Table of Contents

Market Insight: Enameled Magnet Wire

Market Analysis: Industrial Demand for Enameled Magnet Wire in Transformers

Transformer manufacturing represents a dominant and expanding segment for enameled aluminum magnet wire consumption globally. This demand is fundamentally driven by the critical role transformers play in electrical energy infrastructure, spanning power generation, transmission, distribution, and end-use applications. Key growth vectors include the global push for renewable energy integration, necessitating extensive new substation and grid infrastructure, coupled with the ongoing modernization and replacement of aging power grids in developed economies. Simultaneously, the proliferation of power electronics in industrial automation, electric vehicle charging stations, and high-efficiency industrial motors further intensifies demand for specialized, high-performance transformers. Aluminum enameled magnet wire is increasingly favored in distribution and power transformers due to its superior weight-to-conductivity ratio and cost-effectiveness compared to copper, particularly in larger core sizes where weight savings translate to significant logistical and structural advantages.

The operational integrity and lifespan of a transformer are inextricably linked to the quality of the enameled magnet wire employed in its windings. Substandard wire introduces critical failure risks that compromise the entire unit. Primary quality parameters demanding rigorous control include thermal class rating, enamel adhesion, dielectric strength, and mechanical robustness. Thermal class directly dictates the transformer’s maximum operating temperature and expected service life; insufficient thermal endurance accelerates insulation degradation, leading to premature breakdown. Poor enamel adhesion results in flaking during winding or under operational thermal cycling, creating voids prone to partial discharge and eventual short circuits. Inadequate dielectric strength fails to withstand transient voltage surges inherent in power systems, risking catastrophic insulation failure. Mechanical properties, such as elongation and resistance to刮伤, are vital for withstanding the significant stresses of the winding process and operational vibration without compromising the insulation barrier.

The consequences of quality deficiencies extend beyond immediate unit failure. Field failures incur substantial costs through equipment replacement, unplanned downtime, grid instability, and potential safety hazards. Furthermore, transformer manufacturers face severe reputational damage and warranty liabilities when failures are traced to subpar core components like magnet wire. This underscores why industrial buyers prioritize suppliers with deep metallurgical expertise and stringent process control. Aluminum wire presents specific challenges distinct from copper, requiring precise control over conductor purity, annealing profiles, and enamel chemistry compatibility to ensure optimal adhesion and long-term stability under thermal stress.

Critical quality parameters for aluminum enameled magnet wire in transformers are non-negotiable. The following thermal classes represent common industry standards:

| Thermal Class (IEC 60317) | Maximum Hot Spot Temperature (°C) | Typical Enamel Chemistry | Key Application Focus |

|---|---|---|---|

| 155 (Class F) | 155 | Polyesterimide | General Distribution |

| 180 (Class H) | 180 | Polyamide-imide | High-Efficiency, Compact Designs |

| 200+ (Class C) | 200+ | Modified Polyamide-imide | Demanding Industrial, Renewable Integration |

Sourcing decisions must therefore center on verified quality consistency, traceable material certifications (e.g., IEC 60317, NEMA MW), and demonstrable process capability. Suppliers with two decades of specialized experience in aluminum magnet wire, like Luoyang Xinzhaohe Aluminum, possess the metallurgical understanding and process refinement necessary to consistently deliver wire meeting these exacting demands, ensuring transformer reliability and longevity within the demanding modern electrical grid. Quality is not a cost factor but a foundational requirement for operational safety and economic viability.

Technical Specs: Enameled Magnet Wire

Technical Specifications for Enamel-Coated Aluminum Magnet Wire

Enamel-coated aluminum magnet wire, also known as enameled winding wire, is a critical component in the manufacturing of electromagnetic devices such as motors, transformers, solenoids, and inductors. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialization in aluminum-based winding solutions, we ensure strict adherence to international standards including IEC 60317, GB/T 23312, and ASTM B358. The performance of enameled magnet wire is determined by a combination of electrical, mechanical, and thermal properties, with key parameters including insulation breakdown voltage, elongation, and thermal class rating.

Insulation breakdown voltage is a fundamental electrical characteristic that reflects the dielectric strength of the enamel coating. This parameter defines the maximum voltage the insulation can withstand before electrical failure occurs. For standard single-coated aluminum magnet wire, breakdown voltage typically ranges from 1,500 to 3,000 VAC depending on wire diameter and coating thickness. Double or triple coatings can enhance this value, providing superior protection in high-voltage applications. Testing is conducted under controlled conditions using a step-voltage method per IEC 60317-0-7, ensuring consistency and reliability across production batches.

Elongation, measured as a percentage, indicates the ductility of the aluminum conductor. High elongation values are essential for winding processes, especially in applications requiring tight coiling or complex geometries. Aluminum magnet wire from Xinzhaohe typically exhibits elongation values between 15% and 30%, depending on temper (soft or semi-hard) and wire gauge. This mechanical resilience minimizes the risk of cracking during winding and enhances the overall durability of the finished coil. Elongation is tested using standardized tensile testing procedures in accordance with GB/T 4909.3.

Thermal class defines the maximum continuous operating temperature the enamel insulation can endure without significant degradation in performance. Our enameled aluminum magnet wires are available in thermal classes ranging from 130°C to 220°C, enabling selection based on application-specific thermal demands. Higher thermal classes utilize advanced polymer coatings such as polyamide-imide (PAI), polyesterimide (PEI), or dual-layer systems to provide enhanced thermal stability, chemical resistance, and mechanical toughness. Thermal endurance is evaluated via thermal aging tests per IEC 60172, where insulation life is projected using Arrhenius modeling.

The following table summarizes typical technical parameters for enameled aluminum magnet wire offered by Luoyang Xinzhaohe Aluminum Co., Ltd.:

| Parameter | Test Standard | Typical Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-7 | 1,500 – 3,000 VAC (single coat) | Increases with double/triple coating |

| Elongation | GB/T 4909.3 | 15% – 30% | Depends on temper and wire diameter |

| Thermal Class | IEC 60172 | 130°C to 220°C | Coating types: PEI, PAI, or hybrid |

| Conductor Resistivity | GB/T 17049 | ≤ 0.028264 Ω·mm²/m (20°C) | High-purity aluminum (≥99.7%) |

| Adhesion | IEC 60317-0-6 | Pass (tape test) | No flaking or peeling after testing |

| Thermal Shock | IEC 60317-0-8 | Pass at rated temperature | No cracking after rapid cooling |

These specifications ensure compatibility with automated winding equipment and long-term operational reliability in demanding environments. Custom configurations are available upon request to meet specific OEM requirements.

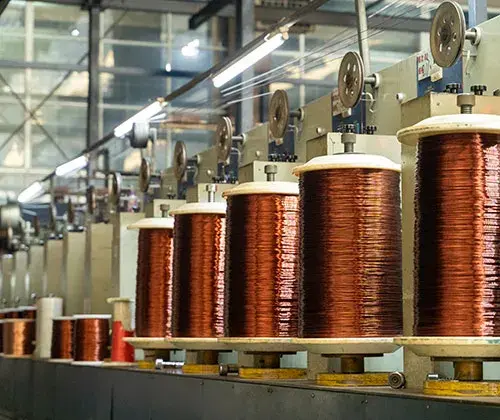

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Enamelled Magnet Wire

The production of high-performance aluminum enameled magnet wire at Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to a rigorously controlled sequence: Rod Drawing, Annealing, Enameling, and Inline Testing. Each stage incorporates stringent quality control protocols validated over our 20+ years of specialized manufacturing experience. This integrated approach ensures consistent electrical, mechanical, and thermal properties essential for demanding electromagnetic applications.

Rod drawing initiates the process, transforming high-purity aluminum rod (typically 99.7% min Al) into precise wire diameters. The rod undergoes multi-pass cold drawing through precision tungsten carbide or diamond dies within a continuous, lubricated system. Critical parameters include controlled reduction ratios per pass (typically 15-25%) and meticulous surface monitoring. Final wire surface roughness is maintained below 0.8 µm Ra, verified via profilometry. Any surface defects exceeding 2µm depth trigger automatic wire rejection. Dimensional accuracy is paramount, with diameter tolerances held to ±0.002 mm for fine gauges, continuously measured using laser micrometers. This stage establishes the foundational mechanical integrity and dimensional precision required for subsequent processing.

Annealing follows drawing to restore ductility and eliminate work hardening. The wire passes through a controlled-atmosphere annealing furnace, where temperature profiles (typically 300-400°C for aluminum) and residence time are precisely calibrated to the specific alloy and gauge. Crucially, the furnace atmosphere utilizes high-purity nitrogen with oxygen partial pressure maintained below 10 ppm to prevent surface oxidation, a critical factor for aluminum’s adhesion and electrical performance. Post-annealing, tensile strength and elongation are verified against ASTM B354 standards via inline tensile testers, ensuring optimal balance between flexibility for winding and mechanical strength. Surface oxide thickness is monitored spectroscopically, with rejection thresholds set at <5nm.

The enameling stage applies multiple thin, uniform polymer coatings. The wire traverses precision applicators (dies or rollers) immersed in enamel resin baths, with viscosity (20-50 cP) and solids content (30-45%) continuously regulated. Each coat undergoes immediate curing in multi-zone infrared or convection ovens, where temperature gradients (180-550°C) and dwell times are optimized for the specific resin chemistry (e.g., polyester-imide, polyamide-imide) to achieve full cross-linking without thermal degradation. Film build is controlled to ±0.005 mm per coat using capacitance gauges. Adhesion is tested in real-time via mandrel wrap tests per IEC 60851-5; insufficient adhesion halts the line.

Final inline testing is comprehensive and non-destructive. Every meter undergoes high-potential (Hi-Pot) testing at voltages exceeding 3kV to detect pinholes or thin spots. Thermal shock resistance is validated by rapid cooling after heating to specified temperatures (e.g., 200°C). Elongation and scrape abrasion resistance are sampled continuously. Breakdown voltage, winding quality, and dimensional stability are confirmed per IEC 60317 standards. Only wire passing all sequential QC checkpoints is precision wound onto spools with environmental protection, accompanied by full traceability documentation linking to raw material certs and process parameters. This end-to-end control guarantees the reliability demanded by global motor and transformer manufacturers.

Packaging & Logistics

Export Packaging for Enamel-Coated Aluminum Magnet Wire – Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in enameled aluminum magnet wire, we maintain rigorous standards in export packaging to ensure product integrity during international sea freight. Given the hygroscopic nature of enamel insulation and the sensitivity of aluminum conductors to environmental exposure, our packaging system is engineered to mitigate moisture ingress, mechanical shock, and corrosion throughout extended maritime logistics cycles.

All export shipments are secured on robust, ISPM-15 compliant wooden pallets constructed from kiln-dried, high-density hardwood. These pallets are designed to support the full weight of wound spools—ranging from 100 kg to 1,000 kg—while maintaining structural stability during containerized transport. Each pallet base is reinforced with cross-beams and edge protectors to prevent deformation under stack loading, a critical factor in multi-tier container stowage. The wooden components are treated to resist fungal growth and pest infestation, meeting international phytosanitary regulations for seamless customs clearance.

Prior to palletization, each spool of enameled wire is individually wrapped in multi-layer moisture-proof composite film. This film consists of an aluminum foil interlayer sandwiched between linear low-density polyethylene (LLDPE) films, providing a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24h at 38°C and 90% RH. The sealing process employs heat-welded seams with double overlap to ensure hermetic closure, preventing ambient humidity from reaching the wire surface. Desiccant packs rated at 1,000 g/m³ are placed inside the sealed envelope to absorb any residual moisture and buffer against minor thermal cycling during transit.

Once sealed, spools are mounted onto the pallet using stainless steel strapping and anti-slip rubber padding to minimize lateral movement. The entire assembly is then overwrapped with UV-stabilized polyethylene stretch hooding, extending from the top of the spool to the base of the pallet. This secondary layer provides additional protection against condensation, salt spray, and handling contaminants commonly encountered in port environments.

Our packaging protocol is validated through accelerated aging tests simulating 60-day sea voyages under 85% relative humidity and temperature fluctuations between 5°C and 45°C. Results consistently demonstrate maintained dielectric strength and insulation resistance in accordance with IEC 60317 and GB/T 23312 standards post-exposure.

For container loading, we recommend fixed dunnage placement and lashing in accordance with CTU (Cargo Transport Unit) Code guidelines to prevent shifting. All packages are labeled with orientation arrows, moisture-sensitive indicators, and handling instructions in compliance with IMDG and IATA maritime freight regulations.

This integrated packaging solution ensures that enameled aluminum magnet wire arrives at destination facilities with undamaged insulation, consistent electrical performance, and full compliance with global quality benchmarks. Luoyang Xinzhaohe Aluminum Co., Ltd remains committed to delivering reliability not only in product performance but also in logistical execution.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Engineered Solution for Aluminum Enamel Magnet Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and integrated supply chain management to deliver premium aluminum enameled magnet wire, meeting the exacting demands of global transformer, motor, and inductor manufacturers. Our core strength lies in mastering the unique challenges of aluminum conductor processing, where precise control over material purity, mechanical properties, and enamel adhesion is non-negotiable for performance and longevity in demanding applications. We operate a fully integrated production facility in Luoyang, China, purpose-built for aluminum magnet wire, ensuring stringent process control from billet selection through final winding.

Our technical capability is anchored in advanced metallurgical processes. We utilize high-purity aluminum billets (99.99% min) subjected to proprietary homogenization and continuous casting to achieve optimal grain structure and minimal hydrogen content. Critical wire drawing operations employ computer-controlled multi-die blocks with precise tension management and die geometry optimization, maintaining consistent ovality (<0.005mm) and surface finish essential for flawless enamel application. The annealing process utilizes inert atmosphere furnaces with real-time oxygen monitoring (<10 ppm), preventing oxidation and ensuring uniform temper (soft or semi-hard) critical for subsequent winding operations. Enameling lines feature multi-zone ovens with precise temperature profiling and viscosity control systems, applying solvent-based or UV-curable polyurethane, polyester, or polyamide-imide coatings to IEC 60317 specifications, with 100% spark testing at 3kV/mm.

Luoyang Xinzhaohe provides robust, scalable production capacity essential for strategic partnerships. Our facility supports annual output exceeding 15,000 metric tons of aluminum enameled wire, ranging from 0.10mm to 5.00mm diameter. This scale is backed by rigorous quality assurance protocols, including in-line monitoring of conductor resistivity (per IACS standards), coating thickness (micrometer verification), thermal class validation (200°C+), and mandrel bend testing. Full traceability from raw material lot to finished coil is standard, supported by ISO 9001 and IATF 16949 certified systems. Our supply chain excellence ensures material continuity; we maintain strategic partnerships with primary aluminum suppliers and operate dedicated billet remelting capacity, mitigating market volatility risks. This vertical integration enables reliable just-in-time delivery performance, consistently achieving 98.5% on-time shipment rates globally.

Partnering with Luoyang Xinzhaohe means securing a supplier deeply invested in the technical success of your winding applications. We understand that aluminum magnet wire performance hinges on the synergy between conductor metallurgy, enamel chemistry, and precise manufacturing execution – areas where our two decades of focused R&D and process refinement deliver tangible advantages in efficiency, reliability, and total cost of ownership. Our engineering team collaborates directly with customers to optimize wire specifications for specific end-use requirements, from high-frequency transformers to traction motors in electric vehicles.

For a detailed technical specifications review, capacity assessment, or to discuss your specific enameled aluminum magnet wire requirements, contact our Chief Sourcing Engineer, Cathy Zhang. Initiate a precision-engineered supply solution today.

cathy@transformerstrip.com

| Key Production Parameter | Luoyang Xinzhaohe Capability | Industry Standard Benchmark |

|---|---|---|

| Conductor Purity | ≥ 99.99% Al | ≥ 99.85% Al |

| Diameter Range | 0.10 mm – 5.00 mm | 0.20 mm – 4.00 mm |

| Max Annual Capacity | 15,000+ MT | 8,000 – 10,000 MT |

| Annealing Atmosphere O₂ | < 10 ppm | < 50 ppm |

| On-Time Delivery Rate | 98.5% | 92% – 95% |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameled magnet wire directly from China.