Table of Contents

Market Insight: Non Grain-Oriented Electrical Steel

Market Analysis: Non-Grain-Oriented Electrical Steel Demand in Transformer Applications

Global demand for non-grain-oriented electrical steel (NGOES) within the transformer sector exhibits sustained growth, driven by critical infrastructure modernization and the energy transition. While grain-oriented electrical steel (GOES) dominates large power transformers, NGOES is the material of choice for distribution transformers below 100 kVA, auxiliary transformers, and specialized units within renewable energy systems and electric vehicle charging infrastructure. This segment experiences significant pressure from regulatory mandates for higher efficiency classes (e.g., IE3, IE4, DOE 2016 standards), necessitating NGOES with increasingly refined magnetic properties. Simultaneously, the proliferation of distributed generation, smart grid deployments, and industrial automation expands the addressable market for smaller, cost-effective transformers where NGOES offers superior manufacturability and design flexibility compared to GOES. Supply chain dynamics remain sensitive to raw material costs, particularly high-purity iron ore and metallurgical silicon, alongside energy-intensive production processes, making stable, high-volume sourcing partnerships essential for OEMs.

The technical performance of NGOES directly dictates transformer efficiency, thermal management, noise levels, and lifecycle cost, making material quality non-negotiable. Key quality parameters include core loss (W15/50), magnetic flux density (B50), lamination burr control, thickness tolerance, and surface insulation coating integrity. Core loss, measured at 1.5 Tesla and 50 Hz, is paramount; deviations exceeding 0.1 W/kg significantly impact no-load losses, directly affecting compliance with stringent efficiency regulations and operational energy costs over the transformer’s 25+ year lifespan. For instance, substandard NGOES with elevated core loss can increase annual energy waste by hundreds of kWh per unit, translating to substantial financial and carbon penalties at scale. Magnetic flux density influences core size and material utilization; inconsistent B50 values lead to under-engineered or over-specified cores, impacting cost and performance predictability. Precise thickness tolerance (typically ±0.02mm for 0.35-0.65mm grades) and minimal lamination burr are critical for achieving optimal stacking factor during core assembly, directly affecting the transformer’s power density and thermal performance. Poor interlaminar insulation resistance due to coating defects or surface contamination causes eddy current losses, localized heating, and premature failure.

Procurement decisions based solely on initial material cost inevitably incur severe downstream consequences. Inferior NGOES necessitates design compromises, increases scrap rates during core stamping and stacking, elevates warranty claims due to overheating or noise issues, and risks non-compliance with international efficiency directives, potentially barring market access. Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical expertise and vertically integrated supply chain management to deliver NGOES meeting the most demanding IEC 60404-8-7 and ASTM A664 specifications. Our rigorous process control ensures batch-to-batch consistency in core loss and flux density, precision slitting for minimal burr, and advanced coating technologies for superior interlaminar resistance. Partnering with a supplier possessing deep technical understanding of NGOES performance drivers within transformer manufacturing is fundamental to achieving optimal total cost of ownership, regulatory compliance, and reliability in today’s competitive and efficiency-driven market.

Technical Specs: Non Grain-Oriented Electrical Steel

Technical Specifications for Non Grain-Oriented Electrical Steel

Non grain-oriented (NGO) electrical steel is a critical material in the manufacturing of efficient electromagnetic cores used in motors, generators, transformers, and other rotating electrical machinery. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and supply chain expertise, we provide high-performance NGO silicon steel designed to meet stringent industrial requirements. The technical performance of NGO steel is primarily evaluated through core loss (iron loss), magnetic flux density, and geometric characteristics such as flatness and dimensional consistency. These parameters directly influence the energy efficiency, thermal behavior, and operational reliability of end-use components.

Core loss, expressed in watts per kilogram (W/kg), measures the energy dissipated as heat under alternating magnetic fields. It is typically evaluated at standard frequencies (50 Hz, 60 Hz) and magnetic polarizations (1.0 T, 1.5 T). Lower core loss values indicate superior energy efficiency and reduced heat generation, which is essential for high-duty-cycle applications. Core loss is influenced by silicon content, grain size, coating quality, and lamination thickness. Thinner gauges generally exhibit lower losses due to reduced eddy current effects.

Magnetic flux density (B), measured in Tesla (T), reflects the material’s ability to carry magnetic flux. Higher flux density enables compact and lightweight electromagnetic designs. For NGO steel, typical flux density values range from 1.60 T to 2.00 T at a magnetic field strength of 5000 A/m (B50). This parameter is dependent on chemical composition, particularly silicon and aluminum content, as well as the annealing process that optimizes magnetic domain structure.

Flatness is a critical geometric specification, especially for high-speed stamping and automated stacking processes. Poor flatness leads to lamination misalignment, increased air gaps, and localized flux concentration, which degrade magnetic performance and increase losses. Flatness is quantified as the maximum deviation per unit length (e.g., mm/m) across the sheet surface. Consistent flatness ensures uniform core packing factor and mechanical stability in the final assembly.

The following table outlines the typical technical parameters for NGO electrical steel offered by Luoyang Xinzhaohe Aluminum Co., Ltd:

| Parameter | Symbol | Test Condition | Typical Value Range | Unit |

|---|---|---|---|---|

| Core Loss (Total Iron Loss) | Pv | 50 Hz, 1.5 T | 3.00 – 6.00 | W/kg |

| Core Loss (Total Iron Loss) | Pv | 60 Hz, 1.5 T | 4.00 – 7.50 | W/kg |

| Core Loss (Total Iron Loss) | Pv | 50 Hz, 1.0 T | 1.20 – 2.50 | W/kg |

| Magnetic Flux Density | B50 | H = 5000 A/m | 1.60 – 2.00 | T |

| Electrical Resistivity | ρ | — | 45 – 60 | μΩ·cm |

| Silicon Content | Si | — | 0.5 – 3.2 | wt% |

| Thickness Tolerance | — | ±0.02 to ±0.05 (depending on grade) | — | mm |

| Flatness | — | Maximum deviation per meter | ≤ 3.0 | mm/m |

These specifications are achieved through precise control of cold rolling, annealing, and insulating coating processes. Our products comply with international standards including IEC 60404-8-7 and GB/T 2521. Consistency in these parameters ensures reliable performance across high-efficiency motor and generator applications.

Factory Tour: Manufacturing

Manufacturing Process for Non-Grain-Oriented Electrical Steel

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise in the precise production of Non-Grain-Oriented (NGO) electrical steel, critical for efficient motor and generator cores. Our integrated manufacturing sequence ensures optimal magnetic properties, dimensional accuracy, and surface integrity, adhering strictly to international standards like IEC 60404-8-7 and JIS C 2552. The core process flow begins with slitting.

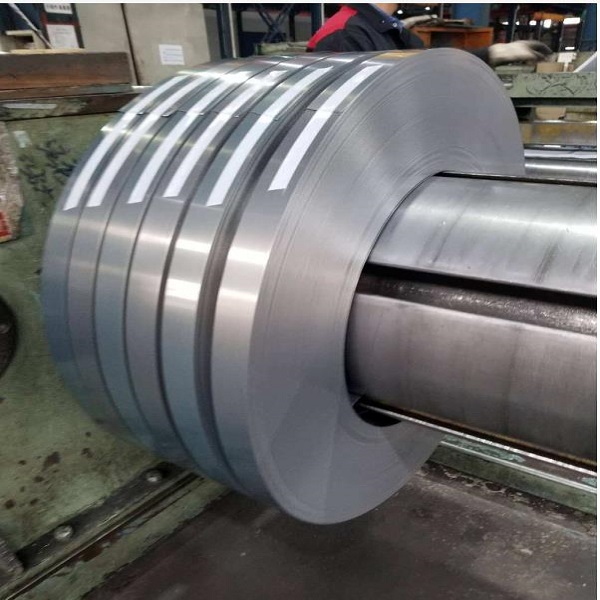

Slitting transforms master coils into narrower strips meeting specific lamination width requirements. This stage employs precision-guided rotary shear slitters with computer-controlled tension management. Critical parameters include maintaining edge squareness within ±0.1 mm and minimizing edge burr formation to prevent interlaminar short circuits. Real-time laser micrometers monitor strip width, while edge quality is visually and tactilely inspected. Any deviation exceeding tight tolerances triggers immediate process adjustment or material rejection.

Annealing follows slitting to relieve mechanical stresses induced during cold rolling and slitting, thereby optimizing magnetic permeability and minimizing core loss. Our continuous annealing lines utilize precise atmosphere control (typically N₂-H₂ mixtures) to prevent oxidation. Temperature profiles are meticulously engineered, typically ramping to 750-850°C with controlled dwell times, ensuring thorough stress relief without excessive grain growth. Decarburization is minimized through optimized dew point control. Magnetic property validation via Epstein frame testing occurs immediately post-anneal on statistical samples, measuring core loss (W/kg) and permeability against specified grades (e.g., 50WW350, 35JN230).

Insulation coating application is paramount for interlaminar resistance and corrosion protection. Xinzhaohe applies thin, uniform inorganic or semi-organic coatings via roll-coating or immersion techniques. Coating weight is strictly controlled, typically 0.5-4.0 g/m² per side, measured gravimetrically. Key quality attributes include adhesion strength (verified by tape tests), electrical resistance (>70 Ω·cm²), and thermal stability. Curing occurs in dedicated ovens at temperatures ensuring complete polymerization without degrading magnetic properties. Coating integrity is non-negotiable for final product performance.

Precision cutting converts slit, annealed, and coated strips into individual laminations. High-speed progressive or compound dies within stamping presses achieve micron-level dimensional accuracy. Critical focuses include maintaining tight tolerances on inner/outer diameters (±0.05 mm), minimizing burrs (<0.03 mm), and ensuring consistent stacking factors. Automated vision systems inspect every lamination for dimensional conformity, burr presence, and coating damage. Laminations failing these criteria are automatically rejected.

Integrated Quality Control Framework

| Process Stage | Key QC Parameters | Measurement Method | Acceptance Criteria |

|---|---|---|---|

| Slitting | Width Tolerance, Edge Burr | Laser Micrometer, Optical Comparator | ±0.1 mm, <0.03 mm |

| Annealing | Core Loss (P1.5/50), Permeability | Epstein Frame Tester | Per Grade Specification |

| Coating | Coating Weight, Surface Resistivity | Gravimetric Analysis, 4-Point Probe | 0.5-4.0 g/m², >70 Ω·cm² |

| Precision Cutting | Dimensional Accuracy, Burr Height | CMM, Optical Comparator | ±0.05 mm, <0.03 mm |

Final product certification requires comprehensive validation against all customer specifications, including full magnetic characterization, coating assessment, and dimensional conformance. This rigorous, stage-gated manufacturing and QC protocol, refined over 20 years, guarantees the consistent delivery of NGO electrical steel meeting the highest demands for energy efficiency and reliability in rotating electrical machinery.

Packaging & Logistics

Export Packaging for Non Grain-Oriented Electrical Steel – Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and international distribution of silicon steel products, we maintain rigorous standards in export packaging to ensure product integrity during global logistics. For non grain-oriented electrical steel (NGOES), which is highly sensitive to mechanical damage, moisture, and contamination, our packaging system is engineered to meet the demands of extended sea freight transit, variable climatic conditions, and multi-stage handling.

All NGOES coils are mounted on robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to support the full weight of the steel coils, which can range from 5 to 25 metric tons depending on coil dimensions and steel grade. The structural integrity of the pallets is verified through load testing to prevent deformation during container stacking or shipboard storage. Each pallet is treated to ISPM-15 standards, ensuring compliance with international phytosanitary regulations for wood packaging material. This certification is critical for customs clearance in key markets including the United States, European Union, and Southeast Asia.

Prior to lashing, each coil is wrapped in multiple layers of industrial-grade moisture-proof film. This multilayer wrapping system consists of an inner vapor corrosion inhibitor (VCI) film, which actively suppresses oxidation by releasing corrosion-inhibiting molecules, and an outer high-density polyethylene (HDPE) layer that provides a physical barrier against humidity, salt spray, and condensation. The film is heat-sealed and tension-wound using automated equipment to ensure uniform coverage and eliminate gaps or weak points. This dual-film strategy is particularly effective in tropical and maritime environments where relative humidity can exceed 80% for prolonged periods.

Coils are further secured using galvanized steel strapping applied at multiple tension points across the flange and core. The strapping is anchored to the wooden pallet using clinch plates to prevent slippage. Edge protectors made from laminated cardboard or steel are installed at the coil’s outer diameter to prevent deformation during transport. For containerized shipments, we utilize ISO-standard 20-foot and 40-foot dry freight containers, with internal bracing to minimize lateral movement.

Our packaging protocol is validated through accelerated climate chamber testing and real-world shipping data collected from over 60 countries. This ensures that NGOES arrives at the destination facility with zero degradation in magnetic properties, surface quality, or dimensional accuracy. Every shipment is accompanied by a packing list detailing coil IDs, weights, dimensions, and packaging specifications for traceability.

Luoyang Xinzhaohe Aluminum Co., Ltd treats export packaging not as a logistical afterthought but as an integral component of product performance. By combining engineered materials, international compliance, and process rigor, we ensure that our non grain-oriented electrical steel maintains its technical integrity from factory to fabrication.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Non-Grain-Oriented Electrical Steel Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver high-performance non-grain-oriented (NGO) electrical steel, engineered for demanding applications in motors, generators, and industrial transformers. Our vertically integrated production facility in Henan Province, China, combines advanced process control with rigorous quality protocols to ensure material consistency and optimal electromagnetic properties. As a trusted supplier to global OEMs, we prioritize supply chain resilience without compromising on technical specifications critical to your end-product efficiency.

Integrated Production Capability

Our 50,000-ton annual production capacity utilizes fully automated annealing and coating lines, enabling precise control over silicon content (1.0–3.5%), lamination thickness (0.35–0.65 mm), and width tolerance (±0.1 mm up to 1250 mm). The facility operates under ISO 9001 and IATF 16949 certifications, with in-line monitoring of key parameters including core loss (W15/50 ≤ 3.20 W/kg) and magnetic induction (B50 ≥ 1.65 T). This ensures compliance with global standards such as JIS C 2550, ASTM A664, and IEC 60404-8-7. Our low-carbon manufacturing process minimizes environmental impact while maintaining material purity, reducing interlaminar losses in stacked cores by up to 12% compared to industry averages.

Precision Quality Assurance

Every coil undergoes multi-stage validation, including Epstein frame testing for core loss and permeability, surface insulation resistance measurement (≥50 Ω·cm²), and dimensional scanning via laser profilometry. Our laboratory is accredited to ISO/IEC 17025, with real-time data integration from melt shop to slitting lines. This end-to-end traceability guarantees batch-to-batch repeatability, critical for high-volume motor laminations where flux density deviations exceed 0.05 T. We also provide customized mechanical property tuning—such as controlled yield strength (180–320 MPa) for high-speed stamping—to reduce scrap rates in your production.

Supply Chain Optimization

We mitigate procurement volatility through strategic raw material hedging and a just-in-time delivery model supported by 15,000 m² bonded warehousing. Clients benefit from VMI programs with 72-hour shipment windows and dedicated logistics coordination for AEO-compliant customs clearance. Our engineering team collaborates pre-shipment to validate material suitability against your lamination geometry and operating frequency requirements, reducing time-to-market by up to 30%.

Partnering with Luoyang Xinzhaohe means securing a supply chain anchor for NGO electrical steel with uncompromised technical rigor. We eliminate performance variability through metallurgical precision and responsive capacity allocation, directly enhancing your product reliability and energy efficiency metrics. For immediate technical consultation or material sampling, contact Cathy Zhang at cathy@transformerstrip.com to discuss your project specifications. Our engineering team stands ready to deliver data-driven solutions within 24 hours.

Material Performance Summary

| Parameter | Typical Value | Test Standard |

|———————|———————|——————|

| Core Loss (W15/50) | ≤ 3.20 W/kg | IEC 60404-2 |

| Magnetic Induction | ≥ 1.65 T @ 5000 A/m | IEC 60404-4 |

| Thickness Tolerance | ±0.025 mm | ASTM A34/A34M |

| Insulation Resistance| ≥ 50 Ω·cm² | JIS C 2550-2011 |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing non grain-oriented electrical steel directly from China.