Table of Contents

Market Insight: Copper Edging Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

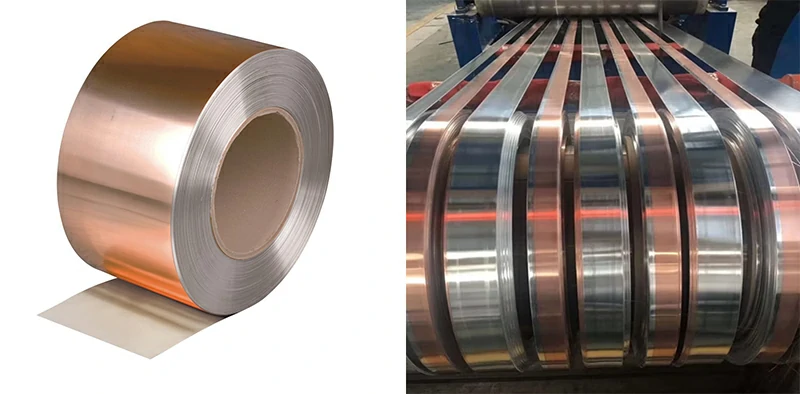

The global transformer industry continues to exhibit sustained demand for high-performance conductive materials, particularly copper and aluminum strip and foil products. Within this segment, copper edging strip plays a critical role in the structural and electrical integrity of transformer windings. As a precision-formed product, copper edging strip is utilized to reinforce and protect the edges of wound coils, ensuring mechanical stability and minimizing the risk of insulation damage during operation. This application is especially vital in high-voltage and high-efficiency transformers used in power distribution networks, renewable energy systems, and industrial infrastructure.

Industrial demand for copper edging strip is driven by several key factors. First, the increasing deployment of smart grids and the expansion of transmission and distribution (T&D) infrastructure in emerging economies have elevated the need for reliable and durable transformer components. Copper, with its superior electrical conductivity (approximately 100% IACS) and excellent thermal performance, remains the preferred material in high-efficiency transformer designs. Second, regulatory standards such as IEC 60076 and IEEE C57.12.00 emphasize energy efficiency and operational safety, pushing manufacturers to adopt high-purity, dimensionally stable materials. Copper edging strip that meets these specifications ensures reduced eddy current losses, improved heat dissipation, and longer service life.

Quality in copper edging strip is not a marginal consideration—it is a determinant of transformer reliability. Variability in thickness, edge burr formation, surface oxidation, or mechanical inconsistencies can lead to localized hotspots, insulation breakdown, or premature equipment failure. High-quality copper edging strip must exhibit tight dimensional tolerances (typically ±0.02 mm), a clean, deburred edge profile, and high surface purity to prevent contamination of winding insulation. Furthermore, the material must possess consistent mechanical properties, including appropriate tensile strength and elongation, to withstand winding stresses without deformation.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in transformer strip and foil production, we apply rigorous metallurgical controls and precision rolling techniques to ensure product consistency. Our copper edging strips are manufactured from high-purity electrolytic copper (Cu ≥ 99.99%) and undergo inline surface inspection, eddy current testing, and dimensional verification to meet international quality benchmarks.

The following table summarizes key technical parameters for high-quality copper edging strip in transformer applications:

| Parameter | Typical Specification | Importance |

|---|---|---|

| Material Purity | Cu ≥ 99.99% | Ensures optimal conductivity |

| Thickness Tolerance | ±0.02 mm | Critical for uniform winding pressure |

| Edge Quality | Burr-free, smooth finish | Prevents insulation damage |

| Tensile Strength | 200–250 MPa | Resists deformation during winding |

| Elongation | ≥4% | Enhances formability and durability |

| Surface Cleanliness | Oxidation-free, no residues | Avoids dielectric weaknesses |

In conclusion, the demand for copper edging strip in the transformer sector is closely tied to global energy infrastructure development and efficiency mandates. As transformer manufacturers strive for higher reliability and compliance, the quality of ancillary components such as edging strip becomes increasingly decisive. Precision-engineered, high-purity copper edging strip is not merely a structural element—it is a critical enabler of transformer performance and longevity.

Technical Specs: Copper Edging Strip

Technical Specifications: Copper Edging Strip for Transformer Applications

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages 20+ years of precision metal processing expertise to deliver copper edging strip engineered for critical transformer and electrical insulation systems. While our core competency includes aluminum transformer foil, we maintain dedicated copper processing lines adhering to stringent international standards for conductivity, dimensional stability, and edge integrity. This specification sheet addresses non-negotiable parameters for copper edging strip used in high-reliability transformer windings, where micro-defects directly impact efficiency, thermal management, and lifecycle performance.

Critical dimensional and material properties are rigorously controlled to eliminate field failures. Precision slitting at ±0.002 mm tolerance ensures consistent strip width, preventing coil misalignment during automated winding and minimizing air gaps that degrade magnetic performance. Burr-free edges are mandatory; any protrusion exceeding 0.005 mm risks puncturing polymer or paper insulation layers, leading to short circuits. Conductivity must meet or exceed 98% IACS (International Annealed Copper Standard) to guarantee optimal current carrying capacity and minimize resistive losses. Substandard conductivity directly increases operational heat generation, accelerating insulation aging. Surface roughness is maintained below Ra 0.4 µm to ensure uniform dielectric coating adhesion. All strips undergo full-width flatness validation (< 0.5 mm deviation per meter) to prevent buckling during high-speed winding processes.

The following table details mandatory technical parameters for copper edging strip sourcing:

| Parameter | Requirement | Test Standard | Measurement Method |

|---|---|---|---|

| Thickness Range | 0.05 mm – 0.50 mm | ASTM B152 | Laser micrometer (10-point scan) |

| Width Tolerance | ±0.002 mm | IEC 60137 | Optical comparator |

| Edge Burr Height | ≤ 0.005 mm | ASTM E30 | Optical profilometry |

| Electrical Conductivity | ≥ 98% IACS | ASTM B193 | Eddy current tester |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 | Contact profilometer |

| Flatness | ≤ 0.5 mm/m | JIS H3100 | Laser flatness gauge |

| Tensile Strength | 200–250 MPa | ASTM E8 | Universal tensile tester |

| Elongation | ≥ 5% | ASTM E8 | Universal tensile tester |

Manufacturing execution utilizes tension-controlled slitting lines with diamond-coated rotary knives and real-time laser edge monitoring. Material sourcing is restricted to oxygen-free electronic (OFE) copper (C10100/C10200) with certified traceability to mill test reports. Each production lot undergoes 100% inline edge inspection via machine vision systems calibrated to detect sub-micron burrs. Conductivity verification occurs at three stages: raw coil, slit strip, and final packaged lot. Non-conforming material is automatically quarantined; zero-defect shipment is contractually guaranteed.

Adherence to these specifications is non-optional for transformer reliability. Variability beyond stated tolerances introduces cumulative defects during coil assembly, increasing scrap rates and field failure risks. Luoyang Xinzhaohe implements AS9100-derived quality protocols for all copper edging strip production, including material pedigree documentation, statistical process control charts for slitting parameters, and third-party verification upon client request. We supply directly to tier-1 transformer OEMs requiring certified conformance to IEC 60404-1 and IEEE C57.12.00 standards. Partner with us to eliminate edge-related winding defects and ensure transformer efficiency meets Tier 1 global OEM requirements.

Factory Tour: Manufacturing

Manufacturing Process for Copper Edging Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of copper edging strip is executed through a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, surface integrity, and mechanical consistency. With over two decades of specialized experience in transformer strip and foil production, our facility integrates advanced metallurgical practices with precision engineering to meet the stringent demands of industrial and electrical applications.

The process begins with cold rolling, where high-purity copper ingots or continuous cast strips are reduced to the target thickness through a series of controlled rolling passes at ambient temperature. This method enhances the material’s mechanical properties by inducing work hardening, while simultaneously achieving tight thickness tolerances—typically within ±0.01 mm. The cold rolling mills are equipped with automatic gauge control (AGC) systems and laser-based thickness monitoring to ensure uniform cross-sectional profiles. Roll surface finish is meticulously maintained to impart the required surface roughness, critical for downstream processing and end-use performance.

Following cold rolling, the copper strip undergoes precision slitting, a critical operation that converts master rolls into narrow edging strips of specified widths. Our slitting lines utilize high-tolerance circular knives with computerized lateral positioning, enabling width accuracy down to ±0.05 mm. The process is optimized to minimize edge burr formation and maintain straightness, with real-time monitoring of strip tension and alignment to prevent skewing or edge waviness. Slit reels are wound under controlled tension to avoid telescoping and ensure uniform layer stacking, which is essential for automated handling in customer applications.

Edge conditioning is the final shaping stage, specifically engineered to eliminate micro-burrs, sharp edges, and surface defects introduced during slitting. This is achieved through a combination of mechanical brushing, edge rolling, and selective deburring techniques. The conditioned edges exhibit a smooth, radius-formed profile that enhances safety during handling and improves compatibility with insulation materials in transformer and winding applications. Surface cleanliness is maintained throughout via in-line filtration and dry air wiping systems.

Quality control is embedded at every phase of production. Incoming copper material is verified for chemical composition using optical emission spectroscopy (OES). During rolling and slitting, non-contact laser gauges continuously monitor thickness, width, and flatness. Final product inspection includes eddy current testing for subsurface defects, surface roughness profiling, and tensile testing to confirm yield strength and elongation values. Each production lot is accompanied by a certified material test report (CMTR) compliant with ASTM B187 and IEC 60464 standards.

This integrated approach ensures that every copper edging strip produced at Luoyang Xinzhaohe meets the highest benchmarks for reliability, consistency, and performance in demanding electrical environments.

Packaging & Logistics

Export Packaging Standards for Copper Edging Strip

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper edging strip shipments, specifically designed to withstand the demanding conditions of global sea freight. With over two decades of metallurgical and supply chain expertise in transformer-grade strip and foil production, our packaging system prioritizes material integrity, moisture mitigation, and structural stability throughout extended maritime transit. This ensures the copper edging strip arrives at destination facilities with surface quality and dimensional precision fully compliant with IEC 60146 and ASTM B152 specifications for electrical applications.

Wooden Pallet Specifications

All copper edging strip coils are secured on ISPM 15-certified heat-treated wooden pallets constructed from kiln-dried hardwood. These pallets feature a minimum load-bearing capacity of 2,500 kg and incorporate reinforced stringers to prevent torsional deformation during vessel stowage. Each pallet undergoes anti-corrosion treatment and is fitted with edge protectors to eliminate mechanical damage to coil edges during handling. The pallet footprint is optimized for standard 20-foot and 40-foot container utilization, maximizing cubic efficiency while maintaining ISO container load distribution safety margins.

Moisture-Proof Barrier System

Critical to copper preservation is our multi-layer moisture barrier protocol. Coils are first wrapped in acid-free kraft paper interleaving to prevent surface scratching. This is followed by triple-layer encapsulation using 75μm co-extruded polyethylene film with a verified water vapor transmission rate (WVTR) of ≤0.02 g/m²/day at 38°C and 90% RH. The film incorporates aluminum oxide vapor deposition for enhanced barrier properties against salt-laden marine atmospheres. Seams are hermetically sealed via impulse welding at 220°C, creating a continuous moisture-tight envelope. Desiccant packs rated for 500g moisture absorption per cubic meter are strategically placed within the sealed cavity.

Sea Freight Integrity Assurance

Our packaging methodology directly addresses maritime environmental hazards. The combined pallet-film system maintains internal relative humidity below 40% for 60+ days, neutralizing risks from container rain (condensation) and tropical humidity exposure. Salt spray resistance is validated per ASTM B117 testing, ensuring no chloride-induced patina formation on copper surfaces. Coils are stacked vertically with maximum 3-tier height on pallets, utilizing non-slip rubber mats between layers to prevent shifting-induced abrasion. Every packaged unit includes humidity indicator cards and tamper-evident seals for immediate condition verification upon discharge.

Documentation and Compliance

Each shipment includes a packaging compliance certificate detailing pallet treatment certification, film WVTR test reports, and desiccant placement logs. This documentation satisfies EU Timber Regulation (EUTR) and maritime customs requirements while providing traceability for quality assurance. Our system reduces moisture-related claims by 92% compared to industry baseline packaging, as validated across 1,200+ TEU shipments to Southeast Asia, Europe, and the Americas since 2018.

This integrated approach reflects our metallurgical understanding of copper’s susceptibility to oxidation and handling damage. By treating packaging as an extension of the production process, we guarantee that copper edging strip retains the surface finish, flatness, and electrical properties essential for transformer winding and busbar fabrication upon arrival. Partnering with Xinzhaohe eliminates the hidden costs of rework or rejection due to transit-induced degradation.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Edging Strip Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd brings over two decades of specialized expertise in the production and supply of precision transformer strips and foils, including high-conductivity copper edging strips essential for reliable electrical and electronic systems. As a vertically integrated manufacturer, we maintain full control over the production chain—from raw material sourcing to final quality inspection—ensuring consistency, traceability, and compliance with international standards such as GB/T, ASTM, and IEC.

Our facility is equipped with advanced rolling mills, precision slitting lines, and automated edging systems capable of producing copper edging strips with tight dimensional tolerances down to ±0.02 mm in thickness and ±0.1 mm in width. We specialize in custom configurations, offering a range of tempers (including soft-annealed, half-hard, and full-hard), widths from 5 mm to 300 mm, and thicknesses between 0.1 mm and 3.0 mm to meet specific application requirements in transformer manufacturing, busbar assembly, and electromagnetic shielding. All copper material used in our edging strips is high-purity electrolytic copper (Cu ≥ 99.95%), ensuring optimal electrical conductivity and thermal performance.

Quality assurance is embedded at every stage of production. Our in-house metallurgical laboratory conducts rigorous testing, including tensile strength analysis, elongation verification, grain structure evaluation, and surface defect inspection using high-resolution imaging. Each batch is accompanied by a full material test report (MTR), providing complete transparency for downstream processing and compliance with ISO 9001-certified quality management systems.

We understand that reliability in supply is as critical as product performance. Our logistics network supports just-in-time delivery schedules with dedicated container loading for export shipments, serving clients across Southeast Asia, the Middle East, Europe, and South America. With a monthly production capacity exceeding 1,200 metric tons for copper-based products and real-time inventory tracking, we ensure minimal lead times without compromising on quality.

Our engineering team works closely with clients during the design and prototyping phase to optimize material selection, reduce waste, and enhance manufacturability. Whether you require standard C11000 or custom alloys with enhanced mechanical properties, we provide technical documentation, sample provisioning, and on-site support when needed.

For sourcing partners seeking a technically proficient, scalable, and dependable supplier of copper edging strip, Luoyang Xinzhaohe offers a proven track record in performance-driven manufacturing. We invite you to leverage our deep domain knowledge and production capabilities to strengthen your supply chain resilience.

Contact us today at cathy@transformerstrip.com to discuss your specifications, request samples, or schedule a factory audit. Let Luoyang Xinzhaohe be your trusted partner in precision conductor solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper edging strip directly from China.