Table of Contents

Market Insight: Auto Transformer Winding Wire

Market Analysis: Auto Transformer Winding Wire Demand and Quality Imperatives

Global demand for auto transformers continues robust expansion, driven by critical infrastructure modernization, renewable energy integration, and electric vehicle (EV) proliferation. Auto transformers, valued for their cost efficiency and reduced size compared to conventional two-winding units, are essential components in voltage regulation for power distribution networks, industrial motor drives, and EV charging systems. This growth trajectory directly fuels the industrial requirement for high-performance winding wire, particularly aluminum-based solutions where weight, cost, and conductivity balance are paramount. The compound annual growth rate (CAGR) for the global transformer market exceeds 6.2%, with auto transformer segments experiencing accelerated adoption in variable frequency drives (VFDs) and distributed generation systems. Consequently, sourcing reliable, specification-compliant winding wire is not merely a procurement exercise but a strategic enabler for transformer manufacturers competing on efficiency, reliability, and lifecycle cost.

Quality in auto transformer winding wire is non-negotiable due to the extreme operational stresses encountered. Aluminum winding wire must exhibit precise and consistent metallurgical properties to ensure transformer integrity and performance. Key parameters include electrical conductivity (typically 52-62% IACS for hard-drawn alloys), tensile strength (150-200 MPa range for formability vs. creep resistance), elongation, and dimensional tolerances (diameter variance < ±0.005 mm). Crucially, surface finish must be flawless; microscopic scratches or protrusions can compromise the enamel insulation layer during winding, creating localized hotspots or dielectric weaknesses. Hydrogen content in the aluminum must be rigorously controlled below 0.10 ml/100g to prevent porosity and subsequent thermal degradation under load. Inconsistent temper or ovality leads to uneven winding tension, risking insulation damage, inter-turn shorts, and catastrophic failure during operation or under short-circuit conditions. Industry standards like IEC 60138 and ASTM B354 mandate stringent testing protocols for these attributes, reflecting their direct correlation to transformer safety and longevity.

The consequences of substandard winding wire manifest as accelerated insulation aging, increased no-load and load losses, reduced thermal stability, and premature field failures. A mere 0.5% variance in conductivity can elevate operating temperatures by 3-5°C, significantly shortening the expected 30+ year service life per IEEE C57.91 guidelines. For transformer OEMs, this translates to warranty liabilities, reputational damage, and grid instability risks. High-purity aluminum (99.70% min) with optimized grain structure, produced under controlled continuous casting and rolling processes, ensures the thermal conductivity and mechanical stability required for efficient heat dissipation and resistance to electromechanical stresses during fault events. In the competitive B2B landscape, where transformer efficiency tiers (e.g., DOE 2016, EU Ecodesign) dictate market access, sourcing winding wire from metallurgically proficient suppliers with traceable quality control systems is fundamental to meeting regulatory mandates and achieving total cost of ownership targets. Quality is not a cost center; it is the foundation of operational risk mitigation and sustainable performance.

Technical Specs: Auto Transformer Winding Wire

Technical Specifications for Auto Transformer Winding Wire

Auto transformer winding wire is a critical component in power and electronics applications, where reliability, thermal endurance, and electrical insulation integrity are paramount. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and wire manufacturing expertise, we engineer aluminum-based winding wires to meet stringent performance demands in automotive, industrial, and energy systems. The technical specifications of such winding wire directly influence the transformer’s operational lifespan, efficiency, and safety under dynamic load and temperature conditions.

A primary performance metric is insulation breakdown voltage, which defines the maximum electric field the insulation layer can withstand before electrical failure occurs. For auto transformers, this value must exceed typical operating voltages by a substantial safety margin to accommodate transient surges and environmental stressors. Our winding wires are designed to achieve a minimum breakdown voltage of 3,000 V AC for single-layer insulation, with options available up to 6,000 V AC for enhanced protection in high-voltage or harsh environments. This performance is verified through standardized testing per IEC 60317 and GB/T 23639, ensuring consistency across production batches.

Elongation is another critical mechanical property, particularly during the winding process where the wire undergoes bending and tension. Insufficient elongation may lead to cracking of the insulation or conductor deformation, compromising electrical integrity. Our aluminum winding wires exhibit a minimum elongation of 18% under tensile testing, achieved through precise control of aluminum alloy composition (primarily 1350-O or equivalent) and annealing processes. This ensures excellent formability and resistance to work hardening during high-speed coil winding operations.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. For auto transformers, which often operate in elevated ambient temperatures, thermal classes ranging from 130°C to 220°C are commonly specified. Our product line includes wires with thermal classes 130 (B), 155 (F), 180 (H), and 220 (C), utilizing insulation systems based on polyurethane, polyester, polyamide-imide, or silicone-based coatings. Each thermal class is validated through thermal endurance testing, including resistance to thermal aging and hot deformation.

The following table summarizes key technical parameters for our auto transformer winding wire series:

| Parameter | Typical Value / Range | Test Standard | Notes |

|---|---|---|---|

| Conductor Material | Aluminum 1350-O | ASTM B233 / GB/T 3955 | High purity, soft temper |

| Insulation Type | Polyurethane, Polyester, Polyamide-imide | IEC 60317 | Multi-layer options available |

| Insulation Breakdown Voltage | 3,000 – 6,000 V AC (rms) | IEC 60216 | Measured at room temperature |

| Thermal Class | 130°C to 220°C (B to C) | IEC 60085 / GB/T 11021 | Continuous operating temperature |

| Elongation (min) | 18% | ASTM B557 / GB/T 4286 | On 250 mm gauge length |

| Temperature Index (TI) | 130 – 220 | IEC 60216 | Based on thermal life testing |

| Dielectric Strength | ≥ 120 kV/mm | GB/T 1410 | Intrinsic insulation property |

These specifications are engineered to support high-efficiency transformer designs with compact footprints and long service life under variable thermal and electrical loads. Luoyang Xinzhaohe Aluminum Co., Ltd. maintains strict quality control throughout production, ensuring compliance with international standards and customer-specific requirements.

Factory Tour: Manufacturing

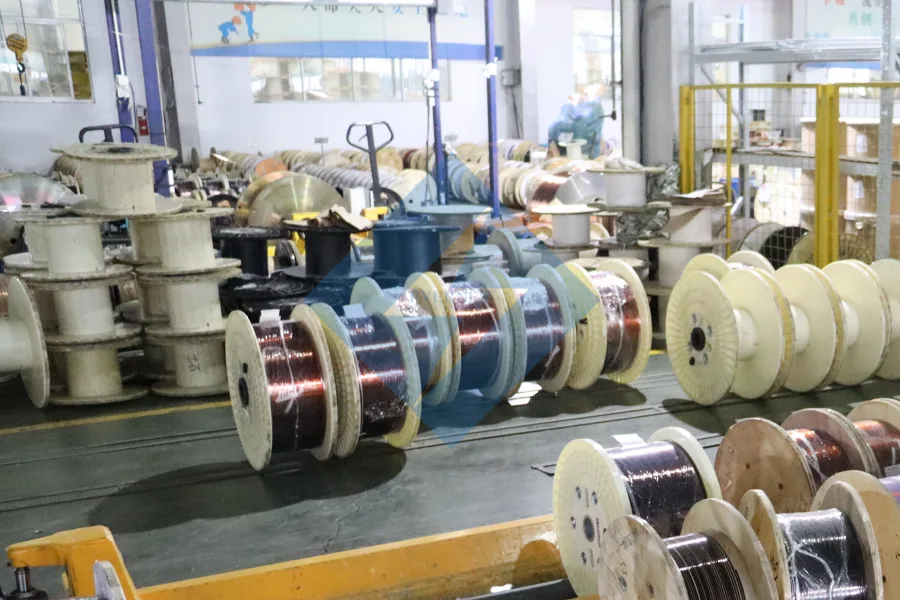

Manufacturing Process for Auto Transformer Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized metallurgical expertise to produce high-reliability aluminum auto transformer winding wire. Our rigorously controlled manufacturing sequence ensures consistent electrical, mechanical, and thermal performance demanded by automotive applications. The core process begins with high-purity aluminum rod (typically 99.70% min Al), subjected to precision rod drawing. This cold working operation occurs on multi-die continuous draw benches under strictly regulated tension and lubrication conditions. The rod undergoes significant cross-sectional area reduction, typically 95-98%, transforming it into precise wire diameters ranging from 0.30mm to 2.50mm. Critical process parameters including reduction ratio per pass, die geometry, and capstan speeds are continuously monitored via PLC systems to maintain dimensional tolerances within ±0.002mm and prevent surface defects or work hardening inconsistencies. In-process diameter verification using laser micrometers occurs at multiple stages.

Subsequent annealing is performed in continuous hydrogen-nitrogen atmosphere furnaces to restore optimal electrical conductivity and ductility. Precise temperature profiling is paramount; the wire traverses distinct zones including pre-heating, high-temperature soaking (typically 380-420°C), and controlled cooling. Atmosphere composition (H₂ concentration 2-5%) and dew point (< -40°C) are meticulously controlled to prevent oxidation and hydrogen embrittlement, ensuring a uniform, stress-relieved microstructure. Conductivity is validated post-anneal to meet IACS standards (typically 59-61% for fully annealed Al 1350). Rigorous QC checks at this stage include tensile strength (100-120 MPa), elongation (25-35%), and surface oxide inspection.

The annealed wire then enters the enameling line, a critical phase for automotive reliability. High-performance polymer resins, primarily polyurethane-imide or polyester-imide formulations meeting UL 1446 Class 200 or 220, are applied via precision die coating. Multiple thin layers are applied and cured in sequence under controlled temperature and dwell time within inert atmosphere ovens. This multi-layer approach ensures pinhole-free insulation with exceptional dielectric strength (>10 kV for standard builds), thermal shock resistance, and adhesion. Key parameters monitored include enamel viscosity, film build uniformity (±0.003mm), cure temperature profile, and solvent content.

Final quality assurance is achieved through comprehensive inline testing. Every meter of wire undergoes 100% high-voltage spark testing at elevated voltages (e.g., 3-5 kV) to detect insulation flaws. Simultaneously, continuous diameter measurement, surface defect scanning via optical systems, and tension monitoring occur. End-of-line QC includes destructive testing on production samples: thermal endurance (155-200°C), thermal shock (bend test after rapid heating), solderability, and adhesion tests per ASTM D2307 and IEC 60851 standards. Statistical process control data from all stages is analyzed to ensure compliance with automotive OEM specifications and prevent non-conforming material release. This integrated process control guarantees wire capable of withstanding the demanding thermal cycling, vibration, and electrical stresses inherent in modern automotive transformers.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in aluminum winding wire for power and electronic transformers, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. Our export packaging system is engineered to meet the rigorous demands of global supply chains, particularly for sensitive electrical materials such as auto transformer winding wire, where dimensional stability, surface cleanliness, and oxidation resistance are paramount.

All export shipments of aluminum winding wire are secured on custom-fabricated wooden pallets constructed from high-grade, kiln-dried hardwood. These pallets are designed to support the mechanical loads associated with multi-layer coil stacking while maintaining structural rigidity throughout extended sea freight cycles. Each pallet undergoes treatment in compliance with ISPM 15 standards to prevent the international transmission of wood-borne pests, ensuring smooth customs clearance across major markets including North America, Europe, and Southeast Asia.

Coils are mounted securely to the pallet using steel strapping and anti-vibration spacers to minimize axial and radial movement during vessel loading, unloading, and over-the-road transport. This mechanical stabilization is essential to prevent deformation of the wound aluminum conductor, which could compromise winding performance or introduce inter-turn insulation risks in downstream applications.

A primary protective layer consists of industrial-grade moisture-proof film, applied via automated stretch wrapping systems to ensure uniform coverage and optimal tensile retention. This multi-layer co-extruded film provides a high-barrier shield against humidity, salt-laden air, and condensation—common challenges in maritime transport, especially in tropical and coastal regions. The film’s low water vapor transmission rate (WVTR) effectively isolates the aluminum surface from atmospheric moisture, mitigating the risk of surface oxidation and pitting corrosion during voyages that may exceed 30 days.

Additional protection is achieved through the inclusion of desiccant packs and humidity indicator cards placed within sealed packaging zones, enabling real-time monitoring of internal microclimate conditions. For high-value or mission-critical orders, vacuum-sealed enclosures with nitrogen purging are available upon request, further enhancing long-term corrosion resistance.

All packaged units are labeled with durable, weather-resistant markings indicating product specifications, batch numbers, handling instructions, and orientation arrows to guide proper stowage. Pallet dimensions and weight distribution are optimized for standard containerization (20′ and 40′ dry van containers), maximizing space utilization while adhering to carrier safety regulations.

Our packaging protocol is validated through internal accelerated aging tests and real-world logistics feedback, ensuring that every coil arrives at its destination in as-manufactured condition. This systematic approach underscores our commitment to quality assurance and supply chain reliability in the global electrical materials market.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Aluminum Winding Wire Source

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver aluminum auto transformer winding wire meeting the most stringent global performance and reliability demands. Our vertically integrated manufacturing ecosystem, centered on advanced aluminum processing, provides OEMs and tier suppliers with a critical competitive advantage in transformer efficiency, weight reduction, and cost optimization. We understand that transformer core performance hinges on the fundamental metallurgical consistency and dimensional precision of the conductor material.

Our core strength resides in the rigorous control of aluminum purity and microstructure throughout the production chain. We utilize exclusively high-purity primary aluminum ingot (99.70% min Al) as feedstock, processed through state-of-the-art continuous casting and rolling lines to ensure optimal homogeneity. The wire drawing process employs precision diamond and tungsten carbide dies within computer-controlled tension systems, maintaining exacting dimensional tolerances essential for tight winding and minimized inter-turn spacing. Critical to electrical performance is our proprietary continuous annealing technology, utilizing precisely calibrated induction furnaces and inert gas atmospheres. This guarantees uniform softening, optimal electrical conductivity, and superior mechanical properties without surface oxidation, directly impacting transformer no-load losses and thermal stability.

Quality assurance is embedded at every process stage, not merely inspected at the endpoint. Our ISO 9001-certified quality management system implements real-time monitoring of key parameters including tensile strength, elongation, resistivity, and surface finish. Statistical process control (SPC) data is continuously analyzed to ensure batch-to-batch repeatability, a non-negotiable requirement for high-volume transformer production lines. We provide comprehensive material test reports (MTRs) traceable to individual melts, offering full transparency into the metallurgical pedigree of every coil supplied.

The following table summarizes key production capabilities for our aluminum auto transformer winding wire:

| Parameter | Specification Range | Key Control Standard |

|---|---|---|

| Material Grade | 1060, 1070, 1350 (Custom Alloys) | ASTM B233, IEC 60122-1 |

| Diameter Range | 0.05 mm – 5.0 mm | Tolerance ±0.002 mm (Fine Gauges) |

| Tensile Strength | 60 – 120 MPa (Annealed) | ASTM E8 / ISO 6892-1 |

| Elongation | ≥ 25% | ASTM E8 / ISO 6892-1 |

| Electrical Resistivity | ≤ 0.028264 Ω·mm²/m (20°C) | IEC 60468 |

| Surface Finish | Mirror Smooth, Oxide-Free | Visual & Microscopic Inspection |

| Coil ID / OD | Custom (Standard: 200mm / 500mm) | Customer Drawing Specific |

Partnering with Luoyang Xinzhaohe means securing a supply chain anchor point defined by technical mastery in aluminum conductor science. We eliminate material-related performance risks through metallurgical precision and process discipline, directly supporting your goals for higher efficiency transformers with extended operational lifespans. Our engineering team collaborates closely with client R&D and procurement departments to solve complex material challenges and ensure seamless integration into your manufacturing workflow.

For technical specifications, sample requests, or to discuss your specific auto transformer winding wire requirements, contact our dedicated sourcing team. Reach Cathy directly at cathy@transformerstrip.com to initiate a precision-driven supply partnership.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing auto transformer winding wire directly from China.