Table of Contents

Market Insight: Aluminum Winding Wire

Market Analysis: Aluminum Winding Wire for Transformers

Global demand for aluminum winding wire in power and distribution transformers is experiencing sustained growth, driven by critical infrastructure modernization, renewable energy integration, and rising electricity consumption. The shift towards energy-efficient transformers, mandated by evolving international standards like IEC 60076 and DOE regulations, intensifies the focus on core materials. Aluminum winding wire presents a compelling solution due to its favorable conductivity-to-weight ratio and cost-effectiveness compared to copper, particularly in large-scale distribution and power transformers where weight reduction significantly lowers transportation and installation costs. This trend is especially pronounced in emerging markets expanding grid infrastructure and in offshore wind applications where weight savings are paramount. Consequently, the aluminum winding wire segment represents a strategic material stream within the electrical steel supply chain, with compound annual growth rates closely tied to global grid investment cycles and renewable energy deployment targets.

The operational integrity and longevity of transformers are fundamentally dependent on the quality of the winding wire. Substandard aluminum wire introduces significant, often latent, failure risks that compromise transformer reliability and safety. Electrical conductivity is non-negotiable; wire must consistently achieve and maintain a minimum of 61.0% IACS (International Annealed Copper Standard), typically targeting 61.5-62.5% IACS for AA-1350 alloy, to ensure optimal current carrying capacity and minimize resistive losses over decades of service. Deviations directly impact transformer efficiency ratings and operational costs. Mechanical properties are equally critical. Precise tensile strength (typically 80-110 MPa for annealed wire) and elongation must be maintained to withstand the significant stresses of the winding process without breakage or permanent deformation, which could lead to short circuits or hot spots. Furthermore, surface integrity is paramount. Any surface defects – scratches, pits, oxide inclusions, or residual lubricants – act as initiation points for partial discharges under high electrical stress, progressively degrading the solid insulation system. This degradation ultimately leads to premature insulation failure, catastrophic transformer breakdown, and costly grid outages.

The consequences of inadequate wire quality extend far beyond the component level. Transformer failures result in substantial direct costs for replacement and repair, coupled with severe indirect costs from power disruption to critical infrastructure, industrial facilities, and residential consumers. The extended lead times for large power transformers amplify the financial and operational impact of such failures. Therefore, rigorous quality control throughout the aluminum wire production process – from high-purity molten metal treatment and continuous casting to precision rolling, annealing under controlled atmospheres, and meticulous surface cleaning – is not merely a specification requirement but a fundamental risk mitigation strategy for utilities and OEMs. Luoyang Xinzhaohe Aluminum leverages over two decades of specialized metallurgical expertise and integrated supply chain management to deliver aluminum winding wire meeting the most stringent global standards, ensuring the electrical, mechanical, and surface quality essential for transformer reliability and grid stability. Consistent quality is the cornerstone of sustainable transformer performance.

Technical Specs: Aluminum Winding Wire

Technical Specifications for Aluminum Winding Wire

Aluminum winding wire is a critical component in electrical and electronic applications, particularly in transformers, motors, and inductors, where high conductivity, lightweight characteristics, and thermal stability are essential. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and manufacturing expertise, our aluminum winding wire is engineered to meet stringent international standards, ensuring reliability and performance under demanding operational conditions. The technical specifications detailed below focus on three key performance indicators: insulation breakdown voltage, elongation, and thermal class rating—parameters that directly influence the safety, flexibility, and thermal endurance of the wire in service.

Insulation breakdown voltage is a measure of the dielectric strength of the wire’s insulating coating. It defines the maximum voltage the insulation can withstand before electrical failure occurs. For aluminum winding wire used in medium-voltage applications, a minimum breakdown voltage of 3,000 V AC is typically required. Our standard products achieve a breakdown voltage ranging from 4,000 V AC to 6,000 V AC, depending on insulation thickness and material type. This ensures robust protection against short circuits and insulation degradation in high-stress electrical environments. Testing is conducted per IEC 60317 and ASTM D227 specifications using step-voltage methods to validate consistency across production batches.

Elongation, expressed as a percentage, reflects the ductility of the aluminum conductor and its ability to undergo plastic deformation without fracturing. High elongation is crucial during winding processes, especially in tight-radius coil formations, where mechanical stress is significant. Our aluminum winding wire is manufactured using high-purity (99.99%) aluminum drawn under controlled conditions to achieve an elongation range of 18% to 28%, depending on temper (soft or semi-hard). This ensures excellent formability and reduces the risk of cracking during handling and installation.

Thermal class defines the maximum continuous operating temperature the wire can endure without significant degradation of its electrical or mechanical properties. Our product portfolio spans thermal classes from 130°C to 220°C, achieved through advanced polymer insulation systems such as polyurethane (PU), polyester (PE), polyamide-imide (PAI), and silicone-based coatings. Higher thermal classes are recommended for applications involving frequent thermal cycling or elevated ambient temperatures, such as in industrial motors and power electronics.

The following table summarizes the key technical parameters of our aluminum winding wire offerings:

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Conductor Material | High-Purity Aluminum (99.99%) | GB/T 3954 |

| Insulation Breakdown Voltage | 4,000 – 6,000 V AC (at 50 Hz) | IEC 60317, ASTM D227 |

| Elongation | 18% – 28% | ASTM B562 |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60172, NEMA MW 1000 |

| Conductor Diameter | 0.08 mm – 5.0 mm | Customizable |

| Insulation Thickness | 0.01 mm – 0.15 mm (depending on class) | IEC 60317 |

These specifications reflect our commitment to delivering aluminum winding wire that meets the exacting demands of modern electrical engineering applications. Each batch undergoes rigorous quality control, including tensile testing, thermal aging, and high-potential (hi-pot) voltage testing, to ensure compliance with global performance benchmarks.

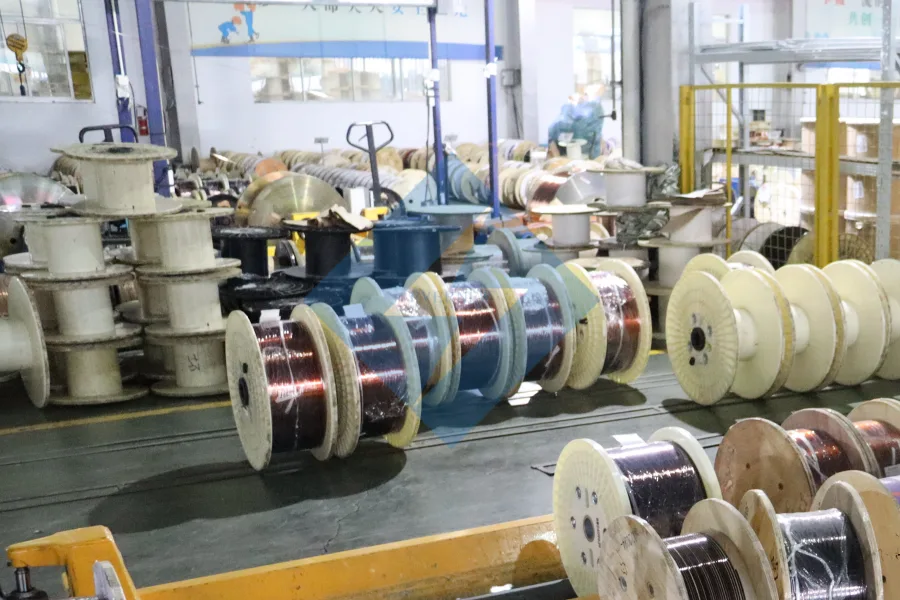

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical expertise to produce aluminum winding wire meeting stringent global electrical standards. Our vertically integrated production process ensures consistent material properties critical for transformer, motor, and inductor applications. The core sequence begins with high-conductivity aluminum rod (minimum 99.7% Al purity), subjected to precision cold drawing through multiple dies under controlled lubrication. This rod drawing stage reduces diameter to the target specification while managing work hardening. Critical parameters include die geometry, reduction ratio per pass (typically 15-25%), and surface cleanliness to prevent micro-cracks or scratches that compromise downstream processing. Real-time laser micrometers continuously monitor wire diameter, ensuring tolerance adherence within ±0.005 mm.

Following drawing, the wire undergoes continuous annealing in a precisely controlled inert atmosphere furnace. This step is metallurgically vital to restore ductility and achieve the required electrical conductivity by relieving internal stresses induced during drawing. Our proprietary annealing profiles utilize temperature ranges of 480-520°C with precise dwell times and nitrogen/hydrogen gas shielding to prevent surface oxidation. Oxygen levels are maintained below 10 ppm to avoid oxide inclusion formation. Post-annealing, conductivity is verified via inline eddy current testing, guaranteeing minimum 61% IACS (International Annealed Copper Standard) as per IEC 60122-3 requirements. Simultaneously, mechanical properties like elongation (typically 25-35%) are validated through automated tensile testing on process samples.

The annealed conductor then enters the enameling line, where multiple polymer layers are applied via precision die coating. We employ solvent-based or 100% solids formulations (polyester, polyamide-imide, or hybrid chemistries) tailored to customer thermal class requirements (e.g., 155°C, 180°C, 200°C). Each layer undergoes immediate UV or thermal curing under optimized temperature and oxygen-controlled conditions to ensure complete cross-linking and adhesion. Critical enamel properties—dielectric strength (>7 kV for 0.05mm film), flexibility, and thermal shock resistance—are monitored through continuous spark testing and periodic destructive analysis per IEC 60851 standards.

Inline quality control is embedded throughout the process. Key parameters are summarized below:

| Parameter | Standard Requirement | Xinzhaohe Control Method |

|---|---|---|

| Diameter Tolerance | ±0.01 mm | Laser micrometers (100% scan) |

| Conductivity | ≥61% IACS | Eddy current (continuous) |

| Elongation | 25-35% | Automated tensile (per batch) |

| Enamel Continuity | Zero pinholes | Spark tester (100% coverage) |

| Thermal Shock | Pass 200°C/15 cycles | Destructive test (per lot) |

Final inspection includes visual examination for surface defects, precise dimensional checks, and verification of spooling integrity. Only wire batches conforming to all electrical, mechanical, and dimensional specifications proceed to packaging in moisture-resistant containers, ensuring material readiness for global logistics and seamless integration into customer winding operations. This rigorous, data-driven approach underpins our commitment to zero-defect delivery.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum winding wire production, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. Our export packaging system is engineered to meet the rigorous demands of sea freight, where prolonged exposure to humidity, temperature fluctuations, and mechanical stress can compromise sensitive wire coils. We utilize a robust, multi-layered packaging approach centered on wooden pallets and industrial-grade moisture-proof film to ensure safe and reliable delivery across global supply chains.

All aluminum winding wire shipments are wound onto precision-engineered spools or reels that are securely mounted onto custom-fabricated wooden pallets. These pallets are constructed from high-strength, kiln-dried hardwood that meets ISPM 15 international phytosanitary standards for wood packaging material. This ensures compliance with customs regulations in all major markets, including the European Union, North America, and Southeast Asia. The structural design of the pallets provides optimal load distribution, minimizing the risk of deformation or collapse during container stacking and long-haul transport.

Each loaded pallet is then wrapped with multiple layers of high-density polyethylene (HDPE) moisture-proof film. This film acts as a vapor barrier, preventing the ingress of ambient moisture that could lead to surface oxidation or corrosion of the aluminum wire. The wrapping process is performed under controlled conditions using automated stretch-wrapping machinery, ensuring uniform tension and complete coverage. Critical sealing points are heat-sealed to eliminate gaps, further enhancing environmental protection.

In addition to moisture resistance, the packaging is designed to mitigate mechanical damage. Reinforced corner boards and edge protectors are applied to vulnerable points of the palletized load, while anti-slip layers are incorporated between the wire reels and the pallet surface to prevent lateral shifting during transit. For high-value or extra-sensitive orders, optional desiccant packs are included within the sealed film envelope to actively absorb any residual moisture.

Our packaging protocol is validated through internal quality audits and real-world performance tracking across diverse shipping routes, including trans-Pacific and trans-Indian Ocean container services. This empirical data confirms that our method effectively maintains coil geometry, surface finish, and electrical performance upon arrival.

Luoyang Xinzhaohe Aluminum Co., Ltd treats export packaging as an extension of our manufacturing precision. By integrating structural durability with environmental protection, we deliver aluminum winding wire that meets exacting technical specifications—regardless of destination. This commitment to secure, compliant, and intelligent packaging underscores our role as a trusted partner in the global supply of high-performance aluminum conductors.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Technical Expert in Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical engineering and precision manufacturing to deliver aluminum winding wire meeting the most demanding global transformer and motor specifications. Our factory is engineered from the ground up for consistent quality and technical excellence in this critical application.

Our core strength resides in advanced metallurgical process control. We utilize proprietary melt purification and degassing systems ensuring aluminum purity consistently exceeds 99.70%, directly optimizing electrical conductivity and minimizing impurity-related failures in end-use applications. Precise thermal profile management during continuous casting-rolling and subsequent annealing cycles guarantees uniform grain structure and mechanical properties across every coil, essential for reliable high-speed winding operations and long-term performance stability under thermal cycling. This deep materials science foundation allows us to tailor wire characteristics precisely to customer voltage class and design requirements.

Production capability is anchored in fully integrated, state-of-the-art facilities. We operate high-precision continuous casting-rolling lines coupled with multi-die drawing blocks capable of producing wire diameters from 0.80mm to 5.00mm with exceptional dimensional tolerances (±0.01mm standard). Our dedicated annealing furnaces support all critical tempers (O, H14, H18) with tightly controlled mechanical and electrical properties. This vertical integration, from molten metal to finished coil, eliminates third-party variables, ensuring batch-to-batch consistency unattainable through fragmented supply chains.

Quality assurance is non-negotiable. Every production run undergoes rigorous in-process and final inspection per IEC 60122-2 and customer-specific standards. Key parameters are systematically monitored:

| Parameter | Standard Range | Testing Frequency |

|---|---|---|

| Electrical Conductivity | 61.0 – 63.0% IACS | Continuous |

| Tensile Strength | 80 – 120 MPa | Per Coil |

| Elongation | 15% – 35% | Per Coil |

| Surface Finish | Mirror Smooth | 100% Visual |

| Dimensional Tolerance | ±0.01mm (diam) | Continuous |

Our supply chain infrastructure is designed for B2B reliability. Strategically located in Henan Province with direct access to major rail and port networks, we maintain dedicated logistics coordination ensuring on-time delivery performance exceeding 98.5%. Robust inventory management systems support JIT requirements while mitigating raw material volatility risks through long-term supplier partnerships and internal metal hedging protocols.

Partnering with Luoyang Xinzhaohe means accessing a supplier whose technical depth solves your winding wire challenges. We move beyond commodity supply to become your engineering extension, providing material data sheets, process optimization support, and rapid technical response. For transformer and motor manufacturers requiring unwavering quality and metallurgical expertise in aluminum winding solutions, we deliver the performance and partnership you demand.

Contact our Technical Sourcing Team today to discuss your specific requirements and receive a detailed capabilities dossier. Reach Cathy directly at cathy@transformerstrip.com to initiate a technical consultation and secure a reliable, high-performance supply chain for your critical winding applications.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum winding wire directly from China.