Table of Contents

Market Insight: Aluminum Foil 1060

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Industrial demand for aluminum foil 1060 within the transformer sector remains robust and strategically critical, driven primarily by global imperatives for energy efficiency and grid modernization. Aluminum 1060 foil, characterized by its minimum 99.6% pure aluminum content, serves as the dominant conductor material in dry-type distribution transformers and increasingly in specific power transformer windings, particularly where weight reduction and cost-effectiveness are paramount. This demand is intrinsically linked to stringent international energy efficiency standards such as DOE 2016 (USA), IE4/IE5 (IEC 60034-30-2), and similar regulations worldwide, which mandate significant reductions in no-load and load losses. Aluminum 1060 foil directly contributes to meeting these standards through its optimal balance of electrical conductivity (minimum 59.0% IACS per ASTM B470), thermal stability, and formability. The accelerating deployment of renewable energy infrastructure, electric vehicle charging networks, and urban electrification projects further intensifies the requirement for reliable, high-efficiency transformers, underpinning sustained global consumption of specification-grade 1060 foil. While copper retains a presence in high-power density applications, aluminum 1060 foil offers a compelling lifecycle cost advantage for the vast majority of distribution-level transformers, solidifying its market position.

The absolute necessity of uncompromising quality in aluminum 1060 transformer foil cannot be overstated, as material defects directly translate into transformer failure risk and operational inefficiency. Impurities exceeding the strict 0.4% total allowable limit, particularly iron and silicon, significantly degrade electrical conductivity, increasing resistive (I²R) losses and generating excessive heat during operation. Surface imperfections such as scratches, dents, or embedded particles act as initiation points for partial discharges under high electrical stress, progressively eroding insulation systems and leading to catastrophic short circuits. Dimensional consistency, especially in thickness tolerance (typically ±2.5% or tighter for critical applications) and edge curl, is vital for automated winding processes; deviations cause misalignment, increased air gaps within the winding, and heightened risk of inter-turn faults. Mechanical properties are equally critical; insufficient tensile strength or elongation in the H19 temper can result in foil breakage during high-speed winding, while inadequate fatigue resistance leads to crack propagation under repeated thermal cycling, ultimately causing open circuits. Consistent grain structure, achieved through precise homogenization and annealing control, ensures uniform deformation behavior and long-term stability under operational stresses.

The consequences of substandard foil manifest as reduced transformer efficiency, shortened service life, increased maintenance costs, and potential grid instability. Industry-leading producers implement rigorous in-process controls, including continuous melt filtration, precision rolling with laser thickness monitoring, and 100% surface inspection systems, to guarantee foil meeting the exacting demands of transformer manufacturers. Procurement based solely on initial foil cost ignores the far greater total cost of ownership associated with transformer failures and energy waste. Luoyang Xinzhaohe Aluminum leverages two decades of specialized metallurgical expertise and integrated supply chain management to deliver 1060 transformer foil where purity, surface integrity, and mechanical properties consistently exceed baseline standards, directly supporting our clients’ goals for reliability and regulatory compliance.

Critical Quality Parameters for Aluminum 1060 Transformer Foil

| Parameter | Standard Requirement | Impact of Non-Conformance |

|---|---|---|

| Aluminum Purity | ≥ 99.60% | Reduced conductivity; increased load losses; overheating |

| Electrical Conductivity | ≥ 59.0% IACS | Higher resistive losses; decreased efficiency; thermal runaway risk |

| Thickness Tolerance | Typically ±2.5% | Winding defects; air gaps; increased partial discharge risk |

| Surface Defects | Zero acceptable | Partial discharge initiation; insulation degradation; failure |

| Tensile Strength | 140-180 MPa (H19) | Foil breakage during winding; poor handling |

| Elongation | ≥ 1.0% (H19) | Reduced fatigue resistance; crack propagation under thermal cycling |

Technical Specs: Aluminum Foil 1060

Technical Specifications: Aluminum Foil 1060 for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-purity aluminum foil 1060 engineered specifically for critical electrical applications, including transformer windings, busbars, and high-efficiency conductors. The 1060 alloy, composed of 99.60% minimum aluminum, delivers excellent electrical conductivity, superior surface finish, and consistent mechanical properties essential for reliable performance in power transmission systems. Our manufacturing process integrates cold rolling, precision slitting, and edge conditioning to meet the stringent dimensional and electrical requirements of modern transformer design.

A defining feature of our aluminum foil 1060 is the precision slitting capability, controlled within a tolerance of ±0.002 mm. This tight dimensional control ensures uniform layer stacking in transformer coils, minimizing localized stress points and reducing the risk of partial discharge. The slit edges are processed through a proprietary deburring system that eliminates micro-tears and raised material, resulting in burr-free edges. This surface integrity is critical during winding operations, where edge defects can lead to insulation damage, short circuits, or reduced dielectric strength.

Electrical performance is a key performance indicator for transformer-grade aluminum foil. Our 1060 foil achieves a minimum conductivity of 59% IACS (International Annealed Copper Standard), in compliance with GB/T 3880 and ASTM B209 standards. This high conductivity ensures low resistive losses, contributing to improved energy efficiency and thermal management in transformers. The foil is supplied in O-temper (annealed) condition, providing optimal ductility for winding while maintaining structural stability under electromagnetic loading.

All material undergoes 100% inline eddy current testing and surface inspection to detect inclusions, scratches, or thickness variations. The foil is available in thicknesses ranging from 0.10 mm to 0.80 mm and widths from 10 mm to 600 mm, customizable to client specifications. Tension leveling and anti-coil memory processing are applied to ensure flatness and ease of handling during automated winding processes.

The following table summarizes the core technical parameters of our aluminum foil 1060 for transformer applications:

| Parameter | Specification | Standard/Method |

|---|---|---|

| Alloy Designation | 1060 | GB/T 3190, ASTM B209 |

| Aluminum Purity | ≥ 99.60% | ICP-OES Analysis |

| Temper | O (Annealed) | GB/T 3880 |

| Thickness Range | 0.10 – 0.80 mm | Laser Micrometer |

| Slitting Tolerance | ±0.002 mm | ISO 2632 |

| Edge Quality | Burr-free, no micro-tearing | Optical Microscopy (200x) |

| Electrical Conductivity | ≥ 59% IACS | ASTM E1004 |

| Tensile Strength | 65 – 95 MPa | ASTM E8 |

| Elongation (min) | 35% | ASTM E8 |

| Surface Condition | Clean, oxide-controlled, no defects | Visual & AOI |

| Coil ID / OD | 200 mm / 800 mm (customizable) | Customer Specification |

This specification sheet reflects the engineering rigor and process control maintained by Luoyang Xinzhaohe Aluminum Co., Ltd. over two decades of supplying mission-critical aluminum products to the transformer industry.

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Foil 1060

The production of high-purity aluminum foil 1060 for transformer applications at Luoyang Xinzhaohe Aluminum CO., Ltd. adheres to a rigorously controlled sequence designed to meet the stringent electrical and mechanical demands of the power industry. Our 20+ years of specialized expertise in transformer strip and foil manufacturing ensures consistent delivery of material with exceptional surface integrity, dimensional precision, and edge quality critical for reliable transformer performance. The core process flow encompasses Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating integrated quality control checkpoints.

Cold rolling transforms hot-rolled aluminum coil stock into the final foil gauge, typically ranging from 0.006 mm to 0.200 mm for transformer windings. This multi-pass operation occurs under precisely controlled tension and rolling force within high-precision tandem mills. Maintaining uniform interstand tension is paramount to prevent center buckling, edge waviness, or thickness variation across the strip width. Continuous monitoring via laser micrometers and X-ray gauges provides real-time feedback for automatic gauge control (AGC) systems. Critical QC during cold rolling includes 100% online thickness profiling per ISO 2178 standards, surface defect detection using high-resolution line-scan cameras to identify scratches, dents, or inclusions, and periodic mechanical property verification (tensile strength, elongation) per ASTM B209 to confirm the H18 or O temper specification.

Following cold rolling, Precision Slitting subdivides the master coil into the exact narrow widths required for specific transformer winding configurations. This operation utilizes advanced slitting lines equipped with high-precision razor blades or shear knives, guided by laser edge tracking systems. Achieving slit width tolerances consistently within ±0.01 mm requires meticulous blade setup, alignment, and tension management to avoid edge distortion or width deviation. Simultaneous QC during slitting involves continuous edge monitoring for burr formation using optical sensors and strict adherence to width tolerance specifications. Every slit edge undergoes immediate visual and tactile inspection for micro-burrs or irregularities that could compromise winding integrity.

Edge Conditioning represents a non-negotiable final step for transformer foil. This specialized process mechanically removes microscopic burrs and stress concentrations generated during slitting, which are potential initiation points for electrical discharge or winding damage. Xinzhaohe employs proprietary edge rounding and deburring techniques, such as controlled brushing or precision grinding, applied uniformly along the entire strip edge. The efficacy of edge conditioning is rigorously validated through mandatory QC checks. These include microscopic edge profile analysis (typically at 50x magnification) to confirm the absence of protrusions exceeding 2 µm, and critical dielectric strength testing per IEC 60243 standards on conditioned samples to ensure the foil meets the required electrical insulation performance.

Key Process Quality Control Parameters

| Parameter | Measurement Method | Compliance Standard |

|---|---|---|

| Thickness Profile | Laser Micrometer / X-ray Gauge (100%) | ISO 2178, Customer Spec |

| Edge Burr Level | Optical Sensor / Microscopic Inspection | IEC 60641-2, Internal Spec |

| Slit Width Tolerance | Precision Calipers / Laser Width Gauge | ±0.01 mm |

| Surface Defects | High-Resolution Line-Scan Camera | ASTM E3086 Level 1 |

| Dielectric Strength | High-Voltage Breakdown Test | IEC 60243 |

This integrated manufacturing and QC framework, refined over two decades, guarantees that Xinzhaohe’s aluminum foil 1060 possesses the dimensional accuracy, pristine surface, and flaw-free edges essential for efficient, high-reliability transformer core and winding construction, minimizing energy losses and preventing catastrophic failures.

Packaging & Logistics

Export Packaging for Aluminum Foil 1060 – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production and export experience in transformer-grade aluminum and copper strips and foils, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity during international transit. For aluminum foil 1060—widely utilized in transformer windings due to its high electrical conductivity, excellent ductility, and consistent mechanical properties—our export packaging system is engineered to mitigate environmental and mechanical risks inherent in sea freight.

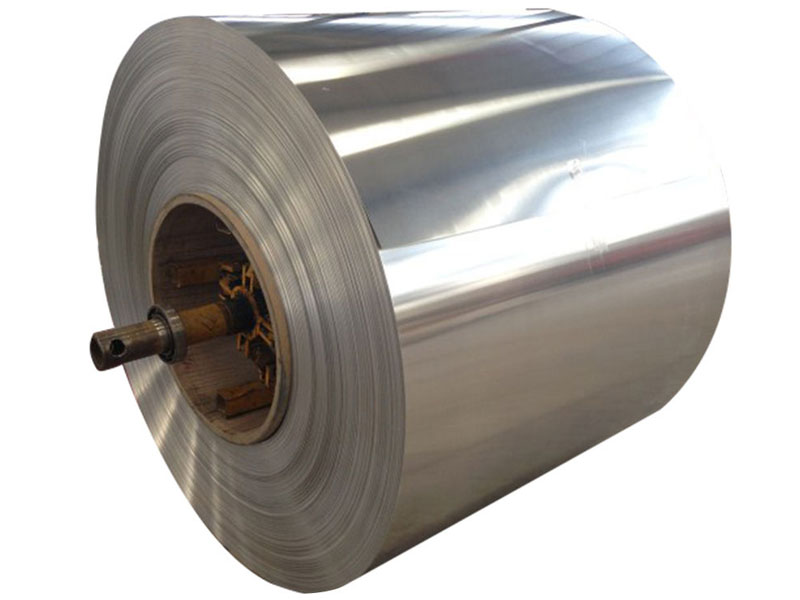

All aluminum foil 1060 coils are wound onto precision-machined aluminum or steel mandrels, ensuring dimensional stability and minimizing edge deformation during handling and transport. The primary protective layer consists of high-density moisture-proof polyethylene film, hermetically sealed to create a vapor barrier. This film is specifically selected for its low water vapor transmission rate (WVTR), effectively preventing condensation and corrosion during prolonged ocean voyages where temperature and humidity fluctuations are inevitable. The foil is then overwrapped with additional layers of anti-corrosion paper and reinforced polypropylene sheeting to guard against mechanical abrasion and salt-laden atmospheres common in maritime environments.

Each packaged coil is mounted on a custom-engineered wooden pallet constructed from kiln-dried, ISPM-15 certified hardwood. These pallets are designed to meet international phytosanitary standards, ensuring unrestricted customs clearance across global markets. The structural integrity of the pallet is optimized to support the full weight of the coil—typically ranging from 500 kg to 2,500 kg—while distributing load evenly to prevent deformation during stacking and containerization. Corner boards and edge protectors made from laminated kraft paper or extruded plastic are affixed to vulnerable points to resist impact damage during crane lifts, forklift handling, and intermodal transfers.

To further enhance stability, all coils are secured to the pallet using high-tensile steel or composite strapping, tensioned to industry-standard specifications. This prevents axial or radial movement during vessel motion, reducing the risk of telescoping or core collapse. Additionally, each package is labeled with UV-resistant, tamper-evident tags indicating product specifications, batch number, net weight, handling instructions, and orientation markers (e.g., “This Side Up”) to ensure proper stowage.

Our packaging protocol adheres to ISO 2230 and ASTM D4169 standards for transit performance, validated through internal shock, vibration, and humidity exposure testing. This systematic approach ensures that aluminum foil 1060 arrives at its destination with unaltered surface quality, dimensional accuracy, and electrical performance—critical factors for downstream processing in transformer manufacturing.

For clients sourcing high-purity aluminum materials for mission-critical applications, Luoyang Xinzhaohe Aluminum Co., Ltd delivers not only premium-grade foil but a fully validated logistics solution designed for the rigors of global sea freight.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Aluminum Foil 1060 Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise to deliver aluminum foil 1060 meeting the exacting demands of transformer and electrical component manufacturing. Our vertically integrated production ecosystem, centered on continuous casting-rolling technology, ensures unparalleled consistency in material properties critical for high-efficiency energy systems. The 1060 alloy (99.6% minimum aluminum purity) produced at our facility exhibits optimized electrical conductivity (≥61% IACS), controlled recrystallization behavior, and minimal hydrogen content (<0.10 ml/100g Al), directly mitigating eddy current losses in core-wound transformers.

Our 2450mm-wide twin-roll caster operates under strict atmosphere-controlled conditions, enabling precise microstructure refinement. Subsequent cold rolling employs computerized tension leveling systems to achieve dimensional tolerances of ±0.002mm in thickness (0.10–0.30mm range) and flatness deviations below 5 I-Units. This precision is validated through in-line laser micrometry and post-production testing per ASTM B209 and IEC 60169 standards. Every coil undergoes rigorous assessment of surface integrity (defects <0.1mm²/mm²), mechanical properties (tensile strength 65–95 MPa, elongation ≥25%), and interlayer insulation compatibility.

Supply chain resilience is engineered into our operations. Strategic partnerships with primary aluminum suppliers guarantee traceable 99.85%+ purity feedstock, while our 50,000-ton annual foil capacity includes dedicated transformer-grade production lines operating under ISO 9001 and IATF 16949 frameworks. Just-in-time logistics coordination from our Henan Province hub reduces inventory risk for global clients, with standard lead times of 15–25 days for containerized shipments.

Critical Performance Parameters for Transformer Foil 1060

| Parameter | Specification | Test Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM E29 |

| Surface Roughness (Ra) | ≤0.45 μm | ISO 4287 |

| Tensile Strength | 65–95 MPa | ASTM E8 |

| Elongation | ≥25% | ASTM E8 |

| Electrical Conductivity | ≥61% IACS | ASTM E1004 |

| Hydrogen Content | <0.10 ml/100g Al | ASTM E161 |

Our engineering team collaborates with clients during the qualification phase to align foil characteristics with specific winding processes and dielectric requirements. This includes custom annealing profiles to balance formability with core loss performance, alongside batch-specific certification dossiers documenting melt chemistry, thermal history, and final validation data.

For transformer manufacturers requiring defect-free 1060 foil with zero supply disruption risk, Luoyang Xinzhaohe provides the technical assurance and operational agility demanded by modern power infrastructure projects. Initiate qualification discussions or request material test reports by contacting our Technical Sourcing Manager Cathy directly at cathy@transformerstrip.com. We stand ready to support your next-generation transformer production with scientifically validated aluminum solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum foil 1060 directly from China.