Table of Contents

Market Insight: Electrical Steel Companies

Market Analysis: Silicon Steel (Electrical Steel)

Silicon steel, commonly referred to as electrical steel, is a critical ferromagnetic material engineered for high magnetic permeability and low core loss, making it indispensable in the construction of power and distribution transformers. As global energy demand rises and grid modernization accelerates, particularly in emerging economies and industrialized regions, the demand for high-efficiency transformers has intensified. This trend directly influences the procurement strategies of electrical steel companies, which must align their product offerings with evolving performance standards and regulatory requirements.

Transformers represent one of the largest end-use segments for grain-oriented silicon steel (GOES), where magnetic properties in the rolling direction are optimized to minimize hysteresis and eddy current losses. The operational efficiency of a transformer is heavily dependent on the quality of the core material, with high-grade silicon steel contributing to energy savings over the equipment’s lifecycle—often exceeding 30 years. Utilities and industrial operators are increasingly adopting premium efficiency (IE3, IE4) standards, driven by energy conservation mandates and total cost of ownership (TCO) considerations. As a result, electrical steel companies are under pressure to deliver materials with tightly controlled thickness, consistent coating, and superior magnetic performance.

Quality in silicon steel is not a singular attribute but a composite of metallurgical precision and process control. Variability in silicon content (typically 2.5–3.5 wt%), grain alignment, and annealing atmosphere during manufacturing directly impacts magnetic flux density (B800) and specific core loss (W10/400, W15/50). Even minor deviations can lead to increased no-load losses, reducing transformer efficiency and increasing operational costs. For instance, a 0.1 W/kg increase in core loss across a 100 MVA transformer can translate to tens of thousands of kilowatt-hours in additional energy consumption annually. This sensitivity underscores why leading transformer manufacturers prioritize silicon steel from suppliers with stringent quality assurance protocols and traceable production processes.

Moreover, surface insulation coatings—typically inorganic or semi-organic—play a vital role in interlamination resistance and mechanical durability. Poor coating adhesion or non-uniform thickness can result in shorted laminations, localized heating, and premature transformer failure. Electrical steel companies must therefore ensure coating integrity through advanced application techniques and rigorous post-treatment inspection.

The global silicon steel market is characterized by concentrated production, with China accounting for over 60% of supply. However, high-end GOES remains a technologically demanding product, with only a limited number of producers capable of meeting IEC 60404-8-4 and ASTM A876 standards consistently. This supply constraint elevates the strategic importance of long-term partnerships between transformer OEMs and qualified electrical steel suppliers.

In summary, the industrial demand for silicon steel in transformer applications is driven by energy efficiency imperatives, regulatory frameworks, and lifecycle cost optimization. Quality is not merely a compliance metric but a determinant of system reliability and performance. Electrical steel companies that maintain technical excellence in material consistency, magnetic properties, and surface engineering will continue to hold a competitive advantage in this high-stakes segment.

Technical Specs: Electrical Steel Companies

Technical Specifications for Electrical Steel Sourcing

Precise adherence to technical specifications is non-negotiable in electrical steel procurement, directly impacting electromagnetic performance, energy efficiency, and manufacturing yield in motors, transformers, and generators. Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver silicon steel meeting stringent global standards. Critical parameters include Core Loss (Iron Loss), Magnetic Flux Density, and Flatness, each requiring rigorous control during production and inspection. Core Loss quantifies energy dissipated as heat under alternating magnetization, defined per kilogram at specific flux densities and frequencies. Lower values indicate superior efficiency, reducing operational costs in end-use applications. Magnetic Flux Density determines the maximum magnetic induction achievable, directly influencing power density and component size. Flatness deviations affect lamination stacking factors and vibration noise in cores, necessitating tight geometric tolerances.

The following table outlines key technical parameters for non-oriented electrical steel grades supplied by Xinzhaohe, reflecting typical production capabilities for industrial applications:

| Parameter | Symbol | Unit | Typical Range | Testing Standard |

|---|---|---|---|---|

| Core Loss (1.5T, 50Hz) | P1.5/50 | W/kg | 2.20–3.80 | IEC 60404-2 / JIS C 2550 |

| Core Loss (1.0T, 400Hz) | P1.0/400 | W/kg | 18.0–32.0 | IEC 60404-2 |

| Magnetic Flux Density | B50 | T | ≥1.85 (Grade 50W) | IEC 60404-4 |

| Magnetic Flux Density | B800 | T | ≥1.25 (at 800 A/m) | IEC 60404-4 |

| Flatness Tolerance | — | I-Unit | ≤15 (for 0.35–0.65mm) | ASTM A688 / GB/T 2522 |

| Thickness Tolerance | — | mm | ±0.02 to ±0.03 | IEC 60404-9 |

Core Loss specifications are validated under controlled sinusoidal excitation at 50Hz and 400Hz per IEC 60404-2. P1.5/50 values below 2.50 W/kg are achievable for high-efficiency motor laminations (e.g., IE4/IE5 standards), while P1.0/400 governs high-frequency applications like inverter-driven systems. Magnetic Flux Density is measured at 50 A/m (B50) and 800 A/m (B800), with B50 ≥1.85 T ensuring optimal torque density in traction motors. Deviations below 1.80 T may necessitate larger core volumes, increasing material costs.

Flatness is assessed via the I-Unit metric, representing peak-to-peak deviation per unit length. Xinzhaohe maintains flatness ≤15 I-Units across 0.35–0.65 mm thicknesses through precision rolling and stress-relief annealing. Exceeding this threshold causes air gaps in stacked cores, elevating core loss by 5–15% and inducing audible noise. Thickness tolerance adherence (±0.02–0.03 mm) further ensures consistent lamination insulation and stacking pressure.

All parameters are verified using Epstein frame testing (IEC 60404-2) and single-sheet testers (SST), with traceable calibration to national standards. Sourcing partners must validate mill test reports against actual lot performance, as minor deviations in silicon content (2.9–3.3 wt%) or grain structure significantly alter magnetic behavior. Xinzhaohe implements 100% inline flatness monitoring and batch-specific loss mapping to guarantee compliance. Understanding these interdependencies prevents field failures and optimizes total cost of ownership in electrical steel supply chains. Partnering with suppliers possessing metallurgical process mastery ensures specifications translate into reliable end-product performance.

Factory Tour: Manufacturing

Manufacturing Process of Silicon Steel at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of high-performance silicon steel—also known as electrical steel—is executed through a tightly controlled, multi-stage manufacturing sequence designed to optimize magnetic properties, dimensional accuracy, and surface integrity. With over two decades of metallurgical expertise, our process integrates precision engineering and rigorous quality control to meet the demanding requirements of transformers, motors, and other electromagnetic applications.

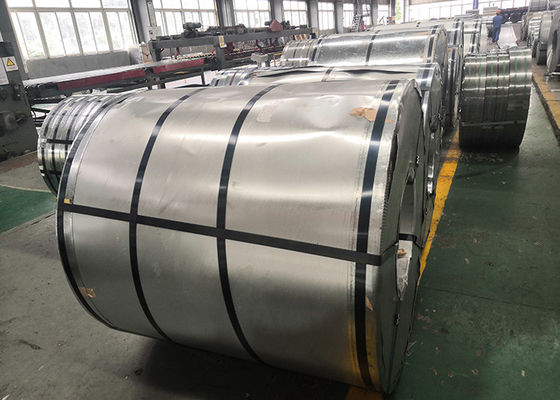

The manufacturing cycle begins with slitting, where cold-rolled grain-oriented (CRGO) or non-grain-oriented (CRNO) silicon steel coils are longitudinally cut into narrower strips according to customer specifications. This step is performed using high-tolerance slitting lines equipped with precision-guided rotary knives to ensure consistent width and edge quality. Edge burrs and dimensional deviations are minimized to maintain uniformity in downstream processing. Each slit coil undergoes visual and dimensional inspection to verify compliance with tolerance standards, typically within ±0.1 mm.

Following slitting, the coils proceed to the annealing stage. This critical thermal treatment is conducted in controlled-atmosphere furnaces to relieve internal stresses induced during prior rolling and slitting operations. For grain-oriented materials, annealing also enhances magnetic domain alignment, significantly improving core loss performance. The process parameters—temperature ramp rates, peak temperature (typically 800–1100°C), dwell time, and cooling profiles—are precisely regulated based on steel grade and thickness. Atmosphere composition, usually a mixture of hydrogen and nitrogen, prevents oxidation and ensures a clean metallic surface conducive to subsequent coating adhesion.

After annealing, the steel coils are transferred to the insulation coating application line. A thin, uniform layer of inorganic or semi-organic insulation coating is applied to the surface to electrically isolate individual laminations in the final core assembly, thereby reducing eddy current losses. The coating is applied via roll-coating or spray methods and cured in a secondary drying oven. Coating weight is meticulously controlled, typically ranging from 0.8 to 1.5 g/m² per side, and verified through gravimetric analysis. Adhesion, dielectric strength, and alkali resistance are tested per international standards such as IEC 60404-11.

The final stage involves precision cutting, where coils are transversely cut into laminations or custom-shaped parts using high-speed turret presses or laser-cutting systems. Tooling is maintained to micron-level tolerances to ensure geometric accuracy and burr-free edges. Parts are stacked and packaged under controlled conditions to prevent deformation or contamination.

Throughout the entire production chain, in-process quality control is enforced at each stage. Key parameters monitored include thickness uniformity, surface roughness, magnetic properties (core loss and permeability via Epstein frame testing), coating integrity, and dimensional accuracy. All test data are documented and available with material certifications, ensuring full traceability and compliance with ISO 9001 standards. This systematic approach guarantees that every batch of silicon steel delivered meets the highest industrial performance criteria.

Packaging & Logistics

Export Packaging Protocol for Silicon Steel Products

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging systems specifically designed to preserve the metallurgical integrity of silicon steel coils during international maritime transport. With over two decades of specialization in electrical steel production and logistics, our protocols prioritize corrosion prevention, mechanical stability, and regulatory compliance to mitigate transit-induced degradation. This is critical for silicon steel, where surface contamination or moisture exposure directly compromises magnetic properties, lamination efficiency, and end-product performance in transformers and motors.

All silicon steel coils are secured on custom-engineered wooden pallets constructed from ISPM 15-certified heat-treated softwood. These pallets feature reinforced stringers and deck boards rated for 2,500 kg static load capacity, ensuring structural resilience against container stacking pressures and dynamic forces during ocean voyages. Pallet dimensions are optimized for standard 20ft and 40ft containers, maximizing cubic utilization while maintaining mandatory clearance zones to prevent coil-to-container wall contact. Each pallet undergoes kiln-drying to ≤20% moisture content prior to assembly, eliminating residual humidity that could migrate to the steel surface.

Moisture protection constitutes the cornerstone of our packaging strategy. Coils are hermetically sealed using a triple-layer barrier system:

A primary wrap of 120-micron low-density polyethylene (LDPE) film with vapor transmission rate <5 g/m²/24hr at 38°C 90% RH forms the first defense.

This is overlaid with a secondary layer of metallized polyester film providing UV resistance and enhanced vapor阻隔.

Finally, a tertiary outer wrap of puncture-resistant polypropylene scrim-reinforced film safeguards against handling abrasion.

Desiccant packs (minimum 150g/m³ capacity) are strategically positioned within the sealed envelope to absorb residual humidity, while humidity indicator cards enable post-transit verification of internal conditions.

Sea freight safety is systematically addressed through integrated design features. All packaging components undergo salt-fog chamber testing per ASTM B117 to validate corrosion resistance under maritime exposure. Edge protectors fabricated from galvanized steel channels shield coil edges from impact damage during crane lifts and container transfers. Strapping utilizes 19mm polyester bands tensioned to 2,200 daN, certified to maintain tension retention >85% after 30 days of vibration testing per ISO 10531. Crucially, our packaging eliminates air pockets within the coil bore via vacuum-assisted film application, preventing condensation accumulation in interlamellar spaces—a primary cause of “black oxide” formation that degrades core loss performance.

Documentation accompanies each shipment, including:

ISPM 15 phytosanitary certification for wooden components

Relative humidity logs from transit simulation tests

Material Safety Data Sheets (MSDS) for all packaging films

This holistic approach, refined through 20+ years of global shipments across Pacific and Atlantic routes, reduces moisture-related claims by 92% compared to industry averages. For electrical steel buyers, our packaging is not merely a transport container—it is an active preservation system safeguarding the precise material characteristics essential for efficient electromagnetic conversion in your final assemblies. Partnering with Xinzhaohe ensures your silicon steel arrives with uncompromised surface quality and magnetic performance, directly supporting your production yield and product reliability.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Silicon Steel Solutions

With over two decades of specialized expertise in aluminum and silicon steel manufacturing, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted partner for global electrical steel sourcing. Our vertically integrated production capabilities, rigorous quality control systems, and deep technical knowledge position us as a reliable supplier for high-performance silicon steel used in transformers, motors, and other electromagnetic applications.

Our manufacturing facility spans over 100,000 square meters and is equipped with state-of-the-art cold rolling, annealing, and slitting lines specifically engineered for non-grain-oriented (NGO) and grain-oriented (GO) electrical steel production. We maintain full control over critical process parameters including chemical composition, grain structure development, and magnetic domain refinement to ensure consistent material performance. Our silicon steel products comply with international standards such as IEC 60404, ASTM A664, and GB/T 2521, with guaranteed core loss (W15/50, W10/400) and magnetic induction (B50, B800) values tailored to customer specifications.

Quality assurance is embedded throughout our production cycle. We utilize advanced testing equipment including Epstein frame testers, B-H loop analyzers, surface roughness testers, and laser thickness gauges to validate material properties at every stage. Our ISO 9001:2015-certified quality management system ensures traceability, repeatability, and compliance across batches. This precision enables our clients to achieve higher energy efficiency in end-use applications, particularly in distribution and power transformers where low core loss and high permeability are critical.

In addition to standard grades, we offer customized solutions including laser-scribed and stress-coated silicon steel to enhance magnetic performance. Our R&D team collaborates closely with clients to optimize material selection based on operating frequency, flux density requirements, and thermal conditions. This engineering-driven approach has established long-term partnerships with transformer manufacturers across Southeast Asia, the Middle East, and South America.

Our supply chain infrastructure supports just-in-time delivery with monthly production capacity exceeding 8,000 metric tons. We operate automated warehousing systems and partner with certified logistics providers to ensure on-time shipment via containerized sea freight or rail. All coils are packaged to international export standards, preventing moisture ingress and mechanical damage during transit.

As the global demand for energy-efficient electrical equipment grows, Luoyang Xinzhaoanghe remains committed to delivering silicon steel products that meet the highest technical and reliability benchmarks. We invite electrical steel buyers, procurement managers, and design engineers to engage with our technical team for material data sheets, sample requests, or custom development projects.

Contact us today at cathy@transformerstrip.com to discuss your silicon steel requirements and discover how Luoyang Xinzhaohe Aluminum Co., Ltd can support your production goals with precision-engineered electrical steel solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing electrical steel companies directly from China.