Table of Contents

Market Insight: Crngo Electrical Steel

Market Analysis: Silicon Steel (Electrical Steel)

The global demand for cold-rolled non-grain-oriented (CRNGO) electrical steel remains robust, driven primarily by the expanding electrical infrastructure and increasing energy efficiency requirements across industrial and utility sectors. CRNGO electrical steel is a critical material in the construction of power and distribution transformers, serving as the core lamination material due to its superior magnetic properties, including high permeability and low core loss. As energy costs rise and regulatory standards tighten, transformer manufacturers are under growing pressure to deliver equipment with minimized no-load losses, directly increasing the demand for high-quality CRNGO steel.

Transformers operate continuously over decades, making material reliability and performance stability paramount. The core, typically comprising stacked laminations of CRNGO steel, accounts for a significant portion of a transformer’s total losses. Inefficient core materials lead to higher hysteresis and eddy current losses, resulting in wasted energy, increased operating temperatures, and reduced service life. High-quality CRNGO steel mitigates these issues by offering tightly controlled silicon content (typically 2.5%–3.5%), precise thickness tolerances, and consistent surface insulation. These attributes collectively enhance magnetic flux density while reducing energy dissipation, directly contributing to the transformer’s efficiency and compliance with international standards such as IEC 60404-8 and DOE 2016.

Industrial demand is further amplified by the global push toward smart grids, renewable energy integration, and urban electrification. Solar and wind power installations require step-up transformers to feed energy into transmission networks, while electric vehicle charging infrastructure and data centers demand reliable distribution transformers. In all cases, the efficiency and thermal performance of these transformers are directly influenced by the quality of the electrical steel used. Substandard or inconsistent CRNGO steel can lead to premature aging, increased maintenance costs, and non-compliance with energy efficiency regulations, exposing end users to financial and operational risks.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced metal processing and supply chain management, we recognize that material quality is not a cost factor but a performance enabler. Our CRNGO electrical steel is produced under strict process controls, ensuring uniform grain structure, optimized magnetic properties, and superior insulation coating adhesion. We supply grades that meet or exceed standard classifications such as M250-35A, M300-35A, and M360-35A, tailored to customer specifications for thickness, width, and coating type.

The transformer industry cannot afford compromises in core material quality. As efficiency standards evolve and lifecycle costs become more scrutinized, sourcing CRNGO electrical steel from technically competent and quality-focused suppliers is essential. Luoyang Xinzhaohe Aluminum Co., Ltd stands as a reliable partner in this domain, delivering material consistency, technical support, and supply chain resilience to meet the rigorous demands of modern electrical infrastructure.

Technical Specs: Crngo Electrical Steel

Technical Specifications for CRNGO Electrical Steel

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise in silicon steel production to deliver CRNGO (Cold Rolled Non-Grain Oriented) electrical steel meeting stringent industrial demands. CRNGO is engineered for rotating machinery and transformers requiring isotropic magnetic properties. Critical performance parameters include core loss (iron loss), magnetic flux density, and dimensional stability, all governed by IEC 60404-8-7 and GB/T 3655 standards. Below is a summary of key technical specifications for our standard CRNGO grades (e.g., 50WW350, 50WW400, 50WW600), reflecting optimized composition (2.9–3.2% Si) and precision cold-rolling processes.

| Parameter | Symbol | Standard Test Condition | Typical Range | Measurement Method |

|---|---|---|---|---|

| Core Loss (50 Hz) | W1.5/50 | 1.5 T, 50 Hz | 2.80–4.00 W/kg | Epstein Frame (IEC 60404-2) |

| Core Loss (400 Hz) | W1.0/400 | 1.0 T, 400 Hz | 18.0–28.0 W/kg | Epstein Frame (IEC 60404-2) |

| Magnetic Flux Density | B50 | 5000 A/m | 1.65–1.75 T | Single Sheet Tester (IEC 60404-3) |

| Thickness Tolerance | – | Nominal 0.35–0.65 mm | ±0.004 mm | Micrometer (per ASTM A34) |

| Flatness Deviation | – | Per meter length | ≤ 8 mm/m | Gap-under-straightedge (GB/T 3524) |

Core Loss Characteristics

Core loss comprises hysteresis and eddy current losses, directly impacting motor and transformer efficiency. Our CRNGO grades achieve W1.5/50 values as low as 2.80 W/kg (50WW350) through controlled decarburization and stress-relief annealing. High-frequency loss (W1.0/400) is minimized via tight thickness tolerance (±0.004 mm) and uniform grain structure, critical for inverter-driven applications. Deviations beyond ±5% from nominal loss values trigger automatic batch rejection in our quality control protocol.

Magnetic Flux Density and Dimensional Control

B50 values of 1.65–1.75 T ensure high saturation performance in stator/rotor cores. This is achieved through precise silicon content management and annealing to eliminate residual stresses. Flatness deviation is held to ≤8 mm/m via tension-leveling post-annealing, preventing lamination burrs during high-speed stamping. Thickness consistency (±0.004 mm) reduces air gaps in stacked cores, directly lowering no-load losses in end applications.

Process-Driven Quality Assurance

All parameters are validated using calibrated Epstein frames and single-sheet testers under controlled laboratory conditions (23±1°C, 50% RH). Batch traceability extends from molten steel analysis to final coating inspection (standard C5 insulation). Our production line integrates real-time flatness monitoring via laser profilometry, ensuring compliance with automotive and industrial OEM flatness specifications. For mission-critical applications, we provide certified test reports with lot-specific loss curves and B-H loop data. Partnering with Xinzhaohe guarantees CRNGO steel that optimizes energy efficiency while maintaining stamping yield and core integrity in demanding manufacturing environments.

Factory Tour: Manufacturing

Manufacturing Process of CRNGO Electrical Steel at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of Cold-Rolled Non-Grain-Oriented (CRNGO) electrical steel at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure optimal magnetic performance, dimensional accuracy, and surface integrity. With over two decades of metallurgical expertise, our process integrates advanced equipment and rigorous quality control to meet the demanding requirements of motors, generators, and transformers.

The process begins with slitting, where wide master coils of cold-rolled non-grain-oriented silicon steel are longitudinally cut into narrower strips according to customer specifications. This operation is performed on precision slitting lines equipped with high-tolerance circular knives to minimize edge burr formation and maintain strip width consistency within ±0.1 mm. Tension control systems ensure uniform strip flatness and prevent edge wave or coil collapse during winding.

Following slitting, the material undergoes annealing in a continuous or batch furnace under a controlled atmosphere of nitrogen-hydrogen mix to prevent oxidation and decarburization. The annealing cycle is precisely programmed to relieve residual stresses induced during cold rolling and prior processing, thereby restoring magnetic permeability and reducing core loss. Temperature profiles are monitored in real time, with typical soaking temperatures ranging from 780°C to 850°C, depending on the silicon content and grade. Rapid cooling rates are applied post-anneal to preserve the desired ferritic microstructure and prevent precipitation of detrimental phases.

After annealing, the steel strip receives an insulation coating to enhance interlaminar resistance and reduce eddy current losses in stacked applications. A thin, uniform layer of inorganic or semi-organic insulative coating is applied via roll-coating or spray techniques. The coated strip is then cured in a dedicated oven at temperatures between 400°C and 500°C, ensuring complete polymerization and strong adhesion. Coating weight is maintained within 0.3–1.0 g/m² per side, verified through gravimetric analysis and electrical resistance testing.

The final stage is precision cutting, where the processed coils are sheared into laminations or blanks using high-speed turret presses or laser-cutting systems. Tooling is maintained under strict preventive schedules to ensure edge quality and dimensional repeatability. Blank dimensional tolerances are held to ±0.05 mm, with angularity and parallelism controlled to support efficient stacking and minimal air gaps in core assemblies.

Throughout the entire production chain, quality control is integrated at critical control points. Incoming material is verified for chemical composition via optical emission spectroscopy. During processing, core loss (W15/50), magnetic induction (B50), and coating continuity are routinely tested. Surface defects are monitored using automated optical inspection systems. Final product undergoes 100% dimensional verification and batch sampling for magnetic property certification, ensuring compliance with IEC 60404-8-7 and GB/T 13237 standards.

This systematic approach ensures that every coil of CRNGO electrical steel delivered from Luoyang Xinzhaohe meets the highest benchmarks in performance, consistency, and reliability.

Packaging & Logistics

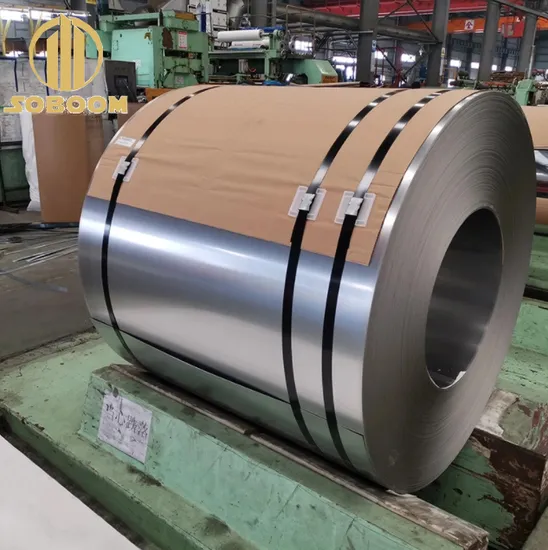

Export Packaging Specifications for CRNGO Electrical Steel

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for Cold Rolled Non-Grain Oriented (CRNGO) electrical steel to ensure material integrity during global maritime transit. With over two decades of metallurgical expertise, we recognize that CRNGO’s electromagnetic performance is critically sensitive to mechanical damage and moisture exposure. Our packaging system is designed to mitigate these risks through structural stability and environmental barriers, directly supporting the preservation of core loss and magnetic induction properties upon delivery.

All CRNGO coils are secured on custom-engineered wooden pallets compliant with ISPM-15 international phytosanitary standards. These pallets utilize heat-treated hardwood components with a minimum load-bearing capacity of 40 metric tons, engineered to withstand 12-meter stack heights in containerized shipping environments. Pallet dimensions are precisely calibrated to maximize 20-foot and 40-foot high-cube container utilization while preventing coil shifting. Each pallet incorporates integrated anchor points for ISO container lashing systems, eliminating the need for external steel strapping that could compromise coil surface integrity.

The primary moisture barrier consists of a triple-layer polyethylene encapsulation system. Coils are first wrapped in 125μm-thick moisture-proof film meeting ASTM D1746 clarity and ISO 15106-3 water vapor transmission rate (WVTR) specifications. This inner layer is overlaid with silica gel desiccant packets (50g/m² density) strategically positioned at coil interfaces to absorb residual humidity. A secondary 150μm UV-stabilized polyethylene outer layer provides puncture resistance and blocks solar radiation during port handling. All film seams are thermally sealed to achieve a continuous hermetic seal, validated through vacuum decay testing at 0.5 mbar pressure differentials.

Critical handling parameters are enforced to maintain packaging efficacy. Maximum coil stack height per pallet is restricted to three tiers to prevent base layer deformation under dynamic sea motion. Corner protectors fabricated from 3mm galvanized steel shield coil edges during crane lifts, while humidity indicators permanently affixed to pallets provide visible verification of internal conditions (<60% RH threshold). Our logistics team conducts pre-shipment verification of container dryness (dew point ≤ -20°C) and monitors voyage humidity logs via IoT sensors in premium shipping lanes.

This methodology directly addresses the hygroscopic vulnerability of silicon steel laminations, where even transient moisture exposure can initiate interlaminar corrosion and degrade magnetic performance. By eliminating condensation risks and physical impact during 30-60 day ocean transits, our packaging ensures CRNGO arrives with surface cleanliness levels meeting ISO 8501-1 Sa 2½ standards and dimensional tolerances within EN 10107 Class A specifications. Non-compliance with these packaging protocols voids our quality warranty, underscoring their non-negotiable role in preserving material value.

| Packaging Component | Technical Specification | Performance Validation |

|---|---|---|

| Wooden Pallet | ISPM-15 HT hardwood, 40MT load capacity | Dynamic load testing per ISO 10531 |

| Primary Film | 125μm PE, WVTR ≤ 1.0 g/m²/day | ASTM F1249 moisture analysis |

| Desiccant System | 50g/m² silica gel, 21% moisture adsorption | MIL-D-3464E compliance |

| Humidity Control | <60% RH internal threshold | Real-time IoT logging with alerts |

Luoyang Xinzhaohe’s packaging framework reflects our commitment to delivering CRNGO electrical steel that meets exacting international performance standards. This system is not merely protective but integral to maintaining the metallurgical consistency that defines our 20-year reputation in global electrical steel supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium CRNGO Electrical Steel

With over two decades of specialized experience in the production and supply of silicon steel, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner for CRNGO (Cold-Rolled Non-Grain-Oriented) electrical steel. Our vertically integrated manufacturing capabilities, combined with rigorous quality control systems, ensure consistent delivery of high-performance electrical steel tailored to the demanding requirements of transformer, motor, and generator manufacturers worldwide.

Our production facility in Luoyang, China, is equipped with advanced cold-rolling lines, continuous annealing systems, and precision slitting equipment, enabling us to produce CRNGO electrical steel with tight dimensional tolerances and optimized magnetic properties. We maintain strict control over the entire production chain—from raw material sourcing and chemical composition management to final inspection—ensuring uniformity in core loss (W15/50), permeability, and lamination characteristics across every coil. Our standard product range includes grades from 50W470 to 50W1300, with thicknesses spanning 0.35 mm to 0.65 mm, customizable widths up to 1,250 mm, and coil weights up to 15 metric tons.

Quality assurance is central to our operational philosophy. Our facility operates under ISO 9001-certified processes, with in-line testing for magnetic induction (B50), iron loss, surface insulation resistance, and mechanical strength. Each production batch is accompanied by a detailed mill test certificate, traceable to raw material heat numbers. We also conduct third-party verification through accredited laboratories to validate compliance with IEC 60404-8-7, GB/T 14547, and other international standards.

As a strategic supplier, we emphasize supply chain reliability and technical collaboration. Our logistics network supports containerized FCL and LCL shipments to global ports, with lead times typically within 15–25 days after order confirmation. We offer tailored packaging solutions—including waterproof wrapping, wooden pallets, and edge protectors—to ensure product integrity during transit. For OEMs and large-volume buyers, we provide consignment inventory programs and just-in-time delivery coordination.

Our engineering team works closely with clients to optimize material selection based on application-specific requirements such as frequency range, flux density, and thermal performance. Whether supplying for distribution transformers, traction motors, or industrial rotating machinery, we ensure material performance aligns with design efficiency targets.

To discuss your CRNGO electrical steel requirements with a technical supply specialist, contact us at cathy@transformerstrip.com. Luoyang Xinzhaohe Aluminum Co., Ltd is committed to delivering engineered solutions that enhance performance, reduce total cost of ownership, and support sustainable manufacturing practices. Partner with a supplier who combines deep metallurgical expertise with global supply capability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing crngo electrical steel directly from China.