Table of Contents

Market Insight: Plate Sheet

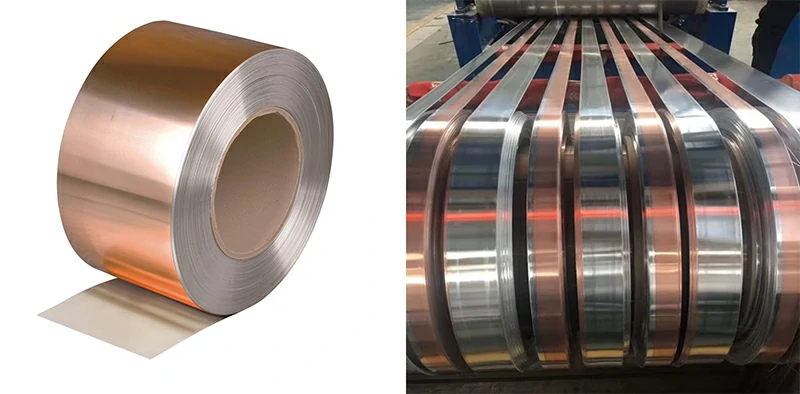

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer strip and foil—fabricated from aluminum and copper—continues to expand in parallel with the growth of power infrastructure, renewable energy integration, and industrial electrification. These precision-engineered plate and sheet materials serve as core components in the windings of power and distribution transformers, where electrical conductivity, mechanical consistency, and thermal stability are paramount. As energy grids modernize and efficiency standards tighten, particularly under regulations such as the DOE 2016 and IEC 60076, the performance of conductive strip materials directly influences transformer design, lifecycle costs, and operational reliability.

Aluminum and copper transformer strips are manufactured to stringent dimensional tolerances, typically ranging from 0.1 mm to 6.0 mm in thickness, with widths varying between 10 mm and 1,200 mm depending on application requirements. Copper remains the benchmark for high-efficiency transformers due to its superior electrical conductivity (~58 MS/m), but aluminum (with conductivity ~35 MS/m) offers a compelling alternative in weight-sensitive and cost-driven applications, particularly in distribution transformers and large power units where material savings translate into logistical and installation advantages. The shift toward aluminum in certain segments has been accelerated by copper price volatility and supply chain constraints, reinforcing the need for high-purity, defect-free aluminum strip with optimized temper properties.

Industrial demand is concentrated in sectors including utility-scale power transmission, renewable energy (especially solar and wind substations), rail traction systems, and industrial manufacturing. Emerging markets in Southeast Asia, Africa, and Latin America are driving volume growth, while developed regions focus on grid resilience and efficiency upgrades. This bifurcated demand underscores the necessity for material suppliers to deliver both cost-effective solutions and high-performance variants compliant with international standards.

Quality is non-negotiable in transformer strip production. Inhomogeneities such as edge burrs, surface oxides, residual stresses, or inconsistent temper can lead to localized heating, winding deformation, or dielectric breakdown under load. Even minor deviations in thickness or flatness compromise winding precision, increasing eddy current losses and reducing transformer efficiency. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized production experience, we implement rigorous process controls across hot rolling, cold rolling, and annealing stages. Our strips are manufactured under ISO 9001-certified quality systems, with 100% eddy current testing, precise tensile property validation, and strict chemical composition monitoring to ensure batch-to-batch consistency.

The following table summarizes key technical parameters for transformer strip materials:

| Parameter | Aluminum Strip | Copper Strip |

|---|---|---|

| Typical Thickness Range | 0.2 – 6.0 mm | 0.1 – 5.0 mm |

| Conductivity (20°C) | ≥ 61% IACS | ≥ 98% IACS |

| Tensile Strength | 80 – 180 MPa | 200 – 350 MPa |

| Elongation | ≥ 3% | ≥ 5% |

| Surface Roughness (Ra) | ≤ 1.5 µm | ≤ 1.0 µm |

In conclusion, the performance of transformer strip and foil directly impacts the efficiency, reliability, and longevity of power systems. As global energy demands evolve, material quality, dimensional precision, and process consistency are critical differentiators in the competitive landscape of transformer manufacturing.

Technical Specs: Plate Sheet

Technical Specifications for Transformer Strip and Foil Plate Sheet

Luoyang Xinzhaohe Aluminum CO., Ltd provides precision-engineered aluminum and copper strip and foil products specifically designed for high-efficiency transformer windings. Our manufacturing processes, refined over 20+ years, ensure strict adherence to critical electrical and dimensional parameters essential for minimizing core losses and maximizing transformer reliability. This section details the mandatory technical specifications governing our plate sheet output, with particular emphasis on precision slitting, edge integrity, and electrical conductivity. Plate sheet in this context refers to slit coil products within the thickness range of 0.10 mm to 3.00 mm, supplied in coil form for automated winding processes.

Precision slitting is paramount for consistent layer build-up and reduced magnetic flux distortion in wound cores. Our facility achieves a standard slit width tolerance of ±0.002 mm across the full coil length and width. This exceptional dimensional control is maintained through computerized tension management systems coupled with high-precision, hardened tool steel slitting knives featuring proprietary geometry and edge preparation. Continuous in-line laser micrometry provides real-time feedback, ensuring every meter of material meets this stringent tolerance. Deviations beyond ±0.002 mm are rejected during automated inspection, guaranteeing uniform strip width critical for optimal core stacking factor and reduced eddy current losses.

Burr-free edges are non-negotiable for preventing inter-layer short circuits and dielectric breakdown within the transformer winding. Our process delivers edges with a maximum burr height of ≤ 0.005 mm, verified through 10x magnification microscopy and tactile profilometry at defined intervals across the coil. This is achieved through optimized slitting clearance settings, precise knife alignment, and controlled material feed rates within our state-of-the-art slitting lines. Any detectable edge lip or tear exceeding the specified limit results in immediate coil rejection, ensuring only flawlessly processed material reaches the customer.

Electrical conductivity directly impacts transformer efficiency and thermal performance. For aluminum strip (primarily 1350 alloy), we guarantee a minimum conductivity of 61.0% IACS (International Annealed Copper Standard), typically achieving 61.2-61.8% IACS through controlled annealing in oxygen-free atmospheres. Copper strip (C11000 ETP) consistently meets or exceeds 100.0% IACS. Conductivity is rigorously tested per ASTM E1004 using non-destructive eddy current methods on every production coil, with results traceable to NIST standards. Material resistivity is maintained within tight bands to ensure predictable performance under operational loads.

The following table summarizes the core technical parameters governing our transformer plate sheet products:

| Parameter | Standard Value | Testing Method |

|---|---|---|

| Slit Width Tolerance | ±0.002 mm | Laser Micrometry (In-line) |

| Maximum Burr Height | ≤ 0.005 mm | Optical Microscopy (10x) |

| Aluminum Conductivity | ≥ 61.0% IACS (1350 Alloy) | ASTM E1004 (Eddy Current) |

| Copper Conductivity | ≥ 100.0% IACS (C11000) | ASTM E1004 (Eddy Current) |

| Thickness Range | 0.10 mm – 3.00 mm | Micrometer / Beta Gauge |

| Edge Squareness | ≤ 0.10 mm deviation per 100 mm | Precision Straight Edge |

| Surface Cleanliness | Free of oils, oxides, contaminants | Visual & Solvent Wipe Test |

Adherence to these specifications is validated through our integrated quality management system, certified to ISO 9001:2015. Each production batch undergoes comprehensive in-process and final inspection, with full material test reports (MTRs) provided. This rigorous technical framework ensures our plate sheet delivers the dimensional precision, edge quality, and electrical properties required for next-generation, high-efficiency transformer manufacturing, directly contributing to reduced no-load losses and extended operational life.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of high-performance transformer strip and foil—available in both aluminum and copper alloys—is executed through a tightly controlled, multi-stage manufacturing sequence. With over two decades of metallurgical expertise, our process ensures dimensional accuracy, superior surface integrity, and consistent electrical and mechanical properties essential for efficient transformer operation.

The process begins with cold rolling, a critical deformation stage that reduces the thickness of hot-rolled aluminum or copper coils to precise final gauges, typically ranging from 0.1 mm to 3.0 mm depending on application requirements. Cold rolling is performed under controlled temperature and tension conditions using precision rolling mills equipped with advanced roll gap and thickness monitoring systems. This stage enhances the material’s mechanical strength through strain hardening while achieving the required flatness and surface finish. Lubrication and roll surface conditioning are meticulously maintained to prevent surface defects such as scratches, roll marks, or micro-cracks.

Following cold rolling, the coils undergo precision slitting, a high-tolerance cutting process that converts master rolls into narrow strips tailored to customer-specified widths. Slitting is performed using rotary shear slitters with computer-controlled guiding systems to ensure edge straightness and minimize width variation, typically holding tolerances within ±0.1 mm. The slit lines are continuously monitored via laser measurement systems to detect deviations in real time, allowing for immediate adjustments. This step is crucial for ensuring compatibility with automated winding equipment used in transformer core assembly.

Edge conditioning is the final mechanical treatment applied to the slit strips. This process removes micro-burrs and sharp edges generated during slitting, reducing the risk of insulation damage during winding and improving overall core reliability. Our edge conditioning systems utilize precision brushing and controlled radius forming to achieve a smooth, uniform edge profile without altering the strip’s dimensional integrity.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. Incoming raw materials are verified for alloy composition via optical emission spectroscopy (OES). During processing, in-line inspection systems monitor thickness uniformity, surface defects, and profile flatness. Final product batches undergo rigorous testing, including tensile strength, elongation, electrical conductivity, and surface roughness measurements. All test data is documented and available with material certification to ensure full traceability and compliance with international standards such as GB/T, ASTM, and IEC.

This integrated approach—combining advanced cold rolling, precision slitting, and edge conditioning with stringent QC—enables Luoyang Xinzhaohe Aluminum Co., Ltd to deliver transformer strip and foil products that meet the highest performance demands in power distribution and industrial applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Export packaging for aluminum and copper transformer strip and foil constitutes a critical engineering safeguard against maritime transit hazards. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of metallurgical and supply chain expertise, we implement rigorously validated packaging protocols to ensure product integrity during global sea freight. Our methodology addresses two primary failure modes: moisture-induced corrosion and mechanical deformation.

All coils undergo mandatory moisture barrier encapsulation prior to palletization. We utilize multi-layer co-extruded polyethylene film with a minimum thickness of 125μm, certified to ASTM D2473 standards for water vapor transmission rate (WVTR ≤ 0.5 g/m²/day at 38°C, 90% RH). Each coil is individually wrapped with overlapping seams sealed via impulse heat welding, creating a hermetic seal. A desiccant packet (calculated at 30g per m³ of enclosed volume) is inserted within the innermost layer to absorb residual humidity. This dual-layer barrier system prevents condensation during temperature fluctuations inherent in containerized shipping, particularly across tropical and temperate maritime routes.

Palletization employs ISPM 15-compliant kiln-dried hardwood pallets with a minimum load capacity of 2,500 kg. Pallet dimensions are engineered to match coil outer diameters (OD), minimizing lateral movement. Steel strapping (16mm width, 3,000 N tensile strength) secures coils to the pallet base at four anchor points, while edge protectors fabricated from 3mm galvanized steel shield coil edges from strap-induced deformation. For narrow strip widths (<300mm), we implement interlayer cardboard spacers between stacked coils to distribute vertical load and prevent telescoping.

The following table details our moisture barrier film configuration and functional requirements

| Layer Position | Material Composition | Primary Function | Performance Standard |

|---|---|---|---|

| Outer Layer | Linear Low-Density Polyethylene (LLDPE) | Puncture/abrasion resistance | ASTM D1709 (Impact Strength ≥ 500g) |

| Middle Layer | Ethylene-Vinyl Alcohol (EVOH) | Oxygen barrier | OTR ≤ 0.5 cc/m²/day/atm |

| Inner Layer | Metallocene-catalyzed Polyethylene | Seal integrity | Hot Tack Strength ≥ 1.5 N/15mm |

Container loading follows ISO 1496-1 standards for cargo securing. Pallets are positioned with 50mm clearance from container walls, dunnage is applied at floor contact points, and void spaces are filled with inflatable airbags to prevent shifting during roll/pitch motions. Relative humidity within the container is continuously monitored via data loggers (calibrated to ±2% RH accuracy), with empirical validation confirming internal humidity remains below 45% RH throughout 60-day voyages.

This integrated packaging system has reduced moisture-related customer claims by 92% over the past decade. We provide certified test reports for WVTR, OTR, and pallet load simulation per ASTM D4169 for all export shipments. Compliance with these specifications is non-negotiable for safeguarding the precise dimensional tolerances and surface purity required in transformer core lamination applications. Partnering with our logistics team ensures alignment with your destination port’s handling infrastructure and regulatory requirements.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of high-performance aluminum and copper transformer strips and foils. Strategically located in the industrial heartland of Henan Province, China, our facility integrates advanced metallurgical engineering with rigorous quality control systems to deliver products that meet the exacting demands of global power transmission and distribution markets.

Our production infrastructure is built around continuous casting and rolling technologies, enabling precise control over material homogeneity, dimensional accuracy, and mechanical properties. The factory operates fully automated cold rolling lines equipped with laser thickness gauging and tension leveling systems, ensuring strip tolerances within ±0.005 mm for foil grades and ±0.01 mm for heavy strips. This level of precision is critical for minimizing eddy current losses and enhancing the magnetic efficiency of transformer windings.

We specialize in aluminum alloys 1060, 1070, and 1350, as well as oxygen-free copper (C10200, C11000), all processed under controlled atmospheric conditions to eliminate surface oxidation and ensure optimal conductivity. Our in-house metallurgical laboratory conducts routine spectrographic analysis, tensile testing, and grain structure evaluation, supporting full traceability from raw material intake to finished coil shipment. All processes comply with ISO 9001:2015 standards, and our products meet or exceed ASTM B418, IEC 60146, and GB/T 3190 specifications.

Capacity-wise, the facility maintains an annual production capability of 15,000 metric tons, supported by a flexible manufacturing schedule that accommodates both large-volume OEM contracts and specialized low-batch runs. We offer strip widths ranging from 50 mm to 1,250 mm and thicknesses from 0.1 mm to 6.0 mm, with custom temper designations including H18, H16, O, and Y2 available upon request. All coils are edge-trimmed, tension-levelled, and packaged with anti-corrosion wrapping and wooden spool protection to ensure integrity during international logistics.

Sustainability and supply chain resilience are embedded in our operational philosophy. Our energy recovery systems reduce specific power consumption by 18% compared to industry benchmarks, and scrap recycling rates exceed 99.3%. We maintain long-term supply agreements with certified bauxite and cathode copper suppliers, ensuring raw material consistency and price stability for our partners.

For engineering teams and procurement managers seeking a technically capable, reliable source of transformer conductive materials, Luoyang Xinzhaohe offers a proven track record in on-time delivery, product consistency, and technical collaboration. Our engineering support team provides material data sheets, coil certification packages, and application-specific testing documentation to streamline integration into your manufacturing workflows.

Contact us today at cathy@transformerstrip.com to request technical specifications, sample kits, or a factory audit package. Let us demonstrate how our metallurgical expertise and production discipline can strengthen your supply chain and enhance the performance of your transformer systems.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing plate sheet directly from China.