Table of Contents

Market Insight: Posco Electrical Steel Replacement

Market Analysis: Silicon Steel Demand for Transformer Applications

Global transformer manufacturers increasingly seek reliable alternatives to POSCO electrical steel due to persistent supply chain volatility and geopolitical constraints affecting Korean steel deliveries. Recent disruptions in Asia-Pacific logistics and fluctuating import tariffs have amplified lead time risks, driving demand for qualified domestic and near-shore silicon steel suppliers. This shift is particularly acute in the high-efficiency transformer segment, where core materials constitute 20–30% of total material costs and directly dictate lifecycle performance. The industrial imperative for replacement solutions is not merely cost-driven but rooted in operational continuity—transformer OEMs cannot tolerate production halts for core lamination shortages given stringent project timelines in grid modernization and renewable energy infrastructure.

Quality in non-oriented and grain-oriented electrical steel (GOES) remains non-negotiable for transformer efficiency and reliability. Minor deviations in silicon content (2.9–3.3% for high-grade GOES), grain alignment, or coating uniformity directly impact core loss (W/kg) and magnetic flux density. For instance, a 0.1 W/kg increase in specific total loss at 1.7 T/50 Hz (per IEC 60404-2) translates to 15–25 kW of wasted energy annually in a 100 MVA transformer. Substandard steel accelerates aging through elevated magnetostriction-induced vibration, risking insulation degradation and premature failure. POSCO’s historical dominance stemmed from sub-0.85 W/kg core loss consistency at 1.7 T—a benchmark now critical for Tier-1 transformer producers targeting IE4/IE5 efficiency standards. Replacement suppliers must replicate this precision; otherwise, OEMs face regulatory non-compliance, warranty liabilities, and reputational damage from underperforming assets.

The following table compares critical quality parameters influencing replacement viability:

| Parameter | POSCO Premium GOES Target | Typical Chinese Mill Range | Luoyang Xinzhaohe Specification |

|---|---|---|---|

| Core Loss (W17/50) | ≤ 0.85 W/kg | 0.90–1.10 W/kg | ≤ 0.88 W/kg |

| Magnetic Flux Density (B800) | ≥ 1.92 T | 1.85–1.90 T | ≥ 1.91 T |

| Thickness Tolerance | ±0.003 mm | ±0.005 mm | ±0.003 mm |

| Coating Weight | 3.0–3.5 g/m² | 2.5–4.0 g/m² | 3.2–3.4 g/m² |

Luoyang Xinzhaohe Aluminum’s 20-year specialization in silicon steel production addresses this quality gap through vertically integrated process control. Our vacuum-degassed melt refining ensures silicon homogeneity within ±0.05%, while laser-guided continuous annealing optimizes Goss texture development—critical for minimizing hysteresis losses. Unlike commodity suppliers, we enforce 100% batch traceability via spectral analysis and Epstein frame testing per ASTM A912, guaranteeing compliance with IEC 60404-8-7. This metallurgical rigor prevents the “efficiency fade” observed in lower-tier alternatives, where inconsistent domain refinement increases no-load losses by 8–12% over 10 years.

For transformer manufacturers, the strategic shift from POSCO necessitates partners with proven process stability, not just nominal specification alignment. Supply chain resilience now hinges on suppliers who treat silicon steel as a precision-engineered component—not a bulk material. Luoyang Xinzhaohe’s dedicated transformer steel division delivers this through ISO 50001-certified production and just-in-time delivery protocols, mitigating inventory costs while ensuring zero compromise on core performance metrics essential for next-generation grid infrastructure.

Technical Specs: Posco Electrical Steel Replacement

Technical Specifications for Replacement of POSCO Electrical Steel

When identifying a technically viable replacement for POSCO electrical steel, particularly in high-efficiency electrical and magnetic applications, precise alignment of core material properties is critical. Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in advanced metallic materials, provides a comprehensive technical framework for evaluating silicon steel alternatives. Key performance indicators include core loss (iron loss), magnetic flux density, and geometric consistency—particularly flatness—which directly influence the efficiency, thermal performance, and manufacturability of electrical components such as transformers, motors, and generators.

Core loss, measured in watts per kilogram (W/kg), is a fundamental parameter that determines the energy dissipated as heat under alternating magnetic fields. For effective substitution of POSCO’s non-oriented electrical steel grades (e.g., 35PN210, 50PN400), the replacement material must exhibit comparable or improved core loss values under standardized test conditions (typically at 1.5 T and 50/60 Hz). Lower core loss translates to higher energy efficiency and reduced operational temperature, which are essential in premium-grade electrical machinery.

Magnetic flux density (B), expressed in Tesla (T), reflects the material’s ability to support magnetic field development. A high flux density enables compact core designs with superior power output and responsiveness. Replacement grades should maintain a minimum guaranteed flux density at standard excitation levels (e.g., B50, B800), ensuring compatibility with existing electromagnetic designs originally calibrated for POSCO materials.

Flatness is another critical quality attribute, especially in automated stacking and core assembly processes. Poor flatness leads to air gaps between laminations, increasing reluctance and localized eddy current losses. The deviation from planarity should be tightly controlled, typically within 2–5 mm over a 1-meter length, depending on the application’s precision requirements. Superior flatness ensures uniform magnetic flux distribution and mechanical stability in wound or stacked cores.

Below is a comparative technical specification table outlining key parameters for typical POSCO electrical steel grades and their equivalent replacements supplied by Luoyang Xinzhaohe Aluminum Co., Ltd., manufactured under ISO 9001-certified processes and tested per IEC 60404-3 and ASTM A343 standards.

| Parameter | POSCO Grade (e.g., 50PN400) | Xinzhaohe Equivalent (XZH-50A400) | Test Condition |

|---|---|---|---|

| Thickness (mm) | 0.50 | 0.50 | ±0.02 mm tolerance |

| Core Loss (P1.5/50) | ≤ 4.00 W/kg | ≤ 3.95 W/kg | 1.5 T, 50 Hz, Epstein frame |

| Core Loss (P1.0/400) | ≤ 1.05 W/kg | ≤ 1.03 W/kg | 1.0 T, 400 Hz |

| Magnetic Flux Density (B50) | ≥ 1.68 T | ≥ 1.69 T | 50 A/m |

| Magnetic Flux Density (B800) | ≥ 1.85 T | ≥ 1.86 T | 800 A/m |

| Specific Electrical Resistivity | ≥ 47 μΩ·cm | ≥ 48 μΩ·cm | 20°C |

| Flatness Deviation | ≤ 3 mm/m | ≤ 2.5 mm/m | Over 1 m length |

| Insulation Coating Weight | 0.3–0.6 g/m² | 0.4–0.6 g/m² | C5 or equivalent |

All materials undergo rigorous quality control, including batch traceability, surface inspection, and magnetic property validation. The specified tolerances and performance metrics ensure seamless integration into existing manufacturing workflows designed for POSCO-sourced electrical steel.

Factory Tour: Manufacturing

Manufacturing Process Overview

Luoyang Xinzhaohe Aluminum CO., Ltd employs a rigorously controlled production sequence for silicon steel to ensure magnetic performance parity with POSCO equivalents. Our 20-year expertise in electrical steel processing guarantees adherence to IEC 60404 standards through four critical stages: slitting, annealing, insulation coating, and precision cutting. Each phase integrates real-time quality verification to eliminate defects affecting core loss or permeability.

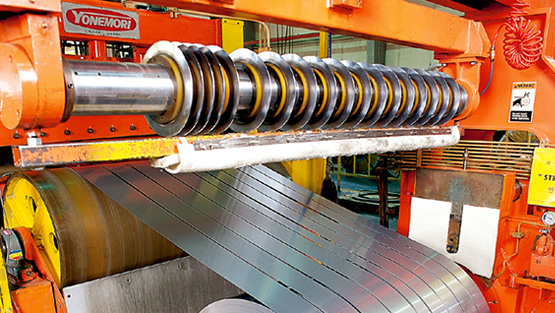

Slitting

Master coils undergo precision slitting using servo-controlled rotary knives with ±0.05 mm width tolerance. This stage separates wide coils into narrower strips matching customer-specified dimensions for transformer or motor laminations. Tension management systems prevent edge burring or coil set, while laser micrometers continuously monitor strip width. Rejected material is immediately quarantined via automated edge trim removal, ensuring only defect-free strips advance to annealing.

Annealing

Slit strips enter continuous annealing lines operating under 95% hydrogen–5% nitrogen atmospheres at 820–860°C. This decarburization and grain growth phase restores the silicon steel’s crystalline structure, optimizing magnetic domain alignment. Precise dew point control (−40°C) prevents surface oxidation, while cooling rates are calibrated to 10–15°C/s to lock in favorable grain orientation. Post-anneal tensile strength and hardness are validated via inline tensile testers, with deviations triggering automatic line-speed adjustments.

Insulation Coating

A thin inorganic phosphate-based insulation layer (3–5 μm) is applied via reverse roll coaters to minimize interlamination eddy currents. Coating weight is maintained at 0.8–1.2 g/m² through viscosity-controlled dosing systems. Immediate infrared curing at 450°C ensures adhesion without degrading magnetic properties. Coating integrity is verified through electrical resistance testing (≥50 Ω·cm²) and adhesion tape tests per ASTM D3359, rejecting strips failing 0% cross-hatch criteria.

Precision Cutting

Laminations are cut using high-speed progressive dies (up to 1,200 strokes/minute) with tooling hardened to 60–62 HRC. Burr formation is constrained to ≤0.02 mm through die clearance optimization (8–10% material thickness) and lubrication monitoring. Final dimensions undergo 100% automated optical inspection against CAD profiles, with tolerances held to ±0.02 mm. Stacking factor validation (≥96%) occurs via laser micrometer stacks of 100 laminations.

Integrated Quality Control

All stages feed into a closed-loop QC system. Magnetic properties are validated via Epstein frame tests (core loss at 1.5T/50Hz ≤1.20 W/kg for M47 grade). Dimensional audits use coordinate measuring machines (CMM) with ±2 μm accuracy. Final coils undergo surface defect scanning via high-resolution cameras detecting scratches >10 μm. Comprehensive test certificates include coating weight, core loss, and dimensional reports traceable to ISO/IEC 17025-accredited labs. This end-to-end control ensures our silicon steel meets or exceeds POSCO-equivalent performance in efficiency-critical applications.

Packaging & Logistics

Export Packaging Standards for Silicon Steel Coils and Sheets

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of high-performance silicon steel, we maintain rigorous export packaging protocols to ensure material integrity during global transit. Our packaging system is specifically engineered to meet the demands of long-haul sea freight, the most common mode of transport for bulk electrical steel shipments. The primary components of our export packaging include standardized wooden pallets and multi-layer moisture-proof wrapping, both of which are critical in safeguarding the quality of silicon steel against environmental and mechanical stressors.

All silicon steel coils and cut-to-length sheets are secured on robust, ISPM 15-compliant wooden pallets constructed from kiln-dried hardwood. These pallets are designed to support the substantial weight of steel products, typically ranging from 5 to 15 metric tons per shipment unit, while maintaining structural stability during containerized transport. The use of treated wood ensures compliance with international phytosanitary regulations, preventing delays at customs and minimizing the risk of pest infestation. Each pallet is reinforced with steel strapping and corner protectors to prevent shifting, deformation, or edge damage during loading, unloading, and stacking operations.

The core protective layer consists of a high-density, multi-laminated moisture-proof film that fully encapsulates the steel load. This film is composed of aluminum foil, polyethylene, and polyester layers, providing an effective barrier against humidity, salt air, and condensation—common challenges in maritime environments. The wrapping process is executed under controlled workshop conditions to avoid surface contamination and is sealed using heat welding techniques to ensure airtight closure. Additional vapor corrosion inhibitors (VCI) may be included within the wrapping for extended voyages or destinations with high ambient humidity.

For containerized shipments, each packaged unit is carefully positioned within 20-foot or 40-foot dry freight containers, maximizing space utilization while minimizing movement. The internal container environment is monitored for temperature and humidity where necessary, and desiccants are deployed to absorb residual moisture. Our logistics team coordinates with certified freight forwarders to ensure adherence to international shipping standards, including proper lashing and documentation.

This comprehensive packaging strategy reflects our commitment to delivering silicon steel products in optimal condition, regardless of destination. By integrating structural durability with environmental protection, we mitigate the risks associated with prolonged sea transport, ensuring that our clients receive material that meets exacting specifications for surface quality, flatness, and magnetic performance. This level of packaging precision is particularly vital when supplying alternatives to POSCO electrical steel, where consistency and reliability are paramount in competitive industrial applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Silicon Steel Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver high-performance silicon steel products engineered as direct, technically validated alternatives to POSCO electrical steel grades. Our vertically integrated manufacturing ecosystem ensures rigorous control from raw material selection through final product certification, directly addressing the critical reliability and performance demands of transformer and motor core applications.

Our 120,000-ton annual production capacity is anchored by state-of-the-art continuous annealing lines and precision slitting technology, enabling consistent delivery of non-oriented and grain-oriented electrical steel with tight dimensional tolerances (±0.02mm thickness control) and optimized magnetic properties. Key technical capabilities include:

| Parameter | Performance Range | Industry Standard Alignment |

|---|---|---|

| Core Loss (P1.5/50) | 0.80–1.35 W/kg (GO), 2.20–3.80 W/kg (NGO) | Meets/exceeds POSCO M-series |

| Magnetic Induction (B800) | ≥1.90 T (GO), ≥1.65 T (NGO) | Compliant with IEC 60404-8 |

| Thickness Range | 0.23mm–0.65mm | Full coverage for EV/core applications |

Material consistency is non-negotiable in electrical steel applications. Xinzhaohe implements a closed-loop quality management system compliant with ISO 9001 and IATF 16949 standards, featuring in-line Epstein frame testing per IEC 60404-2 for every production batch. Our proprietary decarburization and grain growth annealing processes ensure uniform domain refinement, minimizing hysteresis losses while maintaining mechanical stability during stamping and stacking. This process rigor delivers batch-to-batch magnetic property variation of ≤3%—critical for OEMs requiring predictable core performance in volume production.

Supply chain resilience is equally prioritized. We maintain strategic inventory buffers of key grades (including 35WW300 to 50WW1300 equivalents) at our Luoyang facility, enabling 15-day lead times for standard specifications versus industry averages exceeding 60 days. Our dedicated technical service team provides metallurgical support for lamination processing optimization, including custom slit widths down to 50mm and tailored edge conditioning to reduce burr-related core losses.

For global transformer manufacturers seeking to de-risk supply chains without compromising on magnetic performance, Xinzhaohe offers a proven alternative to Korean-sourced electrical steel. Our materials undergo independent validation by third-party labs including SGS and TÜV Rheinland, confirming equivalence to POSCO specifications in core loss, permeability, and aging resistance metrics. Partnering with us secures access to audited, traceable material with full mill test reports and responsive engineering collaboration.

Request certified material test reports and processing guidelines for your specific application by contacting Cathy Zhang, Technical Sales Director, at cathy@transformerstrip.com. Specify your target grade (e.g., equivalent to POSCO M400-50A) and volume requirements to receive a technical feasibility assessment within 48 hours. Luoyang Xinzhaohe stands ready to integrate as your strategic silicon steel partner, ensuring continuity and performance for mission-critical electrical components.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing posco electrical steel replacement directly from China.