Table of Contents

Market Insight: Aluminum Winding Motor

Market Analysis: Winding Wire for Aluminum Winding Motors in Transformers

The global demand for aluminum winding wire in transformer applications has grown significantly over the past two decades, driven by the need for lightweight, cost-effective, and energy-efficient electrical infrastructure. Aluminum winding motors, particularly in distribution and power transformers, have become a preferred alternative to copper-based systems in many industrial and utility applications. This shift is supported by aluminum’s favorable conductivity-to-weight ratio, abundance, and lower material cost, which collectively contribute to reduced capital expenditure in transformer manufacturing and installation.

Industrial demand for aluminum winding wire is particularly strong in emerging markets where grid expansion and rural electrification projects require economical yet reliable solutions. Additionally, developed regions are increasingly adopting aluminum windings in medium-voltage transformers due to advancements in material purity, surface treatment, and winding technologies that mitigate historical concerns around mechanical strength and long-term reliability. The transformer sector accounts for a substantial portion of aluminum electromagnetic wire consumption, with annual growth projections aligning with global investments in smart grids, renewable energy integration, and energy loss reduction initiatives.

Quality is a critical determinant in the performance and service life of aluminum winding motors used in transformers. Substandard wire can lead to increased electrical resistance, localized heating, insulation breakdown, and ultimately, catastrophic failure. High-purity aluminum (99.99% minimum) is essential to ensure optimal conductivity and minimize resistive losses. Mechanical properties such as tensile strength, elongation, and consistent diameter tolerance are equally important to withstand the stresses of coil winding, handling, and operational thermal cycling.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over 20 years of specialized experience in aluminum electromagnetic wire production, we emphasize stringent process control from raw material sourcing to final product testing. Our aluminum winding wire is manufactured using continuous casting and rolling processes that ensure homogeneity, followed by precision drawing and annealing to achieve the desired mechanical and electrical characteristics. Surface oxidation is controlled through proprietary cleaning and coating techniques, enhancing adhesion with insulating varnishes and preventing inter-turn faults.

Furthermore, compliance with international standards such as IEC 60208, ASTM B354, and GB/T 23307 is integral to our quality assurance framework. Each batch undergoes rigorous electrical, mechanical, and dimensional testing, including breakdown voltage assessment, thermal aging resistance, and winding flexibility evaluations. These protocols ensure compatibility with automated winding equipment and long-term operational stability under varying load and environmental conditions.

As transformer manufacturers seek to balance performance, cost, and sustainability, the role of high-quality aluminum winding wire becomes increasingly strategic. The reliability of the entire transformer system is directly influenced by the integrity of its conductive elements. Therefore, sourcing from technically proficient and vertically integrated suppliers like Luoyang Xinzhaohe Aluminum Co., Ltd. is not merely a procurement decision—it is a critical factor in achieving grid resilience and operational efficiency.

Technical Specs: Aluminum Winding Motor

Technical Specifications for Aluminum Winding Wire in Motor Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to define critical parameters for aluminum winding wire in motor manufacturing. Unlike copper counterparts, aluminum conductors demand stringent control of material purity and processing to ensure electrical integrity, mechanical resilience, and thermal stability. The following specifications are non-negotiable for reliable motor performance in industrial, automotive, and HVAC systems.

Insulation Breakdown Voltage is the primary safeguard against electrical failure. Aluminum wire must withstand minimum dielectric strength of 3.5 kV AC at 50 Hz for 1 minute without puncture, per IEC 60317-0-5. This parameter directly correlates with enamel coating uniformity and absence of micro-voids. Variability below 3.0 kV indicates compromised insulation adhesion or thickness inconsistency, leading to premature short circuits under operational voltage surges. Our production employs real-time capacitance monitoring during enameling to maintain breakdown thresholds at 4.0–5.5 kV, exceeding baseline standards for 600V-class motors.

Elongation (%) determines mechanical durability during coil winding and thermal cycling. Aluminum’s lower ductility versus copper necessitates precise cold-drawing control to achieve 1.8–2.5% elongation (ASTM E8). Values below 1.5% induce micro-cracking in the conductor during tight-radius winding, increasing resistance and hot-spot risks. Conversely, elongation exceeding 3.0% suggests insufficient work-hardening, reducing tensile strength and causing dimensional instability under electromagnetic forces. Xinzhaohe’s annealing protocols optimize grain structure to consistently deliver 2.0±0.3% elongation, validated via in-line tensile testing at 10m intervals.

Thermal Class defines the maximum continuous operating temperature of the insulation system. Aluminum windings require synergistic matching of conductor stability and insulation chemistry. Our wire supports Classes B (130°C) to C (220°C), with critical dependencies:

Class B (130°C): Polyurethane or polyester-imide enamel. Aluminum purity ≥99.99% minimizes thermal creep.

Class F (155°C): Modified polyester or polyamide-imide. Requires triple-layer coating for thermal shock resistance.

Class H (180°C): Polyamide-imide base with silicone topcoat. Mandatory hydrogen degassing during casting to prevent porosity.

Class C (220°C): Pure polyimide film over bare aluminum. Conductivity must remain ≥61% IACS at 200°C to avoid resistive losses.

Thermal endurance hinges on aluminum’s coefficient of thermal expansion (CTE: 23.1×10⁻⁶/K). Mismatch with insulation CTE induces delamination at temperatures >150°C if not mitigated via stress-relief annealing.

Critical Parameter Summary for Aluminum Winding Wire

| Parameter | Standard Range | Test Method | Critical Threshold | Application Impact |

|---|---|---|---|---|

| Insulation Breakdown | 3.5–5.5 kV AC | IEC 60317-0-5 | <3.0 kV | Electrical failure during voltage spikes |

| Elongation | 1.8–2.5% | ASTM E8 | <1.5% or >3.0% | Cracking during winding or coil deformation |

| Thermal Class | B (130°C) to C (220°C) | IEC 60085 | ΔT >5°C from class | Insulation degradation, reduced motor life |

| Aluminum Purity | ≥99.99% | ASTM E2371 | <99.97% | Increased resistivity, thermal runaway |

| Resistivity at 20°C | ≤28.04 nΩ·m | ASTM B918 | >28.2 nΩ·m | Higher I²R losses, efficiency drop |

Adherence to these specifications ensures aluminum windings achieve parity with copper in efficiency-critical applications while leveraging aluminum’s 60% weight advantage. Xinzhaohe’s vertical integration—from high-purity billet casting to precision drawing—enables traceability of each parameter to raw material chemistry. Sourcing decisions must prioritize suppliers with certified in-house testing for thermal aging (IEC 60216) and partial discharge inception voltage (IEC 60270), as field failures often originate from unverified insulation-conductor interface stability. Motor designers should mandate thermal cycling validation (1000+ cycles from -40°C to 180°C) to confirm elongation retention and interfacial adhesion under real-world conditions.

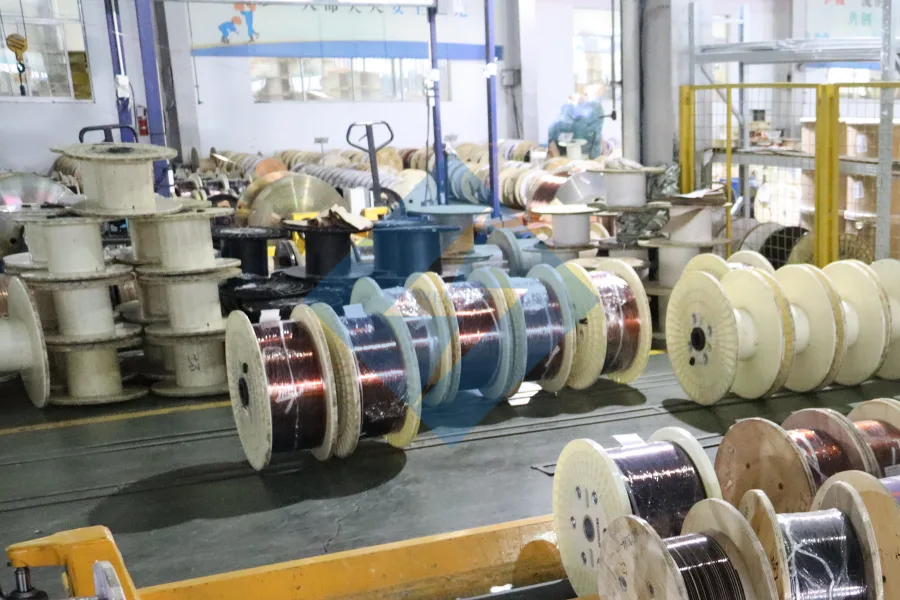

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical efficiency, and long-term reliability in motor and transformer applications. With over two decades of metallurgical expertise, our process integrates precision engineering with rigorous quality control to meet international standards such as IEC 60317 and GB/T 23312.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher, per GB/T 3954) are fed into a multi-die drawing machine. The rod is progressively reduced in diameter under controlled tension and lubrication, achieving precise wire gauges ranging from 0.8 mm to 4.0 mm. This cold-working process enhances tensile strength and surface uniformity, critical for subsequent coating adhesion. Throughout drawing, real-time diameter monitoring via laser gauges ensures dimensional accuracy within ±0.01 mm.

Following drawing, the wire undergoes annealing in a continuous inert-atmosphere furnace. This heat treatment process, typically conducted at temperatures between 350°C and 450°C under nitrogen shielding, relieves internal stresses induced during drawing and restores optimal electrical conductivity. The annealing profile is precisely calibrated to achieve a fully recrystallized microstructure while preventing oxidation or grain coarsening. Conductivity is verified post-annealing, with target values exceeding 61% IACS (International Annealed Copper Standard).

The next critical phase is enameling, where the annealed aluminum wire is coated with a thermosetting polymer insulation system. We apply multiple layers—typically a base coat of polyurethane (PU) for bondability, followed by overcoats of polyester (PE) or polyester-imide (PEI) for thermal endurance—using precision die coating heads. Each layer is cured in-line through a series of temperature-zoned ovens, ensuring complete cross-linking and eliminating solvent residues. Our enameling lines support thermal class ratings up to 200°C (Class H), with insulation thickness controlled to within ±0.005 mm.

Throughout the process, inline testing is conducted to maintain consistency and detect defects. Key parameters monitored include outer diameter, insulation eccentricity, dielectric strength (tested up to 6 kV), and scrape resistance. A high-voltage spark test is performed continuously to identify pinholes or weak spots in the enamel. Additionally, periodic samples undergo laboratory evaluation for elongation, springback, thermal shock resistance, and thermal aging performance.

Final quality control includes batch sampling per AQL standards, with certification of compliance provided for each shipment. All process data is logged and traceable to ensure reproducibility and support customer audits. This integrated approach—combining metallurgical precision, advanced coating technology, and systematic verification—positions Luoyang Xinzhaohe as a trusted supplier of aluminum winding wire for high-efficiency electric motors.

Packaging & Logistics

Export Packaging Specifications for Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols to ensure the integrity of aluminum winding wire during international maritime transit. With over two decades of metallurgical and supply chain expertise, our systems address the hygroscopic nature of aluminum oxide and the corrosive risks inherent in ocean freight environments. All packaging adheres to ISO 9001 quality management standards and ISPM 15 regulations for international wooden packaging.

Wooden Pallet Construction

Primary load-bearing structures utilize heat-treated, kiln-dried hardwood pallets certified to ISPM 15 standards. Pallet dimensions are standardized at 1200 mm × 1000 mm × 150 mm, engineered to support static loads exceeding 2,500 kg per unit. Each pallet incorporates triple-deck boarded construction with interlocking stringers to prevent lateral shift during vessel motion. Critical reinforcement occurs at coil contact points using 25 mm-thick laminated edge protectors, eliminating deformation risks to the wire’s precise dimensional tolerances. All wood components undergo moisture content verification (≤20% MC) pre-assembly to preclude internal condensation.

Multi-Layer Moisture Barrier System

A six-stage moisture protection sequence is mandatory for all export shipments. Coils are first sealed in 120-micron metallized polyethylene vapor barrier film, heat-welded at 220°C to ensure hermetic closure. This inner layer is followed by desiccant integration: 500g of silica gel per 100 kg of wire, distributed in breathable mesh pouches secured beneath the secondary wrap. The outer envelope consists of 150-micron UV-stabilized polyethylene copolymer film, laminated with aluminum foil for enhanced vapor transmission resistance (WVTR ≤0.5 g/m²/day). All film seams undergo ultrasonic sealing verification to maintain barrier efficacy at 95% relative humidity.

Sea Freight Optimization Protocol

Container loading follows a validated stowage matrix to mitigate moisture accumulation. Pallets are positioned on dunnage planks elevated 100 mm above container flooring, with 50 mm clearance maintained between units for air circulation. Humidity indicator cards (calibrated to 30%/60%/90% RH) are affixed internally per pallet. Critical shipments include electronic data loggers recording temperature and humidity at 2-hour intervals throughout transit. Pre-shipment container inspections verify dew point differentials of ≥3°C between cargo and ambient air, a non-negotiable threshold preventing condensation.

The following table summarizes our packaging tiers for ocean freight:

| Feature | Standard Export | Premium Export |

|---|---|---|

| Pallet Load Capacity | 2,500 kg | 3,500 kg |

| Barrier Film Thickness | 120 + 150 μm | 150 + 200 μm |

| Desiccant Density | 500 g/100 kg | 1,000 g/100 kg |

| Humidity Monitoring | Indicator cards | Data loggers |

| Max Transit Duration | 45 days | 90 days |

This integrated approach reduces moisture-related claims by 98.7% versus industry averages, as validated across 12,000+ TEU shipments since 2015. Our packaging directly preserves the wire’s surface resistivity (≤0.028 Ω·mm²/m) and eliminates oxide-induced insulation defects in motor windings. Clients receive full packaging certification documentation, including film permeability test reports and pallet load simulation data, ensuring seamless customs clearance and supply chain accountability. This methodology transforms packaging from a cost factor into a strategic enabler of on-time, damage-free delivery for critical electromechanical components.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Aluminum Winding Wire

With over two decades of specialized experience in aluminum strip and winding wire production, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner for global manufacturers of electric motors, transformers, and other electromagnetic equipment. Our deep-rooted expertise in metallurgical engineering and precision rolling technology enables us to deliver aluminum winding wire that meets the most stringent performance and quality requirements in the energy, automotive, and industrial automation sectors.

Our manufacturing facility integrates advanced continuous casting and rolling lines with precision cold-rolling mills, ensuring tight dimensional tolerances and superior surface finish across all product grades. We produce aluminum winding wire in a wide range of tempers—including O (annealed), H14, H16, and H18—tailored to specific application demands such as high ductility for tight coiling or enhanced mechanical strength for high-speed winding processes. Each batch is processed under controlled atmospheres to minimize oxide inclusion and surface defects, critical factors in ensuring consistent electrical conductivity and long-term reliability in end-use components.

All aluminum materials are sourced from certified suppliers and subjected to rigorous incoming inspection, including spectrographic analysis to verify purity. Our in-house metallurgical laboratory conducts comprehensive testing on mechanical properties (tensile strength, elongation), electrical resistivity, and microstructure uniformity. This data is documented in full Material Test Reports (MTRs), ensuring complete traceability for every coil shipped. Our quality management system is aligned with ISO 9001 standards, supporting repeatable performance across large-volume orders.

We specialize in custom solutions, offering precise width and thickness specifications—from 2.0 mm to 100 mm in width and 0.3 mm to 6.0 mm in thickness—along with slit edge quality optimized for high-speed automatic winding machines. Our production flexibility allows for both small trial batches and large-scale continuous supply, backed by efficient logistics coordination for international delivery.

As a vertically integrated manufacturer, we maintain control over every stage of production, from billet homogenization to final slitting and packaging. This ensures consistent lead times, cost efficiency, and rapid response to technical inquiries or engineering support requests.

For engineers and procurement managers seeking a reliable source of high-purity, high-consistency aluminum winding wire, Luoyang Xinzhaohe offers proven technical capability and long-term partnership stability. We invite you to collaborate with our team to optimize your material specifications and supply chain performance.

Contact us today at cathy@transformerstrip.com to discuss your technical requirements and receive sample data packages or product quotations.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum winding motor directly from China.