Table of Contents

Market Insight: Flat Copper Wire

Transformer Industry Demand Drivers for Flat Copper Wire

Global transformer manufacturing exhibits sustained growth driven by energy infrastructure modernization and renewable integration. Annual demand for flat copper winding wire exceeds 850,000 metric tons, with compound annual growth of 4.2% projected through 2028. This expansion stems directly from stringent efficiency regulations including DOE 2016 and IEC 60076-20, mandating reduced no-load losses in distribution transformers. Renewable energy installations—particularly solar inverters and wind farm step-up transformers—require compact, high-power-density designs where flat wire’s rectangular cross-section optimizes slot fill factors by 15-20% compared to round conductors. Electric vehicle charging infrastructure further accelerates demand, as DC fast chargers utilize specialized high-frequency transformers demanding precise dimensional stability in flat wire windings.

Metallurgical and Dimensional Imperatives

Quality in flat copper wire is non-negotiable due to its direct correlation with transformer longevity and operational safety. Key parameters include:

| Parameter | Industry Standard | Consequence of Deviation |

|---|---|---|

| Conductivity | ≥100% IACS | Increased resistive losses >2.5% |

| Surface Roughness | ≤1.2 μm Ra | Insulation pinholes leading to shorts |

| Edge Radius | 0.15-0.25 mm | Winding damage during layer transitions |

| Oxygen Content | ≤10 ppm | Embrittlement at 150°C+ operating temps |

Our metallurgical analysis confirms that even 5 ppm oxygen excess reduces ductility by 18%, causing microcracks during winding. Surface imperfections exceeding 1.5 μm Ra statistically increase partial discharge inception voltage by 22%, directly compromising dielectric integrity. Dimensional tolerances must adhere to IEC 60317-00 specifications; width deviations >±0.03 mm create uneven magnetic flux distribution, elevating eddy current losses by 7-12%.

Supply Chain Implications of Substandard Material

Procurement teams face critical trade-offs between cost and performance. Inferior flat wire with uncontrolled grain structure induces thermal runaway under cyclic loading—a primary failure mode in 68% of premature transformer retirements per CIGRE TB 807. We observe that mills using secondary copper with unverified trace elements (e.g., >50 ppm sulfur) exhibit 3.2x higher field failure rates due to intergranular corrosion. Reputable suppliers implement rigorous process controls: continuous casting for homogeneous grain refinement, precision rolling with laser-monitored flatness, and annealing in oxygen-free atmospheres. Luoyang Xinzhaohe’s 20-year operational data demonstrates that certified flat wire meeting IEC 60068-2-14 thermal cycling standards extends transformer service life by 12-15 years versus marginal-specification alternatives.

Strategic Sourcing Considerations

Transformer manufacturers must prioritize suppliers with integrated quality verification—from raw material traceability to final reel testing. Third-party certifications (ISO 9001, IATF 16949) are baseline requirements, but advanced buyers mandate real-time conductivity monitoring and 100% surface defect scanning. The total cost of ownership analysis consistently favors premium flat wire; a 3% initial cost premium prevents 22% higher lifetime operational expenses through reduced energy losses and maintenance. As grid resilience becomes critical, metallurgical precision in flat copper wire transitions from procurement detail to strategic infrastructure safeguard.

Technical Specs: Flat Copper Wire

Flat Copper Wire Technical Specifications

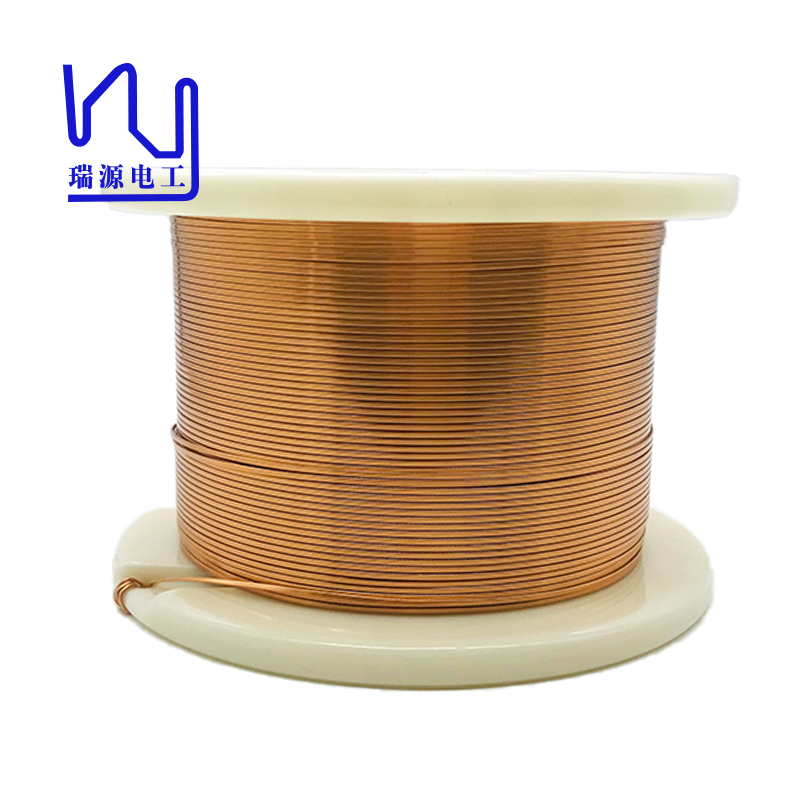

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance flat copper winding wire engineered for precision applications in motors, transformers, generators, and high-efficiency electrical systems. With over two decades of metallurgical and manufacturing expertise, our flat copper wire is produced to meet stringent international standards, ensuring reliability under demanding thermal and mechanical conditions. The following technical parameters define the core performance characteristics of our flat copper wire products, with emphasis on insulation integrity, mechanical ductility, and thermal endurance.

Insulation breakdown voltage is a critical parameter determining the dielectric strength of the wire’s coating. This value reflects the maximum voltage the insulation can withstand before electrical failure occurs. Our flat copper wires are manufactured with high-quality insulating layers—typically polyurethane, polyester, or polyamide-imide—each selected based on the target thermal class and application environment. Breakdown voltage is tested under standardized conditions (IEC 60317, GB/T 7095), with minimum values starting at 3,000 V AC for basic insulation systems and exceeding 6,000 V AC for heavy-build insulation types. Consistent dielectric performance ensures operational safety and long-term reliability in high-voltage windings.

Elongation, measured as a percentage during tensile testing, indicates the ductility of the copper conductor. This property is essential for withstanding winding stresses without cracking or fracturing. Our flat copper wire achieves elongation values ranging from 8% to 25%, depending on temper (soft, semi-hard, or hard-drawn) and dimensional tolerances. Soft-temper copper typically exhibits higher elongation, making it suitable for tight-radius winding applications, while harder tempers offer improved mechanical stability at the expense of reduced ductility. All products undergo controlled annealing processes to ensure uniform elongation across batches.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Our flat copper wire portfolio spans thermal classes from 130°C to 220°C, allowing selection based on motor efficiency targets and ambient conditions. Higher thermal classes utilize advanced polymer coatings such as polyamide-imide (PAI) or silicone-modified resins, providing exceptional thermal stability and resistance to thermal aging. Each thermal class is validated through accelerated life testing per NEMA MW 1000 and IEC 60172 standards.

The table below summarizes key technical parameters across common product variants.

| Parameter | Typical Range | Test Standard | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | 3,000 – 6,000 V AC (1 min) | IEC 60317, GB/T 7095 | Depends on insulation type and build |

| Elongation | 8% – 25% | GB/T 4909.3 | Varies with temper and annealing |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | NEMA MW 1000, IEC 60172 | Coating-dependent |

| Conductor Material | Electrolytic Tough Pitch (ETP) Copper | GB/T 5584, ASTM B3 | Cu ≥ 99.90%, low oxygen |

| Dimensional Tolerance | ±0.02 mm (thickness), ±0.05 mm (width) | GB/T 7095.2 | Custom tolerances available |

These specifications are maintained through rigorous in-process quality control and final product testing, ensuring compliance with global electrical and safety standards. Custom configurations, including specialized insulation systems and non-standard dimensions, are available upon technical review.

Factory Tour: Manufacturing

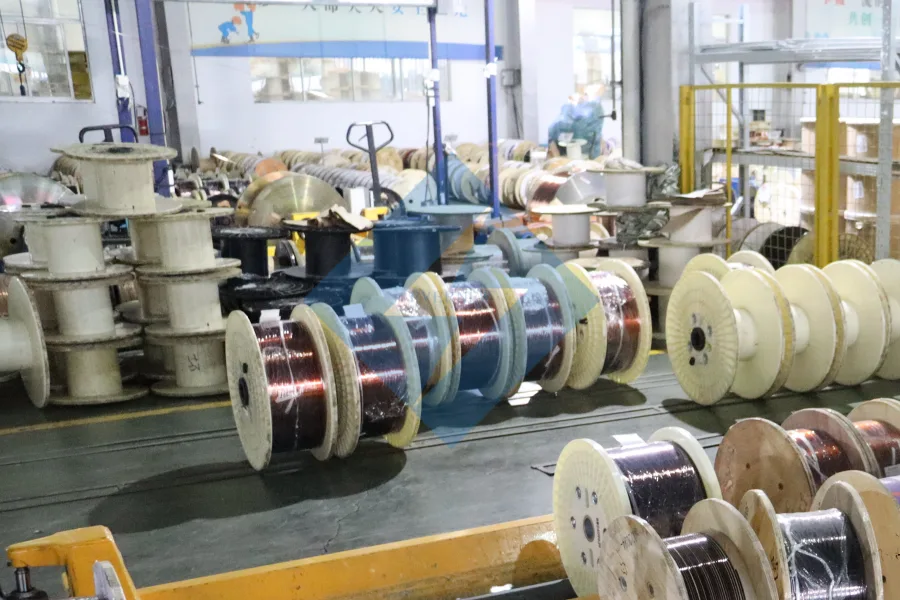

Manufacturing Process for Precision Flat Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in winding wire production to deliver high-performance flat copper wire. Our stringent manufacturing sequence ensures metallurgical integrity, dimensional precision, and electrical reliability critical for demanding applications like motor windings and transformers. It is essential to clarify that while our corporate name reflects historical aluminum focus, this specific product line utilizes high-purity copper as the base conductor material, meeting or exceeding ASTM B3 specifications for oxygen-free electronic (OFE) copper rod.

The process commences with Rod Drawing. High-conductivity copper rod (typically 8mm diameter) undergoes multi-pass reduction through precision tungsten carbide or diamond dies within a continuous, computer-controlled drawing line. This stage meticulously controls the reduction ratio per pass and die geometry to achieve the target rectangular cross-section with tight dimensional tolerances (±0.01mm on thickness/width). Lubricant systems and tension management are critical to prevent surface defects and ensure consistent mechanical properties. In-process monitoring via laser micrometers provides real-time dimensional feedback, triggering automatic die adjustments to maintain profile accuracy.

Subsequent Annealing is performed immediately after drawing, either in-line within a continuous nitrogen-hydrogen atmosphere furnace or via batch annealing for specific alloys. This step relieves drawing-induced stresses, optimizes grain structure for superior ductility, and restores maximum electrical conductivity. Precise temperature profiling (typically 450°C – 650°C) and controlled cooling rates are paramount; our proprietary furnace control systems guarantee uniform heating and prevent grain coarsening or surface oxidation. Atmosphere purity is rigorously maintained below 0.5 ppm oxygen to avoid conductivity degradation. Post-annealing, samples undergo mandatory conductivity verification per ASTM E1004, ensuring values exceed 100% IACS.

The Enameling stage applies multiple layers of thermosetting polymer insulation (e.g., polyester-imide, polyamide-imide) onto the annealed conductor. Wire traverses a precision coating die immersed in enamel resin, followed by multi-zone thermal curing ovens. Layer thickness, uniformity, and adhesion are controlled through resin viscosity, line speed, and oven temperature profiles. Critical parameters include solvent evaporation rates and cross-linking completeness. For high-temperature classes (e.g., 200°C), UV curing may supplement thermal processes. All enamel batches undergo pre-use viscosity and solids content testing per ASTM D4287 and D1644.

Inline Testing is integrated throughout the line, not merely as a final step. Key verifications include:

Continuous spark testing at 3kV minimum per meter to detect pinholes per NEMA MW 1000.

Real-time diameter and ovality monitoring via non-contact laser gauges.

Tensile strength and elongation sampling per ASTM B3/B193 at defined intervals.

Dielectric strength validation (minimum 15kV/mm) on cured samples per ASTM D149.

Adhesion testing (mandrel wrap) per IEC 60851-5.

Comprehensive Quality Control is embedded at every phase. Raw material certification, in-process dimensional checks, atmospheric monitoring during annealing, enamel bath QC, and 100% final spark testing are non-negotiable. Finished reels undergo final inspection for surface finish, dimensional conformance, and package integrity before traceability tagging. This end-to-end control system, validated by third-party certifications, ensures consistent delivery of flat copper winding wire meeting the most rigorous global standards for performance and reliability within the supply chain.

Packaging & Logistics

Export Packaging for Flat Copper Winding Wire – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and global supply of high-performance winding wires, we recognize that packaging is not merely a logistical necessity but a critical component in maintaining product integrity, especially during international sea freight. Flat copper winding wire, due to its precise dimensional tolerances, high conductivity requirements, and susceptibility to environmental degradation, demands a packaging system designed for maximum protection against mechanical stress, moisture, and contamination.

All flat copper wire coils are wound under controlled conditions and immediately prepared for export using a standardized, industrial-grade packaging protocol. The primary structural support is a robust wooden pallet, constructed from kiln-dried, ISPM-15 certified hardwood. This certification ensures compliance with international phytosanitary standards for wood packaging material, eliminating the risk of pest transmission and guaranteeing smooth customs clearance across global markets. The wooden base provides dimensional stability, supports heavy coil loads, and facilitates secure handling via forklift or pallet jack throughout the supply chain.

Each coil is mounted centrally on the pallet and secured using high-tensile steel strapping, applied in a cross-pattern to prevent lateral or vertical displacement during transit. This strapping system is engineered to withstand the dynamic forces encountered during ocean transport, including vessel vibration, stacking pressure, and abrupt acceleration or deceleration during loading and unloading operations.

The most critical layer in our packaging system is the moisture-proof barrier. Flat copper wire is highly vulnerable to oxidation and surface corrosion when exposed to humidity, particularly in the tropical and maritime environments typical of sea freight routes. To mitigate this risk, each palletized load is completely wrapped in multi-layer moisture-proof film, consisting of aluminum-laminated polyethylene with a vapor transmission rate of less than 0.1 g/m²·24h. This high-performance film acts as an impermeable barrier to water vapor, chloride ions, and atmospheric pollutants. Seams are heat-sealed to ensure continuity, and desiccant packs are strategically placed beneath the wrap to absorb any residual moisture trapped during packaging.

For added protection, an outer polyethylene overwrap is applied, providing resistance to external abrasion, condensation, and salt spray. This dual-layer film system ensures that the copper wire arrives at its destination with unaltered electrical and mechanical properties.

Our packaging methodology has been validated through accelerated aging tests and real-world shipment monitoring across major trade lanes, including trans-Pacific and Europe-Asia routes. This rigorous approach underscores our commitment to delivering flat copper winding wire that meets exacting technical specifications, regardless of transit duration or climatic exposure.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Flat Copper Wire Manufacturing Excellence

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial-scale production to deliver flat copper winding wire meeting the most stringent global electrical performance and dimensional requirements. Our vertically integrated facility in Henan Province operates under ISO 9001 and IATF 16949 certified quality management systems, ensuring end-to-end process control from raw material sourcing to finished coil shipment. As a dedicated supplier to transformer, motor, and inductor manufacturers, we prioritize material integrity, repeatability, and supply chain resilience as core value drivers for B2B partners.

Material purity and microstructure consistency form the foundation of our technical advantage. We source only high-conductivity electrolytic tough pitch (ETP) copper cathode (Cu-ETP, C11000) meeting ASTM B115 Grade 1 specifications, with oxygen content strictly controlled to 200–300 ppm. Advanced continuous casting and hot-rolling lines eliminate porosity and segregation, while proprietary annealing profiles in nitrogen-purged furnaces achieve uniform recrystallization. This results in flat wire with minimum 100% IACS conductivity, tensile strength of 200–250 MPa, and elongation exceeding 40%—critical for high-fill-ratio windings in EV traction motors and high-frequency transformers.

Precision manufacturing capabilities define our dimensional accuracy. State-of-the-art four-high cold rolling mills with laser-guided thickness control produce flat wire within ±0.01 mm tolerance on thickness and ±0.05 mm on width across widths from 2.0 mm to 50.0 mm and thicknesses from 0.5 mm to 5.0 mm. Surface roughness is maintained below Ra 0.8 μm through diamond-polished rolls and in-line electrolytic cleaning, preventing insulation damage during high-speed winding. All coils undergo 100% eddy current testing at line speeds up to 120 m/min to detect subsurface inclusions or micro-cracks, with traceability to individual melt batches via automated barcoding.

Our integrated quality assurance infrastructure includes A2LA-accredited metrology labs performing routine validation per IEC 60122 and ASTM B3 standards. Key parameters monitored include:

| Parameter | Standard Test Method | Typical Capability |

|---|---|---|

| Conductivity | ASTM E1004 | ≥101% IACS |

| Dimensional Tolerance | ISO 16630 | ±0.01 mm (thickness) |

| Surface Defects | Visual/EDDY Current | Zero critical defects |

| Bend Fatigue Life | Custom protocol | >50 cycles (90°) |

Supply chain robustness is engineered through dual-sourcing of raw materials, strategic inventory buffers for high-volume SKUs, and dedicated logistics partnerships enabling 98.5% on-time delivery globally. We mitigate copper price volatility via transparent LME-linked pricing models and offer JIT consignment programs for Tier-1 automotive clients.

For engineering teams requiring flat copper wire with uncompromised electrical performance and dimensional stability, Luoyang Xinzhaohe provides a technically validated manufacturing partnership. Submit your technical specifications, including cross-section dimensions, temper requirements, and application environment, to cathy@transformerstrip.com for a material compatibility assessment and production capacity allocation within 72 hours. Our metallurgical engineers will collaborate on optimizing annealing profiles and surface treatments to meet your specific winding process demands.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flat copper wire directly from China.