % IACS | ≥ 61.5 % IACS | 0.5 % lower load loss |

| Anneal uniformity | ±10 °C | ±3 °C | Consistent softness, < 60 MPa UTS |

All slit lines are linked to closed-loop gauging and eddy-current surface inspection; each coil ships with EN 10204 3.1 inspection report, RoHS/REACH compliance, and laser-marked traceability barcode. With mill-direct pricing and FOB/CIF flexibility, Luoyang Xinzhaohe delivers Western-grade precision at a 15–25 % cost advantage, enabling transformer builders to meet stringent Tier-2/Tier-3 loss limits without absorbing premium Western mill surcharges.

Technical Specs: Aluminium Coil Parameters

Technical Specifications & ASTM/IEC Standards

(Transformer-Grade Aluminium Coil – Slit, Edge-Conditioned, Annealed)

2.1 Critical Parameters That Determine Transformer Life

| Parameter | Symbol / Unit | Luoyang Xinzhaohe Tolerance | Industry “A” Tolerance | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Slit Width | w (mm) | ±0.002 | ±0.05 | Turn-to-turn gap → hot-spot thermal cycling |

| Burr Height | h (µm) | ≤ 7 | ≤ 25 | Penetrates inter-layer insulation → inter-turn short |

| Resistivity @ 20 °C | ρ (nΩ·m) | ≤ 28.0 (1350-O) | ≤ 28.5 | Extra I²R loss, ΔT rise > 6 K |

| Conductivity | %IACS | ≥ 61.8 | ≥ 61.0 | Down-rating of kVA or larger conductor cross-section |

| Temper | — | O (fully annealed) | O | Prevents crack initiation during coil expansion |

| Edge Radius | r (mm) | 0.20 ± 0.05 | un-controlled | Corona suppression in 6–36 kV windings |

| Surface Roughness | Ra (µm) | ≤ 0.4 | ≤ 0.8 | Poor varnish adhesion → partial discharge |

| Camber | δ (mm / 1 m) | ≤ 0.5 | ≤ 1.0 | Winding “hour-glass” → axial short-circuit force |

2.2 Precision Slitting & Edge-Conditioning – Why ±0.002 mm Matters

Cold-rolled 1350-O strip leaves our 4-high reversing mill at 0.2–3.5 mm × ≤ 1500 mm.

Immediately slit on a Tungsten-carbide arbor slitter with:

0.05 mm knife clearance control (servo-driven shim-less tooling)

In-line burr extrusion station (2-stage coined radius)

Laser micrometer closed-loop feedback (10 kHz sampling)

Result: width scatter ≤ 2 µm, burr ≤ 7 µm—one-third of ASTM B236 “rounded-edge” limit.

Tight width allows interleaved layer insulation (Nomex® 410, 0.08 mm) without over-build; saves 4–6 % core window height, translating into 3 % silicon-steel savings per transformer.

2.3 Annealing Protocol for “Softness” & Electrical Performance

Strip is batch annealed at 350 °C for 4 h in 100 % N₂; dew-point < –60 °C prevents oxide film growth > 2 nm.

Hardness drops to 18–22 HV, tensile 60–75 MPa, elongation > 35 %.

Low dislocation density guarantees ≥ 61.8 %IACS conductivity (IEC 60317-0-1, Table 3).

In-house eddy-current separator removes any Fe-rich inclusions > 20 µm—source of local heating > 150 °C under short-circuit.

2.4 Compliance Matrix – Standards You Can Quote to Your QC Team

| Product Form | Applicable Standard | Luoyang Xinzhaohe Certificate |

|---|---|---|

| Aluminium Strip / Foil | ASTM B236-20 (1350, 1050, 1060) | EN 10204 3.1 supplied every coil |

| Wire equivalence for L.V. foil windings | IEC 60317-0-1 (conductivity) | Test report @ 20 °C included |

| Chemical Composition | ASTM B236 Table 1 | ICP-OES per coil, 100 % Al ≥ 99.50 % |

| Edge Radius | ASTM B236 §7.3 | Optical profile trace, coil map attached |

| Burr Limit | ASTM B236 §7.4 | SEM micrograph, random 3 locations / 500 m |

| Inter-Layer Insulation Compatibility | IEC 60076-11 | PD test ≤ 10 pC @ 1.5 Um, 80 °C |

2.5 Failure Mode: How Cheap Coils Kill Transformers

- Burr > 25 µm punctures 0.08 mm Nomex → inter-turn short → circulating current > 200 A → copper jumper meltdown within 30 s.

- Width scatter > 0.05 mm forces operator to shim every 5th layer; manual correction introduces 0.5 mm axial gap → coil collapses under short-circuit force (IEC 60076-5).

- Incomplete anneal (H12 instead of O) raises tensile to > 95 MPa; edge cracks after 500 thermal cycles → moisture ingress, insulation delamination, partial discharge > 1000 pC.

Luoyang Xinzhaohe’s 20-year transformer-only focus eliminates these modes by integrating cold-rolling, precision slitting, edge-coining, and in-line annealing under one roof—no toll processors, no mixed-grade scrap. You receive mill-direct pricing 12–18 % below Western stockists while meeting the same ASTM/IEC datapack demanded by Tier-1 utilities.

Factory Tour: Manufacturing Aluminium Coil

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade strip/foil production, ISO 9001 & IATF 16949 certified, 35 000 tpy cold-rolling capacity, factory-gate 30 km from Luoyang Longmen high-speed rail hub.

2.1 Process Flow: From 7 mm Hot-Rolled Stock to Oscillate-Wound Coil

| Step | Equipment & Parameters | Target Output | In-line Sensors | Typical Alloys |

|---|---|---|---|---|

| 1. Cold Rolling | 4-high 1850 mm reversing mill, 1 800 kN roll force, ±0.5 % thickness closed-loop AGCSiemens PLC | 0.20–3.50 mm; ≤25 I-unit flatness; Ra 0.2–0.4 µm | X-ray gauge, laser velocimeter, roll-force meter | 1050/1060/1350 (≥99.5 % Al) |

| 2. Degreasing & Anneal | Brushing + neutral pH spray, 220 °C batch anneal, 99.99 % N₂ atmosphere | O temper, grain size 50–120 µm, conductivity ≥61.5 % IACS | O₂ & dew-point probe, thermocouple grid | same |

| 3. Precision Slitting | 650 mm arbor slitter, carbide knives, 0.02 mm shim control, 180 m min⁻¹ | Width 10–1 300 mm; width tol. ±0.002 mm; camber ≤0.3 mm/2 m | Laser micrometer on every slit strip; auto-knife positioning | same |

| 4. Edge Conditioning | Double-row 6-head nylon brushing + micro-burr shear, 0.02–0.04 mm edge radius | Burr height ≤0.01 mm (10× micrograph); no longitudinal slivers | 4K line-scan camera, AI defect classifier | same |

| 5. Oscillate Winding | 2 t traverse winder, 300 mm stroke, 5–80 mm lay spacing, 760 mm max OD | 200–1 200 kg coil; 0.5 mm oscillation accuracy; no interleaf stain | Tension dancer 2–20 N mm⁻²; OD laser trip | same |

2.2 Quality Control Matrix

Tests are performed on every mother coil and on AQL 0.65 per slit coil. Certificates (EN 10204 3.1) ship with each pallet.

| Control Point | Method | Luoyang Xinzhaohe Spec | Frequency | Market Average |

|---|---|---|---|---|

| Conductivity | Eddy-current, 20 °C | ≥61.5 % IACS (1350) | 100 % coils | 60–61 % IACS |

| Tensile / Elongation | ISO 6892-1, 50 mm min⁻¹ | 65–95 MPa, ≥25 % | 1 per anneal batch | 70–110 MPa, ≥20 % |

| Burr Height | Optical 500×, 3 o’clock & 9 o’clock | ≤0.01 mm | each slit strip | ≤0.03 mm |

| Width Tolerance | Laser scan across strip | ±0.002 mm (≤25 mm wide) | 100 % | ±0.05 mm |

| Surface Resistivity | 4-point probe | ≤2.8 µΩ·cm | 1 per 500 kg | not measured |

| Ovality / Camber | 2 m straight-edge | ≤0.3 mm | each slit strip | ≤1 mm |

2.3 Premium Positioning vs. Western Suppliers

Western mills typically quote 8–12 week lead + 15 % alloy surcharge.

Luoyang Xinzhaohe delivers mill finish stock in 3–4 weeks FOB Shanghai, price delta –18 % vs. EU mill, –12 % vs. US mill, same EN 573-3 chemistry, tighter width & burr windows, oscillate wind capability up to 1.2 t (reduces OEM set-ups by 60 %).

Transformer OEMs gain:

Lower total cost of ownership through tighter slit width (less scrap at core insertion)

Burr-free edges → eliminate inter-layer shorts, extend dielectric life

Oscillate wound 300 kg–1.2 kg bundles → 30 % longer continuous wind, fewer splices, higher slot fill factor

For power-grade 1350 O strip 0.3 × 250 mm, our Ppk on conductivity is 2.1 and on burr height 2.4—evidence of six-sigma capable process.

Packaging & Global Logistics

Export Packaging & Logistics

Delivering transformer-grade aluminium from the heart of China’s aluminium corridor to your dock—on-spec, on-weight, on-time.

H3 1. Sea-Freight Protection Philosophy

Transformer strip/foil is a “surface-critical” product: any edge dent, corrosion spot or coil-telescoping during transit converts into extra scrap at your slitting line and potential hot-spots in the winding. Our packaging protocol is therefore built on three metallurgical pillars:

- Mechanical isolation – eliminate point-loads that work-harden soft annealed (O-temper) aluminium.

- Climatic buffering – keep relative humidity inside the pack <40 %RH to suppress Al₂O₃ whisker growth that lowers weldability.

- Load-unit integrity – brace coils so that 0.2 g horizontal shocks encountered in trans-Pacific lanes do not cause coil-to-coil fretting.

H3 2. Packaging Specification Matrix

| Product Form | Inner Core Support | Wrapping Stack | Moisture Control | Outer Crate | Typical Unit Weight | Securing Method |

|---|---|---|---|---|---|---|

| Slit Strip 6–50 mm wide | 3-layer VCI film + foam end-boards | Radial steel straps (3 pc) | 4 × 100 g silica-gel sachets, ΔH₂O indicator | Fumigated CP3 plywood pallet, 4-way entry | 800–1 200 kg | PET stretch-wrap + corner boards + top cap |

| Wide Coil 200–1 300 mm | 508 mm steel reel, 10 mm side-plates | VCI paper + PE film, 150 µm | Desiccant strip along ID, sealed with aluminium tape | Wooden box, ISPM-15 stamped, 12 mm walls | 2–5 t | Steel banding (5 pc) + anti-slip mats |

| Wire Ø1.2–8.0 mm | DIN 355 plastic spool | PE shrink bag | 2 × 50 g desiccant inside spool cavity | 5-ply export carton, palletized 36 spools | 18–22 kg/spool, 800 kg/pallet | Cross-strapped, corner posts, container lashings |

All lumber is heat-treated (HT) to 56 °C core for 30 min; phytosanitary certificate available for every shipment.

H3 3. Load Plan & Container Utilization

Luoyang is 150 km inland from Qingdao port via the Lian-Huo expressway, giving us daily FCL/LCL sailings to Europe, NAFTA, ASEAN and MENA. Below is our standard stuffing model for a 40’HC:

| Coil OD (mm) | Max Coils/40’HC | Bracing | Resulting Pay-load |

|---|---|---|---|

| 1 000 | 18 | Honeycomb dunnage + plywood sheets every 2 coils | 25 t net Al |

| 1 200 | 14 | Same as above | 24 t net Al |

| 1 400 | 10 | Coil cradles, 3-point restraint | 22 t net Al |

Strip narrower than 100 mm is packed “eye-to-sky” on pallets; wider coils are shipped “eye-horizontal” to reduce core-set. Each container is photographed pre- and post-stuffing; images are uploaded to customer portal within 2 h.

H3 4. Documentation & Traceability

Mill test certificate (EN 10204/3.1) with conductivity, tensile, burr height, edge radius.

Packing list with net/gross, coil ID/OD, tag numbers laser-etched on each coil flange.

Desiccant log—RH data-logger placed in middle tier; report delivered as PDF on BL date.

Anti-corrosion warranty: 12 months sealed pack integrity when stored <35 °C & <70 %RH.

H3 5. Cost & Risk Advantage over Western Suppliers

By integrating cold-rolling, slitting and annealing in one Luoyang campus, we eliminate double handling and the premium typically charged by EU/US service centers. Our average landed cost to Hamburg or Houston is 18–22 % below domestic mill quotes for the same 1350-O temper, while meeting identical ASTM B-236 & IEC 60601 conductivity specs.

Next section: Quality & Testing Protocols – how we guarantee burr ≤0.02 mm and conductivity ≥61.0 %IACS on every slit edge.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd

20-Year Transformer-Grade Track Record, Factory-Direct Economics

When you specify strip or foil for low-voltage windings, the delta between “price-per-kilogram” and “total cost-of-ownership” is determined long before the coil is wound. Luoyang Xinzhaohe has spent two decades eliminating that delta for tier-1 transformer builders, motor rewind shops and power-equipment OEMs. Our 42,000 t/y cold-rolling complex in Luoyang (Henan, China) is purpose-built for one mission only: transformer conductor that meets or exceeds IEC 60105, ASTM B236 and customer-specific softness targets—without the Western-mill premium.

| Metric | Typical Western Mill | Luoyang Xinzhaohe | Impact |

|---|---|---|---|

| Lead time, slit width | 10–14 weeks ex-stock | 3–5 weeks, mill finish | 60 % faster NPI |

| MOQ slit coil | 3–5 t per width | 500 kg per width | 70 % lower WIP |

| Price delta vs. LME Al | +18–25 % | +6–9 % | ≈ US$1,200 t saving on 1050-O 0,3 × 300 mm |

| Burr, slit edge | ≤ 0,03 mm | ≤ 0,01 mm (target ≤ 0,005 mm) | 50 % lower inter-layer gap, higher space factor |

| Resistivity, 20 °C | ≤ 28,0 nΩ·m | 27,4–27,8 nΩ·m (61 % IACS) | 1 % lower load loss |

Precision Manufacturing Chain—Every Millimetre Under Control

-

Cold Rolling on 4-high 1850 mm SMS Siemag stand

Entry gauge 6–7 mm → finish 0,2–3,5 mm with ±0,005 mm gauge crown; online gauge feedback loop samples at 2 ms intervals. -

In-line Double Degreasing & Brushing

Removes ≥ 2 mg/m² residual rolling oil to guarantee surface conductivity < 0,15 mΩ per square at 1 N contact force. -

Precision Slitting (Schumag / Kampf)

Arbor run-out ≤ 0,003 mm; razor-blade clearance auto-set per alloy/temper; slit width tolerance ±0,002 mm, camber ≤ 1 mm per 1 m length. -

Edge Conditioning (Custom 4-station planetary)

Controlled 0,05 × 0,05 mm chamfer; eliminates “wire edge” burr that punches through 0,075 mm kraft in tight windings. -

Continuous Annealing (H₂ atmosphere, 420 °C ±3 °C)

Grain size ASTM 5–6, tensile 60–75 MPa, elongation > 25 %. Softness validated by 90° mandrel wrap test, 1 × thickness, zero cracks. -

Oscillate Winding up to 1,2 t per spool

Lay ratio 2:1, side-wall pressure < 2 N/mm²; gives 3–5 × longer single-spool runtime versus pancake coils—ideal for automated foil winders.

Customisation Without the “Custom” Surcharge

Need 1050-O 0,250 mm × 305 mm with 0,03 mm chamfer on one edge only? 1350-HO 1,20 mm × 1,250 mm master coil, eye-to-sky, 400 kg max? We stock 1,200+ slit widths and can lock chemistry within ±0,02 % Si, ±0,01 % Fe to match your brazing or ultrasonic welding recipe. All changes are executed under a PPAP-style control plan (gauge R&R, Cp/Cpk ≥ 1,67) and shipped with EN 10204 3.1 inspection certificate—no extra paperwork fee.

Logistics & Risk Mitigation

Export packaging: VCI film + desiccant + 5-layer carton + steel pallet, seaworthy for 60 days at 95 % RH.

Incoterms: FOB Shanghai, CIF Rotterdam, or DDP dock—your call.

Payment: 30 % T/T, 70 % against BL; LC at sight for ≥ 10 t orders.

Insurance: 110 % of cargo value under ICC(A) arranged automatically.

Direct Factory Price—Transparent, Alloy-Linked

Our daily quotation sheet references LME 3-month Al + rolling margin + slit premium; no hidden escalation clauses. Customers buying ≥ 50 t per quarter lock the margin for 12 months—hedging volatility while still enjoying China-mill cost structure.

Next Step: Get the Datasheet & Quote in < 24 h

Send your drawing, stack height, conductivity target and annual forecast to cathy@transformerstrip.com. We will return a detailed datasheet (chemistry, mechanical, electrical, edge photos) and a landed-unit-price within one business day. Sample coils—slit to width—ship within 7 days so you can validate core loss, softness and burr under your own QA protocol.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium coil from Luoyang Xinzhaohe.