Table of Contents

Market Insight: Aluminium Bright

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer strip and foil—both aluminum and copper—continues to expand in parallel with rising electrical infrastructure investments, renewable energy integration, and industrial electrification. Within this sector, aluminum bright strip has emerged as a critical material for medium and high-capacity distribution and power transformers, particularly where weight reduction, cost efficiency, and conductivity balance are paramount. Aluminum bright, characterized by its high surface reflectivity, minimal oxide layer, and consistent dimensional tolerance, offers distinct advantages in winding applications where electrical performance and thermal management are critical.

Industrial demand for aluminum bright strip in transformers is primarily driven by its favorable conductivity-to-weight ratio, which is approximately two times better than copper on a per-unit-weight basis. This property makes aluminum an ideal choice for large-scale transformers used in utility substations, wind and solar power stations, and railway traction systems. As global energy grids modernize and decentralize, the need for lightweight, transportable, and cost-effective transformer solutions has elevated aluminum’s role in core electromagnetic components. Additionally, aluminum’s abundance and lower material cost compared to copper contribute to reduced manufacturing expenditures, especially in emerging markets undergoing rapid grid expansion.

However, the performance of aluminum bright in transformer applications is highly sensitive to material quality. Impurities, inconsistent thickness, surface defects, or inadequate mechanical properties can lead to increased electrical resistance, hot-spot formation, and reduced dielectric integrity. These issues compromise transformer efficiency, accelerate aging, and elevate lifecycle maintenance costs. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized production experience, we emphasize stringent process control in hot rolling, cold rolling, and tension leveling to ensure uniform thickness tolerance (typically ±0.01 mm), precise width accuracy, and defect-free surface finish. Our aluminum bright strip is produced from high-purity 1xxx series alloys (e.g., 1060, 1070, 1350), which are optimized for electrical conductivity (exceeding 61% IACS) and long-term reliability under continuous thermal cycling.

Quality also extends to edge condition and coil integrity. Burrs, edge cracks, or coil deformation can damage insulation during winding, leading to premature failure. Our production lines incorporate precision slitting and edge conditioning systems to ensure clean, smooth edges, while advanced coil handling protocols maintain structural consistency from factory to end-user. Furthermore, consistent temper (typically H18 or O) ensures predictable mechanical behavior during winding and stacking operations.

In summary, the industrial adoption of aluminum bright strip in transformers reflects a strategic alignment of performance, economics, and scalability. Yet, the material’s success hinges on metallurgical precision and process reliability. For OEMs and tier suppliers, partnering with a vertically integrated, quality-focused manufacturer like Luoyang Xinzhaohe Aluminum CO., Ltd ensures compliance with international standards (e.g., ASTM B419, IEC 60164) and supports the production of efficient, durable, and safe transformer systems.

| Parameter | Typical Specification |

|---|---|

| Alloy | 1060, 1070, 1350 |

| Temper | H18, O |

| Thickness Tolerance | ±0.01 mm |

| Conductivity | ≥61% IACS |

| Surface Finish | Bright, oxide-controlled |

| Edge Quality | Burr-free, slit to tight tolerance |

Technical Specs: Aluminium Bright

Technical Specifications for Aluminium Bright Transformer Strip

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical and precision rolling expertise to deliver Aluminium Bright strip meeting the most stringent demands of transformer core and winding applications. Our product is engineered for optimal magnetic performance, electrical efficiency, and seamless integration into high-speed winding processes. Critical specifications are rigorously controlled throughout production, from high-purity ingot casting through our proprietary cold rolling and precision slitting lines. Adherence to these parameters is non-negotiable for ensuring core loss minimization, thermal stability, and long-term reliability in final transformer assemblies.

Precision slitting accuracy is paramount for uniform winding tension and core integrity. Our Aluminium Bright strip achieves a thickness tolerance of ±0.002 mm across the entire coil width and length. This exceptional dimensional consistency is maintained through computer-controlled rolling mills with real-time laser gauging and servo-driven slitting heads operating under strict environmental controls. Such precision directly translates to reduced air gaps in wound cores, lower no-load losses, and enhanced transformer efficiency. Equally critical is edge quality. All slit edges are burr-free, defined as maximum edge protrusion ≤ 0.005 mm, verified by optical profilometry and tactile measurement. Burr-free edges prevent insulation layer damage during winding, eliminate potential short-circuit paths, and ensure smooth coil layer transitions, significantly reducing the risk of premature transformer failure.

Electrical conductivity, measured as a percentage of the International Annealed Copper Standard (%IACS), is a fundamental indicator of material purity and suitability for conductive applications. Our Aluminium Bright strip consistently achieves 61.0% to 62.0% IACS. This high conductivity level, resulting from stringent control of iron and silicon content (Fe ≤ 0.15%, Si ≤ 0.10%) and optimized annealing profiles, minimizes resistive (I²R) losses in windings, directly contributing to overall transformer energy efficiency and thermal management. Surface finish is maintained at a specular bright level (Ra ≤ 0.15 µm) to ensure optimal adhesion for subsequent insulation coatings and visual defect detection.

The following table details key technical parameters and their verification methodology:

| Parameter | Specification | Test Standard | Functional Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM E29, ISO 2178 | Ensures uniform core density, minimizes losses |

| Edge Burr | ≤ 0.005 mm | ISO 1302, Internal | Prevents insulation damage, avoids shorts |

| Electrical Conductivity | 61.0% – 62.0% IACS | ASTM B193 | Minimizes winding losses, improves efficiency |

| Surface Roughness (Ra) | ≤ 0.15 µm | ISO 4287 | Optimizes insulation adhesion, defect control |

| Tensile Strength | 80 – 100 MPa | ASTM E8 | Balances formability and handling strength |

| Elongation | ≥ 5% | ASTM E8 | Ensures crack resistance during winding |

| Coil Inner Diameter | 508 mm (20″) | Customer Spec | Compatibility with winding machinery |

| Coil Outer Diameter | Max 1200 mm | Customer Spec | Logistics and handling optimization |

Quality assurance is embedded within our process. Statistical Process Control (SPC) monitors all critical parameters in real-time during rolling and slitting. Every coil undergoes 100% eddy current testing for subsurface defects and edge integrity verification. Comprehensive material certification, including conductivity, mechanical properties, and chemical composition (verified via OES), is provided with each shipment. This systematic approach guarantees the dimensional precision, edge perfection, and electrical properties essential for high-performance transformer manufacturing, reflecting Luoyang Xinzhaohe Aluminum CO., Ltd’s commitment to supplying mission-critical materials for the global power infrastructure sector.

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Bright Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-purity aluminum bright transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, surface integrity, and electrical performance. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of power and distribution transformer applications.

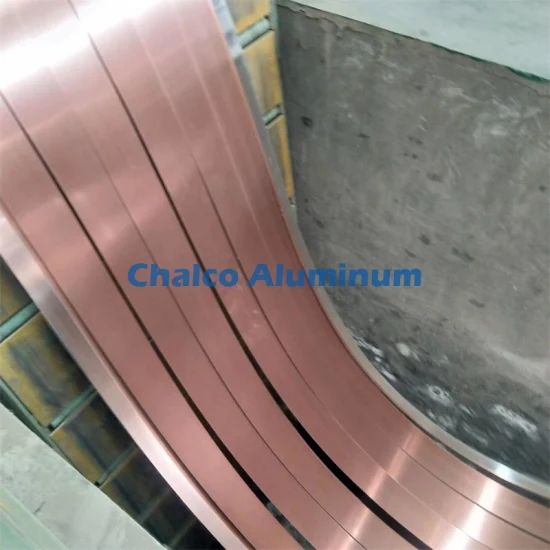

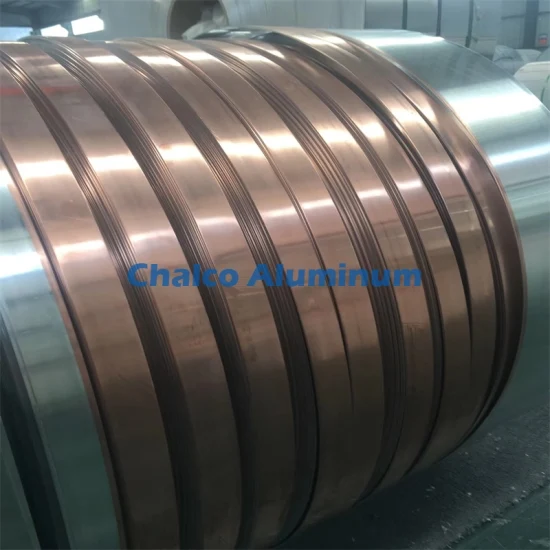

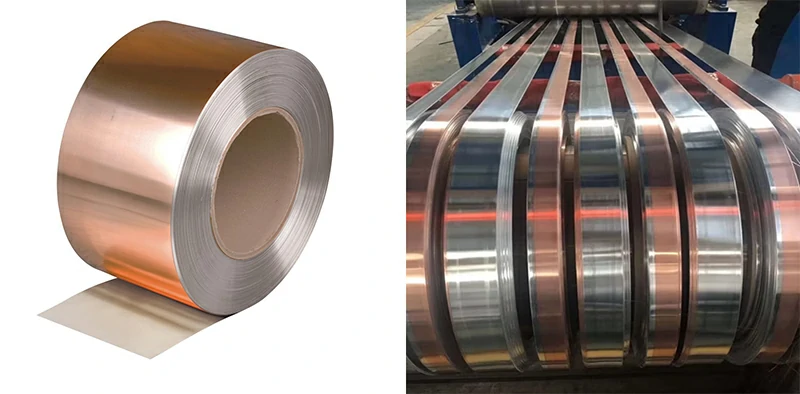

The process begins with cold rolling of high-conductivity aluminum ingots, typically from 99.7% to 99.85% pure, sourced under strict supplier qualification protocols. The ingots are first homogenized and scalped before undergoing hot rolling to intermediate gauges. Subsequent cold rolling reduces the material to final thicknesses ranging from 0.10 mm to 0.50 mm, depending on customer specifications. This stage is critical for achieving the desired mechanical properties and surface finish. Rolling is performed under precise tension and lubrication control to minimize thickness variation, with online laser gauges monitoring strip profile and flatness in real time. The cold-rolled coils exhibit a bright, mirror-like surface finish—essential for minimizing interlayer losses in transformer windings.

Following cold rolling, the coils proceed to precision slitting. This operation segments the master rolls into narrow strips, typically between 10 mm and 100 mm in width, tailored to transformer core design requirements. The slitting line is equipped with high-precision circular knives and tension control systems to ensure edge straightness and consistent width tolerance, typically held within ±0.1 mm. During slitting, the strip is continuously inspected for surface defects such as scratches, roll marks, or contamination using automated optical inspection systems.

Edge conditioning is the final mechanical treatment in the process. The slit edges are gently rounded or chamfered to eliminate sharp burrs and micro-cracks that could initiate delamination or electrical discharge under operational stress. This step significantly enhances winding reliability and dielectric performance in the finished transformer. Edge geometry is verified through routine metrological sampling using optical profilometry.

Throughout the manufacturing sequence, rigorous quality control protocols are enforced. In-process checks include thickness profiling, surface roughness measurement (Ra typically <0.4 µm), and tensile testing to confirm yield strength and elongation. Final inspection includes 100% eddy current testing for subsurface defects and visual examination under controlled lighting. All coils are traceable via batch numbering, with full material test reports (MTRs) provided, including chemical composition, mechanical properties, and dimensional data.

This disciplined approach to cold rolling, slitting, and edge conditioning ensures that Luoyang Xinzhaohe’s aluminum bright transformer strip and foil consistently meet international standards, including GB/T 3880 and IEC 60146, delivering reliability in high-efficiency transformer manufacturing.

Packaging & Logistics

Export Packaging Specifications for Aluminum Bright Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO.,Ltd implements rigorously engineered export packaging protocols for aluminum bright transformer strip and foil, prioritizing material integrity during global maritime transit. Sea freight exposes aluminum to high-humidity environments, salt-laden air, and temperature fluctuations, which can induce surface oxidation, hygroscopic corrosion, or staining—compromising the critical surface finish required for transformer core lamination. Our 20+ years of metallurgical expertise inform a dual-layer packaging system designed to mitigate these risks comprehensively.

All shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried hardwood. These pallets feature reinforced stringers and deck boards to support unitized loads up to 2,500 kg, preventing deformation during container stacking or crane handling. Pallet dimensions strictly adhere to ISO container standards (1,200 × 1,000 mm or 1,100 × 1,100 mm), ensuring optimal space utilization and stability. Crucially, pallets undergo anti-fungal treatment and are fumigation-free, eliminating chemical residue risks to the aluminum surface.

The primary barrier against moisture ingress is a triple-layer moisture-proof film system. Each coil is first wrapped in acid-free kraft paper to absorb residual surface oils. This is followed by a 125μm-thick, multi-laminate vapor barrier film comprising:

Outer layer: 20μm polyethylene for puncture resistance

Core layer: 8μm aluminum foil for near-zero moisture vapor transmission

Inner layer: 15μm heat-sealable polypropylene

Film seams are hermetically sealed via impulse welding at 280°C, achieving a seal strength of ≥80 N/15mm to prevent delamination. Desiccant packs (60g/unit, silica gel) are strategically positioned between the coil and film interior, calculated at 1.2% of the coil’s net weight to maintain internal RH below 40% for 60+ days. The entire assembly undergoes partial vacuumization (0.8 bar) to eliminate trapped ambient air before final heat sealing. This process reduces oxygen concentration to <5%, inhibiting oxidation without inducing mechanical stress on thin gauges.

Verification is non-negotiable. Every packaged unit includes a humidity indicator card (0–60% RH range) visible through a film window, providing real-time validation of internal conditions. Pre-shipment moisture testing via calcium chloride desiccant method confirms <0.02 g/m²/24h vapor transmission. Documentation includes a packing list with pallet ID, seal batch numbers, desiccant placement map, and RH test certificates—ensuring full traceability for customs and quality audits.

This packaging architecture delivers quantifiable protection: field data from 1,200+ containers shipped to Southeast Asia, Europe, and the Americas since 2020 shows zero moisture-related claims. For transformer-grade aluminum bright, where surface reflectivity and oxide layer uniformity directly impact core loss performance, such reliability is not optional—it is foundational to supply chain continuity. Partner with Xinzhaohe to eliminate transit-induced metallurgical degradation through packaging engineered at the intersection of materials science and logistics precision.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Transformer Strip and Foil Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd brings over two decades of specialized expertise in the production and supply of high-purity aluminum and copper transformer strip and foil. Established in 2003, our facility in Luoyang, Henan Province, China, has evolved into a trusted partner for global manufacturers requiring precision-engineered conductive materials for power transformers, reactors, and high-efficiency electrical systems. Our vertically integrated manufacturing platform ensures strict process control from raw material selection through final inspection, delivering consistent metallurgical and dimensional performance to meet the most demanding industry specifications.

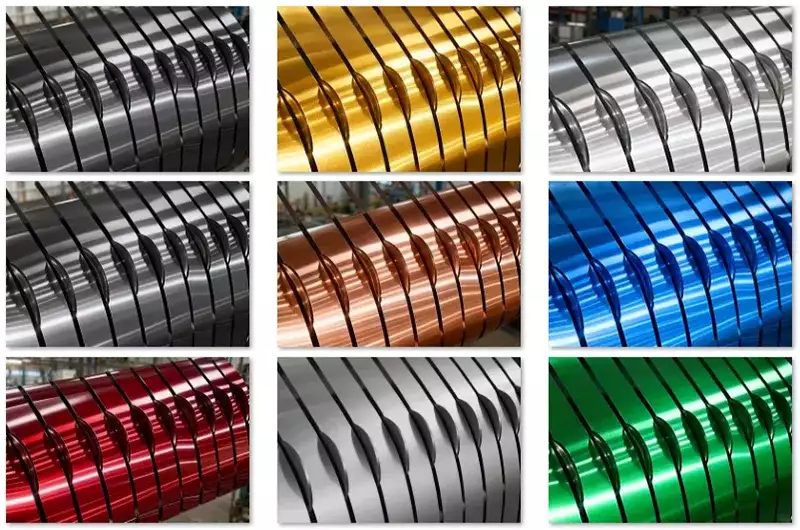

Our production capabilities are anchored in advanced cold rolling technology, precision slitting lines, and in-house annealing systems designed to maintain optimal grain structure and electrical conductivity. We produce aluminum transformer strip in thicknesses ranging from 0.1 mm to 3.0 mm and widths up to 600 mm, with alloys including 1060, 1070, and 1350, all compliant with GB/T 3190, ASTM B418, and IEC 60164 standards. Copper strip is available in C11000 and C10200 grades, processed to tight tolerances with surface finishes suitable for high-voltage insulation systems. All materials undergo rigorous quality assurance protocols, including eddy current testing, tensile strength verification, and resistivity measurement, ensuring defect-free performance under continuous thermal and electromagnetic loading.

We operate a fully equipped metallurgical laboratory with OES spectrometry, metallographic analysis, and microhardness testing, enabling real-time process adjustments and full traceability for every production batch. Our ISO 9001:2015-certified quality management system supports compliance with international procurement requirements, while our lean manufacturing practices ensure on-time delivery and cost efficiency. With an annual production capacity exceeding 15,000 metric tons, we serve both large-volume OEMs and specialized transformer manufacturers requiring custom temper, edge conditioning, or coil weight configurations.

Sustainability and supply chain resilience are integral to our operations. We source primary aluminum from certified refineries and maintain strategic inventory buffers to mitigate raw material volatility. Our logistics network supports containerized FCL and LCL shipments to global ports, with documentation prepared in English, Spanish, or German as required.

For engineering teams and procurement managers seeking a reliable, technically capable partner in transformer conductor materials, Luoyang Xinzhaohe offers proven performance, responsive technical support, and long-term supply stability. We welcome direct collaboration to review material specifications, provide samples, or conduct factory audits.

Contact us today to discuss your transformer strip or foil requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium bright directly from China.