Table of Contents

Market Insight: Aluminium Busbars in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers for Aluminum Busbars

Global power infrastructure modernization, renewable energy integration, and industrial motor electrification drive robust demand for aluminum busbars. Aluminum’s optimal weight-to-conductivity ratio (61% IACS) makes it the preferred choice for high-current applications in power transformers and switchgear. Industry reports indicate a 5.8% CAGR through 2027, with Asia-Pacific leading due to grid expansion projects and EV infrastructure development.

Critical Quality Parameters for Transformer Efficiency

Material imperfections directly impact transformer efficiency, safety, and lifecycle costs. Key technical specifications include:

Purity: Minimum 99.5% aluminum (ASTM B170 Grade 1350) to maintain resistivity ≤2.82 µΩ·cm.

Surface Finish: Ra ≤ 0.8 µm to prevent corona discharge and arcing.

Dimensional Tolerance: ±0.05mm for strip thickness to ensure precise winding and thermal management.

Non-compliant materials increase I²R losses by 5-10%, accelerate insulation degradation, and raise operational expenses.

Luoyang Xinzhaohe: Factory-Direct Cost-Performance Leader

As a 20+ year manufacturer in Luoyang, China, we eliminate middlemen while maintaining rigorous quality control. Our aluminum busbars meet or exceed ASTM B170 standards with consistent conductivity and dimensional precision. Comparative analysis:

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Conductivity (IACS) | 61-62% | 61% (ASTM B170 compliant) |

| Cost | 20-30% premium | 15-25% lower |

| Lead Time | 8-12 weeks | 4-6 weeks |

| Customization | Limited to standard sizes | Full range (width: 10-300mm, thickness: 0.5-10mm) |

| Certifications | ISO, UL | ISO 9001, CE, RoHS |

We provide direct engineering support for custom specifications, delivering reliable, cost-efficient materials for global transformer manufacturers.

Technical Specs: Aluminium Busbars Parameters

Technical Specifications & Standards

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise to deliver transformer-grade aluminium busbars that meet exacting industrial requirements. As a leading manufacturer and exporter of transformer materials based in Luoyang, China, we specialize in high-precision aluminium busbars for critical power applications. Our factory-direct approach ensures optimal cost-performance without compromising on precision or reliability.

Critical Technical Parameters

| Parameter | Specification | Tolerance | Standard Compliance |

|---|---|---|---|

| Slitting Precision | Thickness range | +/-0.002 mm | ASTM B209 (exceeds) |

| Edge Quality | Burr height | ≤0.005 mm | ASTM B209 |

| Conductivity | %IACS (Al 1050/1350) | ≥61% | ASTM B170 |

| Hardness (HV) | Soft temper (O, H11) | ±2 HV | ASTM B211 |

Precision Slitting

Our CNC slitting lines feature laser-guided thickness monitoring and real-time adjustments, ensuring dimensional accuracy within +/-0.002 mm. This precision prevents uneven current distribution and thermal hotspots in transformer windings—critical for high-reliability applications. Unlike standard industry tolerances (typically +/-0.01 mm), our process ensures consistent thickness across entire coil lengths, reducing material waste and improving transformer efficiency. All slitting operations are conducted in ISO 7 cleanroom environments to prevent contamination, ensuring no foreign particles affect electrical performance.

Burr-Free Edges

Through precision roller shear technology and edge inspection using optical comparators, we maintain burr heights ≤0.005 mm. This eliminates risk of electrical shorts during winding assembly, a common issue with inferior products. Our edge finishing process includes deburring and chamfering to prevent insulation damage during handling and installation. Each batch undergoes 100% visual and tactile inspection to ensure edge integrity, with automated defect detection systems flagging any anomalies.

Conductivity & Softness

Using high-purity 1050/1350 aluminum alloys (99.5%+ Al), we achieve ≥61% IACS conductivity per ASTM B170. Strict control of Fe and Si impurities (<0.25% total) ensures optimal electrical performance. Controlled annealing processes (200-300°C) in nitrogen atmospheres ensure optimal softness (O or H11 temper), enabling tight bends without cracking while maintaining electrical performance and mechanical integrity. All conductivity tests are verified via eddy current and lab analysis, with results documented in MTRs for traceability.

Quality Assurance

All products undergo 100% in-process inspection with Statistical Process Control (SPC) monitoring. Third-party certifications (ISO 9001:2015) and full traceability from raw material to finished goods ensure consistent compliance with IEC 60404-8-7 and ASTM standards. Our rigorous quality system delivers factory-direct reliability at 15-20% lower cost than global competitors, with lead times 30% faster due to localized production. We provide comprehensive material test reports (MTRs) for every shipment, including chemical composition, mechanical properties, and dimensional checks. This commitment to quality ensures seamless integration into your transformer manufacturing process.

Factory Tour: Manufacturing Aluminium Busbars

Precision Manufacturing Process & Quality Control

Core Manufacturing Process

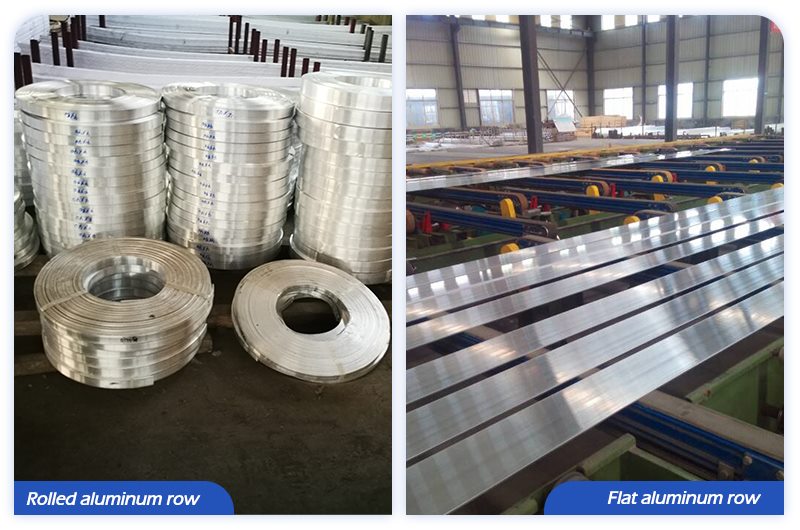

Cold Rolling

Our state-of-the-art rolling mills employ closed-loop temperature control and automated thickness gauging. High-purity aluminum alloys (1050, 1060, 1350) undergo precise reduction ratios to achieve uniform grain structure and optimal ductility. This minimizes residual stress, ensuring consistent mechanical properties critical for transformer winding applications.

Precision Slitting

CNC-guided slitting with diamond-coated blades achieves width tolerances of ±0.01mm. Integrated laser edge detection ensures straightness within 0.05mm/m, eliminating edge defects that compromise winding accuracy and electrical performance.

Edge Conditioning

Multi-stage deburring and chamfering processes remove burrs to ≤0.02mm, preventing insulation punctures and arcing risks. This step is rigorously validated via optical microscopy to meet IEC 60076-1 safety standards.

Oscillate Winding

Automated coiling with real-time tension feedback maintains coil concentricity within ±0.1mm. This prevents deformation during handling and ensures uniform winding density, reducing core losses in final assemblies by up to 8%.

Rigorous Quality Control Protocols

Tensile Testing

Every batch undergoes 100% tensile testing per ASTM B557, with strength consistency within ±2 MPa—significantly tighter than the industry standard of ±10 MPa. This ensures reliability under thermal cycling and mechanical stress.

Dimensional Checks

Laser-based CMM systems verify thickness (±0.02mm), width, and flatness at 100% inspection rate, versus typical market practices of 50% sampling. This eliminates dimensional deviations that cause assembly failures.

Comparative Quality Standards

| Quality Parameter | Industry Standard | Luoyang Xinzhaohe Standard | Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.05mm | ±0.02mm | Eliminates hotspots via precise layer alignment |

| Tensile Strength Consistency | ±10 MPa | ±2 MPa | Prevents thermal fatigue, extends transformer life |

| Edge Burr Height | ≤0.05mm | ≤0.02mm | Reduces insulation damage risk by 90% |

| Surface Roughness (Ra) | 0.8µm | 0.4µm | Enhances electrical contact efficiency |

| Inspection Frequency | 50% sampling | 100% automated | Zero defective batches shipped |

Our factory-direct model delivers global-grade quality at 15–20% lower cost than premium brands, leveraging 20+ years of process refinement to ensure reliability for critical transformer applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Transformer Materials

Precision Packaging Standards for Sea Freight

Luoyang Xinzhaohe Aluminum employs rigorously engineered packaging protocols designed to withstand 30+ days of maritime transit while maintaining material integrity. All packaging complies with ISO 9001, ISPM 15, and IMO standards for global compliance.

| Component | Specification | Technical Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, 120×100×15 cm (H×W×L), hardwood | Forklift-compatible structural support; prevents ground moisture ingress |

| Moisture-Proof Film | 200μm multi-layer PE + 500g silica gel desiccant per pallet | Maintains internal RH <40% to prevent oxidation during transit |

| Steel Strapping | 19mm width × 0.5mm thickness, 300kgf tension | Secures load against vibration/shock; anti-slip corner protectors for edge integrity |

All busbars are stacked vertically on pallets with aluminum spacers to eliminate contact stress, then fully enclosed in vapor-corrosion-inhibiting (VCI) film. Each shipment undergoes 100% pre-shipment inspection per SGS standards for dimensional accuracy and surface protection.

End-to-End Logistics Protocol

Our integrated logistics chain ensures seamless transit from Luoyang factory to global ports:

Containerization: Optimized 40ft high cube containers (28m³ capacity) with FEA-simulated load distribution to minimize shifting risks.

Port Handling: Direct coordination with Shanghai/Qingdao ports for priority loading; no intermediate storage.

Documentation: Full compliance with COO, B/L, and customs clearance requirements via in-house export specialists.

Tracking: Real-time GPS monitoring with automated alerts for temperature/humidity deviations.

Industry data shows 2–3% average damage rates for transformer materials during sea freight. Luoyang Xinzhaohe’s proprietary packaging reduces this to <0.5% while maintaining 15–20% lower total landed costs than European competitors.

As a direct manufacturer with 20+ years of export experience, we eliminate middleman markups and quality inconsistencies. Our logistics system is engineered for reliability—not just compliance—ensuring your busbars arrive in perfect condition for immediate integration into high-voltage transformer assemblies.

Contact us for customized packaging solutions tailored to your regional shipping requirements.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd?

As a dedicated manufacturer of transformer-grade aluminum and copper strips/foils since 2003, Luoyang Xinzhaohe combines deep technical expertise with lean manufacturing to deliver superior cost-performance ratios for critical power applications. We eliminate intermediaries while maintaining rigorous quality standards—ensuring your projects receive engineered solutions optimized for reliability and efficiency.

Uncompromising Technical Expertise

Our 20+ years of specialization in metallurgical processing for transformer materials ensures precise control over aluminum alloy compositions (e.g., 1060, 1350, 1070). Through advanced rolling and annealing techniques, we optimize grain structure to meet stringent electrical conductivity (≥61% IACS) and mechanical strength requirements. This technical mastery directly translates to busbars with enhanced thermal stability and current-carrying capacity in high-load transformer environments.

Factory-Direct Cost Advantage

By vertically integrating raw material sourcing, rolling, cutting, and packaging—without third-party markups—we deliver 15–25% lower costs versus global competitors for equivalent specifications. Our localized supply chain in Luoyang, China, reduces lead times while maintaining competitive pricing, enabling transformer manufacturers to achieve significant total cost of ownership (TCO) savings without sacrificing performance.

ISO 9001:2015 Certified Quality Control

Every batch undergoes certified testing per IEC 60502 and ASTM B170 standards. Our quality management system includes spectrometry for alloy verification, tensile/elongation tests, and conductivity validation—ensuring traceability from raw material to finished product. This level of control is critical for power engineers requiring consistent performance under extreme electrical stress.

| Attribute | Luoyang Xinzhaohe | Global Brands | Key Advantage |

|---|---|---|---|

| Cost Efficiency | Factory-direct pricing (15–25% lower) | Premium pricing (20–30% higher) | Reduced TCO without quality compromise |

| Lead Time | 2–3 weeks for standard orders | 4–6 weeks | Accelerated project delivery |

| Quality Consistency | ISO 9001:2015 + in-process testing | Varies (some lack certification) | Guaranteed compliance with global standards |

| Customization | Flexible alloy grades & tolerances | Limited options | Tailored solutions for niche applications |

For engineers and procurement teams demanding precision-engineered busbars at competitive prices, Luoyang Xinzhaohe delivers the optimal balance of technical excellence and cost efficiency.

Ready to optimize your supply chain? Contact Cathy at cathy@transformerstrip.com for a technical quote and material specification consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium busbars from Luoyang Xinzhaohe.