Table of Contents

Market Insight: Enameled Copper Flat Wire

Industrial Demand Drivers for Enameled Copper Flat Wire in Transformer Applications

Global transformer manufacturing exhibits sustained demand for enameled copper flat wire, driven by stringent energy efficiency regulations and thermal management requirements. The transition toward IE4 and IE5 efficiency classes under IEC 60034-30-2 necessitates optimized winding geometries to minimize copper losses and hotspot temperatures. Flat wire’s rectangular cross-section achieves 10–15% higher fill factor in windings compared to round wire, directly enhancing power density and reducing material consumption per kVA rating. This geometric advantage is critical in distribution transformers (10–2500 kVA) and high-frequency power transformers for renewable energy inverters, where space constraints and thermal cycling durability dictate performance. Market expansion is further accelerated by electrification trends in EV charging infrastructure and industrial automation, with Asia-Pacific accounting for 58% of global consumption due to grid modernization programs.

Technical Imperatives of Wire Quality in Transformer Reliability

Quality deviations in enameled copper flat wire directly compromise transformer longevity and safety margins. The enamel insulation system—typically polyurethane, polyesterimide, or polyamide-imide—must maintain dielectric integrity under combined thermal, mechanical, and chemical stresses. Microscopic defects (e.g., pinholes >5 µm) initiate partial discharge at operating voltages >1 kV, accelerating insulation degradation via treeing. Thermal class adherence (e.g., 180°C vs. 200°C) is non-negotiable; a 10°C exceedance of rated temperature halves insulation life per Arrhenius kinetics. Dimensional precision is equally critical:

| Parameter | Tolerance Impact | Failure Consequence |

|---|---|---|

| Thickness (±0.02 mm) | Reduced fill factor → 3–5% higher I²R losses | Thermal runaway at 110% load |

| Width (±0.05 mm) | Edge misalignment → inter-turn short circuits | Catastrophic winding failure |

| Twist (≤0.5°/m) | Uneven stress distribution → enamel cracking | Moisture ingress during varnishing |

Copper purity (≥99.97% Cu) and consistent annealing are essential to prevent hard spots that cause enamel fractures during winding. Substandard wire introduces latent defects undetectable in routine hipot testing but manifesting as premature field failures under harmonic loads.

Supplier Quality Systems as Risk Mitigation

For transformer OEMs, wire quality transcends cost-per-kilogram metrics. Luoyang Xinzhaohe Aluminum Co., Ltd. implements ISO/TS 16949-aligned controls: continuous oxygen-free copper casting (O₂ <10 ppm), multi-stage enamel curing with real-time IR thermography, and 100% automated optical inspection for surface defects. Our 20-year metallurgical expertise ensures compliance with IEC 60317-0-4 for flat wire, including mandatory thermal shock testing at -65°C and voltage endurance validation beyond 1.5x rated stress. Partnering with suppliers possessing in-house process mastery—not merely trading capabilities—mitigates supply chain risks associated with inconsistent dielectric strength or adhesion loss during vacuum pressure impregnation. In high-reliability applications, this rigor prevents field failure costs exceeding wire material value by 200x. Transformer manufacturers must prioritize validated process control over spot-market pricing to ensure grid resilience and avoid warranty liabilities.

Technical Specs: Enameled Copper Flat Wire

Technical Specifications for Enamel-Coated Copper Flat Wire

Enamel-coated copper flat wire is a critical component in high-efficiency electromagnetic devices, including transformers, motors, generators, and inductors. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and wire manufacturing expertise, we engineer enameled copper flat wire to meet stringent international standards, ensuring reliability, thermal resilience, and electrical performance under demanding operational conditions. The technical parameters governing performance are insulation breakdown voltage, elongation, and thermal class—each playing a pivotal role in determining the wire’s suitability for specific industrial applications.

Insulation breakdown voltage is a primary indicator of dielectric strength, reflecting the maximum electric field the enamel insulation can withstand before electrical failure occurs. For enameled copper flat wire, this value is measured perpendicular to the wire surface and is directly influenced by insulation thickness, coating uniformity, and resin formulation. Our standard production ensures breakdown voltages exceeding 2,500 V AC for single-coated wires, with high-performance variants reaching up to 6,000 V AC for double or triple insulation layers. This ensures robust protection against short circuits and dielectric failure in high-voltage windings.

Elongation, expressed as a percentage, measures the ductility of the copper conductor before fracture under tensile stress. It is a key mechanical property affecting the wire’s ability to withstand winding stresses during coil fabrication. Our enameled copper flat wires are drawn from high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.97%) and heat-treated to achieve controlled temper. Standard soft temper (annealed) wires exhibit elongation values of 30–40%, while semi-hard tempers range between 8–15%. Higher elongation supports tighter winding radii and reduces the risk of cracking during processing, especially in complex coil geometries.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation in electrical or mechanical properties. Our enameled copper flat wires are available in thermal classes ranging from 130°C to 220°C, utilizing advanced polymer coatings such as polyurethane (PU), polyamide-imide (PAI), and polyester-imide (PEI), often in combination for enhanced performance. Higher thermal classes, such as 180 (180°C) and 220 (220°C), are essential for applications in electric vehicle motors, industrial inverters, and high-speed rotating machinery where thermal management is critical.

The following table summarizes key technical parameters for standard enameled copper flat wire products:

| Parameter | Test Standard | Typical Value Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, GB/T 4074 | 2,500 – 6,000 V AC (1 min) | Depends on insulation thickness and layer count |

| Elongation | GB/T 4909.4 | 8% – 40% | Varies with temper (soft to semi-hard) |

| Thermal Class | IEC 60172, GB/T 11021 | 130 (B), 155 (F), 180 (H), 200, 220 | Based on insulation system |

| Conductor Resistivity | GB/T 3953 | ≤ 0.017241 Ω·mm²/m at 20°C | High-purity ETP copper |

| Adhesion (Needle Scratch) | IEC 60851-5 | Pass (no flaking) | Confirms coating integrity |

These specifications are validated through in-house quality control systems compliant with ISO 9001 and IATF 16949 standards. Consistent dimensional tolerances, surface smoothness, and insulation continuity further enhance performance in automated winding operations. Luoyang Xinzhaohe Aluminum Co., Ltd. provides customized formulations to meet application-specific requirements, ensuring optimal balance between electrical insulation, mechanical formability, and thermal endurance.

Factory Tour: Manufacturing

Manufacturing Process for Enameled Copper Flat Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical and supply chain expertise to guide clients through the critical production stages of enameled copper flat wire. This precision winding wire requires stringent process control to ensure electrical integrity, mechanical durability, and thermal stability in demanding applications such as motors, transformers, and inductors. The manufacturing sequence begins with high-conductivity oxygen-free copper rods (minimum 101% IACS), which undergo multi-pass rod drawing to achieve the specified rectangular cross-section. Dimensional tolerances are maintained within ±0.01 mm for thickness and ±0.02 mm for width, with surface roughness held below 0.8 μm Ra to prevent enamel defects. In-process optical gauging and laser micrometry provide real-time dimensional verification, while ultrasonic cleaning removes residual lubricants prior to annealing.

Subsequent continuous annealing occurs in a controlled nitrogen-hydrogen atmosphere furnace at 450–550°C. This step eliminates work hardening from drawing, restoring ductility and achieving target tensile strength (150–220 MPa) and elongation (≥40%). Critical quality checkpoints include post-anneal conductivity testing (≥100% IACS via eddy current) and oxygen content validation (<10 ppm) to prevent internal oxidation. Any wire exhibiting discoloration or surface pitting is automatically rejected via inline vision systems.

The enameling process employs multi-layer polymer application through precision die coating. Common insulation systems include polyurethane, polyesterimide, or polyamide-imide, applied in 2–5 sequential dips with intermediate UV or thermal curing. Each layer’s thickness is monitored via capacitance sensors to ensure uniform build (typically 30–150 μm total) and compliance with thermal class ratings (e.g., 180°C for Class H). Solvent content is regulated to <0.5% to avoid pinholes, while viscosity control (±5 cps) guarantees adhesion. Critical parameters like cure temperature profiles and line speed are logged for traceability.

Final inline testing validates performance against IEC 60317 standards. Key checks include:

Dielectric strength testing at 3 kV AC (minimum 60-second hold)

Mandrel wrap flexibility assessment (no cracking at 6x wire width bend radius)

Thermal shock resistance (-65°C to 200°C cycling)

Solderability verification at 460°C (wetting time ≤3 seconds)

Automated optical inspection scans for surface flaws at 100% coverage, while batch sampling undergoes accelerated life testing (240-hour thermal aging at 200°C). Luoyang Xinzhaohe’s supply chain protocols mandate full material traceability from copper cathode to finished spool, with certified test reports documenting all QC milestones. This integrated approach ensures consistent delivery of enameled flat wire meeting automotive (AEC-Q200), industrial, and renewable energy sector requirements. Partnering with Xinzhaohe guarantees access to rigorously vetted manufacturing partners adhering to these exacting process controls.

Packaging & Logistics

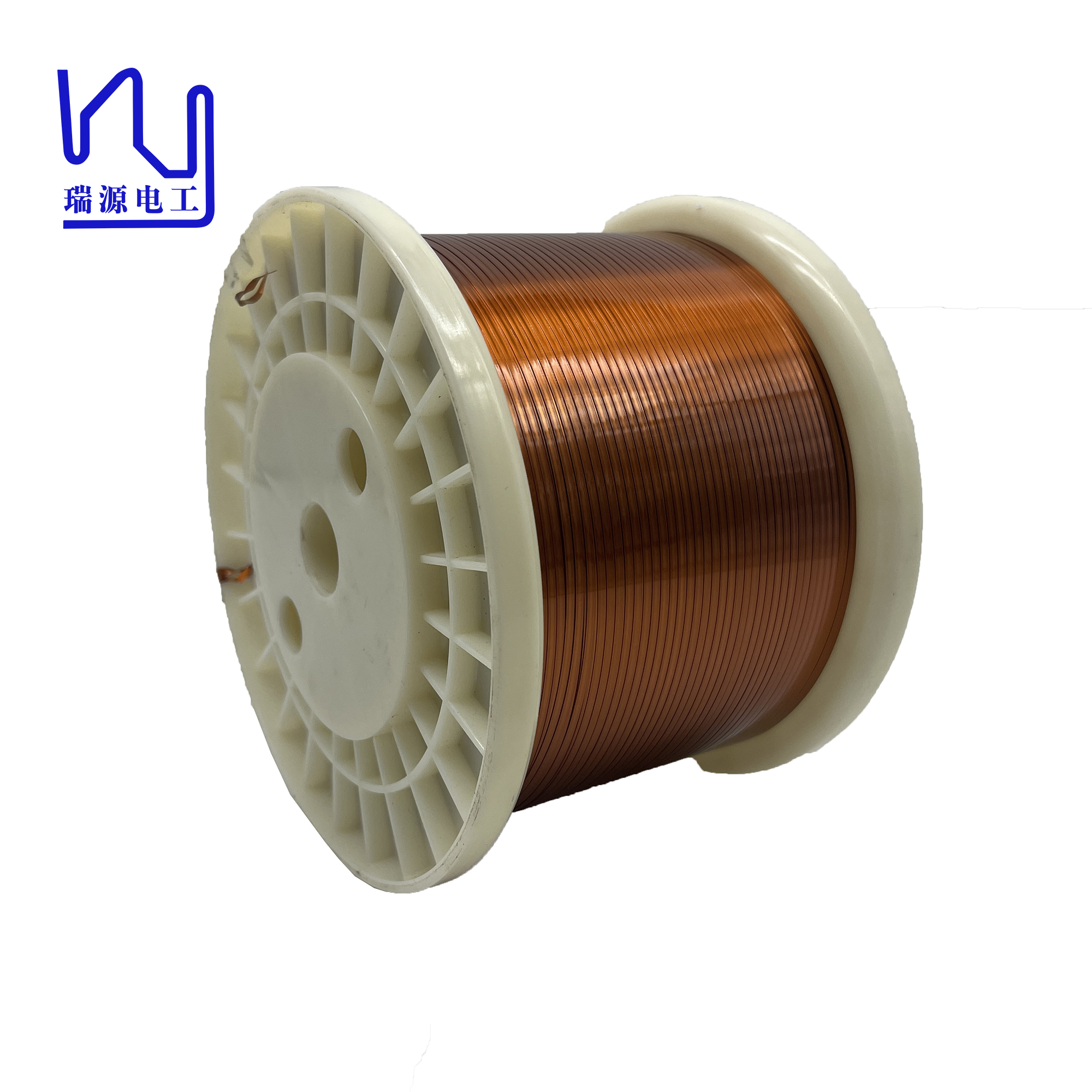

Export Packaging for Enamel-Coated Copper Flat Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in winding wire products, we recognize that proper export packaging is as critical to product performance as the precision of the wire itself. For enamel-coated copper flat wire, which is highly sensitive to mechanical damage, moisture ingress, and contamination, our export packaging system is engineered to maintain material integrity throughout extended sea freight cycles.

All export shipments of enameled copper flat wire are secured on robust, ISPM 15-compliant wooden pallets. These pallets are constructed from kiln-dried hardwood or engineered timber, providing dimensional stability and load-bearing strength capable of withstanding stacking pressures in containerized transport. The wire spools are axially mounted and firmly braced to prevent lateral movement or vibration-induced abrasion during transit. Each spool is individually positioned to ensure uniform weight distribution and to minimize torsional stress on the wound material.

A critical component of our packaging protocol is the multi-layer moisture barrier system. Immediately after spooling, each package is wrapped in high-density polyethylene (HDPE) moisture-proof film, heat-sealed to form a continuous vapor barrier. This layer effectively isolates the copper conductor and the enamel insulation from ambient humidity, salt-laden air, and condensation risks inherent in marine environments. For extended voyages or shipments to tropical or coastal regions, an additional internal desiccant pack is included within the sealed film envelope to actively absorb any residual moisture.

External protection is provided through a secondary overwrap of UV-stabilized polyolefin shrink film, which shields against dust, splashing water, and minor physical impacts during handling. Pallets are further secured with steel or PET strapping to maintain structural rigidity during crane lifts and intermodal transfers.

Labeling is executed in accordance with international logistics standards. Each pallet bears a weather-resistant tag containing product specifications, batch number, net and gross weights, handling instructions, and export documentation references. This ensures full traceability and compliance with customs and port authority requirements.

Our packaging design is validated through accelerated climatic testing and real-world shipment monitoring across major trade lanes, including trans-Pacific and Europe-Asia routes. The system has consistently demonstrated its ability to prevent delamination of the enamel coating, oxidation of the copper substrate, and deformation of the flat wire profile—key failure modes associated with inadequate protection.

By integrating industrial-grade materials with process-controlled packaging techniques, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every coil of enameled copper flat wire arrives at its destination in the same condition as when it left our facility. This reliability is fundamental to maintaining downstream processing efficiency for our global customers in the electric motor, transformer, and inverter manufacturing sectors.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Engineering for Demanding Enameled Copper Flat Wire Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver enameled copper flat wire meeting the most stringent global industrial requirements. As a vertically integrated producer, we control the entire value chain from high-purity copper rod casting through precision rolling, annealing, enameling, and final winding. This end-to-end oversight ensures unparalleled consistency in critical parameters essential for high-performance electromagnetic components, particularly in power transformers, motors, and inductors where thermal stability, electrical insulation integrity, and mechanical reliability are non-negotiable.

Advanced Production Capabilities and Material Science Expertise

Our dedicated winding wire facility utilizes state-of-the-art continuous casting and rolling lines capable of producing copper flat stock with dimensional tolerances held to ±0.005 mm in thickness and ±0.01 mm in width. This precision forms the foundation for subsequent enamel application. We employ multi-stage enamel coating systems utilizing solvent-based and UV-curable chemistries, enabling precise control over insulation thickness (±2.5 µm) and uniformity across widths ranging from 3.00 mm to 50.00 mm and thicknesses from 0.50 mm to 5.00 mm. Our metallurgical team optimizes annealing profiles to achieve target tensile strength (150-250 MPa) and elongation (≥5%) while maintaining high electrical conductivity (≥100% IACS). We support all major thermal classes (155, 180, 200, 220) per IEC 60317 standards, with formulations engineered for superior thermal shock resistance and adhesion during high-speed winding operations.

Rigorous Quality Assurance and Process Control

Every meter of enameled copper flat wire undergoes comprehensive inline and offline validation. Key process parameters—including line speed, oven temperature profiles, tension control, and enamel viscosity—are monitored in real-time via integrated SCADA systems. Final product verification includes mandatory testing per IEC 60851 protocols: dielectric strength (≥3 kV AC), pinhole density (<5 points/m²), flexibility (mandrel bend test), thermal endurance (20,000-hour life projection), and solderability. Our ISO 9001-certified laboratory utilizes automated optical inspection for surface defect detection and DSC/TGA analysis for enamel composition validation. Batch traceability is maintained from copper cathode origin through final shipment, ensuring full compliance with customer-specific material certifications.

Reliable Supply Chain Execution for Global Partners

We mitigate supply chain volatility through strategic copper inventory management and dual sourcing of key enamel resins. Our 30,000-ton annual production capacity is supported by dedicated logistics coordination, enabling on-time delivery performance exceeding 98.5% globally. Standard lead times for qualified orders are maintained at 15-25 days, with expedited processing available for critical projects. We provide comprehensive technical documentation, including full material test reports (MTRs), RoHS/REACH compliance certificates, and winding performance data sheets tailored to your application requirements.

Partner with Luoyang Xinzhaohe to secure a technically rigorous, supply-chain-resilient source for mission-critical enameled copper flat wire. Contact our Technical Sales Manager Cathy directly at cathy@transformerstrip.com to discuss your specifications, request sample reels, or schedule a virtual factory audit. We deliver engineered wire solutions—not just commodities.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameled copper flat wire directly from China.