Table of Contents

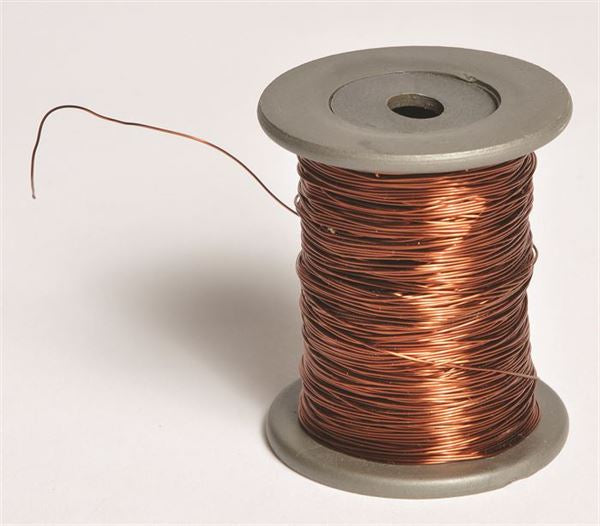

Market Insight: Enameled Copper

Market Analysis: Winding Wire Demand for Transformers

The global transformer market, a critical segment within electrical infrastructure, drives substantial and sustained demand for high-performance enameled copper winding wire. As the backbone of power transmission, distribution, and increasingly renewable energy integration, transformers require winding materials capable of enduring decades of continuous operation under significant electrical, thermal, and mechanical stress. Current market dynamics, including aging grid infrastructure upgrades, stringent energy efficiency regulations (e.g., DOE 2016, EU Ecodesign), and the rapid expansion of solar/wind farms with associated step-up transformers, are intensifying demand for premium-grade enameled copper. This demand is not merely volumetric; it is fundamentally quality-driven, as transformer reliability directly impacts grid stability, operational costs, and safety. Substandard winding wire represents a critical failure point, potentially leading to catastrophic outages with multi-million dollar consequences.

Quality in enameled copper wire for transformers is non-negotiable and governed by rigorous international standards such as IEC 60317 and ASTM B391. Key quality parameters directly impact transformer performance and longevity. Thermal endurance is paramount; the enamel insulation must maintain dielectric integrity and mechanical cohesion at sustained operating temperatures, typically classified under IEC 60317 thermal classes (e.g., Class 155, 180, 200, 220). Inferior thermal performance accelerates insulation degradation, leading to premature breakdown. Dielectric strength is equally critical, as the enamel must withstand high voltage stresses without puncture, especially during transient events like lightning strikes or switching surges. Mechanical robustness during the winding process is essential; the enamel must resist cracking or abrasion under tension and bending to prevent short circuits between turns. Furthermore, chemical compatibility with transformer insulating oils and resistance to thermal aging byproducts are vital for long-term stability within the transformer tank environment. Consistency in copper purity (typically >99.97% Cu) and precise dimensional tolerances (diameter, ovality) are fundamental to achieving designed electrical resistance, current density, and thermal management.

The consequences of compromised wire quality manifest as reduced transformer lifespan, increased no-load and load losses (directly impacting efficiency compliance), unexpected failures requiring costly repairs or replacements, and potential safety hazards. Transformer manufacturers and utilities prioritize suppliers with demonstrable metallurgical expertise, stringent process controls, and comprehensive testing capabilities. This includes continuous monitoring of copper melt chemistry, precision enamel application, controlled curing profiles, and rigorous batch testing for thermal index, dielectric breakdown, flexibility, and solderability. Luoyang Xinzhaohe Aluminum CO., Ltd leverages its 20+ years of metallurgical and industrial materials experience to rigorously vet and supply enameled copper meeting the highest transformer specifications, understanding that material integrity is inseparable from the asset’s operational reliability.

Critical Enamel Insulation Performance Parameters per IEC 60317

| Thermal Class | Nominal Temperature Rating (°C) | Minimum Thermal Index (°C) | Key Application Context |

|---|---|---|---|

| Class 155 | 155 | 155 | General distribution transformers |

| Class 180 | 180 | 180 | High-efficiency, demanding duty |

| Class 200 | 200 | 200 | High-temperature, compact designs |

| Class 220 | 220 | 220 | Extreme duty, specialized units |

Technical Specs: Enameled Copper

Technical Specifications for Enamel-Coated Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance enameled copper winding wire engineered for reliability in demanding electrical and thermal environments. With over two decades of metallurgical and process engineering expertise, our products are designed to meet international standards including IEC 60317, GB/T 23312, and NEMA MW series. Critical performance parameters such as insulation breakdown voltage, elongation, and thermal class are rigorously controlled to ensure compatibility with motors, transformers, relays, and other electromagnetic devices.

The insulation breakdown voltage is a key indicator of dielectric strength and determines the wire’s ability to withstand electrical stress without failure. Our enameled copper wires undergo precision coating processes to achieve uniform insulation layers, resulting in consistent and repeatable breakdown performance. Measured at standard ambient conditions (23°C, 50% RH), the breakdown voltage is tested using a ramp method per IEC 60172. Values are reported as the voltage at which insulation failure occurs across a specified coil configuration. Higher thermal class grades typically incorporate dual or triple-layer insulation systems (e.g., polyurethane/polyamide-imide) to enhance dielectric integrity under elevated temperatures.

Elongation, measured as a percentage of original length at the point of fracture during tensile testing, reflects the wire’s ductility and suitability for winding operations. Adequate elongation ensures the wire can endure the mechanical stresses of high-speed coiling without cracking or breaking. Our standard elongation specifications range from 8% to 25%, depending on wire diameter and temper condition. Smaller diameters (below 0.10 mm) are processed to maintain minimum elongation of 8%, while larger gauges (above 1.00 mm) are typically delivered with elongation values exceeding 20%. All tests are conducted per GB/T 4909.3.

Thermal class defines the maximum continuous operating temperature the insulation system can endure while maintaining electrical and mechanical integrity over a 20,000-hour service life. Our product portfolio spans thermal classes from 130°C to 220°C, enabling selection based on application-specific thermal loads. Higher thermal classes utilize advanced polymer coatings such as polyamide-imide (PAI), polyester-imide (PEI), or polyimide (PI), which offer superior thermal stability and chemical resistance. Each thermal class is validated through thermal endurance testing and Arrhenius plotting per IEC 60216.

The following table summarizes key technical parameters for standard enameled copper winding wire grades:

| Parameter | Test Standard | Typical Range / Value | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60172 | 1.5 kV – 8.0 kV (depending on diameter and class) | Measured at 10 mm coil gap |

| Elongation | GB/T 4909.3 | 8% – 25% | Increases with wire diameter |

| Thermal Class | IEC 60216, GB/T 23312 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on insulation system |

| Temperature Index (TI) | IEC 60216 | 130 – 220 | Derived from thermal aging data |

| Resistance to Soldering Heat | IEC 60726 | No cracking or peeling at 300°C, 3 sec | Applicable to thermally bonded types |

| Dielectric Strength | IEC 60258 | ≥ 60 kV/mm (film level) | Measured on flat film samples |

These specifications are maintained through in-line process control, automated optical inspection, and final quality verification. Custom configurations are available to meet OEM-specific requirements.

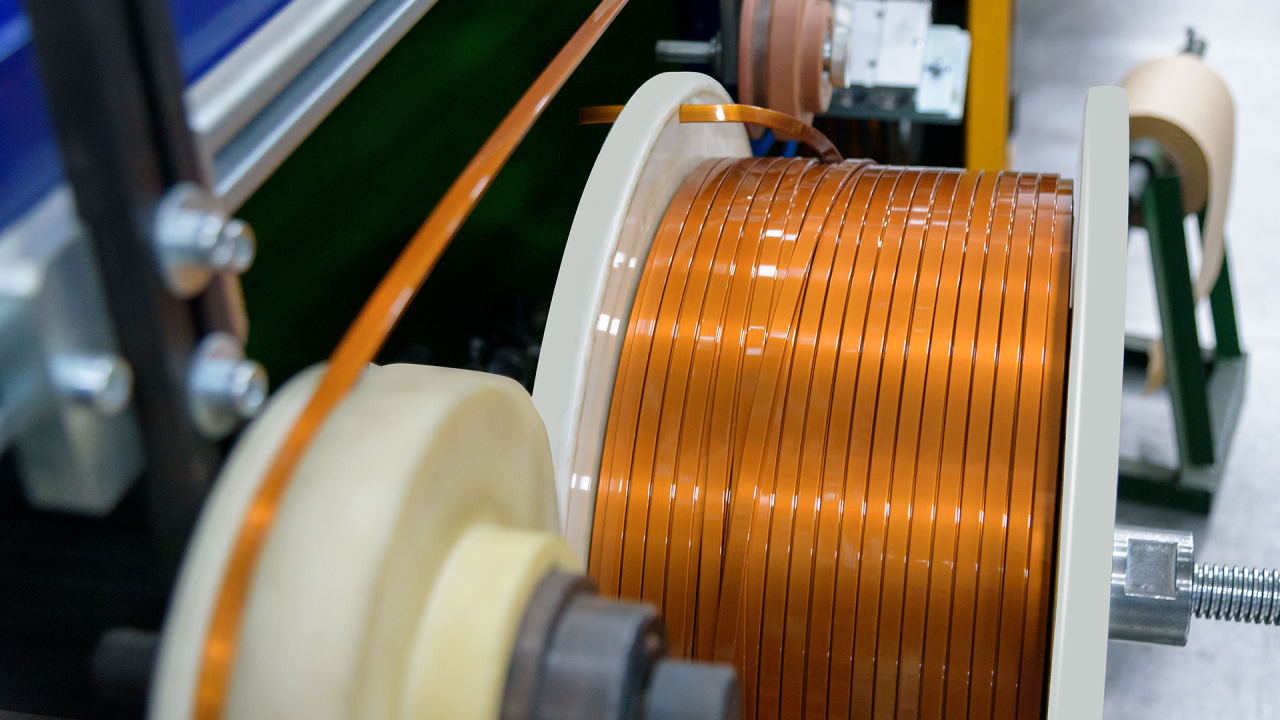

Factory Tour: Manufacturing

Manufacturing Process for High-Performance Enameled Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd employs a rigorously controlled, fully integrated production sequence to manufacture enameled copper winding wire, ensuring compliance with IEC 60317 and customer-specific performance standards. The process initiates with high-purity electrolytic tough pitch (ETP) copper rod (minimum 99.95% Cu, oxygen content 200–300 ppm), subjected to precision rod drawing. Using multi-die continuous drawing blocks with diamond dies, the rod undergoes incremental cold working to achieve the target diameter (ranging from 0.05 mm to 3.00 mm). Critical parameters include controlled reduction ratios per pass (typically 15–25%), emulsion-based lubrication for surface integrity, and real-time diameter monitoring via laser micrometers. This stage establishes the wire’s mechanical properties and surface smoothness, with ovality maintained below 0.002 mm to prevent coating defects.

Subsequent annealing occurs in a continuous hydrogen-nitrogen atmosphere furnace (H₂ concentration 3–5%, dew point <-40°C) at 450–550°C. This recrystallizes the copper structure, restoring ductility and electrical conductivity to ≥100% IACS while eliminating residual stresses from drawing. Temperature uniformity across the wire cross-section is verified through thermocouple arrays, with residence time calibrated to the wire gauge to prevent grain coarsening. Post-annealing, the wire undergoes ultrasonic cleaning to remove contaminants, ensuring optimal enamel adhesion.

The enameling stage utilizes a multi-layer application system. A base coat of modified polyester-imide resin is applied via precision ceramic applicators, followed by intermediate and top coats of polyamide-imide or self-bonding formulations as specified. Each layer passes through vertical curing ovens with zone-controlled temperatures (350–450°C) and residence times of 10–60 seconds, achieving full cross-linking without thermal degradation. Viscosity is maintained at 20–50 seconds (Ford Cup #4) via automated resin feed systems, while coating thickness is regulated to ±0.005 mm per layer using optical sensors. Critical quality checkpoints include solvent retention analysis (<0.5%) and gel content verification (>95%).

Inline testing occurs continuously throughout production. Key electrical tests include spark testing at 3–15 kV (depending on film build) to detect pinholes, with reject thresholds set at ≤1 fault per 500 meters. Mechanical validation comprises elongation testing (minimum 10–20% per IEC 60172), mandrel wrap adhesion (0T–3T bend without cracking), and thermal shock resistance at 200–240°C. Surface defects are monitored via high-resolution CCD cameras. Final quality control integrates batch traceability through laser marking and 100% rewind inspection under controlled lighting. All process parameters are logged in our ERP system for full auditability, ensuring repeatability and adherence to ISO 9001:2015 protocols.

Critical Inline Testing Parameters

| Test Type | Standard Range | Acceptance Criteria | Frequency |

|——————–|———————-|—————————|—————–|

| Spark Test | 3–15 kV | ≤1 fault/500 m | Continuous |

| Elongation | 10–20% | ≥ Specified minimum | Every 2 hours |

| Mandrel Wrap | 0T–3T | No cracks/flaking | Every batch |

| Coating Thickness | Per IEC 60317 Class | ±5% of nominal | Continuous |

This integrated approach, refined over 20+ years of metallurgical expertise, guarantees enameled wire with superior thermal class (up to 240°C), dielectric strength, and mechanical resilience for demanding motor and transformer applications.

Packaging & Logistics

Export Packaging for Enamel-Coated Copper Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, the export packaging of enamel-coated copper winding wire is engineered to meet international logistics standards, ensuring product integrity during extended sea freight transit. With over two decades of specialization in the production and global distribution of high-performance winding wire, our packaging protocols are designed to mitigate environmental and mechanical risks inherent in maritime transportation.

All export-grade enamel-coated copper wire coils are mounted on precision-manufactured wooden pallets constructed from kiln-dried, pest-free hardwood. These pallets comply with ISPM 15 regulations, which govern the phytosanitary standards for wood packaging material in international trade. The structural rigidity of the pallets ensures load stability, preventing coil deformation during handling, stacking, and long-distance shipping. Each coil is axially secured to the pallet using high-tensile steel straps, minimizing lateral movement and vibration-induced damage during vessel transit.

Immediately following palletization, the entire assembly is wrapped in multilayer moisture-proof composite film. This film consists of aluminum-laminated polyethylene with a high moisture vapor transmission rate (MVTR) barrier, effectively shielding the copper windings from humidity, salt spray, and condensation—common hazards in marine environments. The wrapping process is performed under controlled ambient conditions to prevent the entrapment of moisture beneath the film. Seams are heat-sealed to form a continuous vapor barrier, and critical junctions are reinforced with adhesive tapes rated for prolonged exposure to high humidity.

For additional protection, desiccant packs are strategically placed within the sealed film enclosure to absorb any residual moisture and maintain an internal dew point below ambient conditions. This is particularly critical when shipping to tropical or high-humidity destination zones, where diurnal temperature fluctuations can lead to internal condensation within containers.

Each packaged unit is labeled with durable, weather-resistant markings indicating product specifications, batch number, net weight, handling instructions, and orientation arrows. These labels are affixed to external surfaces not covered by film, ensuring visibility during customs inspection and warehouse operations.

Our packaging system has been validated through accelerated climatic testing, including 96-hour salt spray exposure and cyclic humidity trials (85% RH at 40°C), confirming the integrity of the enamel insulation and copper substrate post-exposure. This rigorous approach ensures that customers receive winding wire with unchanged electrical performance, surface quality, and mechanical properties, regardless of transit duration or route complexity.

By integrating robust wooden pallets with advanced moisture barrier technology, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every shipment of enamel-coated copper winding wire arrives in optimal condition, meeting the exacting demands of industrial motor, transformer, and electronics manufacturing sectors worldwide.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Enamelled Copper Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial supply chain mastery to deliver premium enamelled copper winding wire, meeting the exacting demands of global transformer, motor, and inductor manufacturers. Our core strength lies in the rigorous integration of advanced copper processing expertise with stringent quality assurance protocols, ensuring consistent performance in high-stress electromagnetic applications. We operate beyond standard wire production, functioning as a technical extension of your engineering and procurement teams.

Our manufacturing foundation is built upon precise metallurgical control of high-conductivity electrolytic tough pitch (ETP) copper, processed under oxygen-free atmospheres to achieve minimum 101% IACS conductivity and exceptional surface integrity. This critical base material undergoes proprietary multi-stage drawing with real-time diameter monitoring, maintaining tolerances within ±0.001mm. The enamelling process utilizes state-of-the-art vertical ovens with precisely calibrated temperature zones and solvent recovery systems, enabling flawless application of single or multi-layer insulation including polyesterimide (PEI), polyamide-imide (PAI), and self-bonding formulations. Each batch undergoes comprehensive in-house validation against IEC 60317 and ASTM B3 specifications, including dielectric strength testing up to 6kV, thermal endurance class verification (180°C to 240°C), and mandrel bend flexibility assessments.

Vertical integration within our 50,000m² facility provides significant supply chain resilience. We maintain direct oversight from copper rod sourcing through to final spooling, minimizing third-party dependencies. Our automated warehouse system, coupled with SAP-integrated logistics planning, ensures on-time delivery performance exceeding 98.5% globally. Advanced process control systems continuously monitor key parameters like enamel viscosity, film thickness uniformity, and annealing atmosphere composition, feeding data into our statistical process control (SPC) database for proactive deviation correction. This systematic approach results in industry-leading defect rates below 50 PPM for critical attributes such as pinholes and adhesion failure.

| Key Performance Indicator | Luoyang Xinzhaohe Standard | Industry Benchmark |

|---|---|---|

| Dimensional Tolerance (±mm) | 0.001 | 0.002 – 0.005 |

| Dielectric Strength (kV) | ≥ 6.0 | ≥ 4.0 – 5.5 |

| Thermal Class Consistency | ±5°C | ±10°C |

| On-Time Delivery Rate | >98.5% | 92% – 95% |

| Critical Defect Rate (PPM) | <50 | 100 – 300 |

Partnering with Luoyang Xinzhaohe means accessing metallurgical problem-solving capabilities honed through 20+ years of resolving complex winding wire challenges. Our engineering team provides material certification packages traceable to individual melt batches, alongside technical support for application-specific formulations and failure mode analysis. We understand that wire performance directly impacts your end-product efficiency and longevity; therefore, we prioritize collaborative development and transparent communication throughout the sourcing lifecycle. For technical specifications, production capacity details, or to initiate a qualification sample program, contact our Chief Technical Officer Cathy directly at cathy@transformerstrip.com to discuss your precise enamelled copper wire requirements.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameled copper directly from China.